Patents

Literature

85 results about "Blob detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer vision, blob detection methods are aimed at detecting regions in a digital image that differ in properties, such as brightness or color, compared to surrounding regions. Informally, a blob is a region of an image in which some properties are constant or approximately constant; all the points in a blob can be considered in some sense to be similar to each other. The most common method for blob detection is convolution.

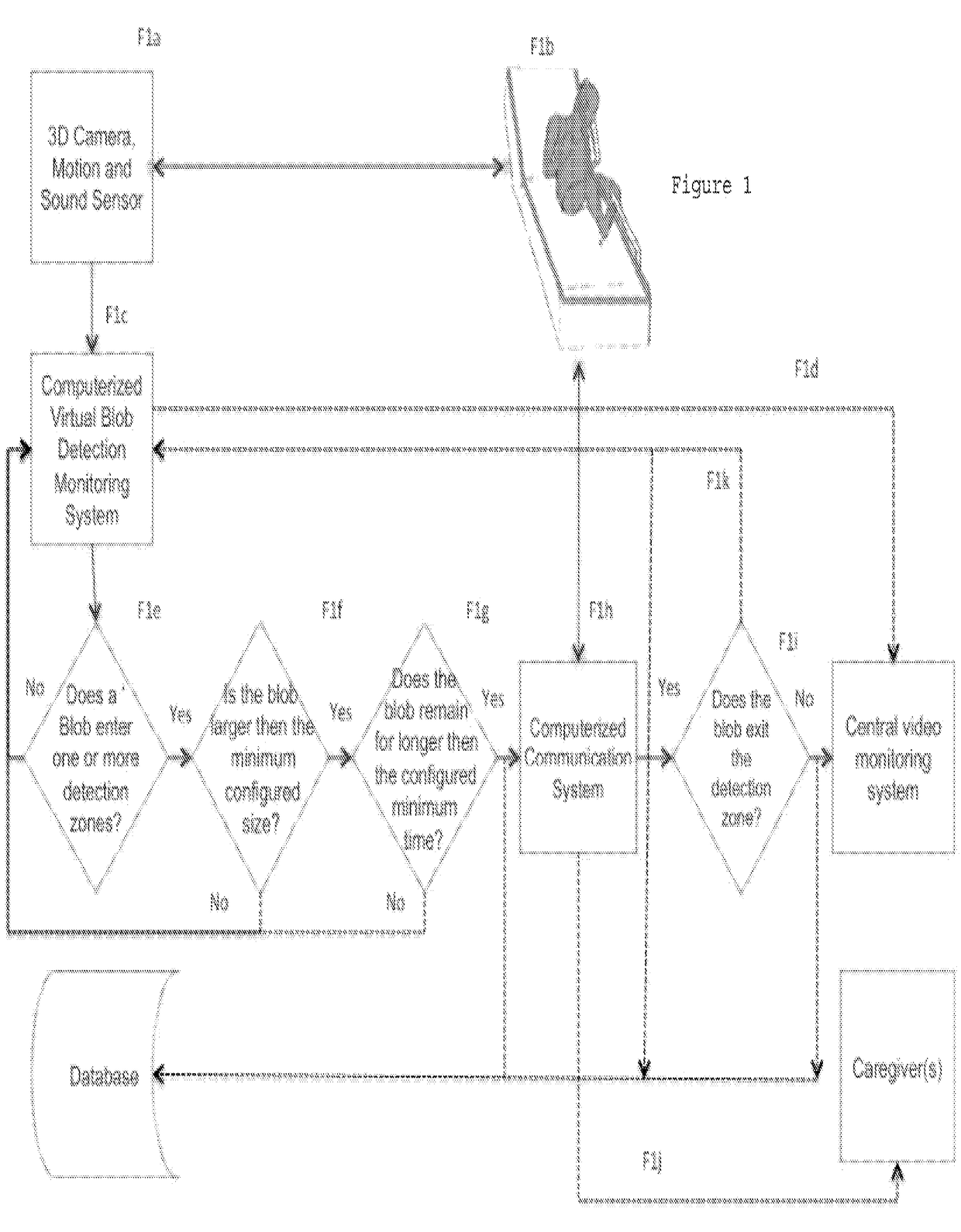

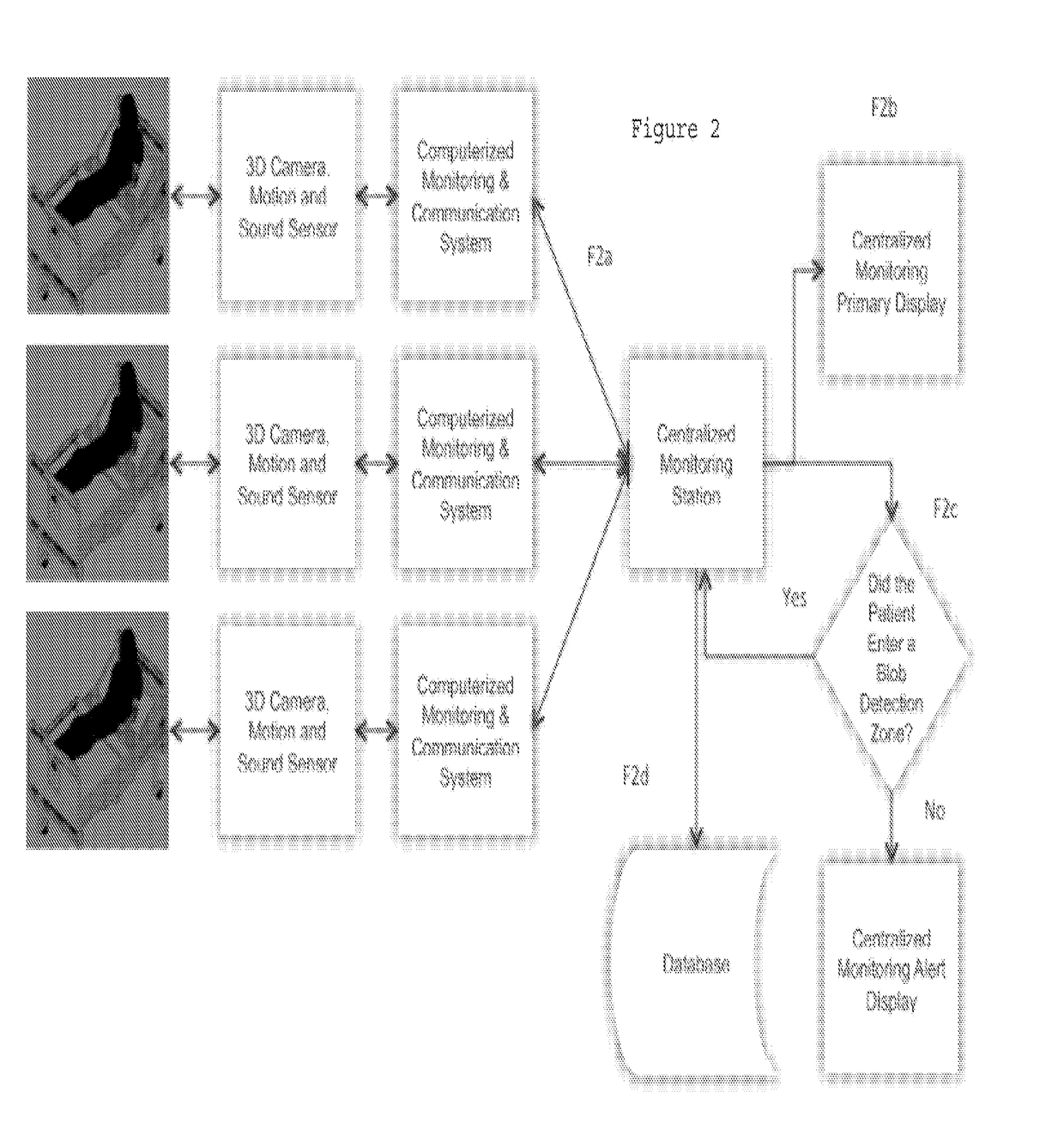

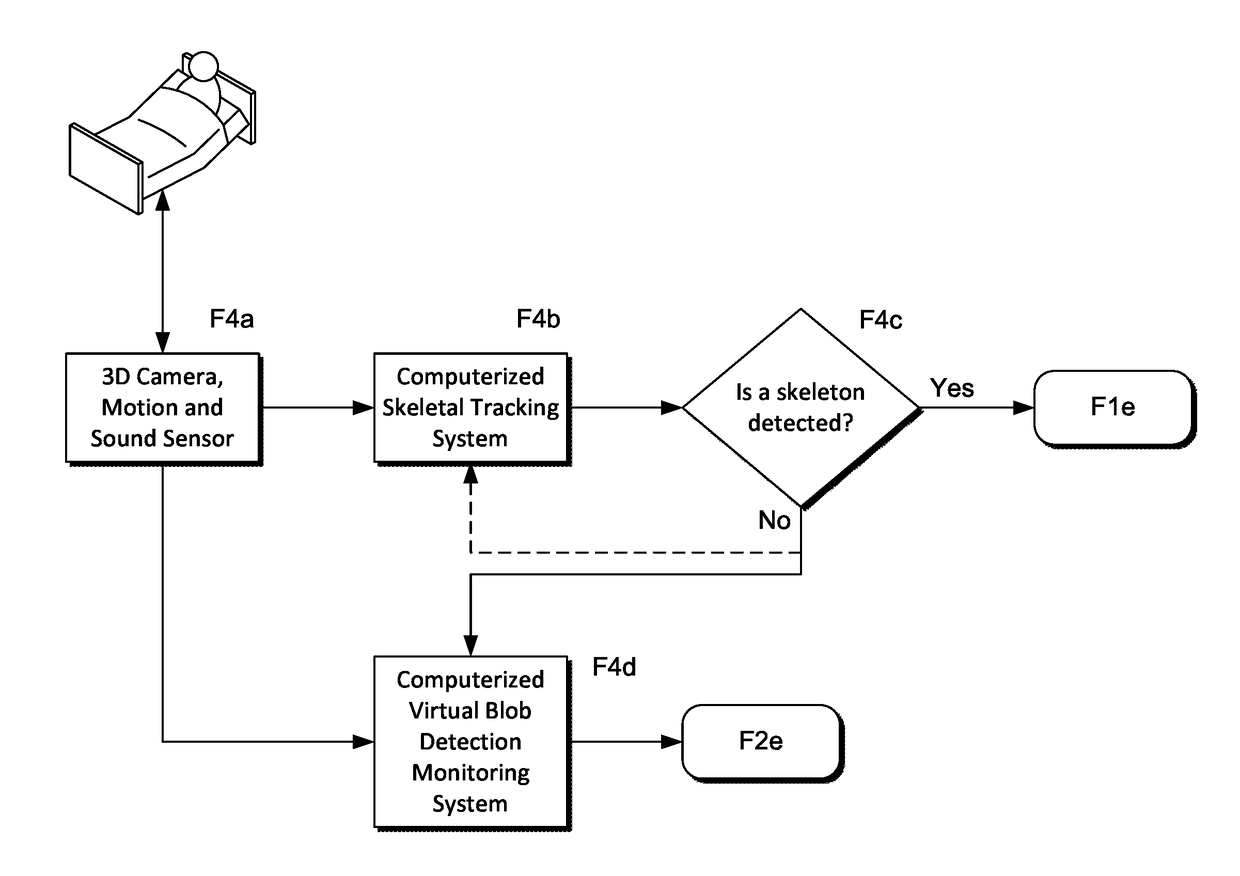

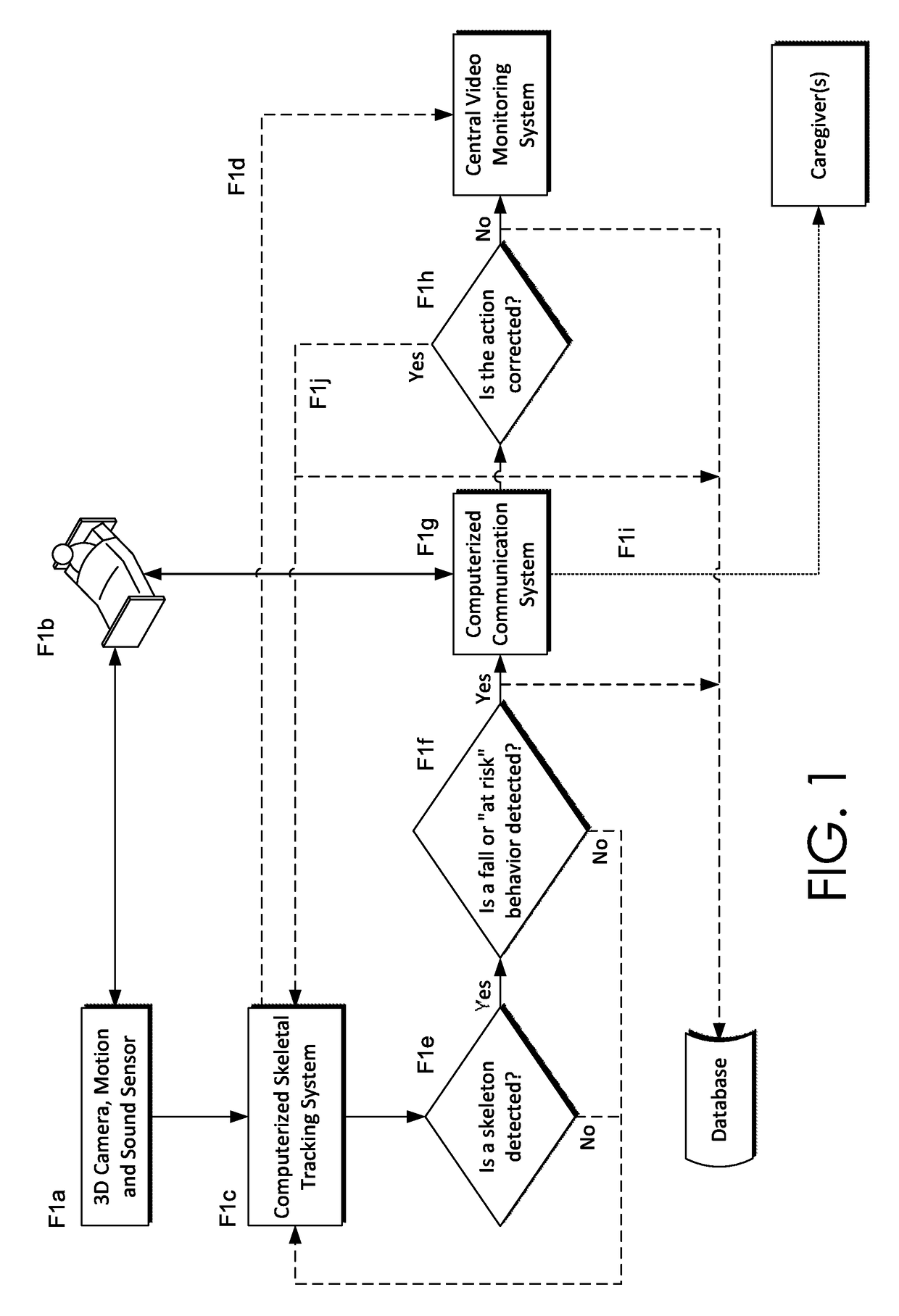

Method for determining whether an individual enters a prescribed virtual zone using skeletal tracking and 3D blob detection

ActiveUS9892611B1Reduce impactPrevent and reduce fallImage enhancementTelevision system detailsOlder peopleBlob detection

