Rubber sealing ring surface defect detection method based on machine vision

A rubber sealing ring and defect detection technology, applied in the field of detection, can solve the problems of disadvantageous defect detection, low light intensity, and reduced detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

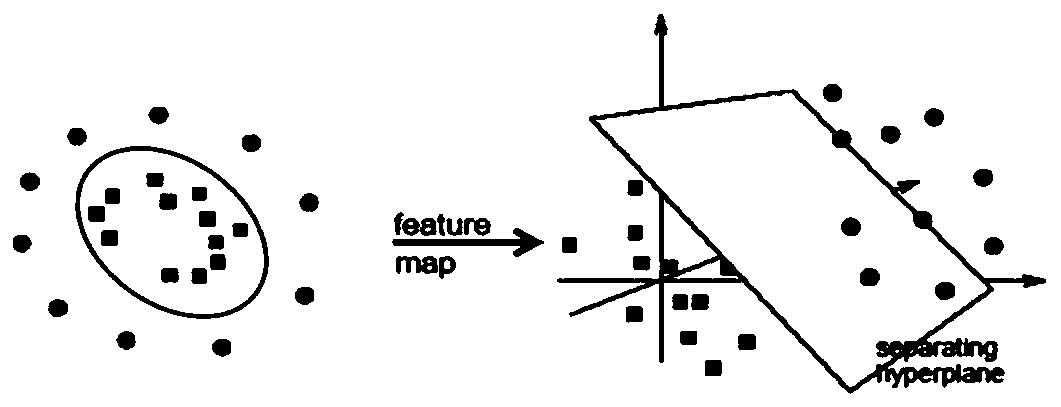

Method used

Image

Examples

Embodiment Construction

[0075] 1) Preparation

[0076] Real-time detection environment: O-ring rubber sealing ring surface defect detection algorithm runs on the sealing ring production line, and related equipment includes computers, high-precision CCD line scan industrial cameras, loading platforms, bowl-shaped LED light sources, etc. The industrial camera communicates with the computer and transmits data through the universal serial bus (USB). In order to eliminate the influence of stray light such as production environment lighting as much as possible, a dark room should be set up; in order to realize automatic detection, an external trigger mechanism is used in the acquisition system. Both the camera and the light source are located above the loading platform. Whenever the sealing ring to be detected on the industrial computer moves directly below the camera and the light source, the external trigger mechanism will send a signal to the camera. After the camera receives an effective trigger signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com