Paper cup machine

A technology of paper cup machines and paper cups, which is applied in the direction of paperboard winding articles, etc., can solve the problems of restricting the speed of paper cups, the production cannot be improved, etc., and achieve the effects of strong coherence of actions, high-speed production of paper cups, and outstanding substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

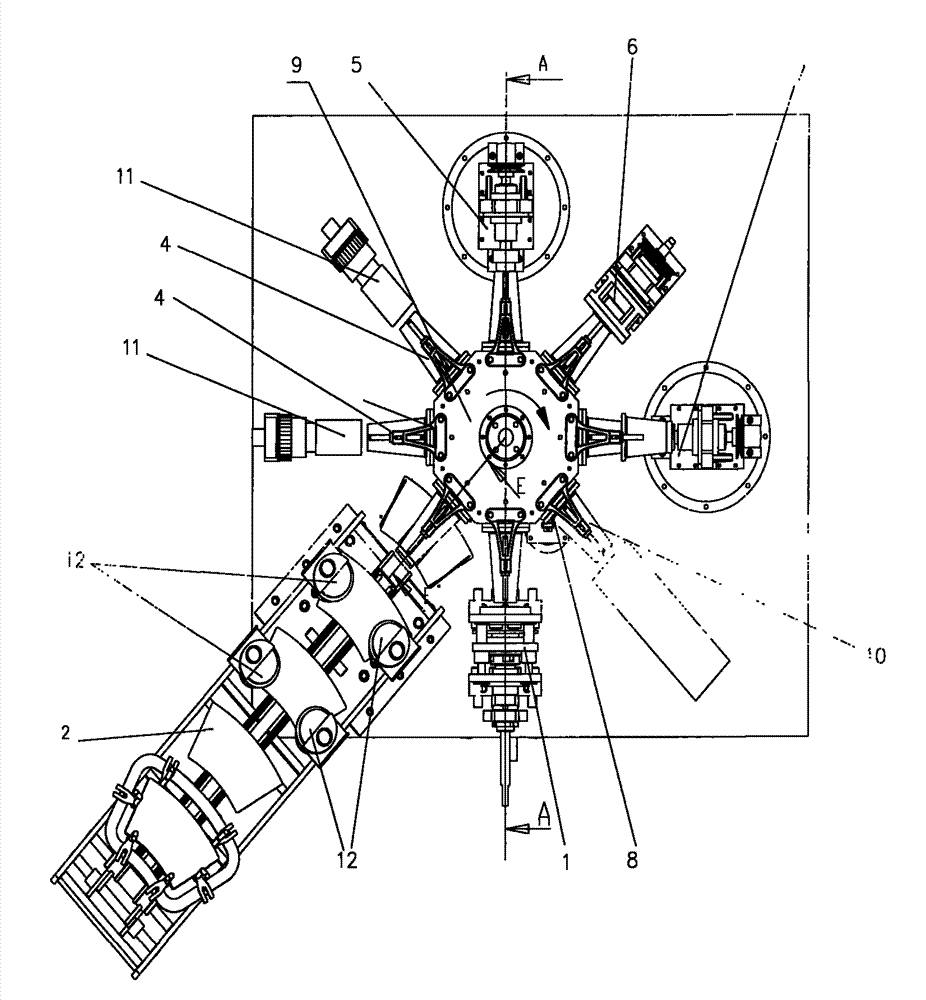

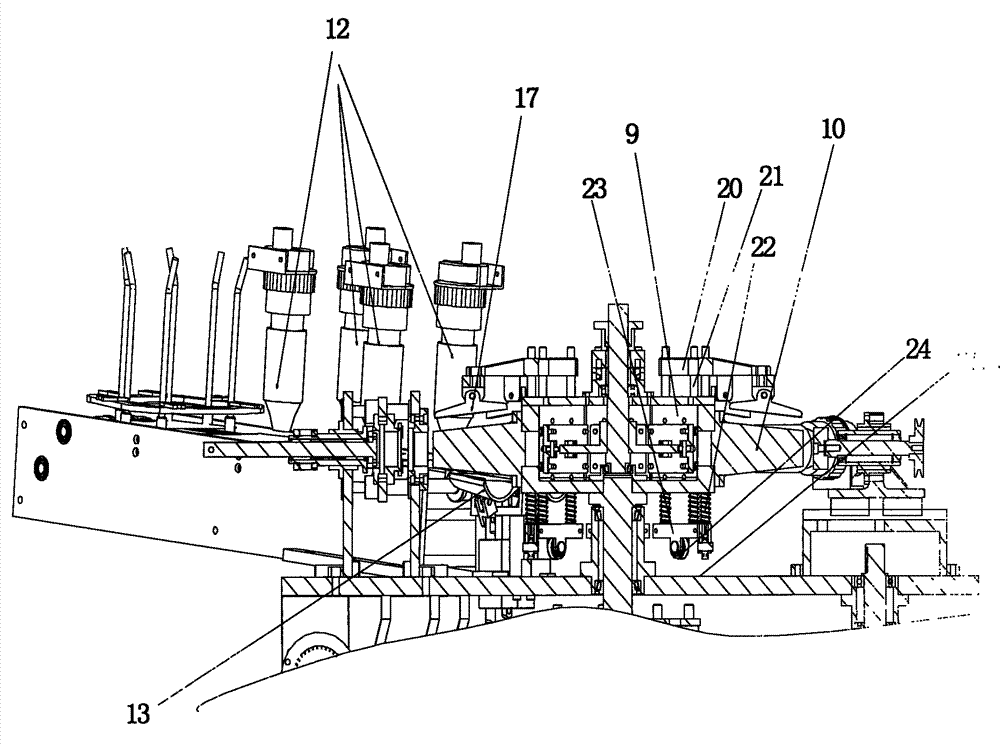

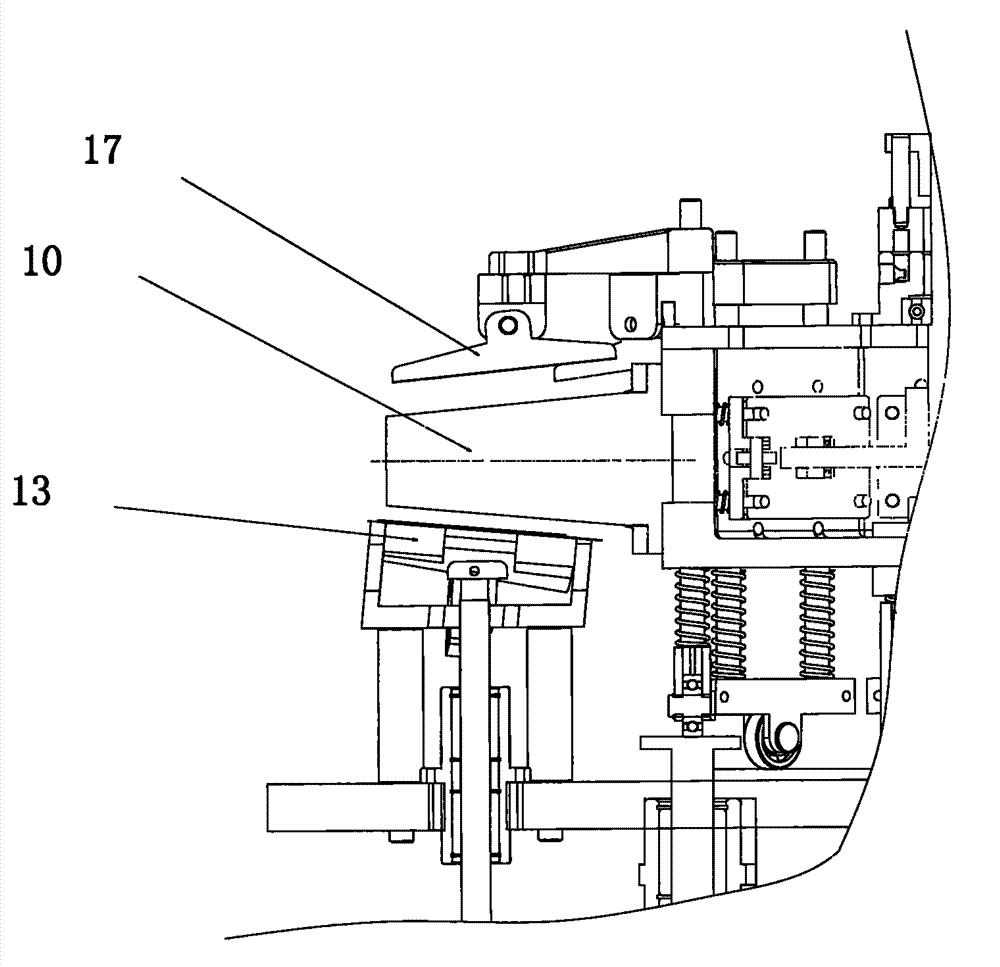

[0012] The accompanying drawings show the structure of the present invention and its embodiments. The details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings: This kind of horizontal paper cup machine has a cup bottom paper feeding station 1, a cup paper feeding station Station 2, paper cup forming and bonding station 3, two cup bottoms and paper cup heating station 4, cup bottom rolling station 5, cup bottom bonding and knurling station 6, cup edge curling station 7, forming The last paper cup unloading station 8 and a rotating disk 9, the rotating disk 9 is connected to the transmission device, the rotating disk 9 is provided with a cup mold 10, and the cup mold 10 is horizontally arranged on the circumference of the rotating disk 9 On the other hand, when the rotating disk 9 rotates, the cup mold 10 passes through the above-mentioned stations in sequence, and the first heater 11 is equipped at the two cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com