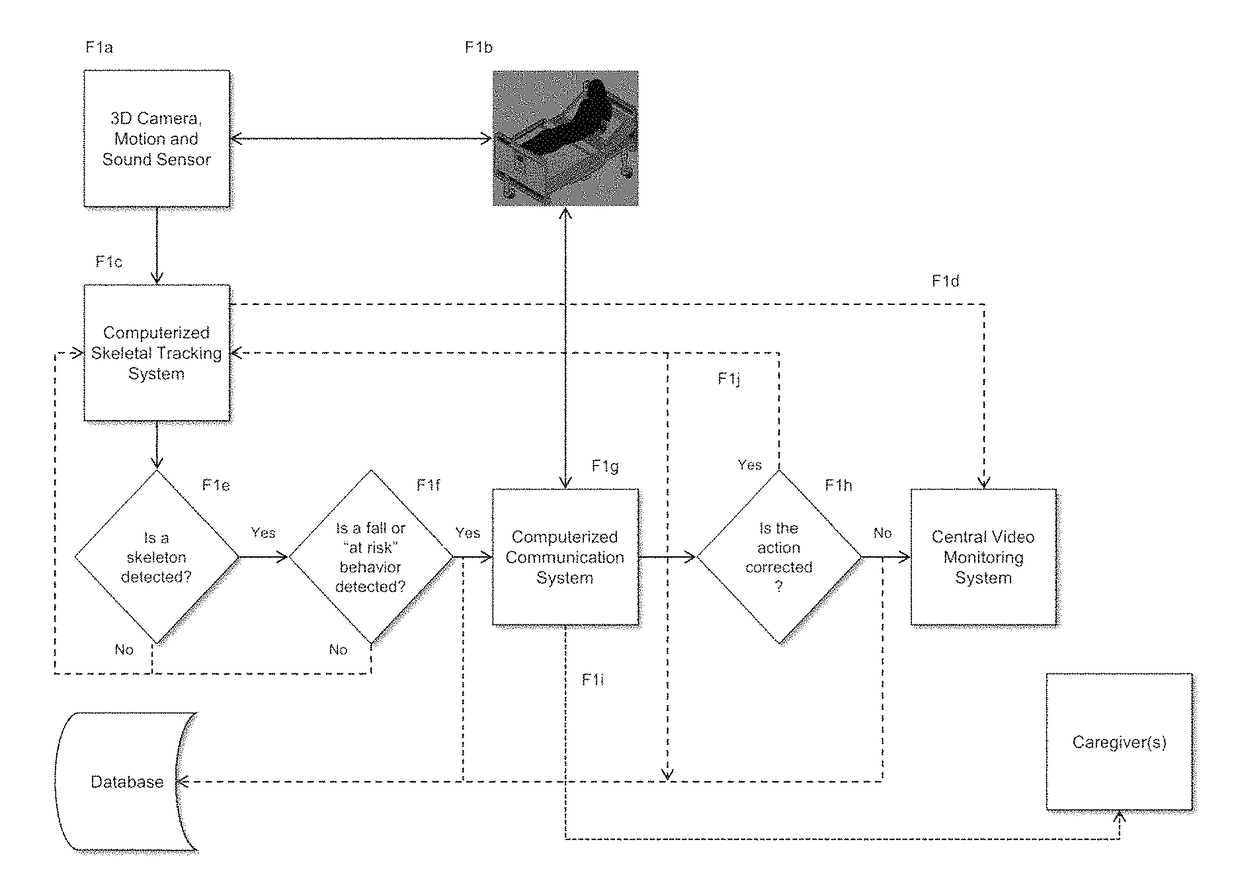

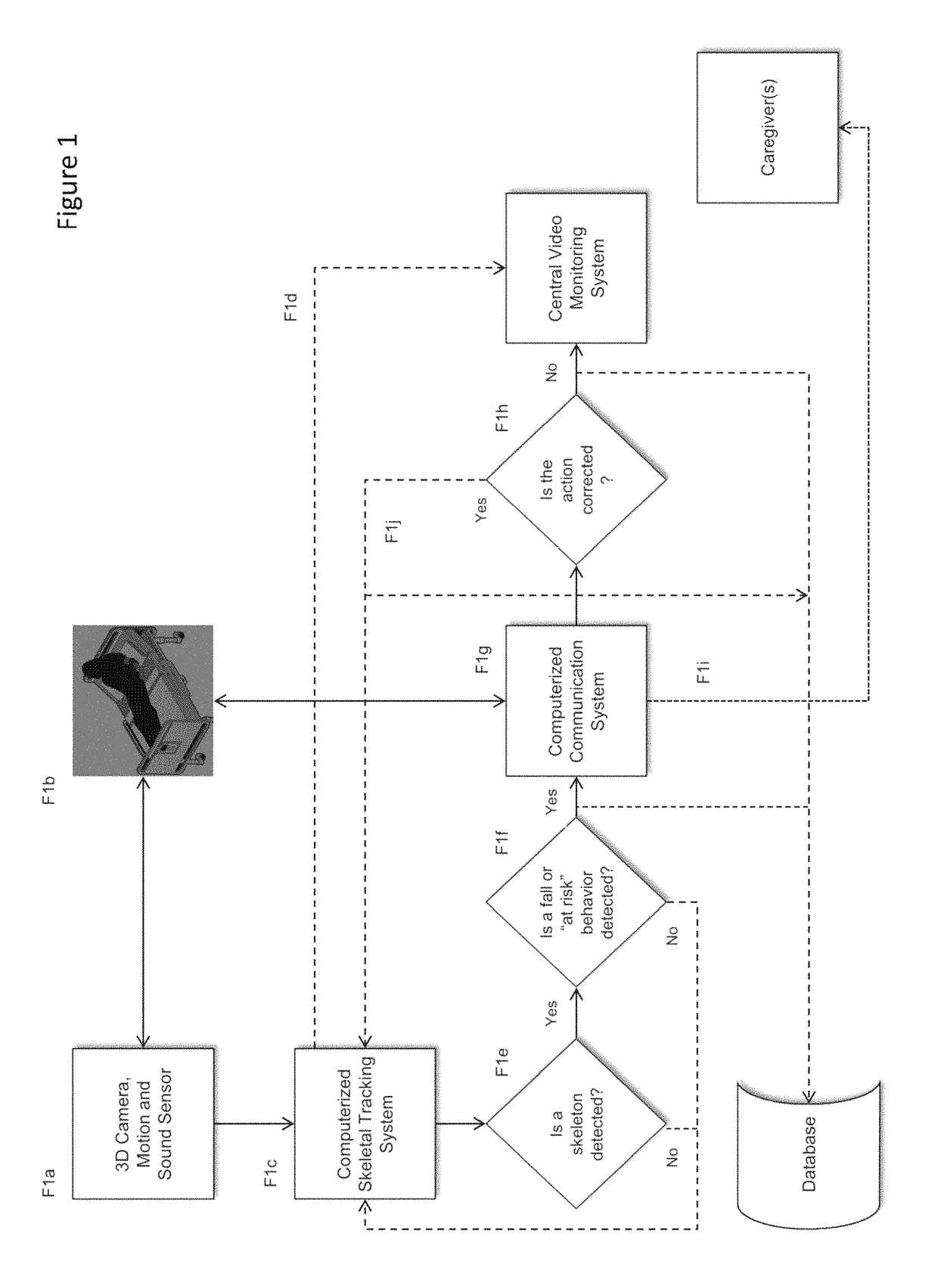

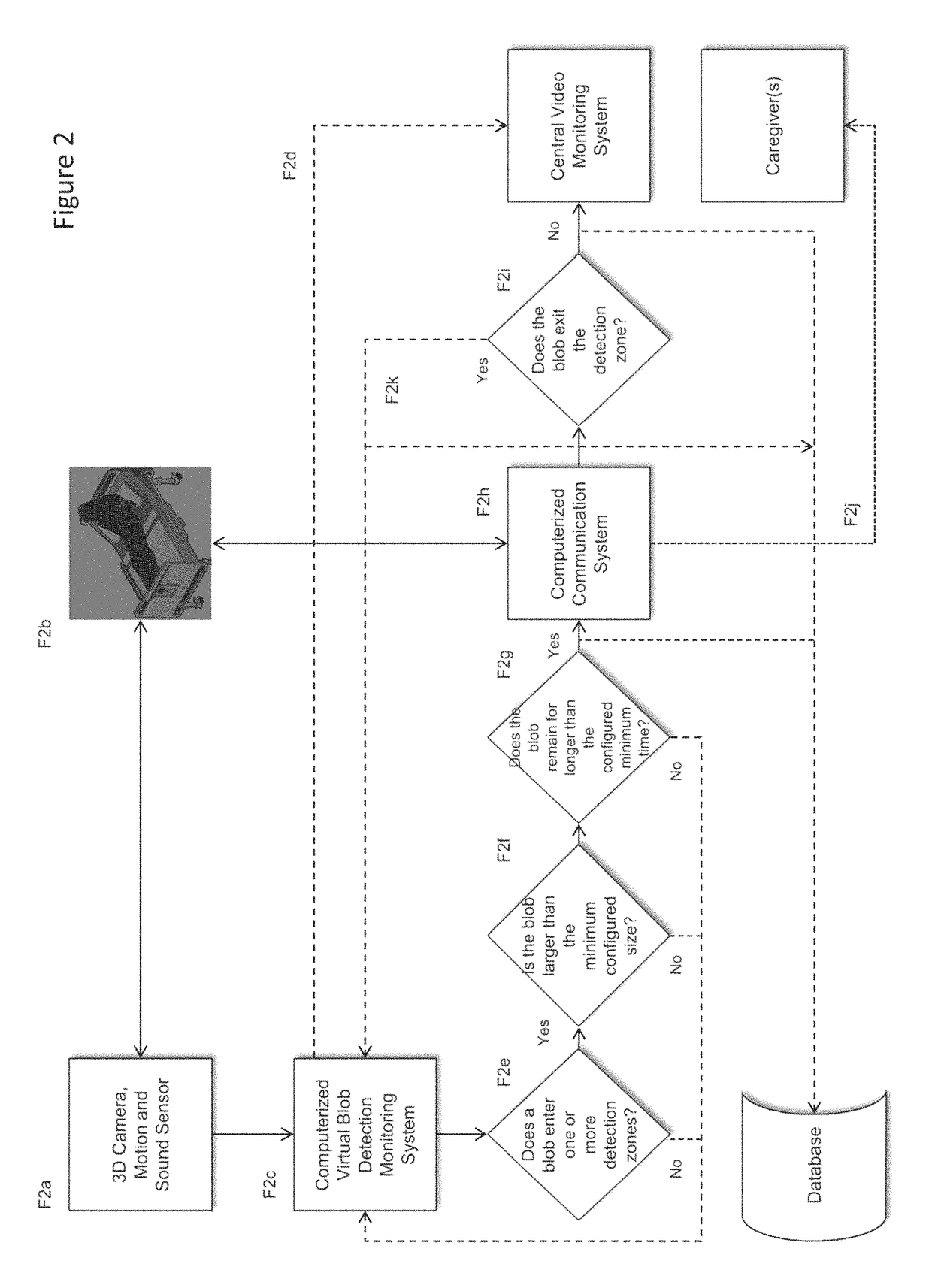

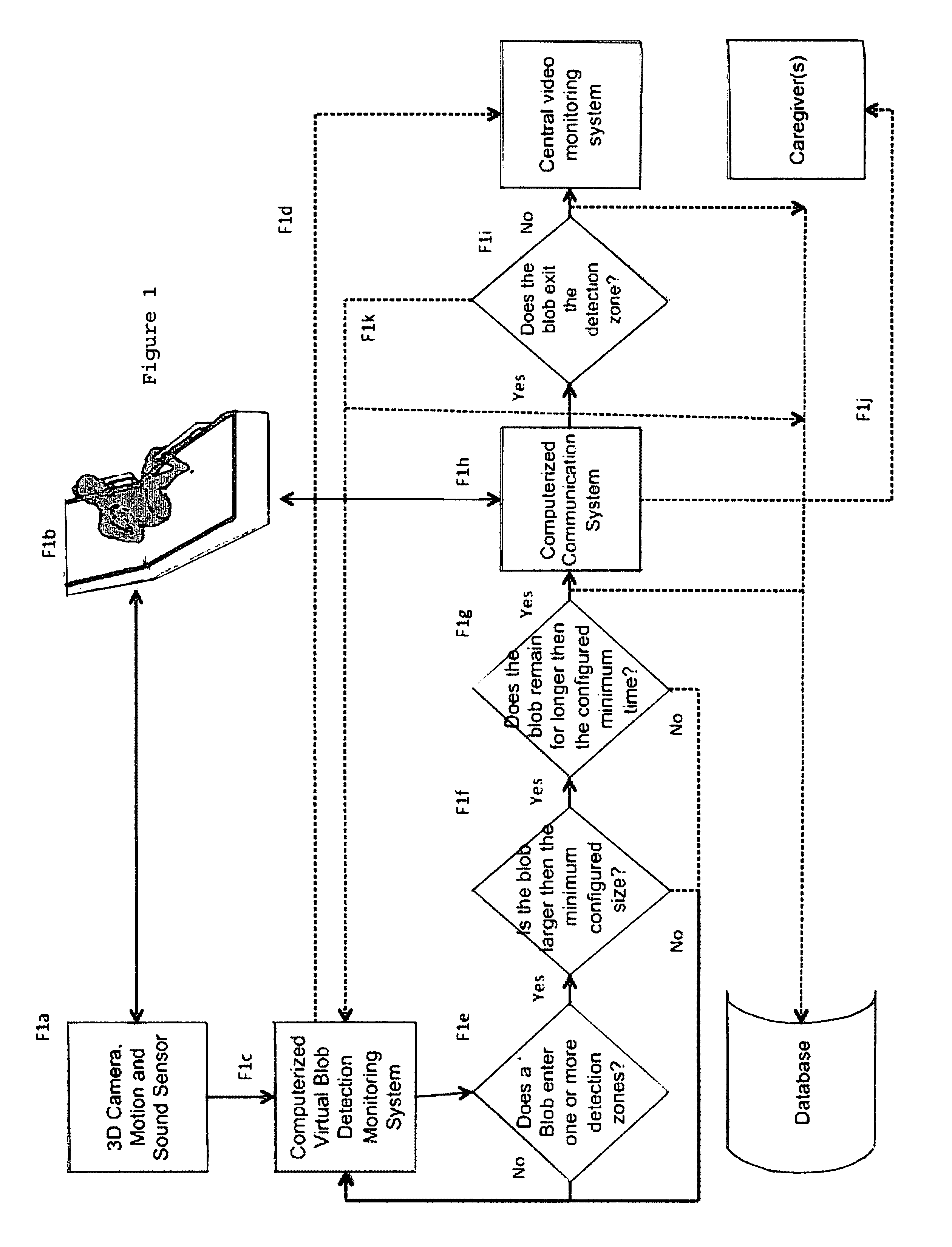

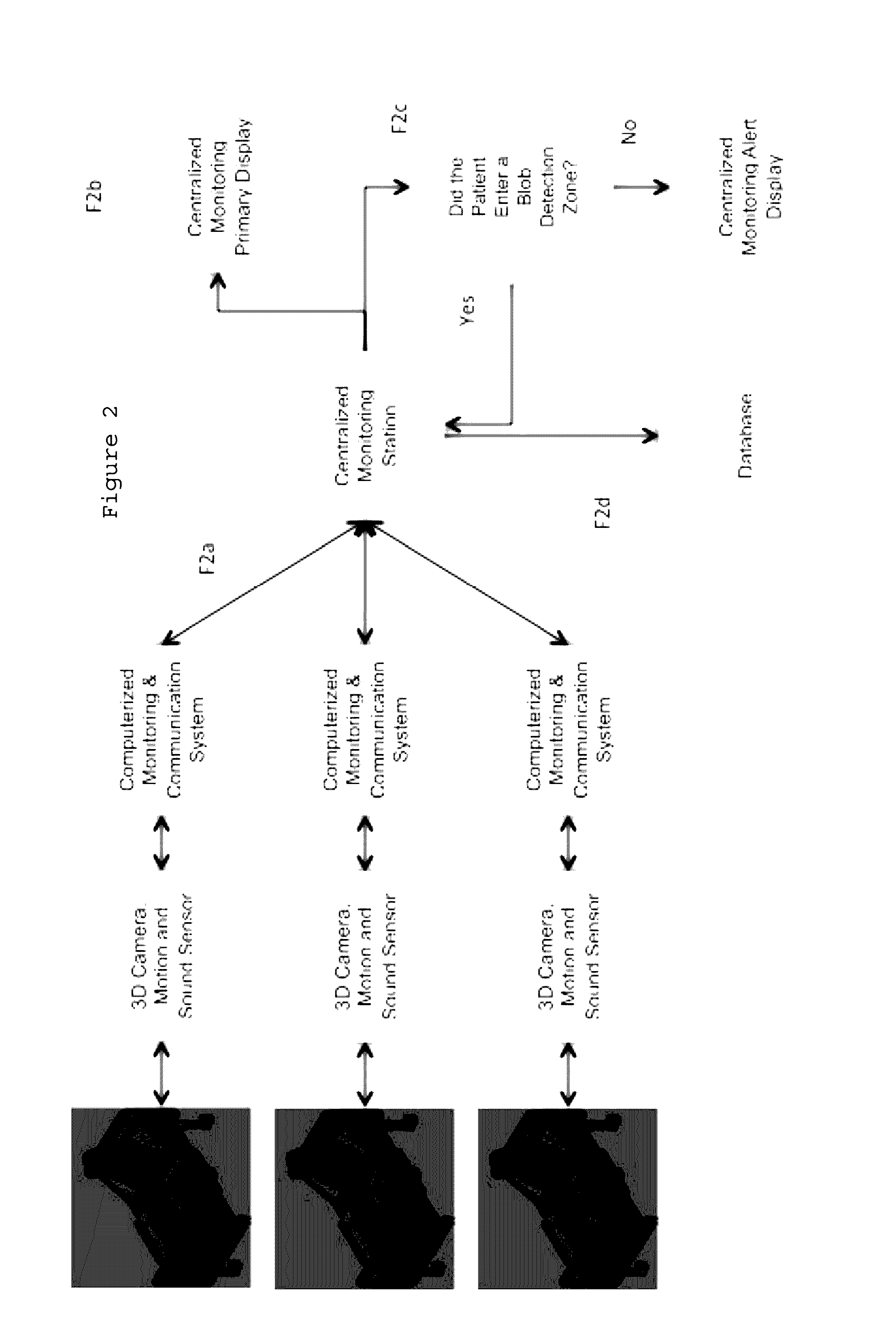

A method and system that allows healthcare providers, hospitals, skilled nursing facilities and other persons to monitor disabled, elderly or other high-risk individuals to prevent or reduce falls and / or mitigate the impact of a fall by delivering automated notification of “at risk” behavior and falls by such an individual being monitored where assistance is required. Two systems are used to identify patients, a skeletal tracking system, which identifies patients by biometric indicators, and a virtual blob detection system. In the virtual blob system, the monitored individual is virtually represented as a blob object of at least a specific size by a computerized monitoring system and such system detects and alerts when the blob object enters or crosses into a virtually defined or designated blob detection zone and remains in the zone for at least a predetermined period of time. These systems may be used concurrently, or one system may be used primarily, with the other system acting as a failsafe.

Owner:CERNER INNOVATION

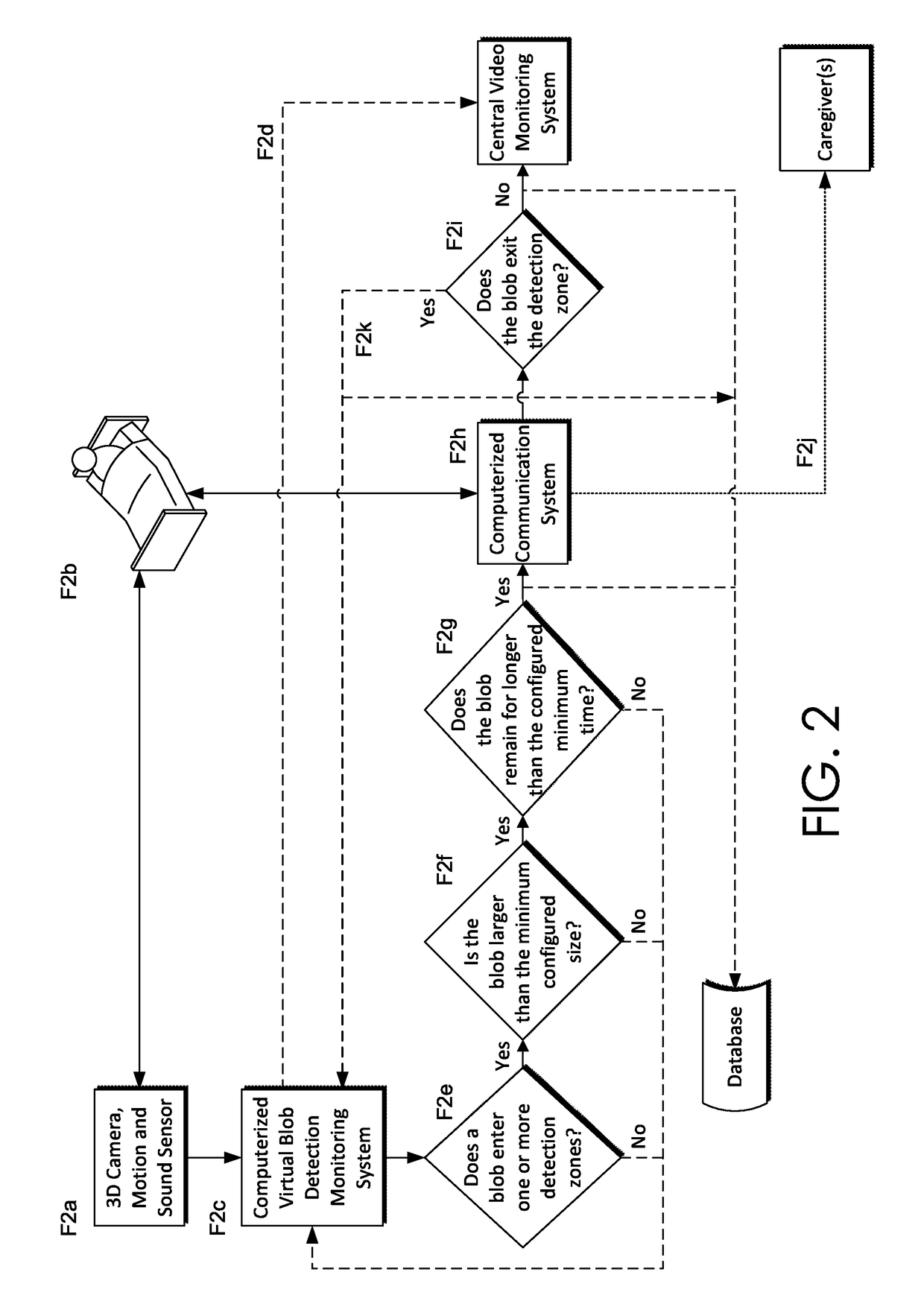

System for determining whether an individual enters a prescribed virtual zone using 3D blob detection

ActiveUS9524443B1Prevent and reduce fallReduce the impactImage analysisStill image data indexingBlob detectionOlder people

A method and system that allows healthcare providers, hospitals, skilled nursing facilities and other persons to monitor disabled, elderly or other high-risk individuals to prevent or reduce falls and / or mitigate the impact of a fall by delivering automated notification of “at risk” behavior and falls by such an individual being monitored where assistance is required. The monitored individual is virtually represented as a blob object of at least a specific size by a computerized monitoring system and such system detects and alerts when the blob object enters or crosses into a virtually defined or designated blob detection zone and remains in the zone for at least a predetermined period of time.

