Metal pouring die of hydraulic core pulling structure

A technology of core-pulling structure and metal pouring, which is applied in the direction of metal processing equipment, cores, manufacturing tools, etc., can solve the problems of high guide fit precision, non-adjustable stroke distance, and large wearability of supporting parts, etc., to achieve structural design Effects of novelty, labor cost reduction, and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

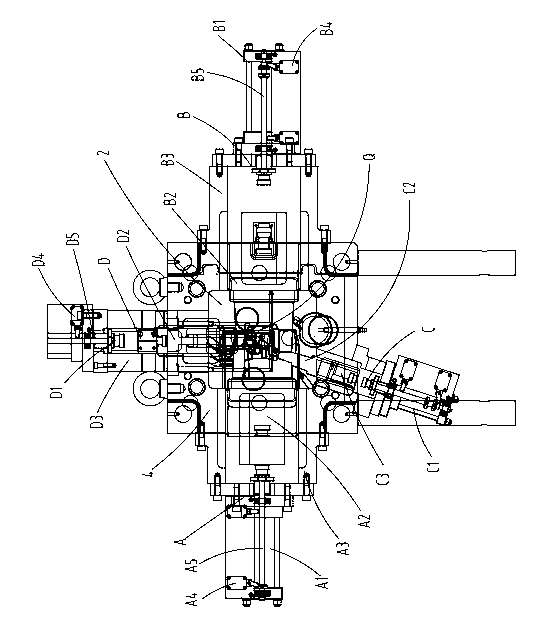

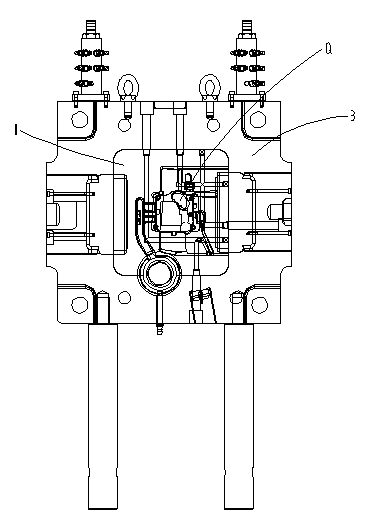

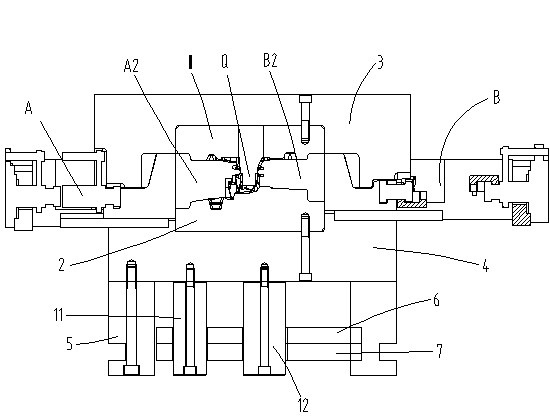

[0037] Such as Figure 1 to Figure 16 As shown, the description of the icon numbers is as follows: upper mold core 1, lower mold core 2, upper mold frame 3, lower mold frame 4, mold foot 5, upper top plate 6, lower top plate 7, guide slide rod 8, first support pillar 11 , the second support column 12, a core-pulling assembly A on the side, a core-pulling hydraulic cylinder A1 on the side, a core-pulling block A2 on the side, a core-pulling seat A3 on the side, a travel switch A4 on the side, a travel switch lever A5 on the side, Second core-pulling assembly B, side two core-pulling hydraulic cylinder B1, side two core-pulling block B2, side two core-pulling seat B3, side two stroke switch B4, side two stroke switch lever B5, side three core-pulling assembly C, side three Core-pulling hydraulic cylinder C1, three-side core-pulling block C2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com