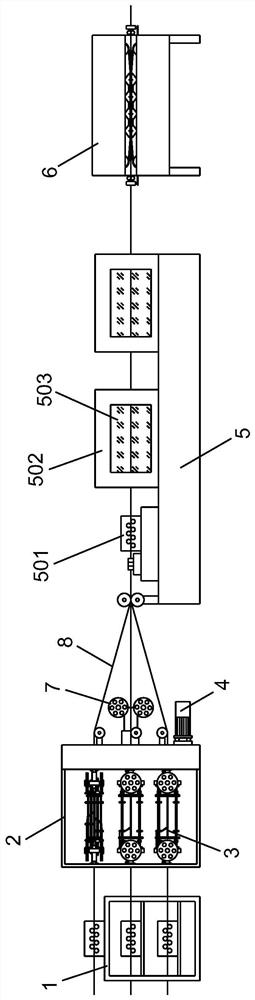

Electromagnetic wire wrapping device

An electromagnetic wire and wrapping technology, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve problems such as the inability to wrap more than three layers, improve wrapping efficiency, reduce equipment investment, and ensure order sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: as Image 6 Each briquetting block 604 on the crawler tractor 6 is controlled by a pneumatic device respectively, and a number of pressure rollers are arranged at the bottom of each briquetting block 604, and the pneumatic device can be used to press the briquetting block 604 tightly on the crawler belt 603 to generate sufficient friction force, and the adjacent pressing blocks 604 are movably connected by connecting rods 605, so that each pressing block 604 is driven by the pneumatic device to maintain consistency as much as possible.

Embodiment 2

[0053] Embodiment 2: as Figure 7 , the inner side of the track 603 is provided with cogs, the roller 602 and the briquetting block 604 are gears meshed with the cogging, the roller 602 and the briquetting block 604 are driven by the motor to rotate, and the roller 602 on the upper side and the briquetting block 604 are fixed On the back plate 606, the back plate 606 is controlled by a pneumatic device to lift up and down, so that the upper and lower crawlers 603 fit together; the crawler belt 603 directly relies on the cogging drive on the inner side, which can avoid slipping between the crawler belt 603 and the roller 602, ensuring that the crawler belt 603 driving force.

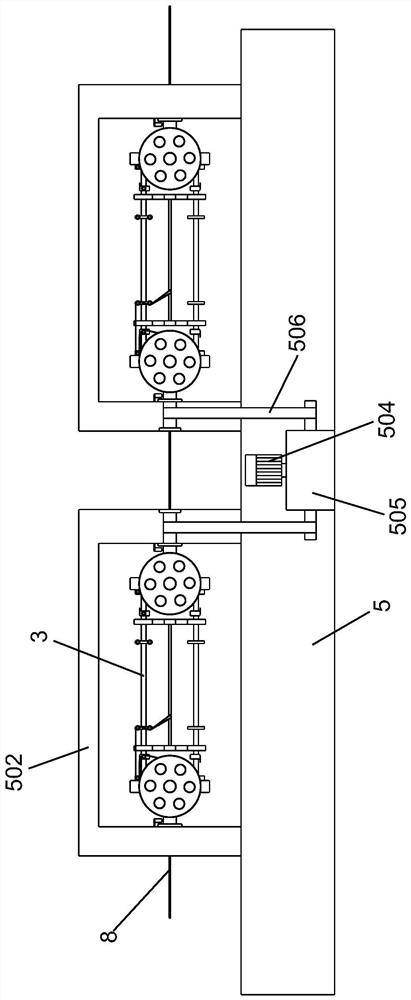

[0054] In order to facilitate speed regulation and realize stepless speed change, both the first motor 4 and the second motor 504 are variable frequency motors.

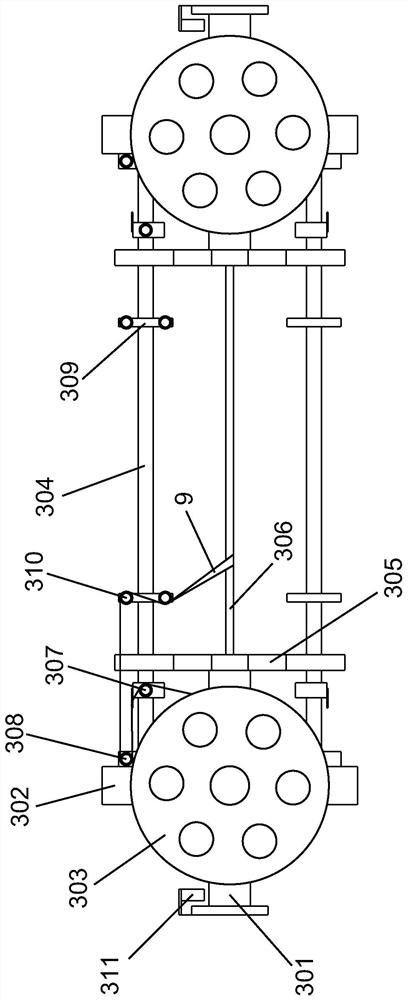

[0055] The first straightening assembly 1 includes several sets of straightening rollers arranged vertically and staggeredly to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com