Owner:CERNER INNOVATION

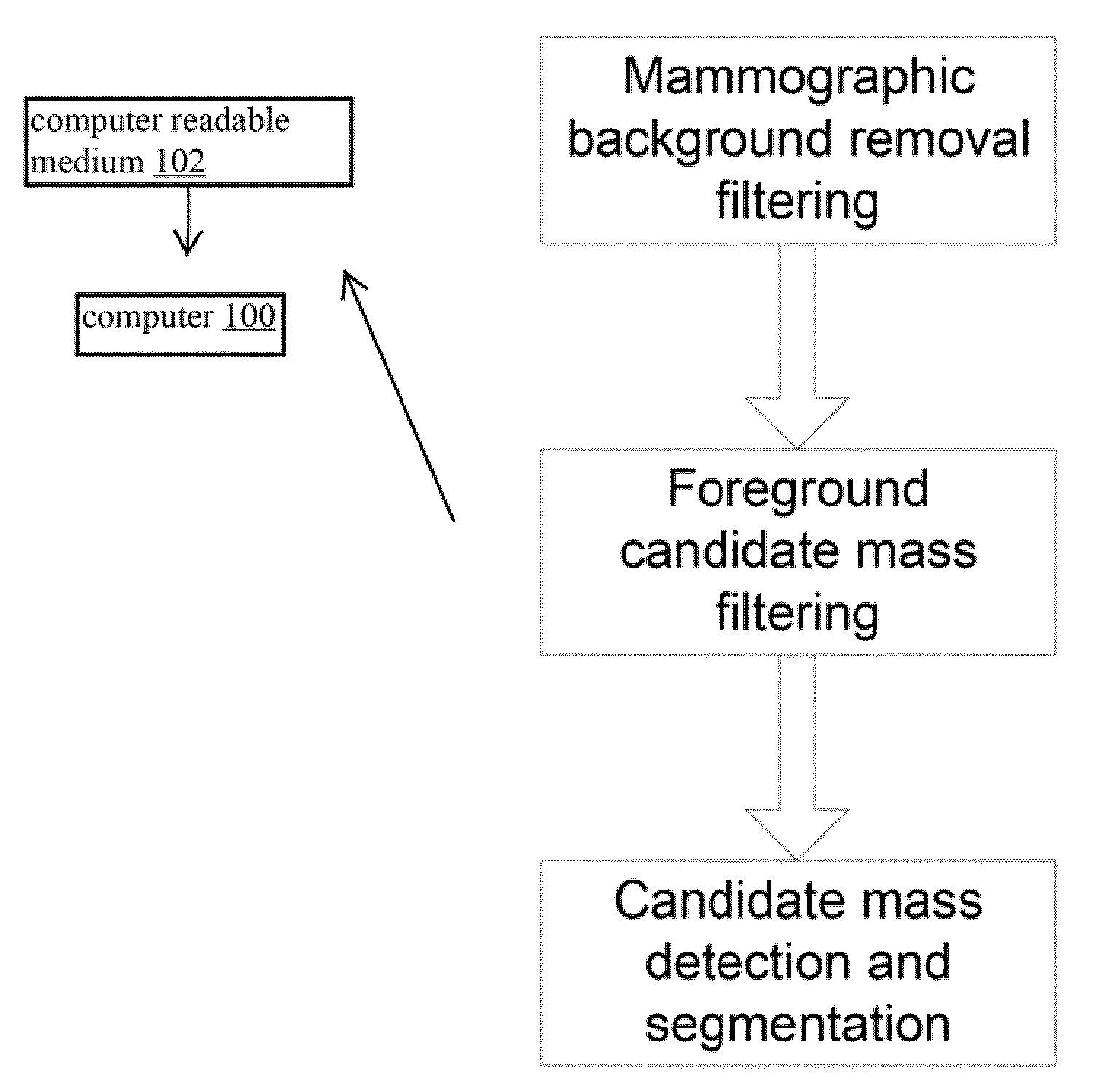

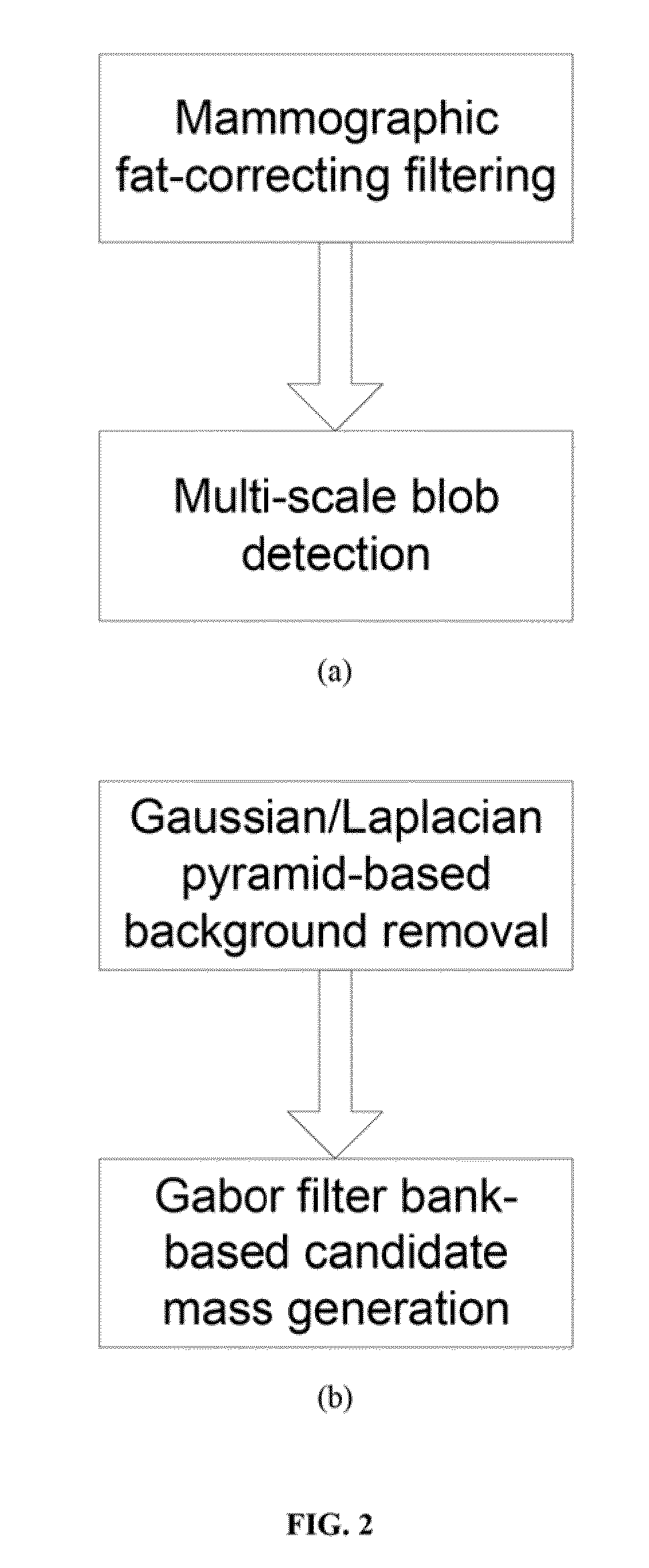

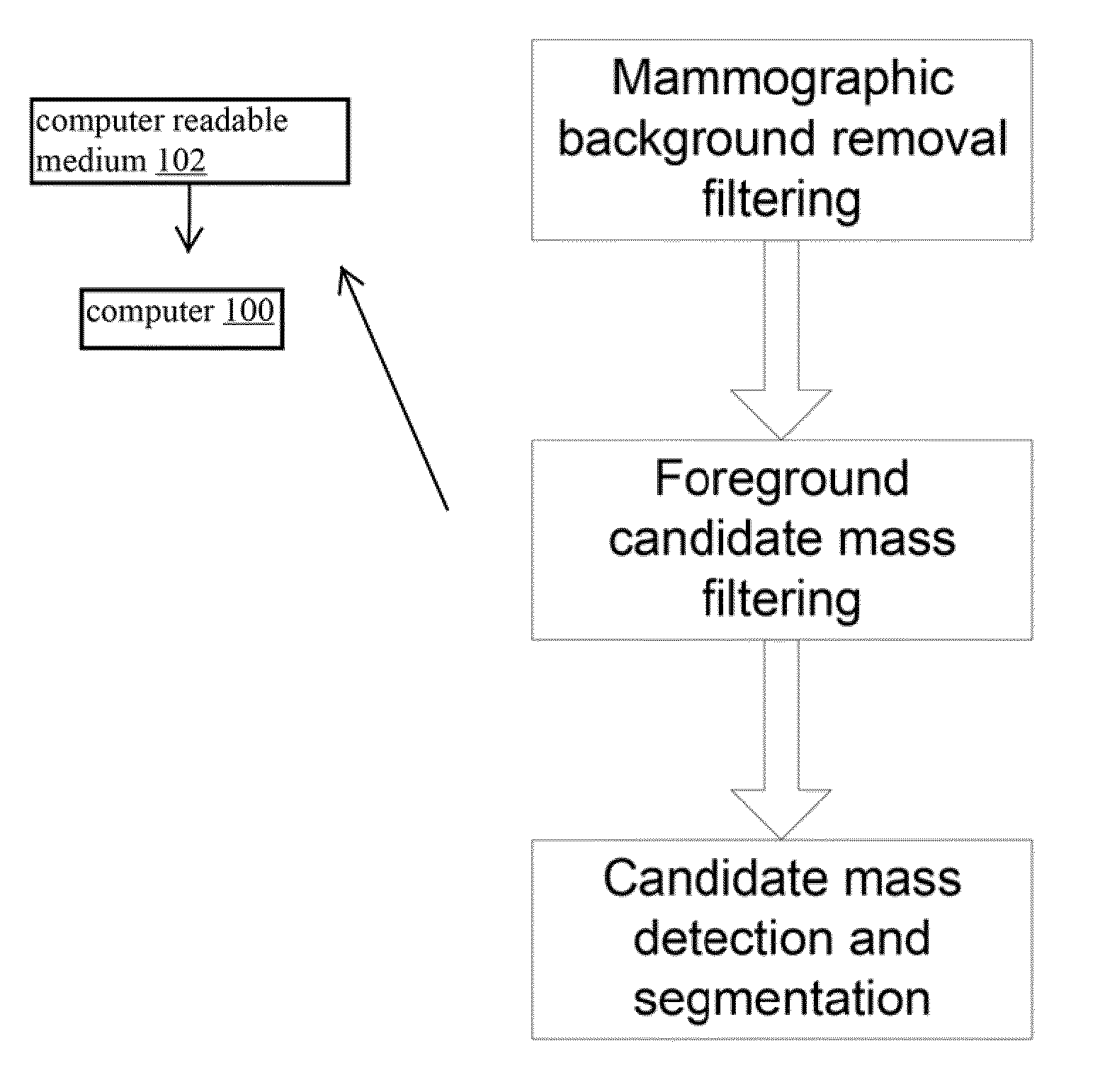

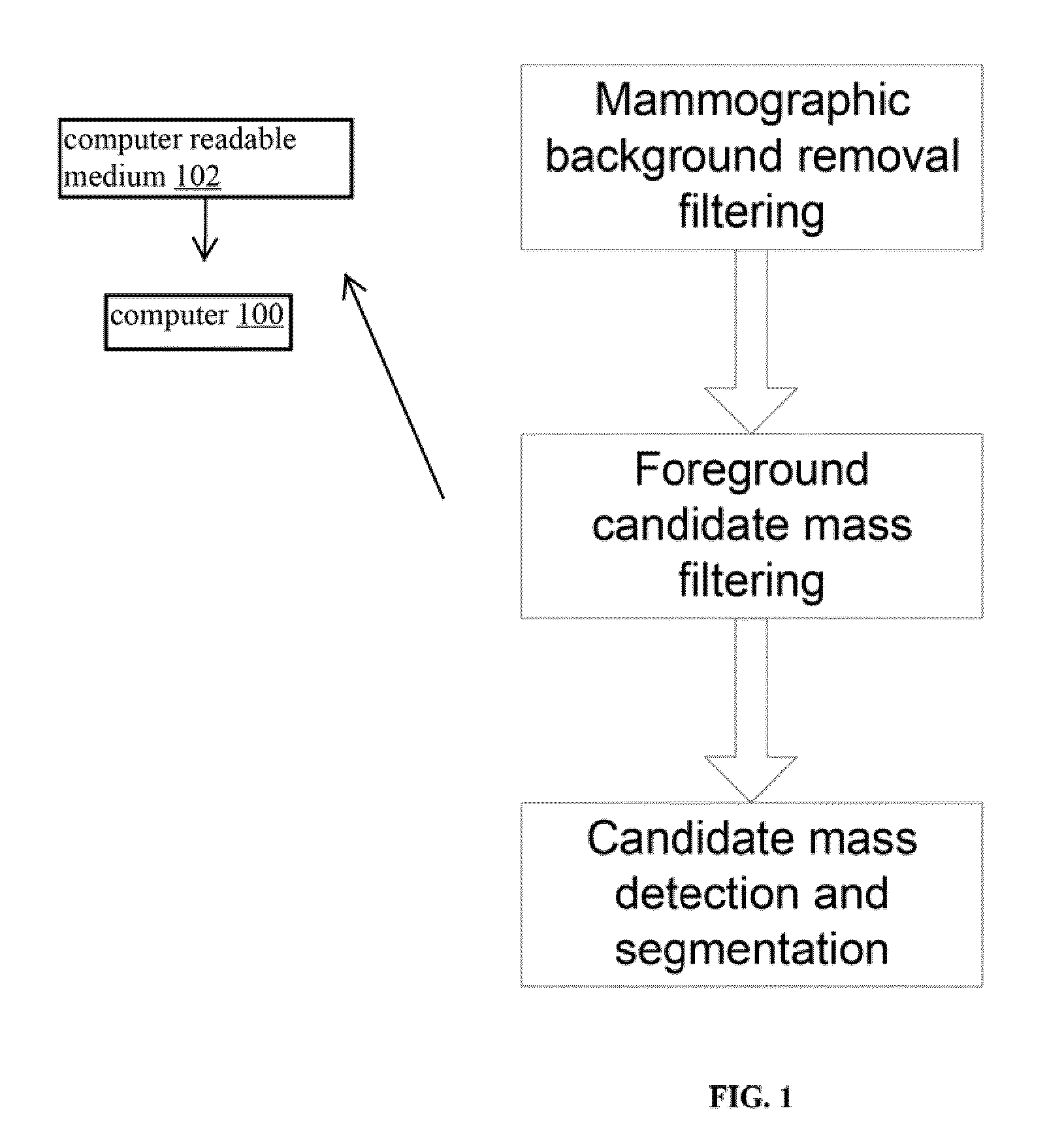

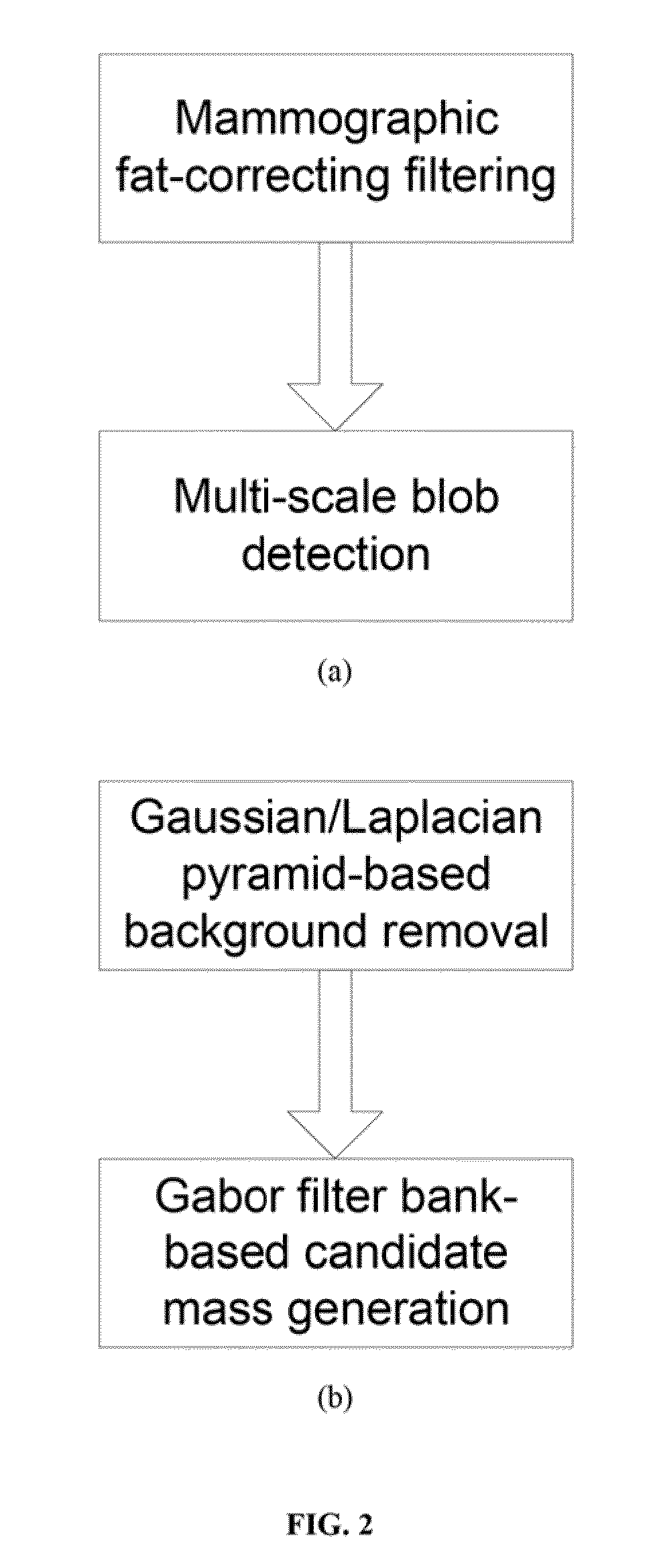

Method for Mass Candidate Detection and Segmentation in Digital Mammograms

A basic component of Computer-Aided Detection systems for digital mammography comprises generating candidate mass locations suitable for further analysis. A component is described that relies on filtering either the background image or the complementary foreground mammographic detail by a purely signal processing method on the one hand or a processing method based on a physical model on the other hand. The different steps of the signal processing approach consist of band-pass filtering the image by one or more band pass filters, multidimensional clustering, iso-contouring of the distance to centroid of the one or more filtered values, and finally candidate generation and segmentation by contour processing. The physics-based approach also filters the image to retrieve a fat-corrected image to model the background of the breast, and the resulting image is subjected to a blob detection filter to model the intensity bumps on the foreground component of the breast that are associated with mass candidates.

Owner:AGFA NV

Methods for determining whether an individual enters a prescribed virtual zone using 3D blob detection

ActiveUS20170091562A1Reduce impactPrevent and reduce fallStill image data indexingClosed circuit television systemsOlder peopleBlob detection

A method and system that allows healthcare providers, hospitals, skilled nursing facilities and other persons to monitor disabled, elderly or other high-risk individuals to prevent or reduce falls and / or mitigate the impact of a fall by delivering automated notification of “at risk” behavior and falls by such an individual being monitored where assistance is required. The monitored individual is virtually represented as a blob object of at least a specific size by a computerized monitoring system and such system detects and alerts when the blob object enters or crosses into a virtually defined or designated blob detection zone and remains in the zone for at least a predetermined period of time.

Owner:CERNER INNOVATION

Method for Determining Whether an Individual Enters a Prescribed Virtual Zone Using Skeletal Tracking and 3D Blob Detection

ActiveUS20180068545A1Reduce impactPrevent and reduce fallImage enhancementImage analysisBlob detectionOlder people

A method and system that allows healthcare providers, hospitals, skilled nursing facilities and other persons to monitor disabled, elderly or other high-risk individuals to prevent or reduce falls and / or mitigate the impact of a fall by delivering automated notification of “at risk” behavior and falls by such an individual being monitored where assistance is required. Two systems are used to identify patients, a skeletal tracking system, which identifies patients by biometric indicators, and a virtual blob detection system. In the virtual blob system, the monitored individual is virtually represented as a blob object of at least a specific size by a computerized monitoring system and such system detects and alerts when the blob object enters or crosses into a virtually defined or designated blob detection zone and remains in the zone for at least a predetermined period of time. These systems may be used concurrently, or one system may be used primarily, with the other system acting as a failsafe.

Owner:CERNER INNOVATION

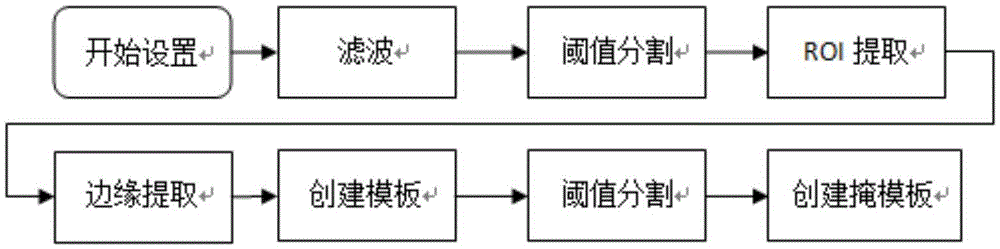

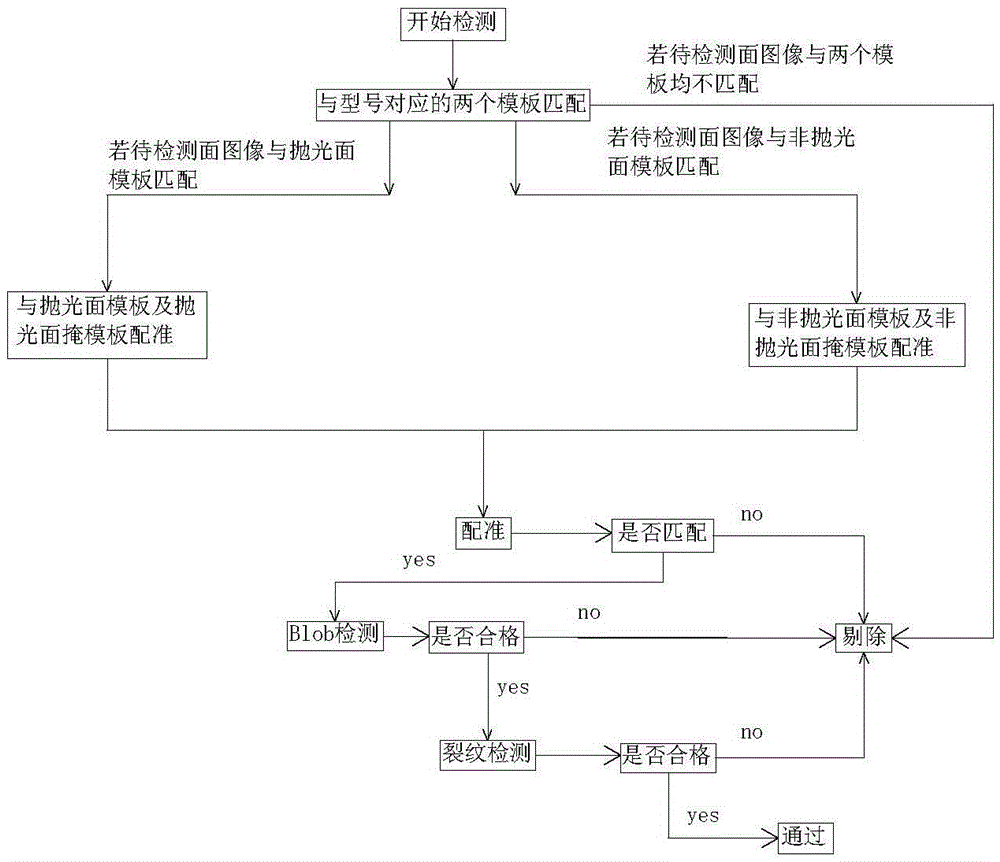

Method for detecting surface defects of ceramic valve cores based on machine vision

InactiveCN105548208AImprove detection stabilityReduce testing costsOptically investigating flaws/contaminationMachine visionBlob detection

The invention discloses a method for detecting surface defects of ceramic valve cores based on machine vision. The method comprises the following steps: respectively establishing templates and mask plates for the ceramic valve cores in different sizes; respectively performing template shape matching with the polishing surface templates and non-polishing surface templates in corresponding sizes according to a to-be-detected surface image of a to-be-detected ceramic valve core; confirming the surface, position and direction of the to-be-detected surface image, and then aligning the to-be-detected surface image with a selected template and mask plate; performing Blob detection on the to-be-detected surface image of the to-be-detected ceramic valve core; and performing crack detection on the to-be-detected surface image. According to the method for detecting surface defects of ceramic valve cores based on machine vision provided by the invention, the surface defects of the to-be-detected ceramic valve core can be automatically detected, the detection stability is high, the detection cost is low, the detection speed is high and the detection rate reaches 95%. Besides, the total time for detecting and recognizing various defects is less than 0.3 second. The method can be widely applied to the field of detection for the surface defects of the ceramic valve cores.

