Process and system for manufacturing military nitre or black gunpowder

A technology of black powder and military nitrate, which is applied in the process and system field of military nitrate or black powder particles, can solve the problem that the uniformity of mixing and the controllability of quality cannot meet the design requirements, and the uniformity and quality controllability of ball milling The problem of low collision frequency and uncontrollable degree of crushing can achieve the effect of realizing assembly line program control, reducing personal casualties and property losses, and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

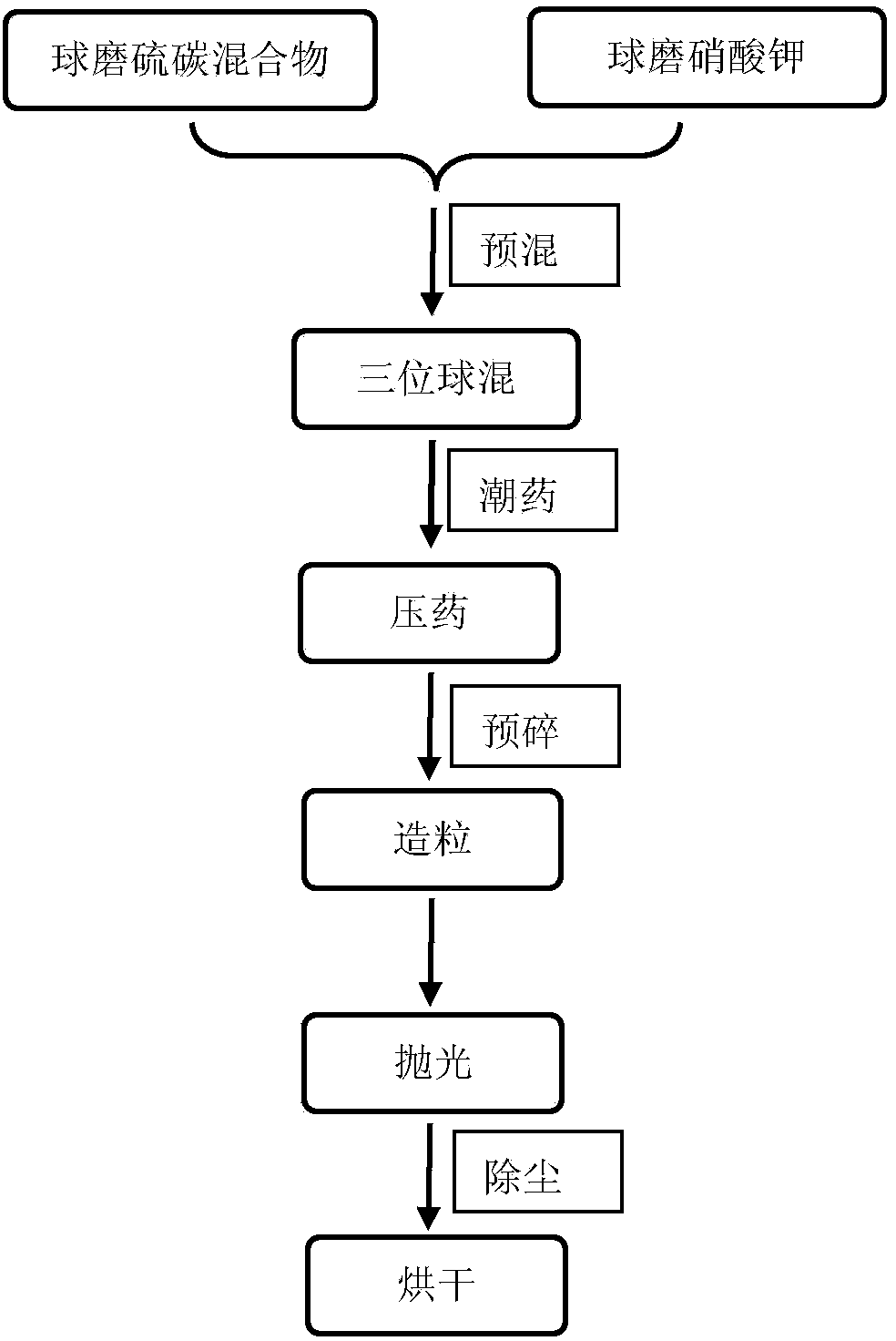

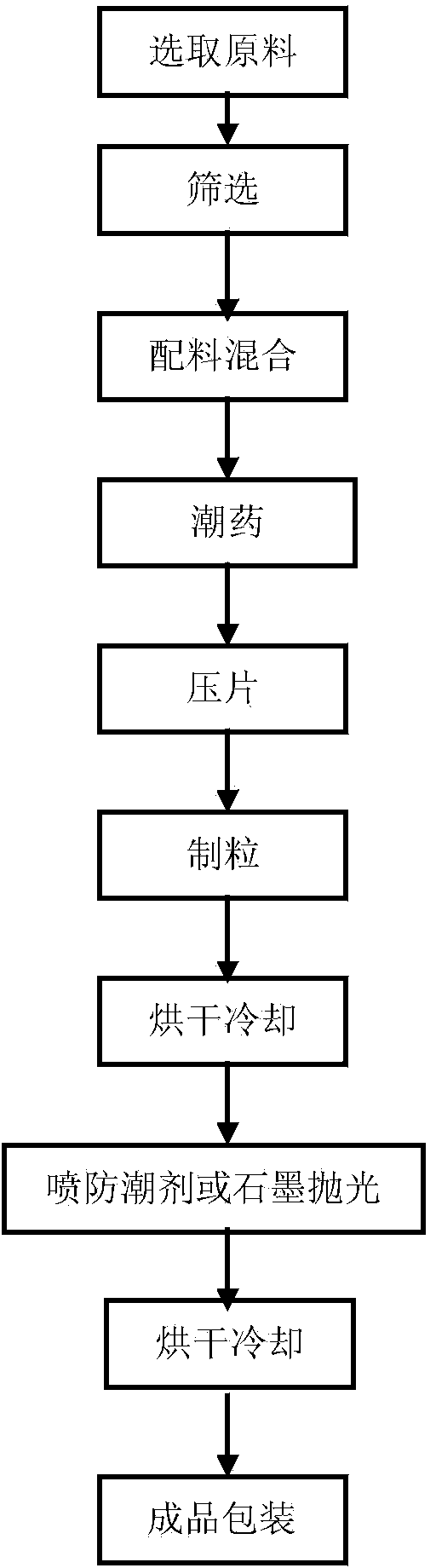

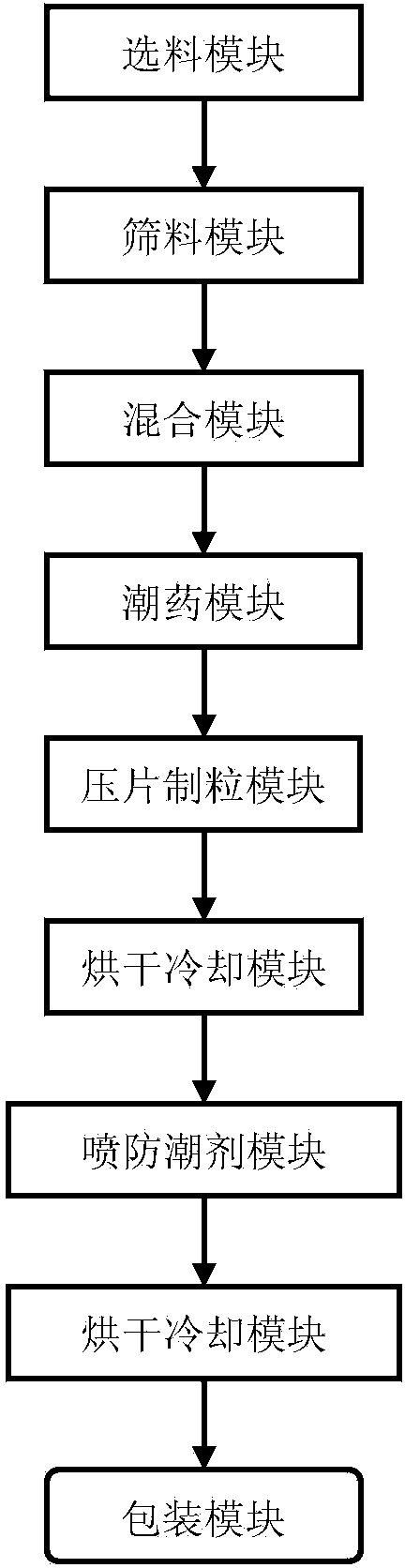

[0040] figure 2It shows a process example of manufacturing military nitrate or black gunpowder of the present invention, and the production steps include material selection, sieving, mixing, damp medicine, granulation, drying, cooling, spraying moisture-proof agent, drying, cooling , and finally pack the finished product of military nitrate or black powder granules. Be specifically: (1) select raw material, described raw material comprises: potassium nitrate 75%, carbon sulfur compound 25% (2) screening: the raw material is respectively passed through more than 100 mesh screening; (3) proportioning mixes: through step (2) ) The single raw material screened is directly mixed by pyrotechnic powder automatic mixer 21 according to the proportioning ratio, and stirred for 3-5 minutes until uniform, and the direct mixing of raw materials is adopted. In this process, the explosion accidents that often occur in the traditional process are not easy to occur, and the mixing efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com