Surface wrapping technology of puffed food based on sine wave push

A puffed food, sine wave technology, applied in the confectionery industry, food coating, confectionery, etc., can solve the problems of low wrapping efficiency, leak wrapping, insufficient uniform wrapping on the food surface, etc., and improve wrapping efficiency. , The effect of wrapping the material evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The surface wrapping technology of bar food, its step is:

[0040] (1) Wrapping and conveying process of stick food:

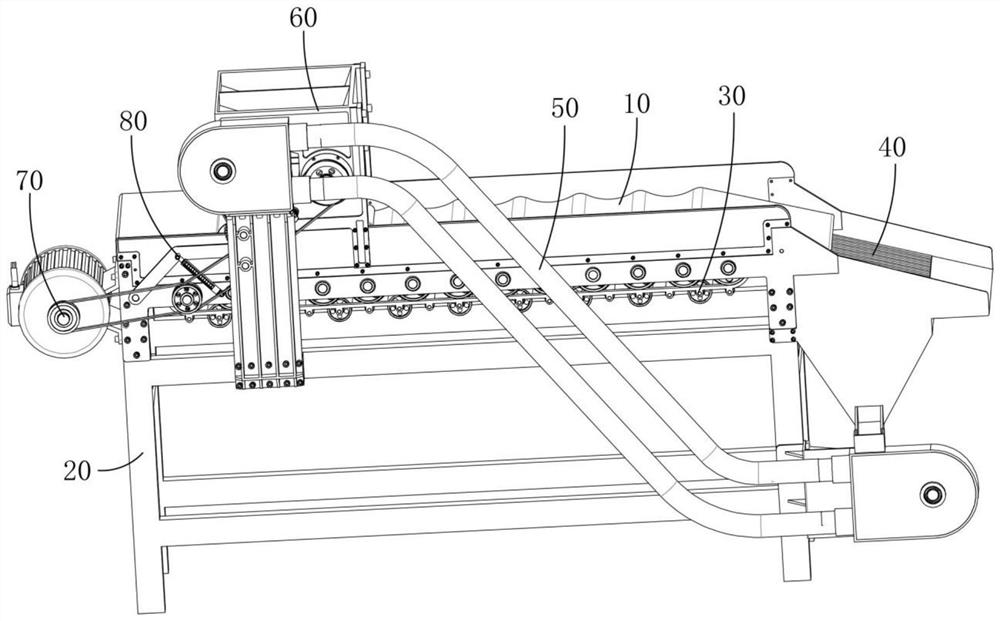

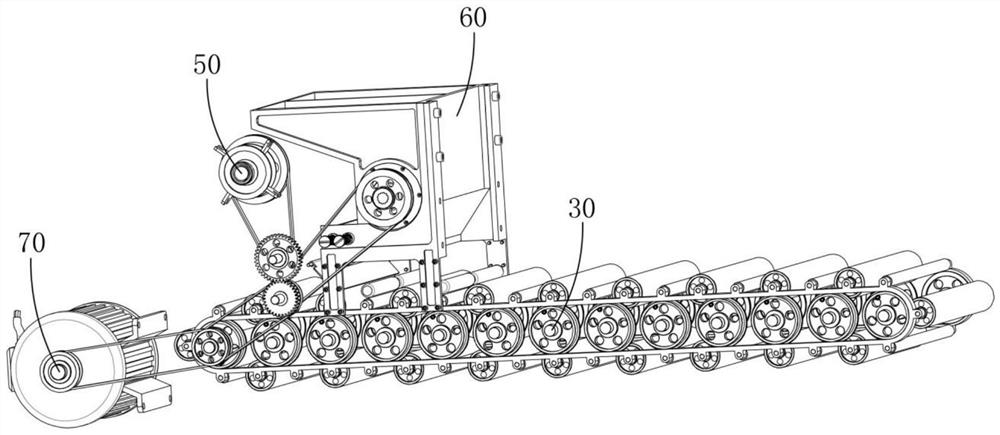

[0041]S1. The stick-shaped food enters the wrapping machine and falls onto the conveyor belt 10 of the wrapping machine. The conveyor belt 10 is powered by the transmission conveying mechanism 30 set on the wrapping machine, and is powered by the power supply mechanism set on the wrapping machine. 70 provides power, and the power supply mechanism 70 includes a motor 710, a first transmission component, a second transmission component, and a third transmission component. The transmission transmission mechanism 30 includes several transmission transmission elements, and the transmission transmission elements include The first transmission pulley 310, the second transmission pulley 330, and the connecting shaft 320, the first transmission part includes a drive pulley 720 coaxially fixedly sleeved outside the output shaft of the motor 710, coaxially fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com