Owner:HUBEI UNIV OF TECH

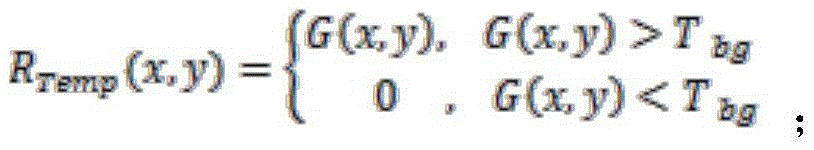

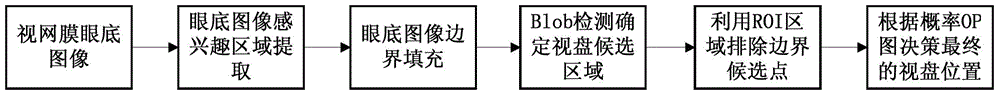

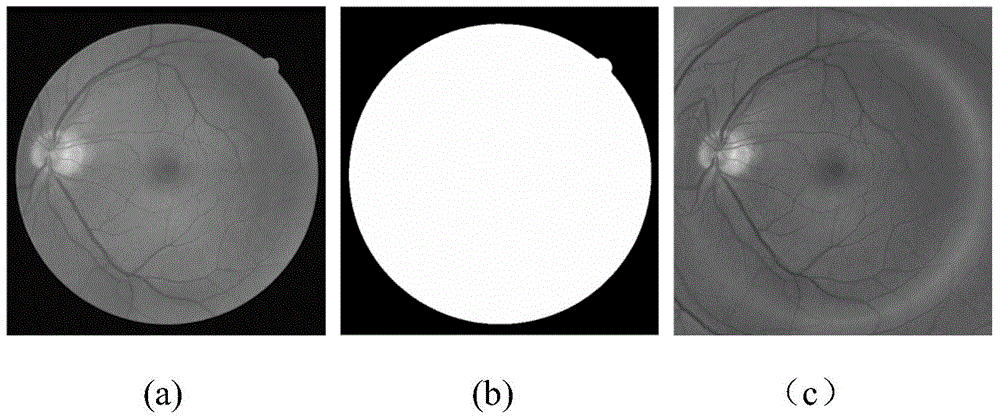

Quick optic disc positioning method based on multi-scale macula detection

InactiveCN104794721AReal-time detection effectSimple methodImage enhancementImage analysisData setBlob detection

The invention discloses a quick optic disc positioning method based on multi-scale macula detection. The quick optic disc positioning method includes the steps of 1, masking fundus images; 2, performing boundary filling to the fundus images; 3, determining candidate regions of optic discs; 4, excluding boundary candidate positions; and 5, determining positions of the real optic discs. As the optic discs are represented by bright-yellow circular regions of different sizes, multiple candidate regions of optic discs are determined according to the multi-scale space theory and the LOG macula detection technology, and then the real optic discs are positioned on the basis of appearance characteristics of the candidate regions and local vasculature characteristics. By the quick optic disc positioning method, optic disc positioning is performed on the fundus images after the fundus image are reduced, and the real-time detection effect is achieved; due to the multi-scale detection capacity, the method is adaptable to different size of image data sets, and has the advantages easiness, high accuracy, quick positioning and the like.

Owner:XIANGTAN UNIV

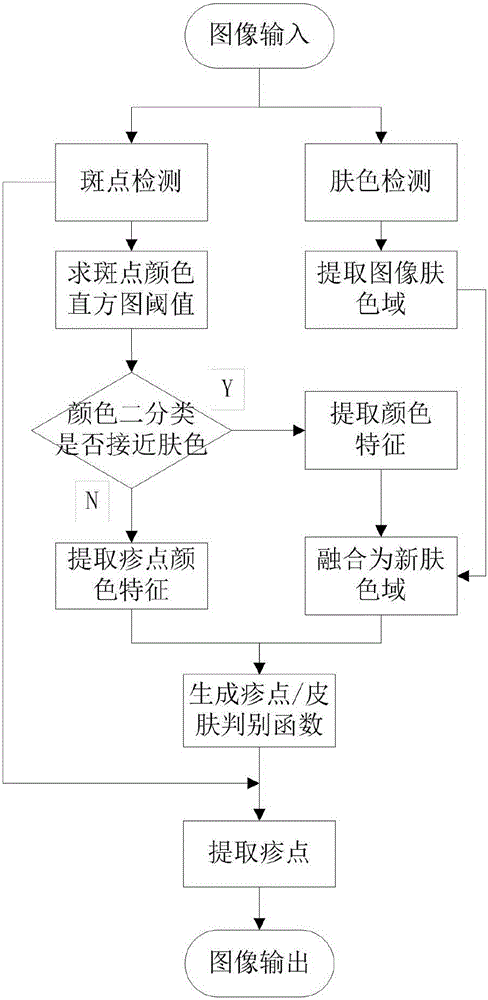

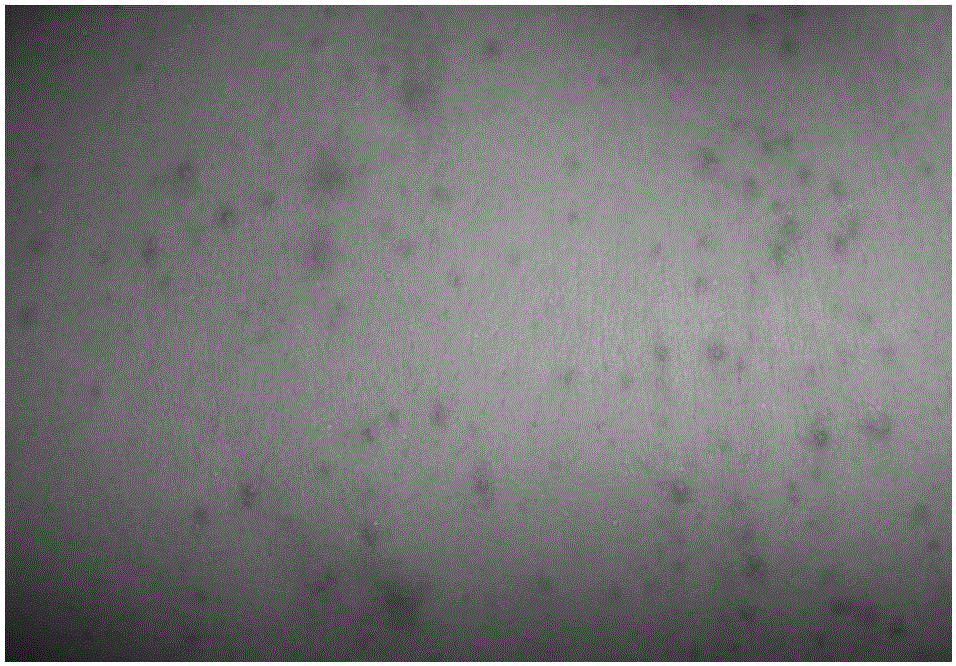

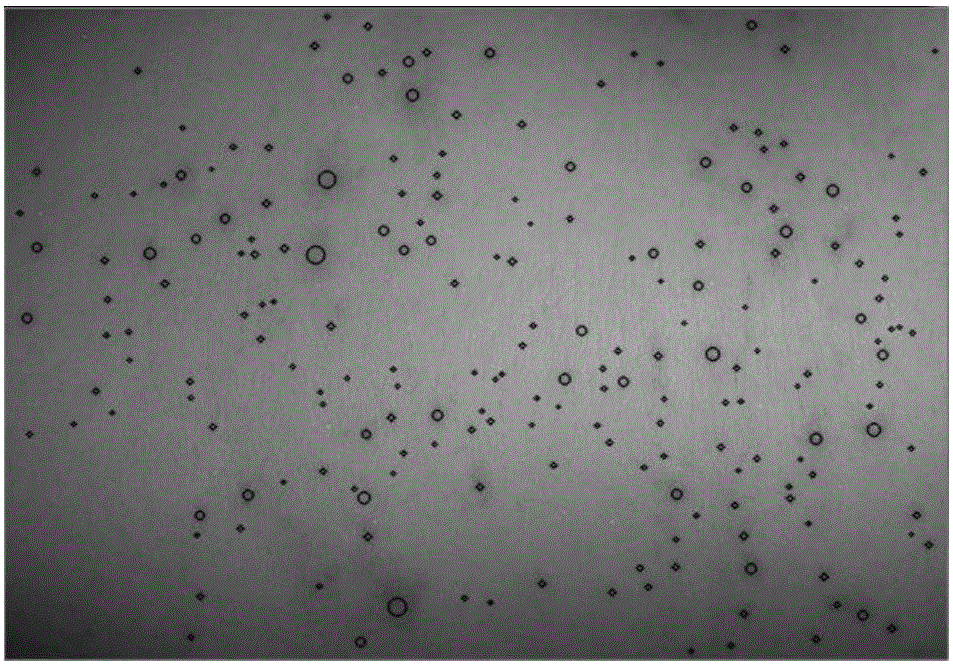

Skin rash point extraction method based on spot detection

InactiveCN105787929ARun fastReduce false detection rateImage enhancementImage analysisPattern recognitionBlob detection

The invention relates to a skin rash point extraction method based on spot detection. The method comprises the following steps: preprocessing an input skin image, and detecting a skin color area and a non skin color area in the image; counting respective color mean values of three component values of the skin color area in the skin image in an RGB space; detecting spots; dividing the spots into spots close to a skin color and spots greatly differing from the skin color; integrating the spots close to the skin color with a skin RGB distribution range to form a new skin color mean value; calculating a color mean value for the spots greatly differing from the skin color, and taking the color mean value as a typical rash point RGB color mean value; and generating a weight color spatial distance function for determining rash points / skin. The method provided by the invention has the advantages of fast operation speed and low false detecting rate and miss rate.

Owner:TIANJIN UNIV

Method for mass candidate detection and segmentation in digital mammograms

A basic component of Computer-Aided Detection systems for digital mammography comprises generating candidate mass locations suitable for further analysis. A component is described that relies on filtering either the background image or the complementary foreground mammographic detail by a purely signal processing method on the one hand or a processing method based on a physical model on the other hand. The different steps of the signal processing approach consist of band-pass filtering the image by one or more band pass filters, multidimensional clustering, iso-contouring of the distance to centroid of the one or more filtered values, and finally candidate generation and segmentation by contour processing. The physics-based approach also filters the image to retrieve a fat-corrected image to model the background of the breast, and the resulting image is subjected to a blob detection filter to model the intensity bumps on the foreground component of the breast that are associated with mass candidates.

Owner:AGFA NV

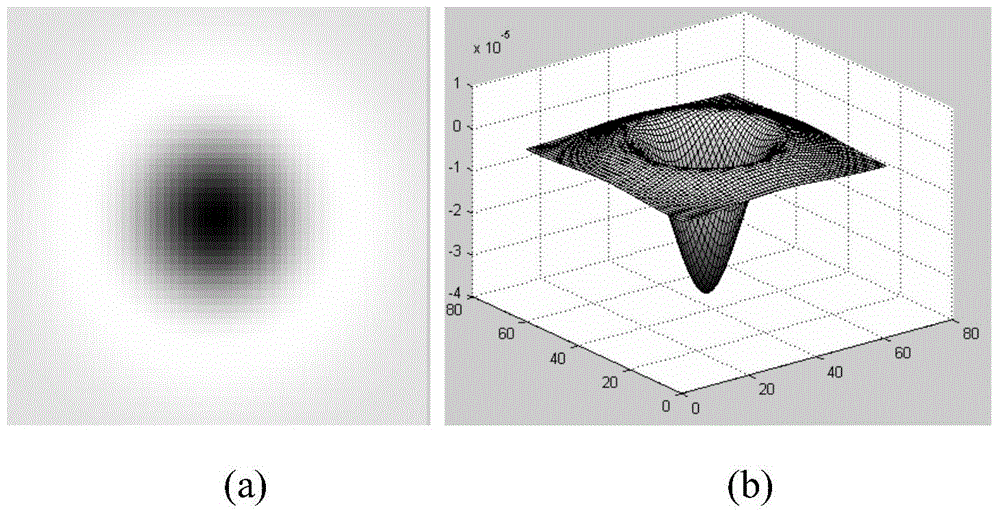

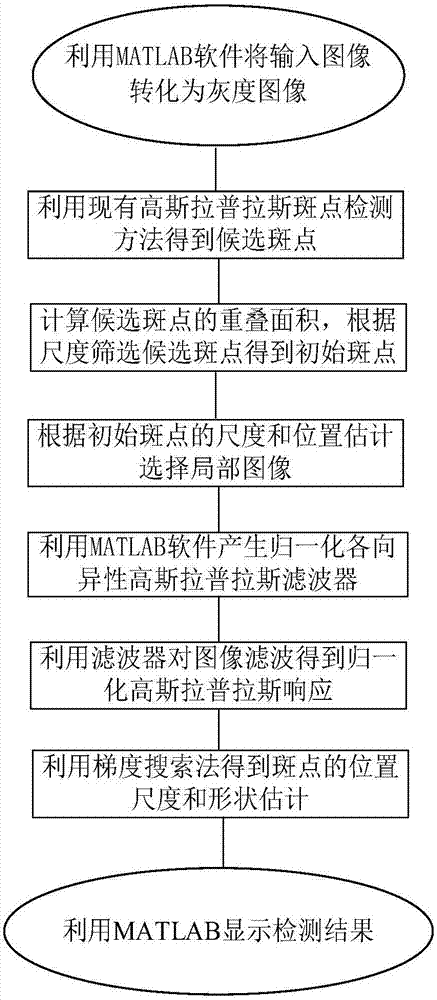

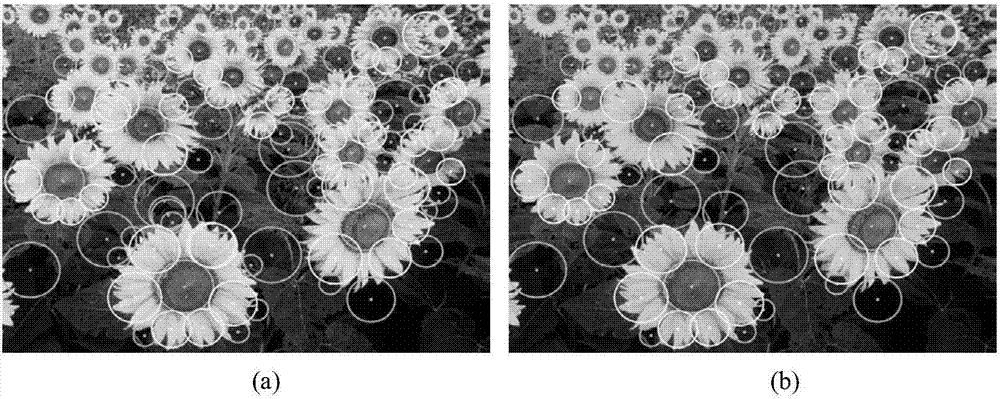

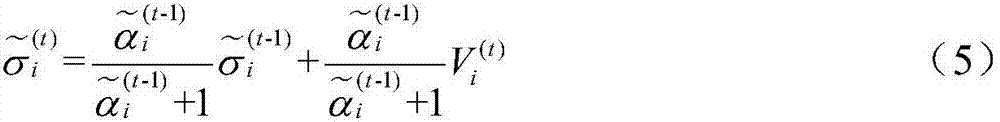

Image spot detection method based on anisotropic Gaussian kernel and gradient search

ActiveCN107292869ASolve the problem of inaccurate estimatesHigh precisionImage analysisComputation complexityBlob detection

The invention discloses an image spot detection method based on the anisotropic Gaussian kernel and gradient search. The invention solves problems that a conventional method is not accurate in estimation of the spot shape and is complex in calculation, and the method comprises the steps: converting an input image into a gray scale image through MATLAB; obtaining candidate spots through Gaussian-Laplacian spot detection; screening the candidate spots according to the spot overlapping rate, and obtaining initial spots; selecting a local image for each initial spot; generating a normalized on anisotropic Gaussian-Laplacian filter through MATLAB, carrying out the filtering of the local image, obtaining the response, and taking the response of the central position as a target function; searching the parameter corresponding to the maximum value of the target function as the final spot detection result through the gradient search method; displaying and comparing the spot detection result through MATLAB. The method is high in detection precision, is low in calculation complexity, and can be used for image feature detection, image registering and image recognition.

Owner:XIDIAN UNIV

Aerial video moving object detection method based on motion information and regional characteristic

InactiveCN107330922AReduce false alarm rateImage enhancementImage analysisObject detectionBlob detection

The invention discloses an aerial video moving object detection method based on motion information and a regional characteristic, and is used to solve the technical problem of poor object detection integrity of an existing moving object detection method. The technical scheme comprises the following steps: firstly, moving pixel detection is performed using a background difference method, and then a candidate motion region in an image is obtained; spot detection is performed on the image through adoption of a watershed algorithm based on local extreme values then, and all static candidate objects are obtained; and, finally, moving object extraction is performed through combinations with the motion information and the regional characteristic, a complete moving object detection frame is obtained, and the false alarm rate is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

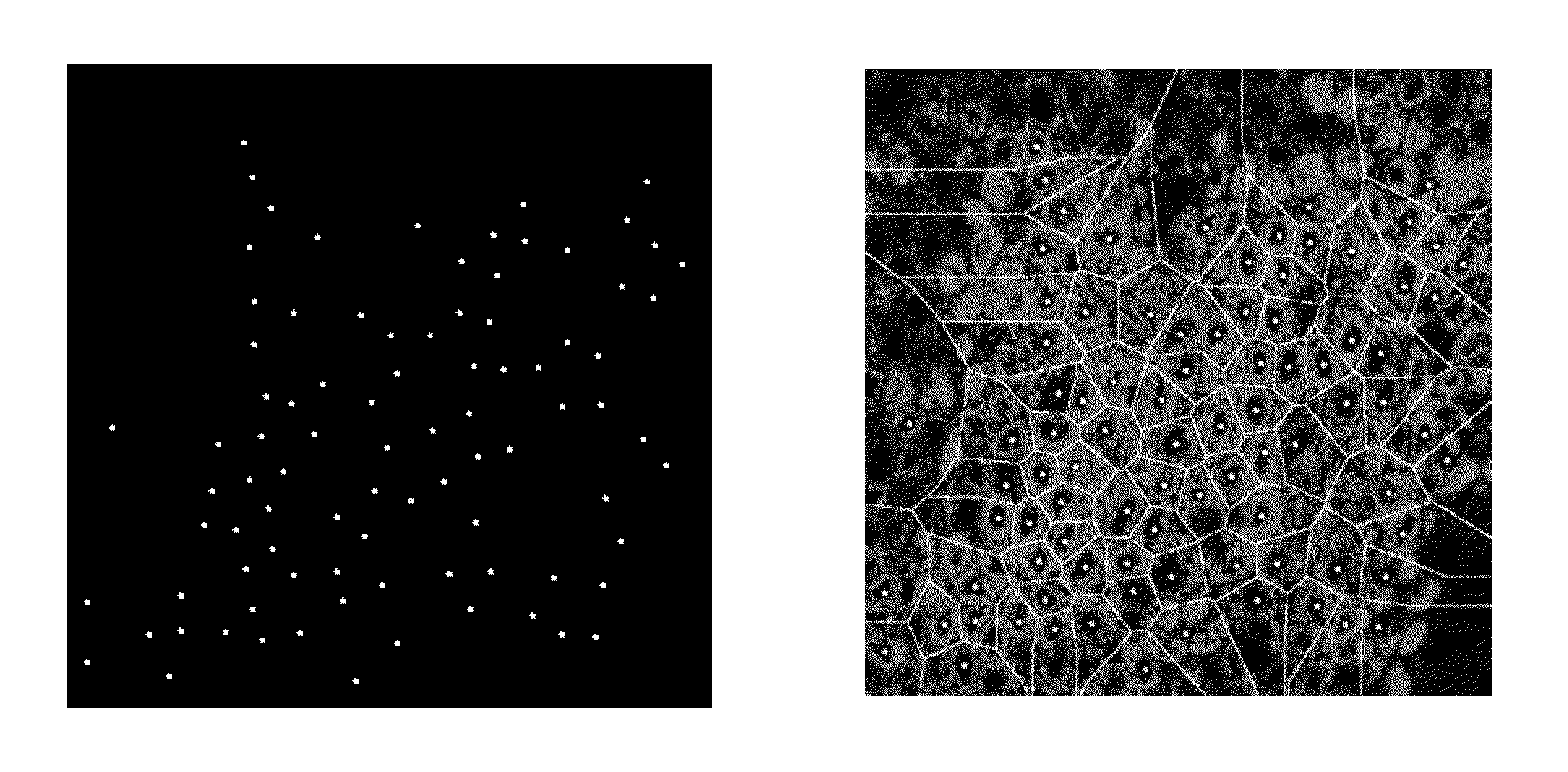

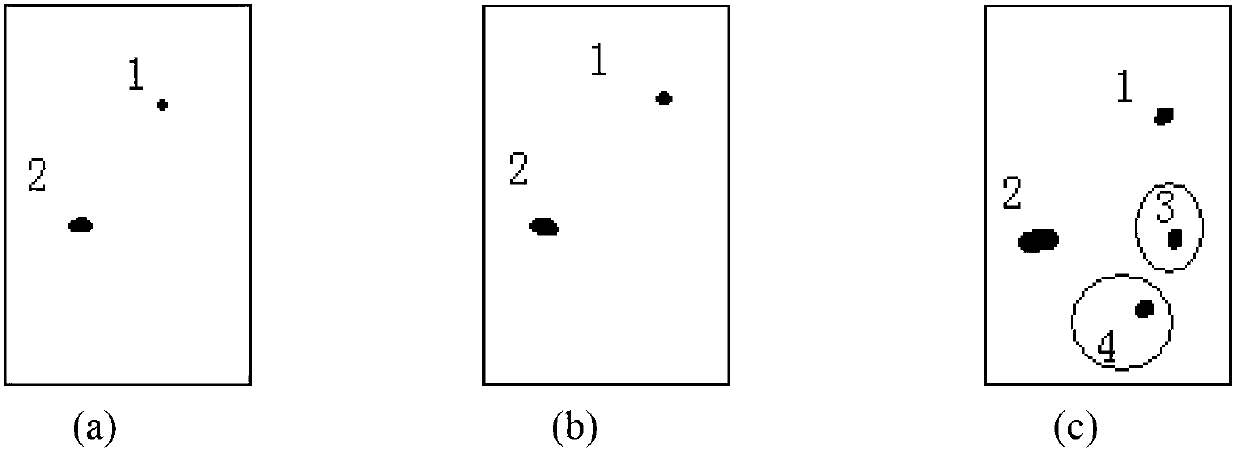

Cell image segmentation method and a nuclear-to-cytoplasmic ratio evaluation method using the same

ActiveUS9122907B2Improve accuracyImprove efficiencyImage enhancementImage analysisBlob detectionCell image segmentation

A cell image segmentation method includes receiving a cell image, performing a nuclei initialization step to find an internal marker and an external marker to obtain a potential nuclei and a potential cell boundary, calculating a gradient map of the received cell image, performing a filtering step on the gradient map to generate a filtered gradient map, performing a nuclei detection step to obtain a segmented nuclei, and performing a nuclei validation step to obtain a valid nuclei. The nuclei initialization step includes performing a blob detection step to obtain a nuclei candidate, an outlier removal step to obtain the internal marker, a distance transform step to obtain a distance map, and a cell boundary initialization step to obtain the external marker. In another embodiment, a nuclear-to-cytoplasmic ratio evaluation method using the above cell image segmentation method is proposed.

