Fireproof cable

A fire-resistant cable and fire-resistant mica technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of waste and consumption of fire-resistant mica tapes, and increase the outer diameter of cables, so as to save fire-resistant mica tapes, increase fire prevention effects, and improve The effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

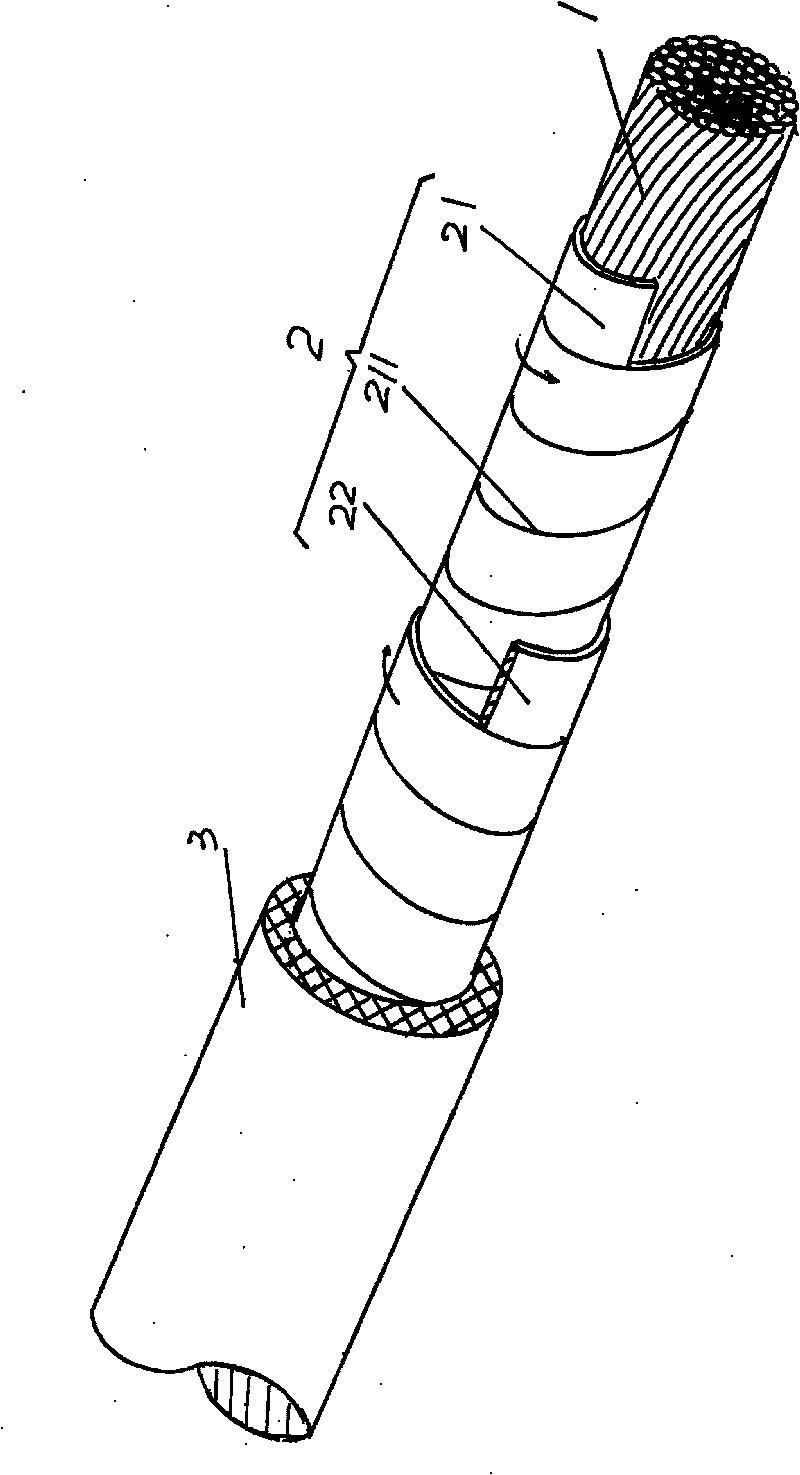

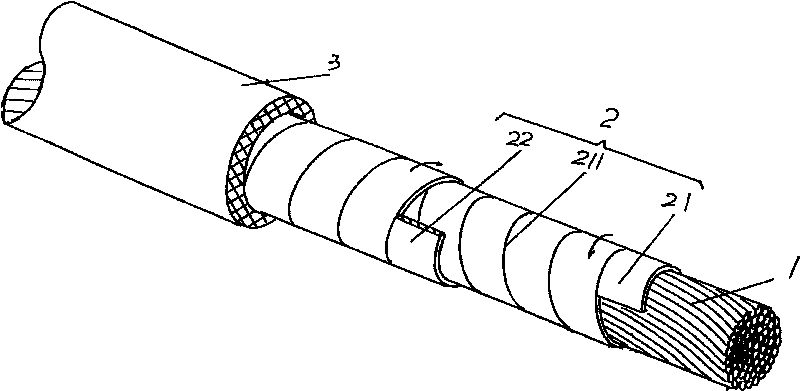

[0009] Please refer to the accompanying drawings, the conductive wire core 1 is formed by twisting a plurality of metal wires such as copper wire or copper-aluminum composite wire or aluminum wire, and the wrapping layer 2 is wrapped around the conductive wire core 1. The wrapping layer 2 is composed of a first fire-resistant mica tape 21 and a second fire-resistant mica tape 22. The first fire-resistant mica tape is wrapped around the conductive wire core 1 in the direction of the arrow shown in the drawing. The so-called joint type It means that there is no overlap between adjacent pitches, but wrapping in an end-to-end manner. The second refractory mica tape 22 is also connected and wrapped around the first refractory mica tape 21 according to another arrow direction marked in the accompanying drawings, and the pitch of the first refractory mica tape 21 is bounded by the second refractory mica tape 22 The gap 211 between them is closed. This way of wrapping the first and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com