Fully-automatic screw locking machine

A screw locking machine and fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as poor continuity, low efficiency, and slow progress, and achieve continuous work continuity and convenient use and management , strong coherent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

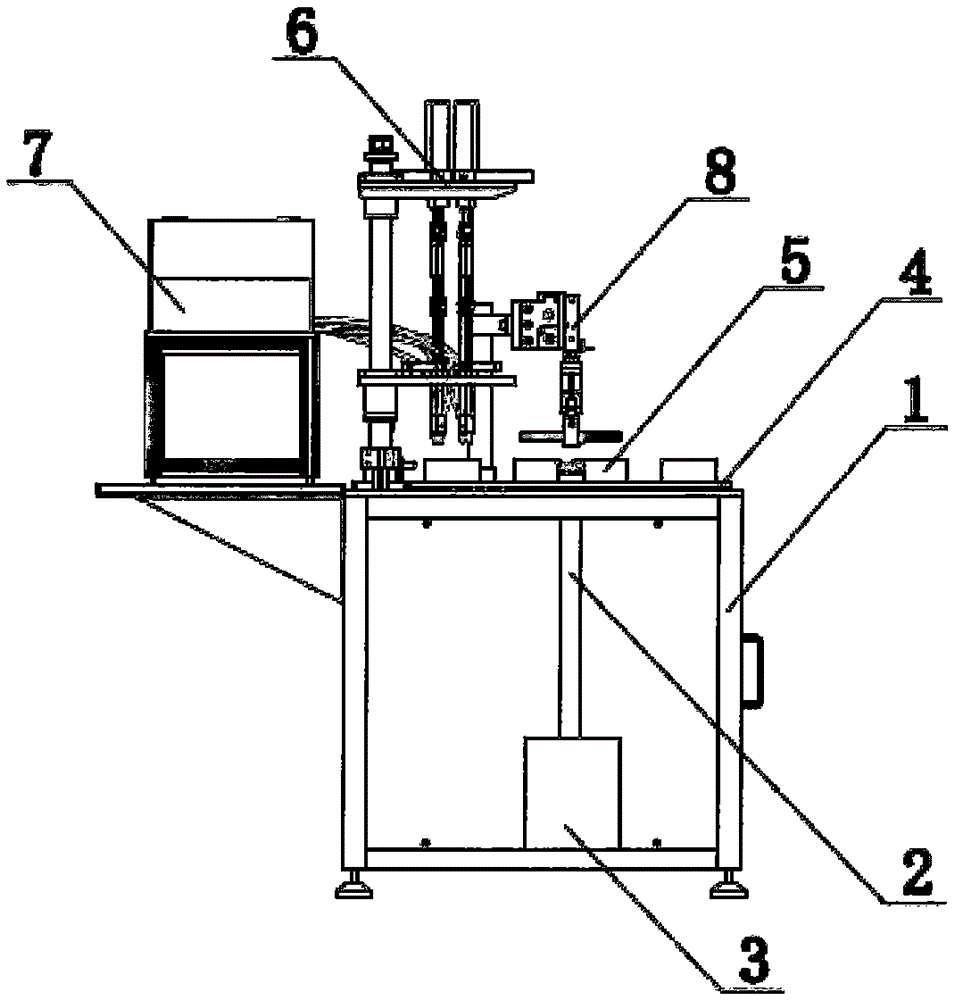

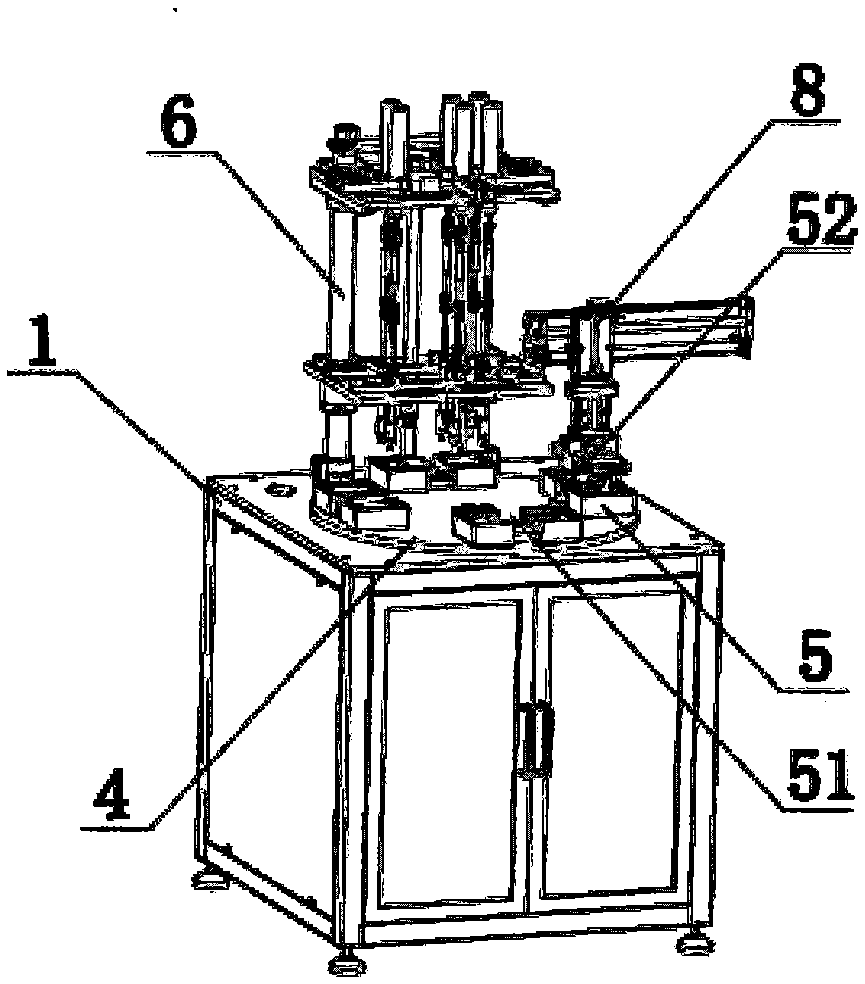

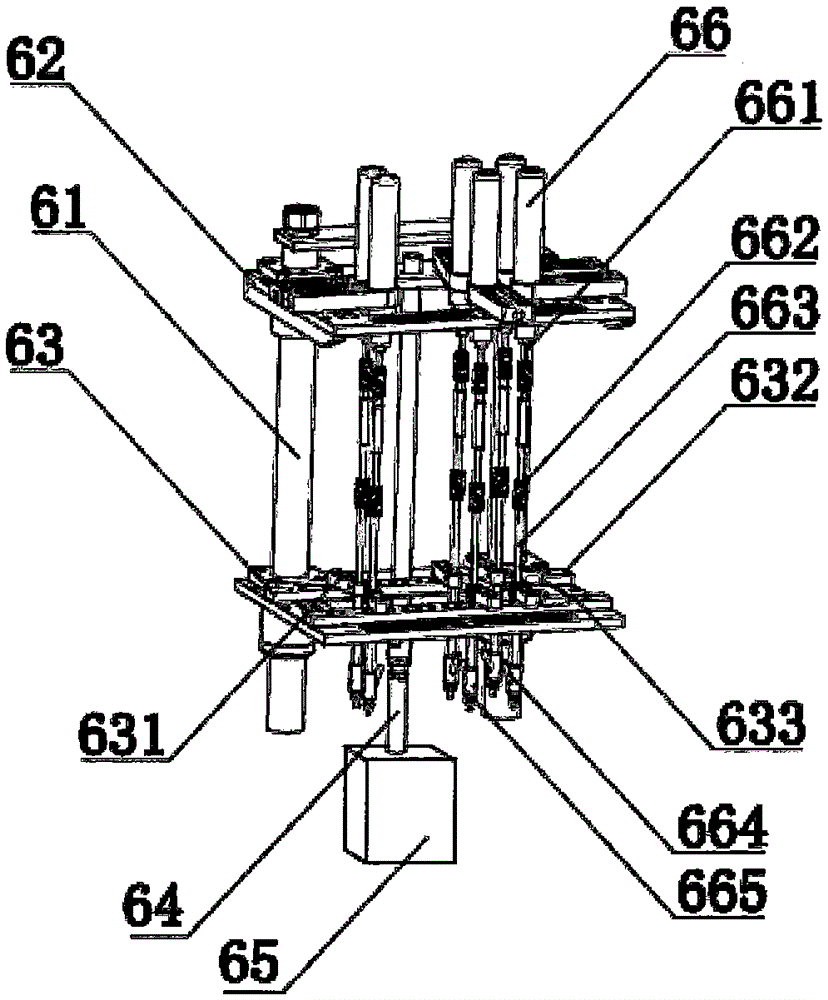

[0029] Example: such as figure 1 and 2 As shown, a fully automatic screw locking machine includes a frame 1, a main shaft 2 is vertically arranged in the middle of the frame 1, the lower end of the main shaft 2 is accommodated in the frame 1 and connected with a main motor 3, and the upper end of the main shaft 2 extends Out of the frame 1 and connected to a turntable 4, the main shaft 2 is just connected to the bottom of the center of the turntable 4, and a circle of four mold boxes 5 is arranged around the center of the turntable 4, and these mold boxes 5 are arranged at equal arc lengths. , the radius of each mold box 5 from the center of the turntable 4 is equal, that is, the pattern layout is consistent, so as to ensure that each mold box 5 always moves away from the position when the previous mold box 5 moves away from the position during the step-by-step rotation of the turntable 4 The state of placement is consistent, and the exposed surface of the upper end of each m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com