Owner:COGNINU TECH CO LTD

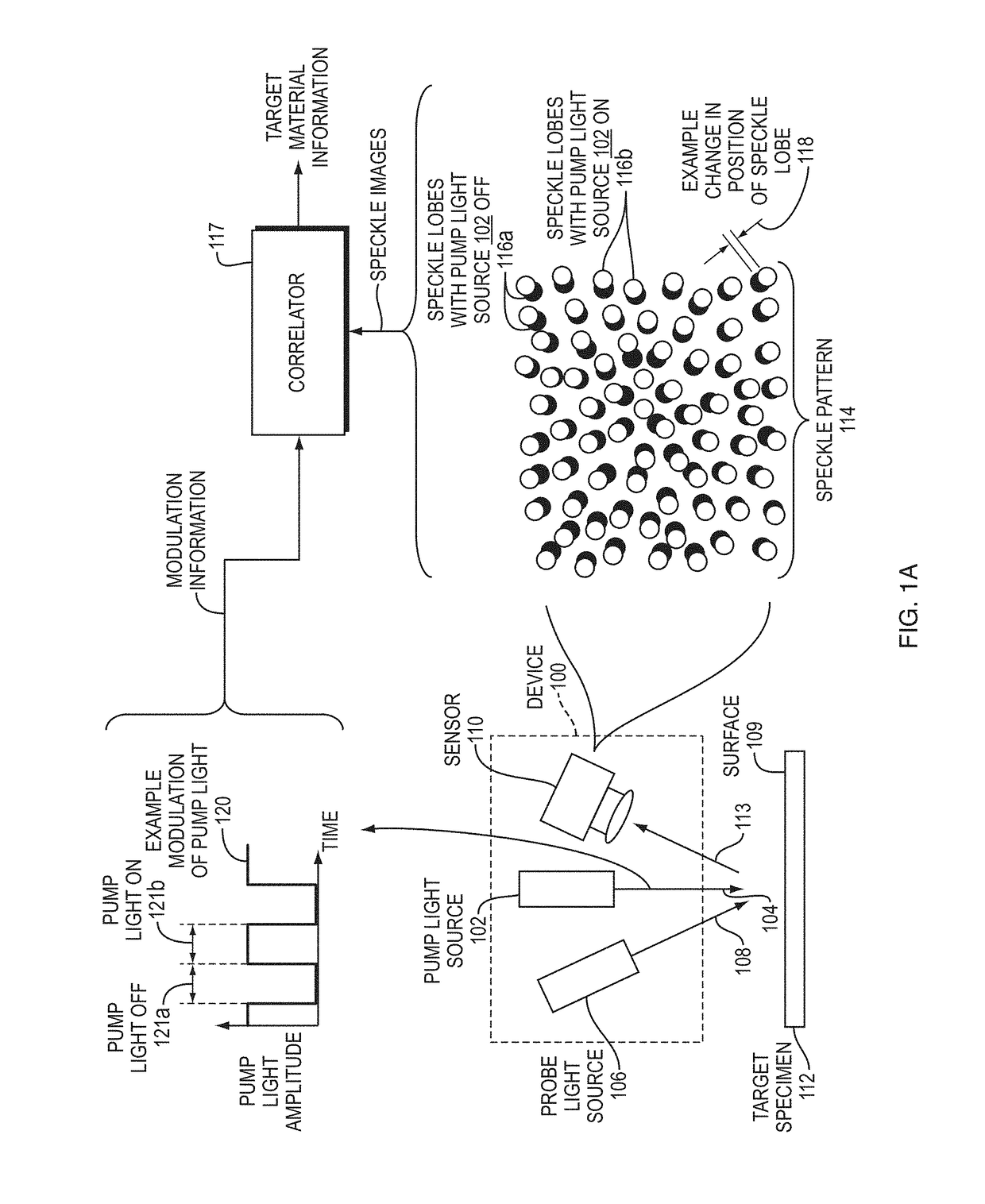

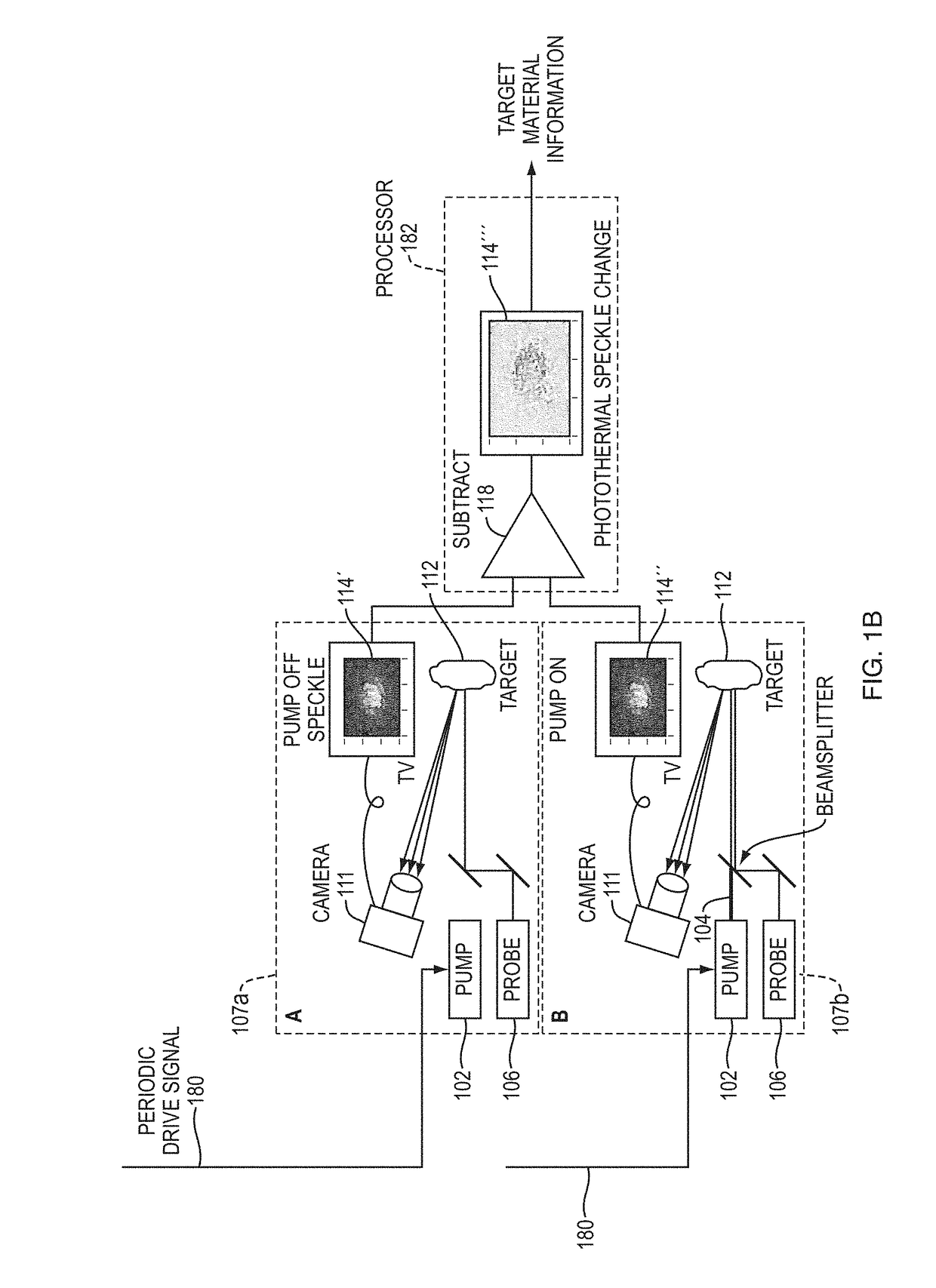

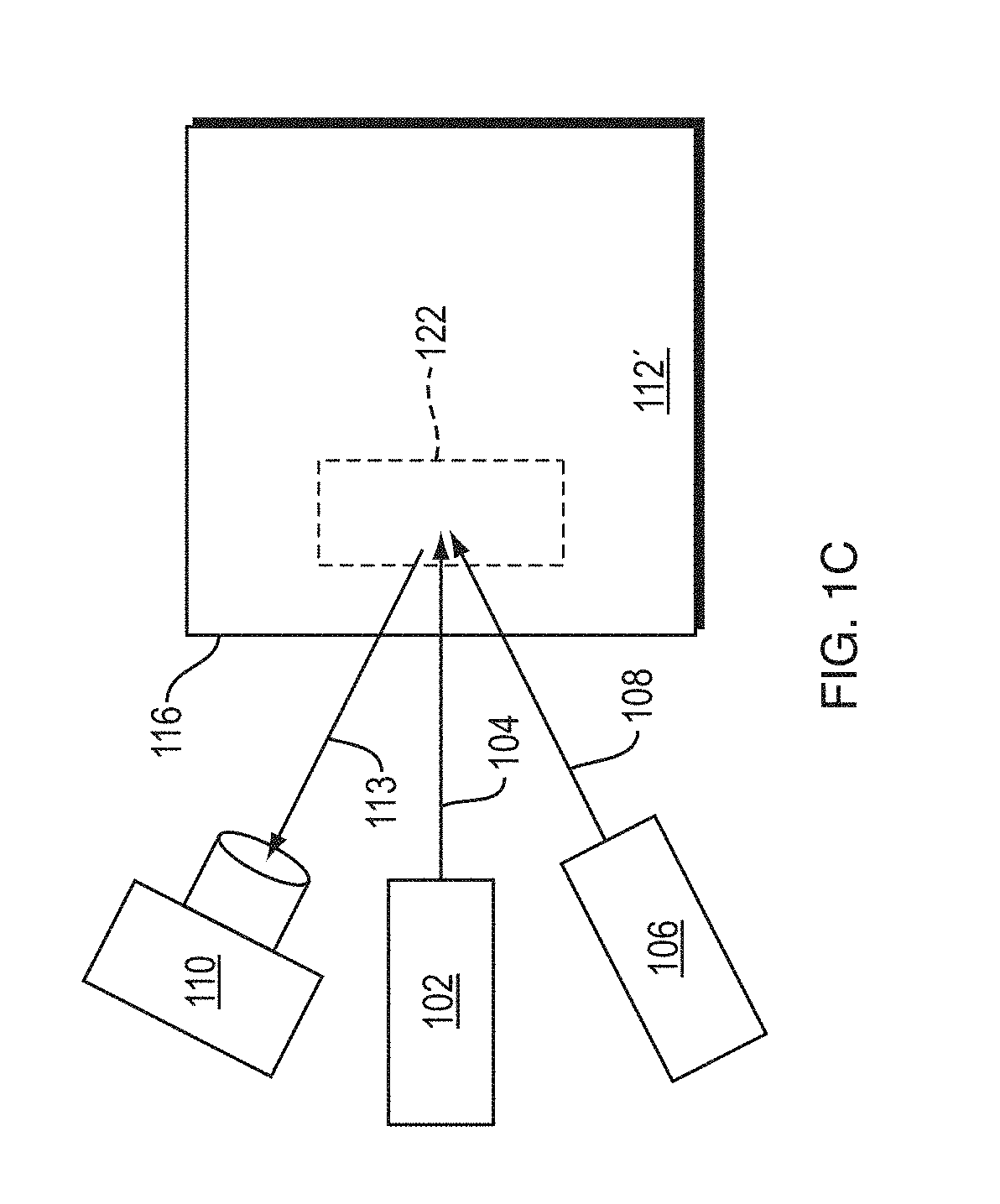

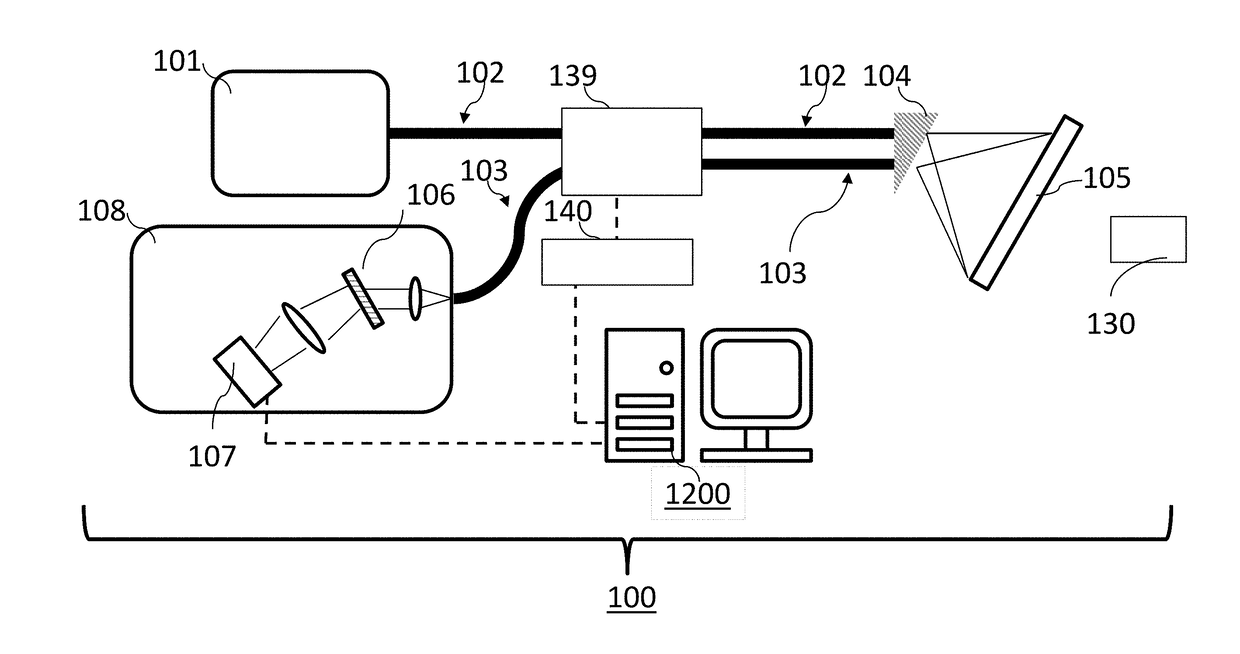

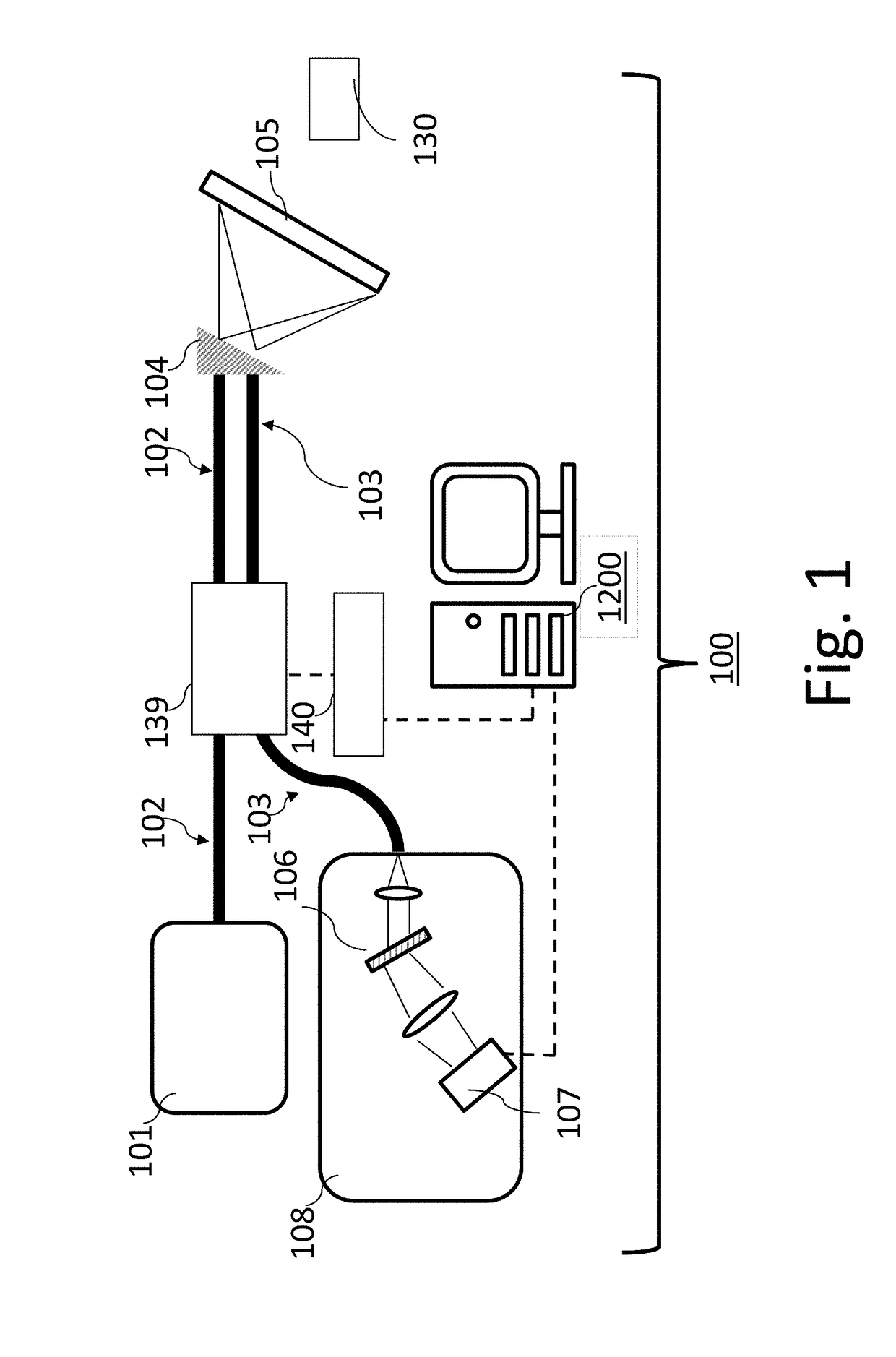

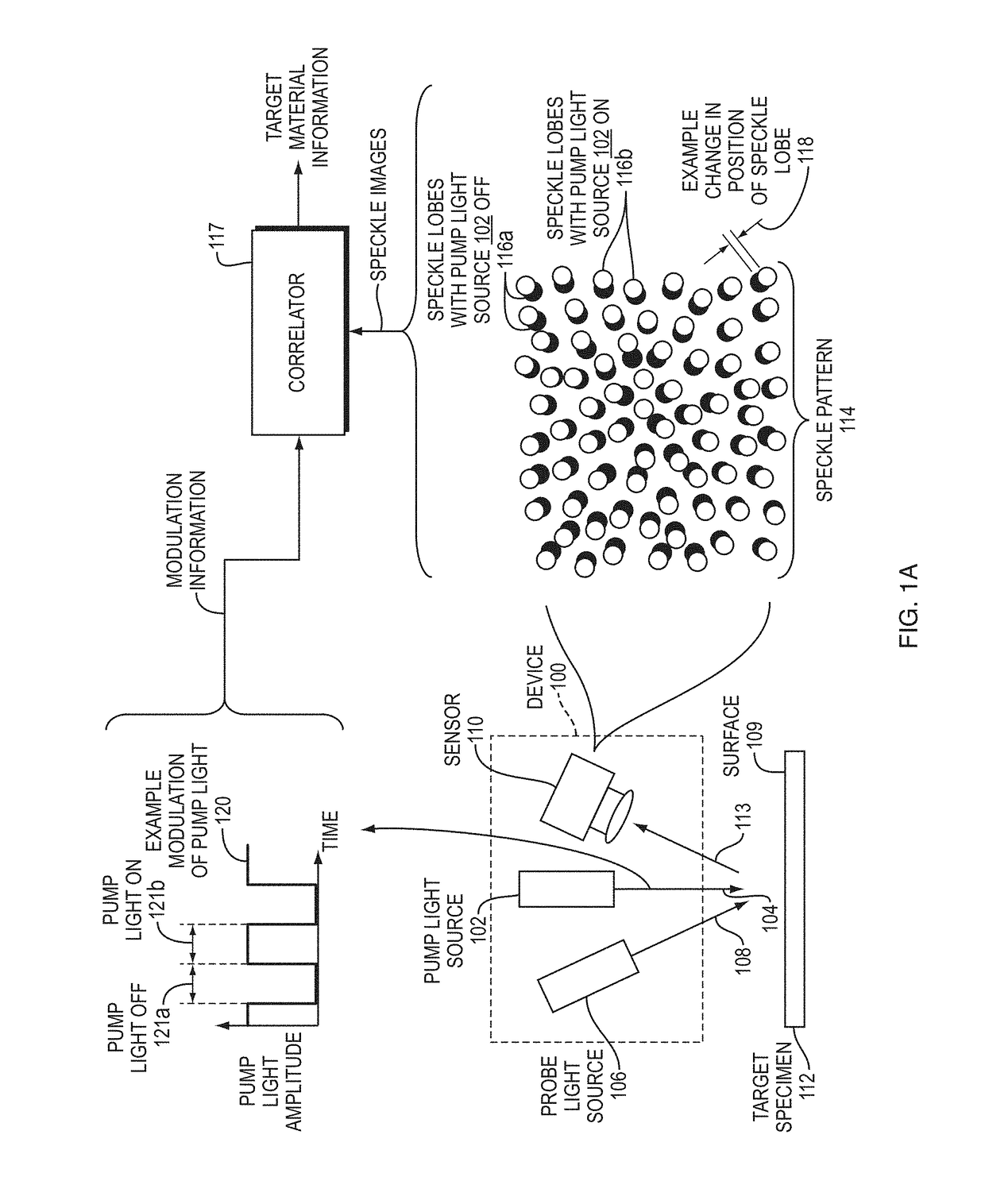

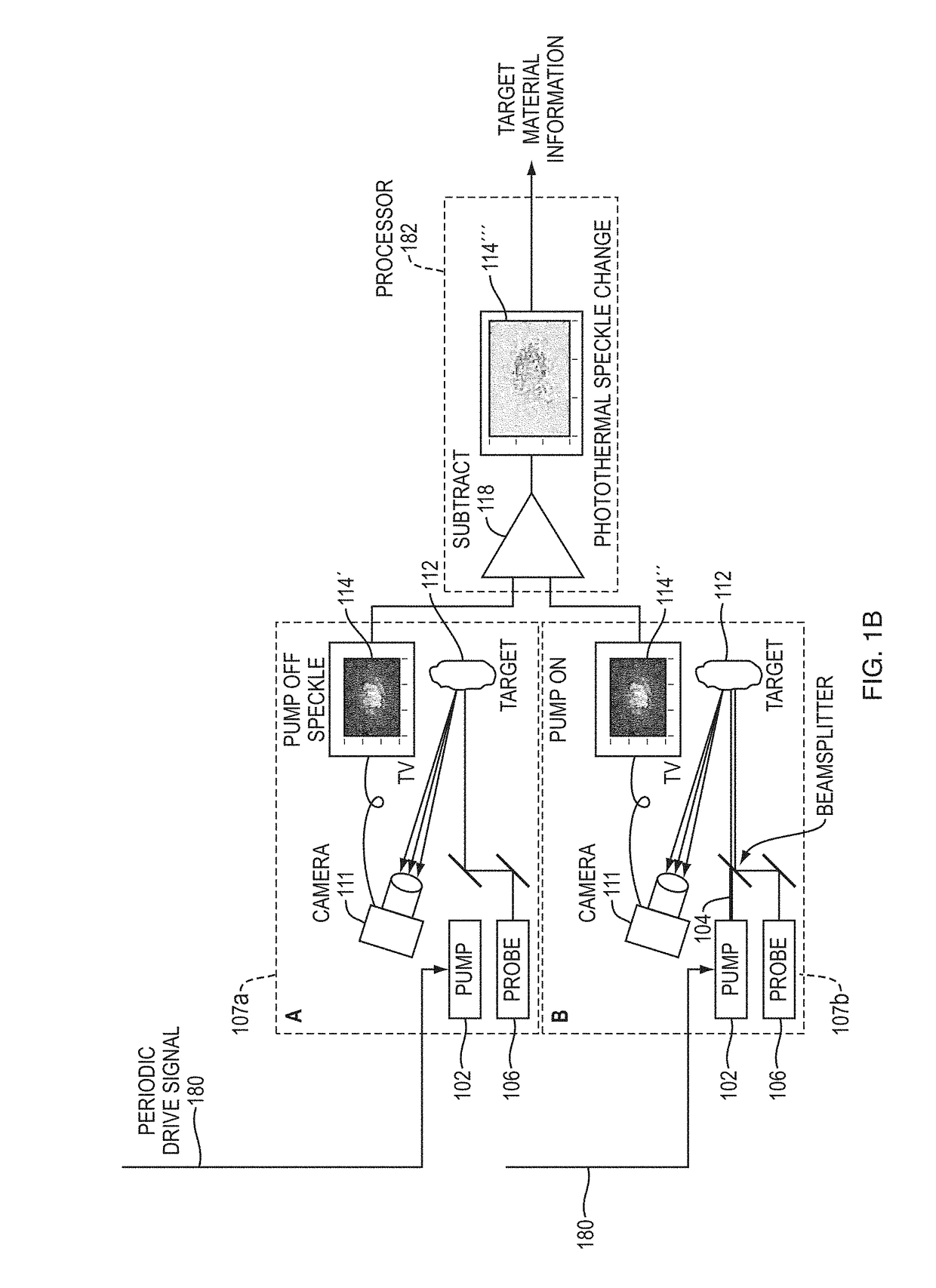

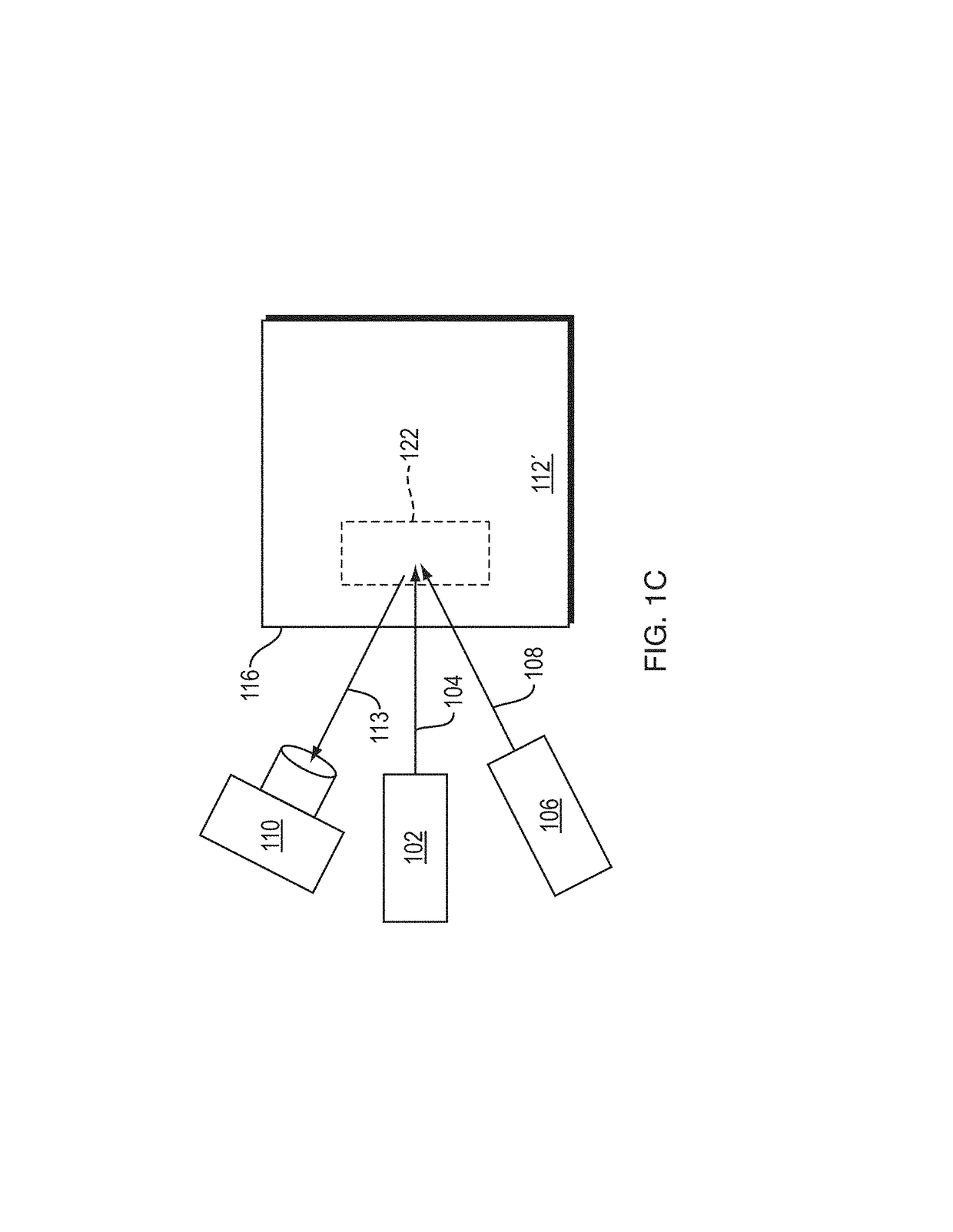

Devices and methods for sensing targets using photothermal speckle detection

A device, and corresponding method, can include a pump light source configured to be modulated at a pump modulation and to irradiate a target specimen. The device can also include a probe light source arranged to generate a speckle pattern from the target specimen, as well as a sensor configured to detect changes in at least one of position and intensity of one or more speckle lobes of the speckle pattern having correlation with the pump modulation. The device and method can be used for non-contact monitoring and remote sensing of surfaces, gases, liquids, particles, and other target materials by analyzing speckle pattern changes as a function of pump light irradiation. Advantages can include much higher sensitivity than existing methods; the ability to use visible probe wavelengths for uncooled, low-cost visible detectors with high spatial resolution; and the ability to obtain target material properties without detecting infrared light.

Owner:MASSACHUSETTS INST OF TECH

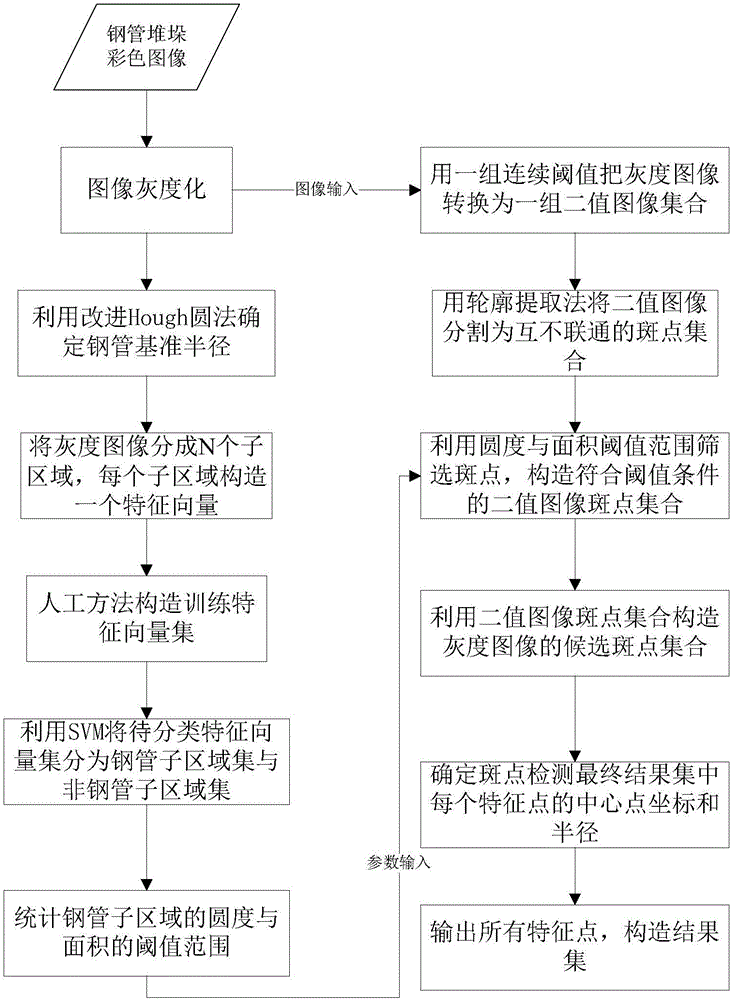

Steel tube counting method by combining support vector machine threshold statistics and spot detection

ActiveCN105976390AImprove anti-interference abilityImprove robustnessImage enhancementImage analysisSupport vector machineBlob detection

