Automatic packaging machine with wrapping molding device

A technology of automatic packaging machine and forming device, which is applied in the direction of wrapping paper bending device, packaging, transportation packaging, etc., can solve the problems of increasing labor cost and production cost, increasing labor intensity, and low degree of intelligence, so as to reduce labor intensity , low production cost and high folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

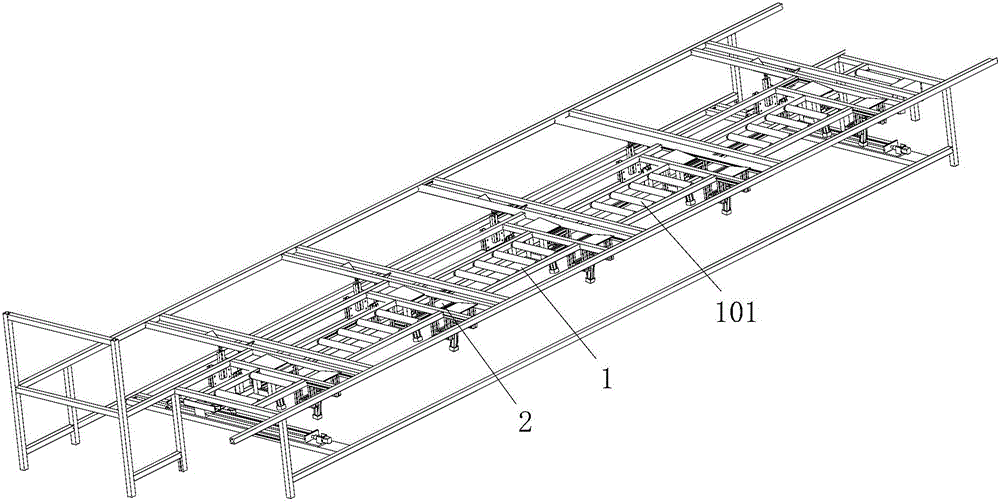

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

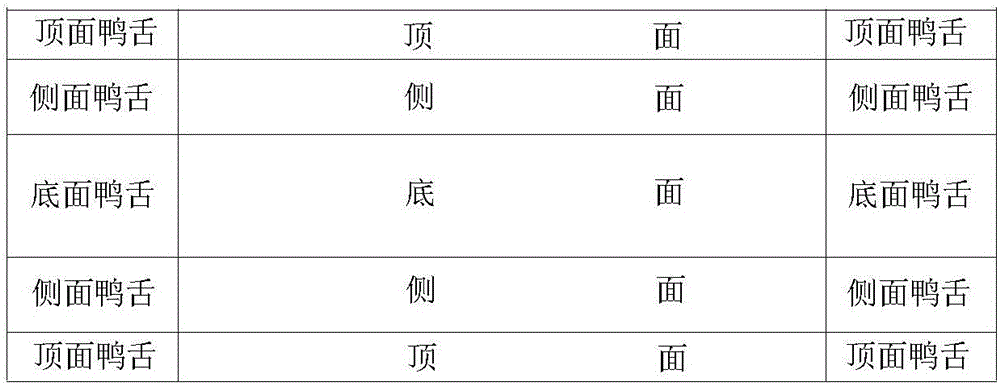

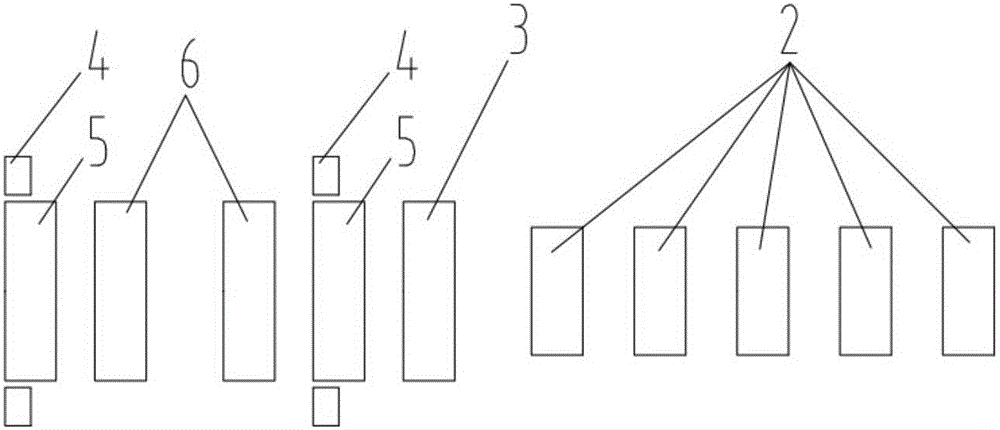

[0033] like Figure 1 to Figure 8 As shown, an automatic packaging machine with a wrapping forming device, including a frame and a control system, a wrapping forming area is arranged on the frame along the length direction of the frame, and a carton placement area 1 is arranged in the wrapping forming area , the carton placement area 1 is provided with a number of unpowered conveying rollers 101 along its length direction, and the cartons with the packaged objects to be transported are laid flat on the carton placement area 1, and the side folding, top folding, and side ducking need to be completed in sequence. Tongue folding, top duck tongue folding, and bottom duck tongue folding, this series of folding processes need to rely on the following structures:

[0034] On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com