Mining equipment operation data transmission, intelligent early warning and remote consultation analysis system and method

A technology of operating data and mining equipment, which is applied in the field of remote consultation and analysis system, mining equipment operating data transmission, and intelligent early warning. problems, to achieve the effect that is conducive to overall process management, realize full life cycle management, and reduce production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

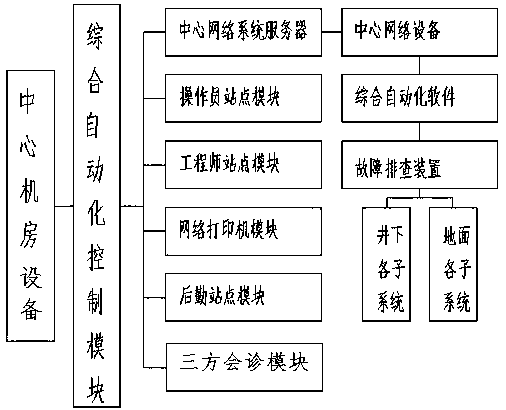

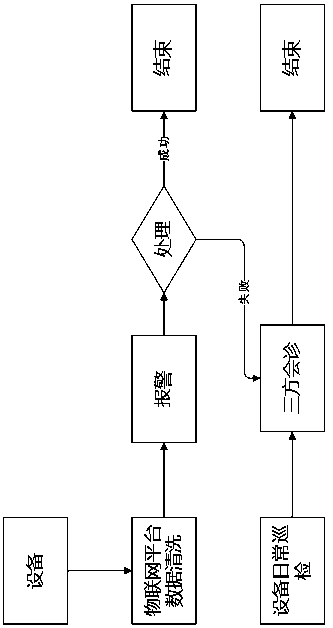

[0020] Such as figure 1 , 2 As shown, a mine equipment operation data transmission, intelligent early warning, remote consultation and analysis system includes central computer room equipment, and the central computer room equipment is connected with the central network system server, operator station module, engineer station module, The network printer module, the logistics station module and the three-party consultation module are connected, the central network system server is connected with the central network equipment, and the central network equipment is equipped with comprehensive automation software, and the central network equipment is connected with the troubleshooting equipment through the comprehensive automation software. The troubleshooting equipment is installed at the positions to be detected of each sub-system in the underground and each sub-system on the ground.

[0021] The underground subsystems and ground subsystems are all connected to the central netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com