The invention provides a steel tube counting method by combining support vector machine threshold statistics and spot detection. The method comprises: stacking cross section two-dimensional images of to-be-identified steel tubes are processed into stacking cross section grayscale images; the grayscale images are classified by using an SVM algorithm, threshold statistics is carried out on a roundness feature parameter and an area feature parameter of a target subarea, and then a roundness threshold range and an area threshold area are generated based on threshold statistic results; and identification of similar circular spots in the stacking cross section grayscale images is carried out by using a spot detection algorithm, identification results are screened by using the roundness threshold range and an area threshold range, and then statistics of the number of spots in the screened spot set is carried out and thus a target steel tube number is obtained. According to the invention, the method has the excellent anti-interference performance and high robustness; the image shooting requirement is low; and for image identification of lots of steel tube targets, excellent performances are presented with low algorithm complexity. The method is suitable for embedded mobile equipment to realize real-time counting.

Owner:南京标博信息科技有限公司

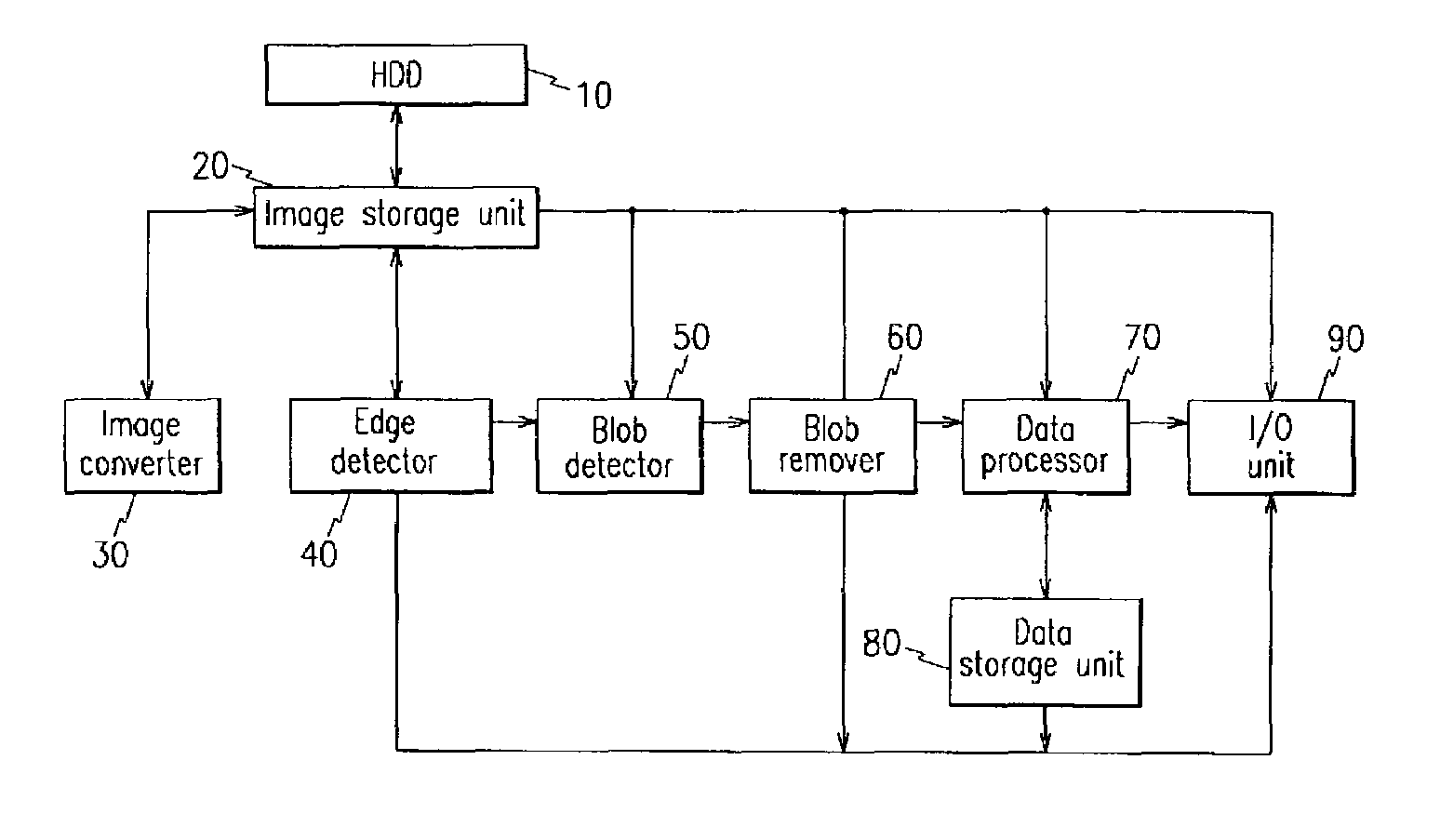

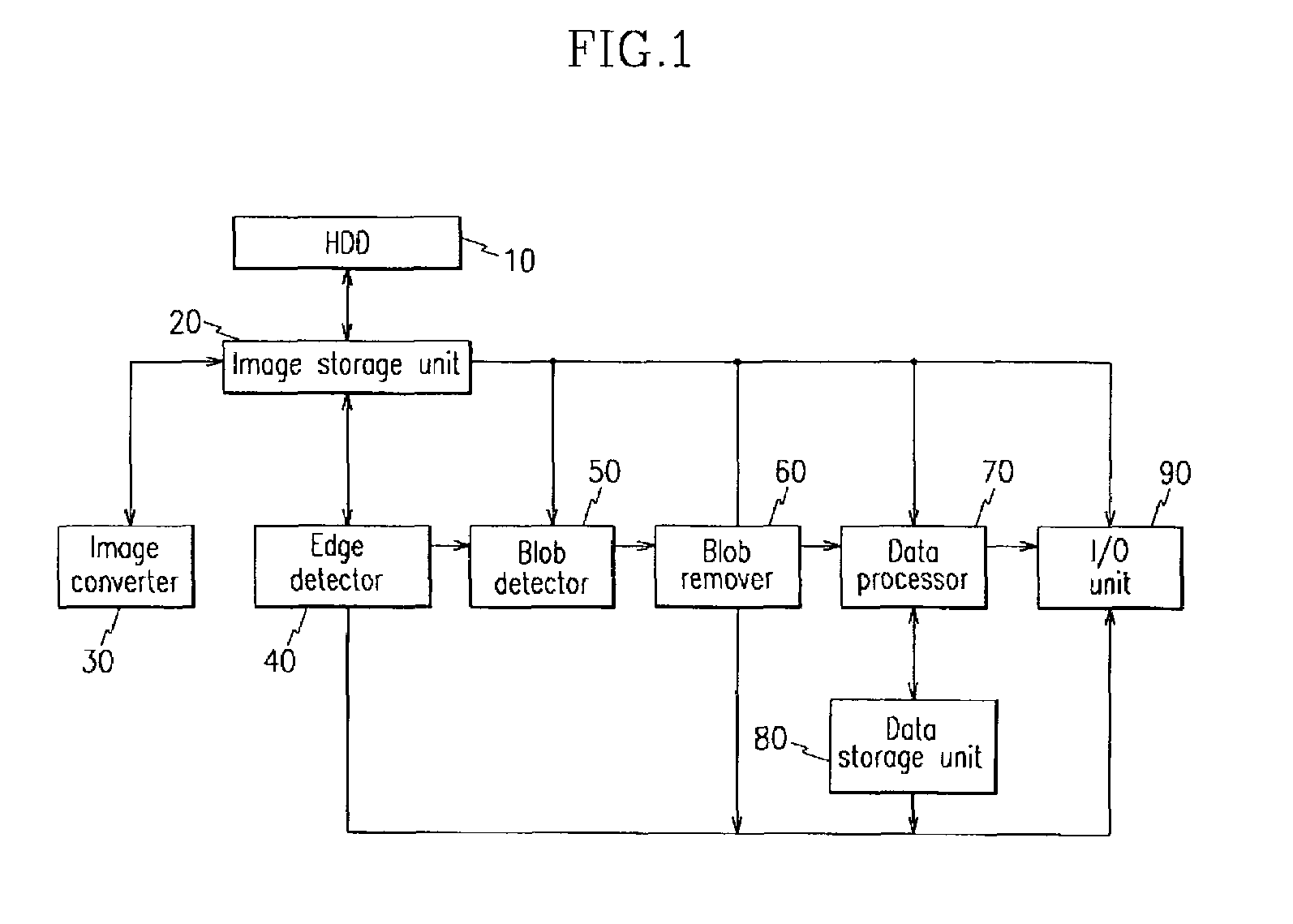

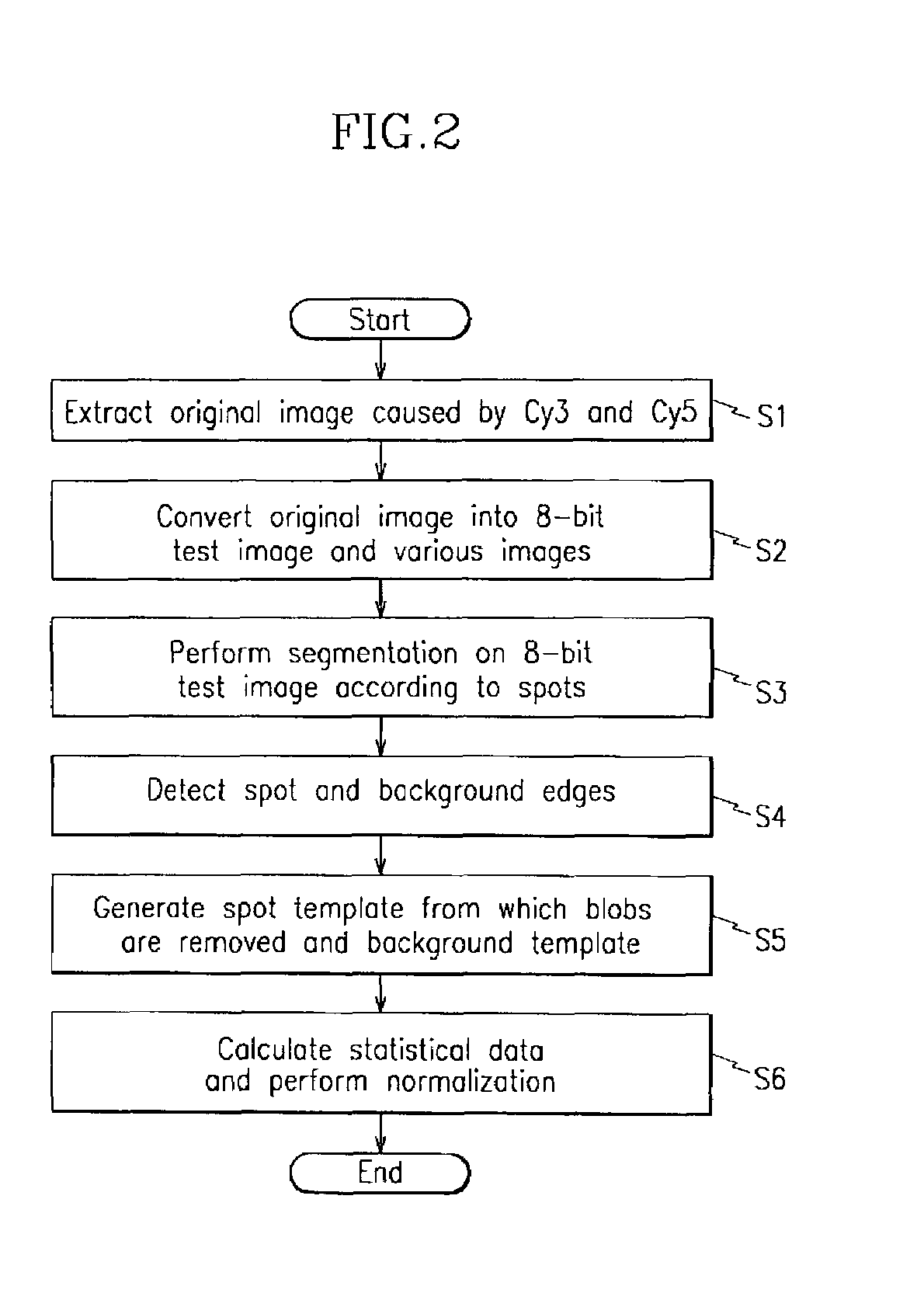

Biochip image analysis system and method thereof

InactiveUS7068828B2Reduce data error rateReduce decreaseImage enhancementImage analysisPattern recognitionColor image

A biochip image analysis system comprises an image storage unit storing image information including an original image of the biochip including genes extracted from experimental and control groups' samples tagged by fluorescent dyes of different colors; an image converter converting the original image into a test image, generating an overlapped image and a color image; an edge detector separating spots of the test image into segments and detecting edges from spot and background areas to measure expression degrees of genes; a blob detector detecting blobs from the spot and background areas to generate a blob template; a blob remover generating a spot template and a background template; a data processor calculating statistical data and correcting intensity; and a data storage unit storing the data.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

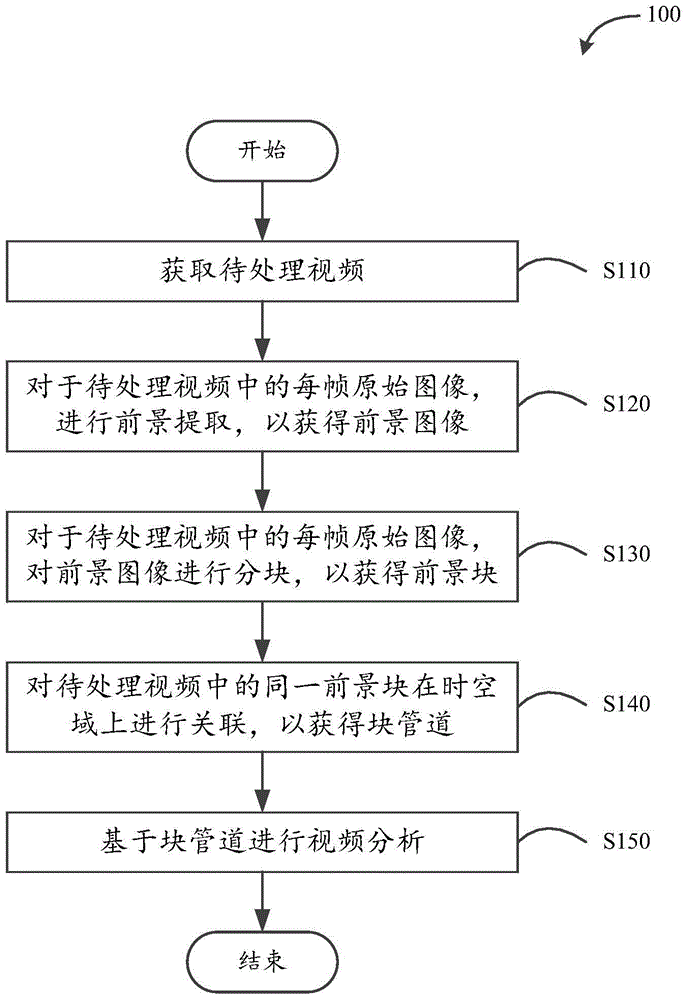

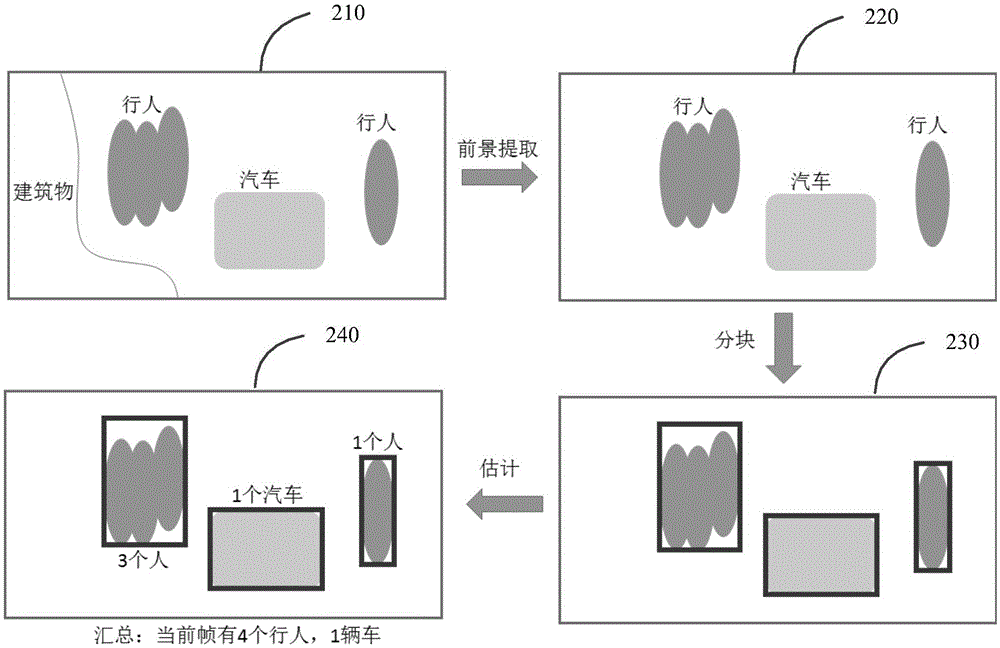

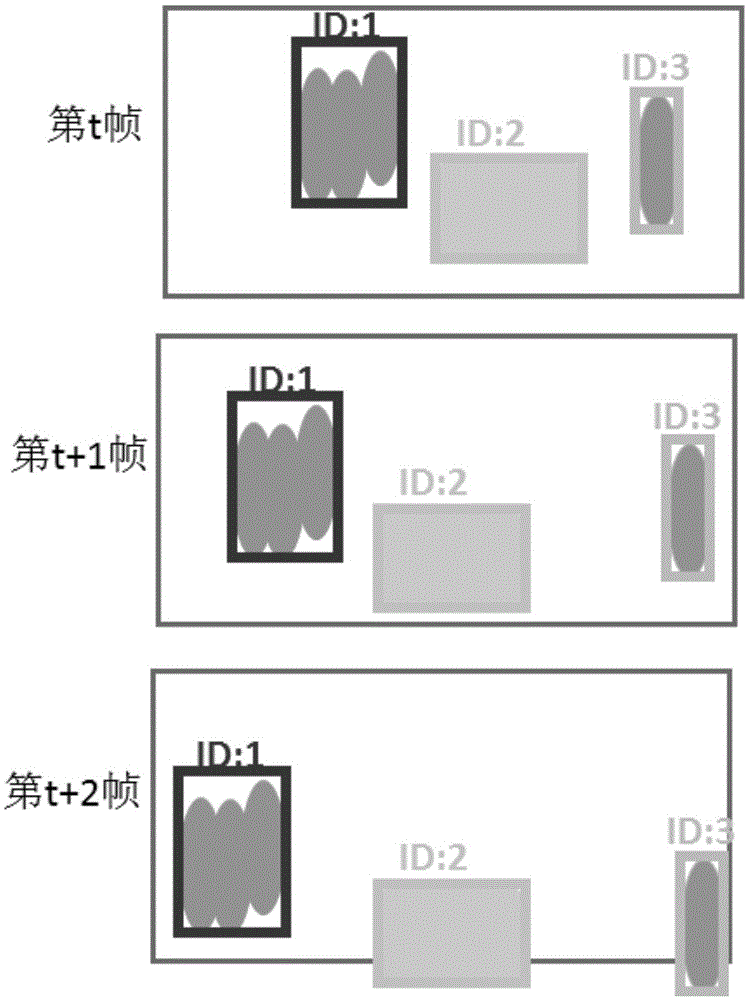

Video processing method and apparatus

ActiveCN105554456ARapid Analytical ProcessingCharacter and pattern recognitionClosed circuit television systemsBlob detectionVideo processing

The invention discloses a video processing method and apparatus. The video processing method comprises the steps of: obtaining a video to be processed; performing foreground extraction for each frame of original image in the video to be processed to obtain a foreground image; performing blob detection on each foreground image to obtain foreground blobs; associating the same foreground blobs in the video to be processed in a time-space domain to obtain blob pipelines; and performing video analysis based on the blob pipelines. The video processing method and apparatus provided according to the invention process videos in a manner of blob detection and foreground blob associated tracking, so that analysis and processing, such as concentration, can be efficiently and quickly performed on video data.

Owner:BEIJING KUANGSHI TECH +1

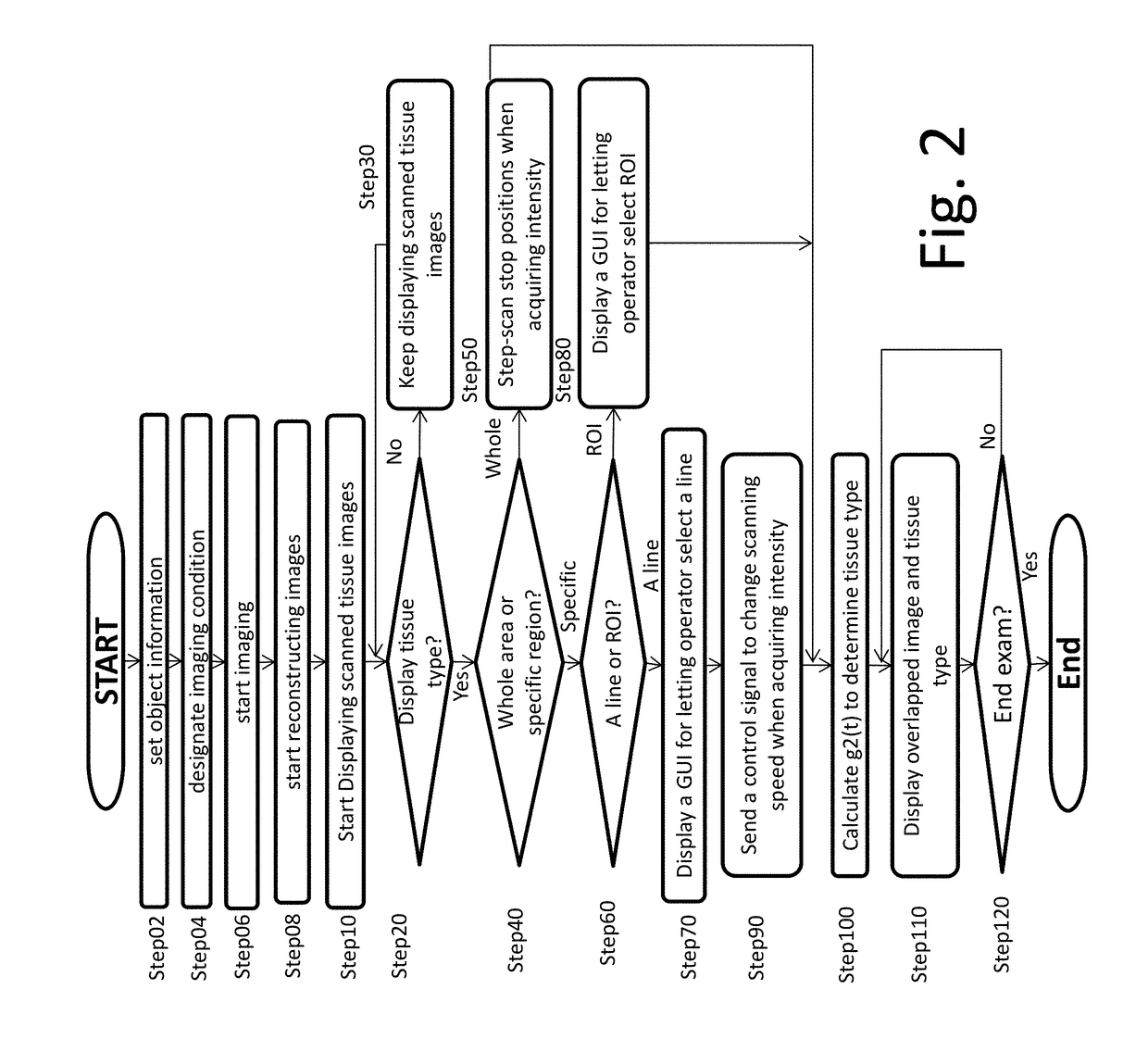

Diagnostic spectrally encoded endoscopy apparatuses and systems and methods for use with same

InactiveUS20180120212A1Low costReducing and minimizing numberSurgeryDiagnostics using spectroscopyBlob detectionCorrelation function

One or more spectrally encoded endoscopy (SEE) devices, systems, methods and storage mediums for characterizing, examining and / or diagnosing, and / or measuring viscosity of, a sample or object using speckle detection are provided. Examples of such applications include imaging, evaluating and diagnosing biological objects, such as, but not limited to, for Gastro-intestinal, cardio and / or ophthalmic applications, and being obtained via one or more optical instruments. Preferably, the SEE devices, systems methods and storage mediums include or involve speckle intensity autocorrelation function(s). One or more embodiments involve a serial time-encoded 2D imaging system with speckle detection to reconstruct images, store reconstructed images of the sample or object, and / or measure viscosity of the sample or object.

Owner:CANON USA

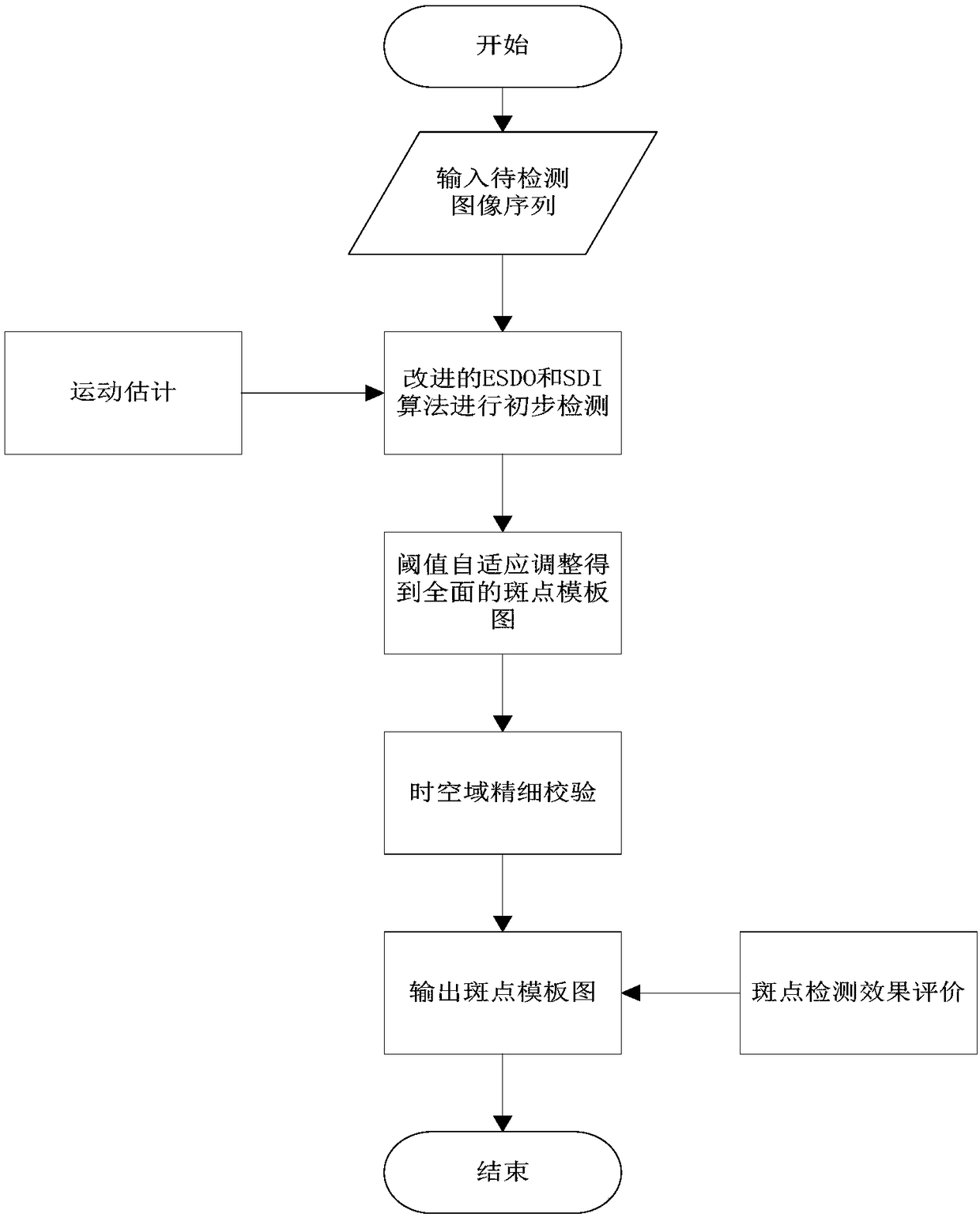

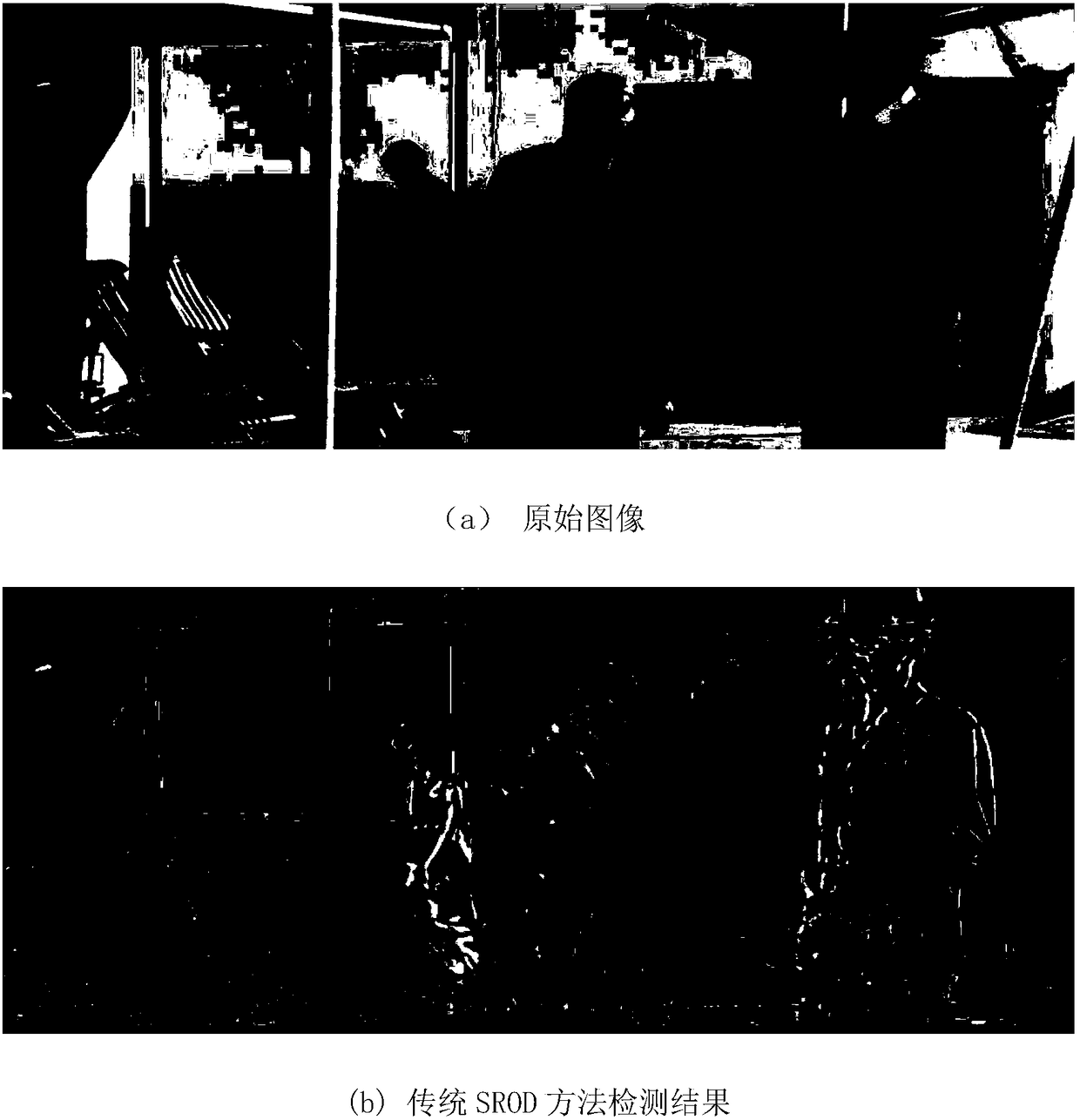

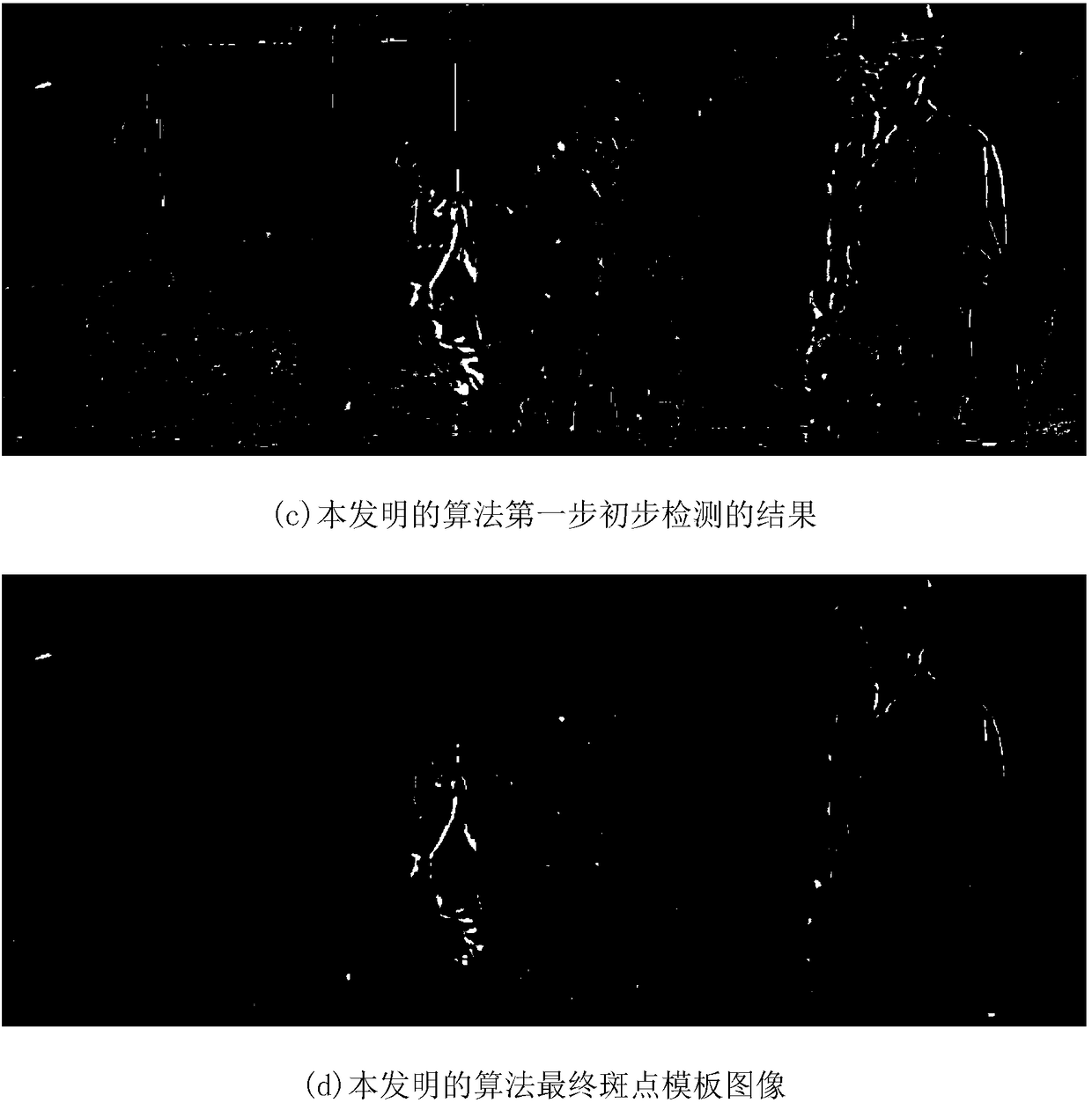

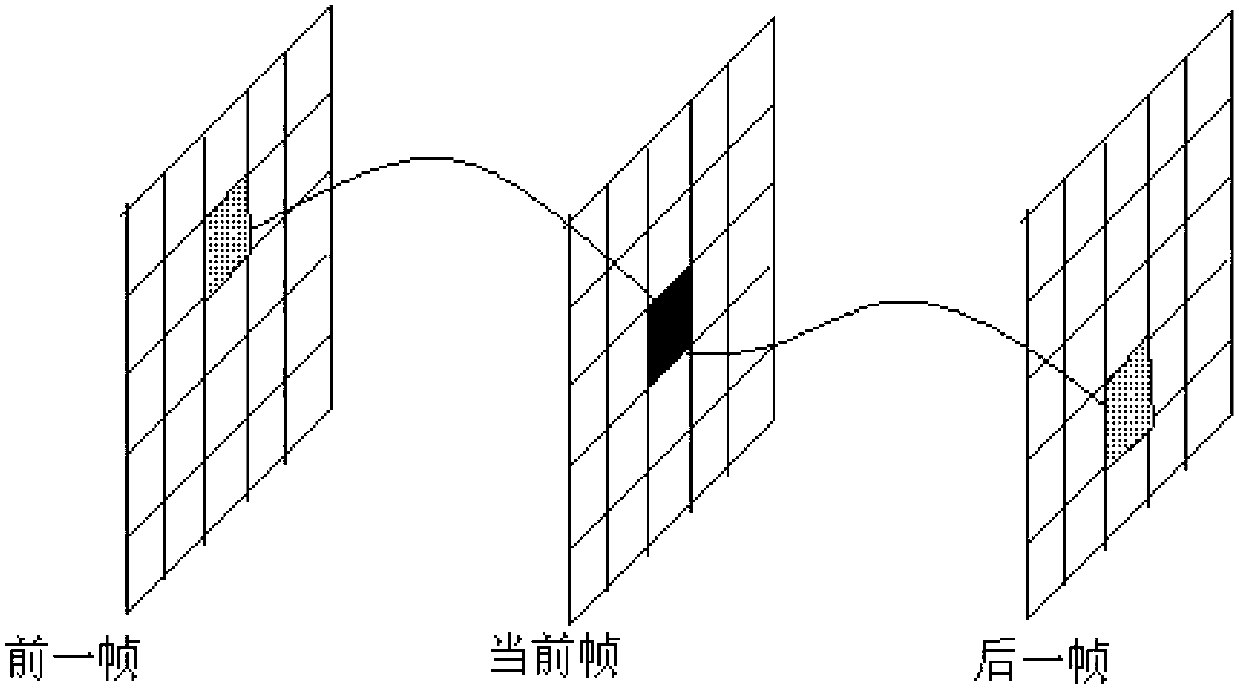

Old movie spike noise detection method based on adaptive threshold value time-spatial information

The present invention provides an old movie spike noise detection method based on adaptive threshold value time-spatial information, and relates to the field of digital image processing. Time domain and space domain information is subjected to full constraint, spike damaging in an old movie is detected, and a detected spike template graph can clearly reflect the information of positions where thespikes are located. The method comprises the steps of: performing motion estimation of an image of a frame to be detected, taking a pixel block as a unit to perform matching between front and rear frames, obtaining two motion vector matrixes for each image, and respectively recording motion vectors of each pixel of a current image at positions corresponding to the front and rear frames; based on the motion estimation result obtained in the step 1, employing an improved SDI (Spike Detection Index) algorithm and an ESROD algorithm to perform comprehensive detection of spikes and perform adaptiveadjustment of the threshold value to detect all the areas which are possible to become spikes; and finally, performing further screening of the spike areas, and employing a time-spatial constraint condition to screen out an accurate spike position to obtain a spike detection result.

Owner:BEIJING UNIV OF TECH

Detection and identification method for circular high-reflection workpieces

PendingCN109859192AQuickly know the detection situationEasy to masterImage analysisPattern recognitionBlob detection

The invention relates to the technical field of visual inspection, in particular to a detection and identification method for a circular high-reflection workpiece, which comprises the following stepsof: 1, performing image acquisition on the workpiece; 2, performing binarization processing on the acquired image; 3, performing spot detection algorithm operation and circular detection algorithm operation on the binarized image, and identifying whether a workpiece has defects or not and identifying circular size information on the workpiece; and step 4, converting the judgment result of whetherthe workpiece has defects or not and the identified circular size information into readable data information and outputting the readable data information. The display interface displays the acquired image and defect position and size information marked on the image, so that an operator can conveniently and quickly know the detection condition of the workpiece, the whole steps are simple, conventional technicians can conveniently and quickly master skilled work, and the operation efficiency is indirectly improved.

Owner:东莞中科蓝海智能视觉科技有限公司

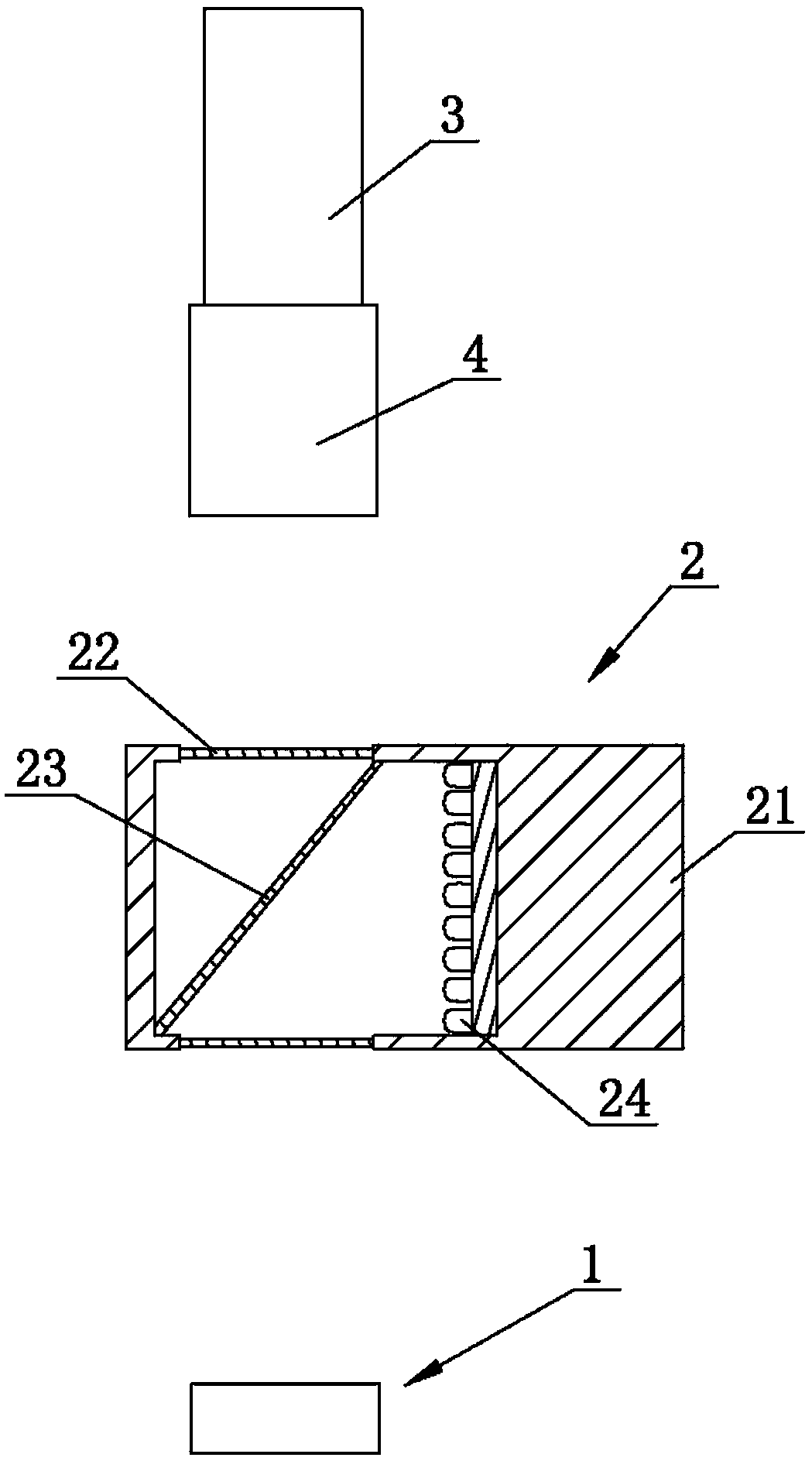

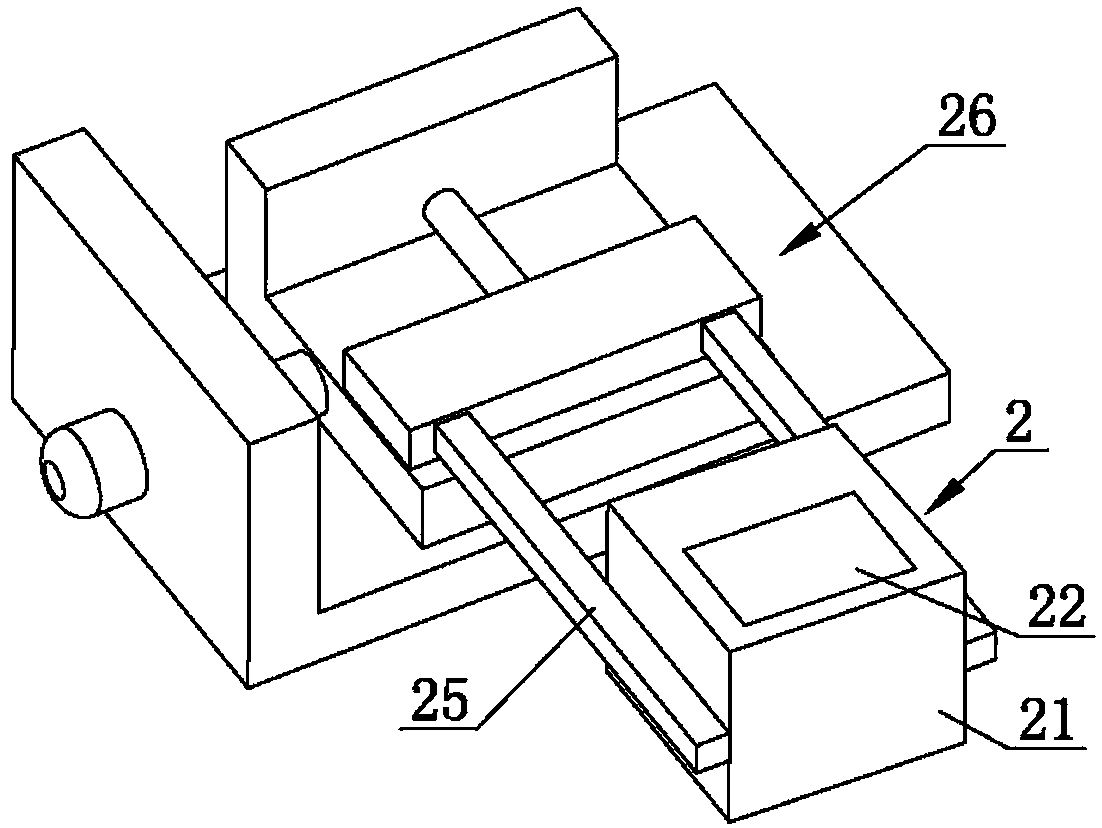

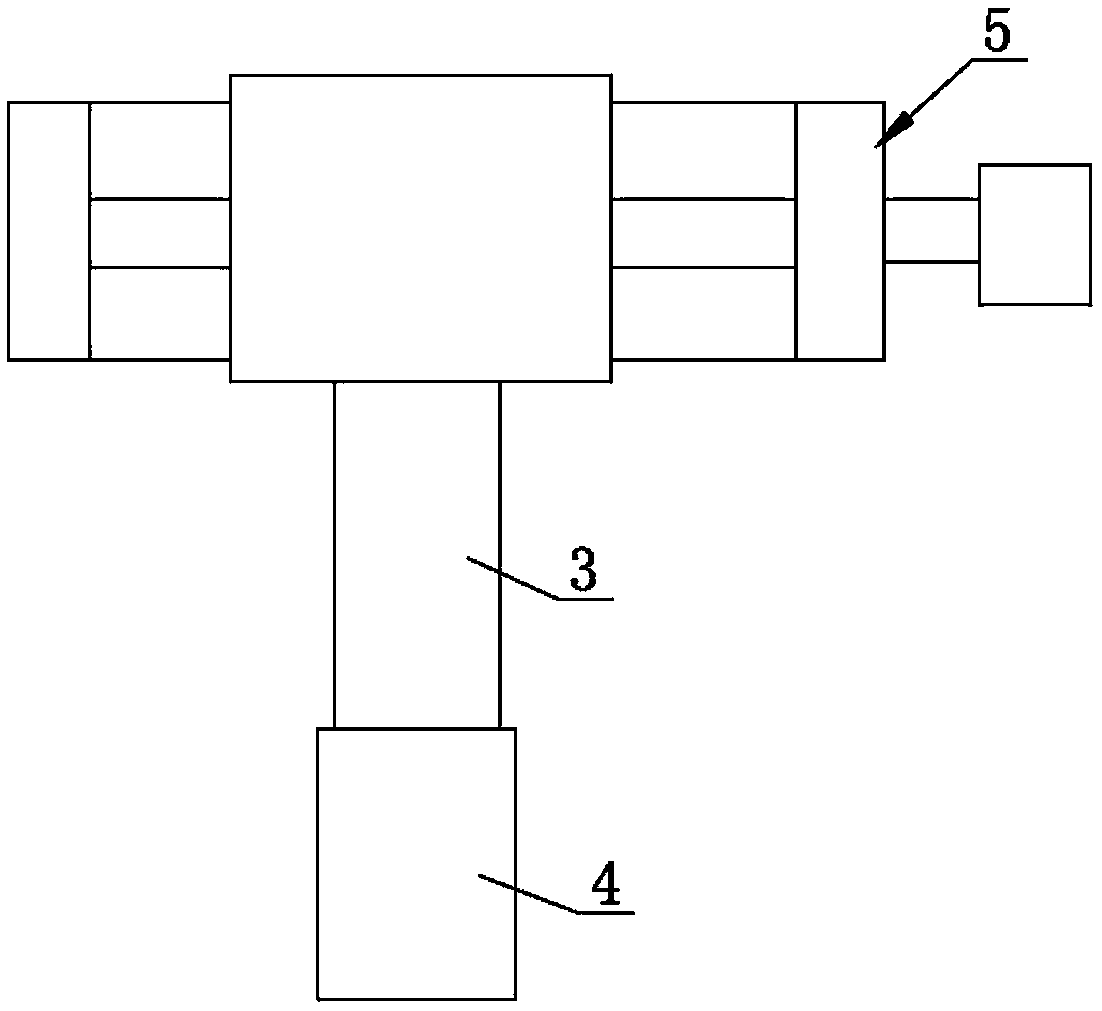

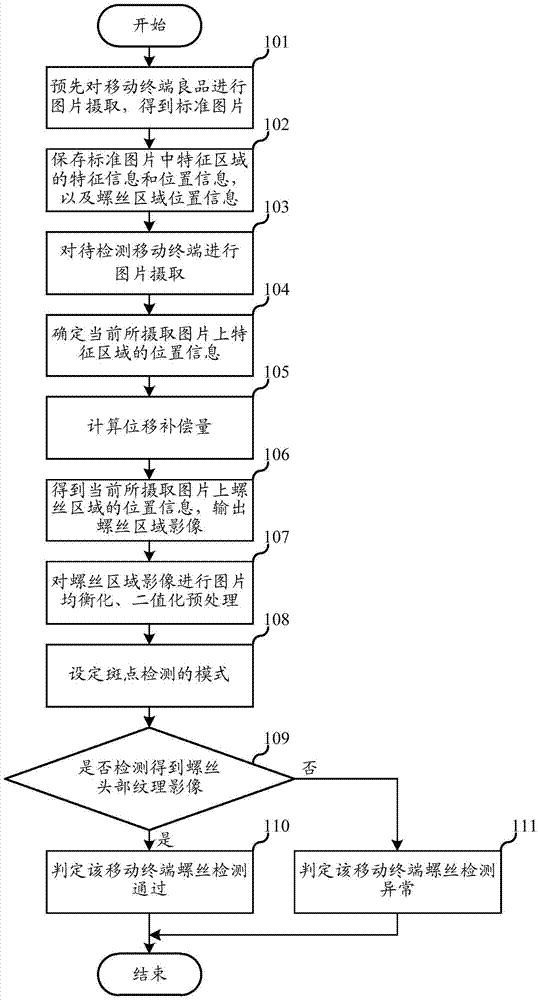

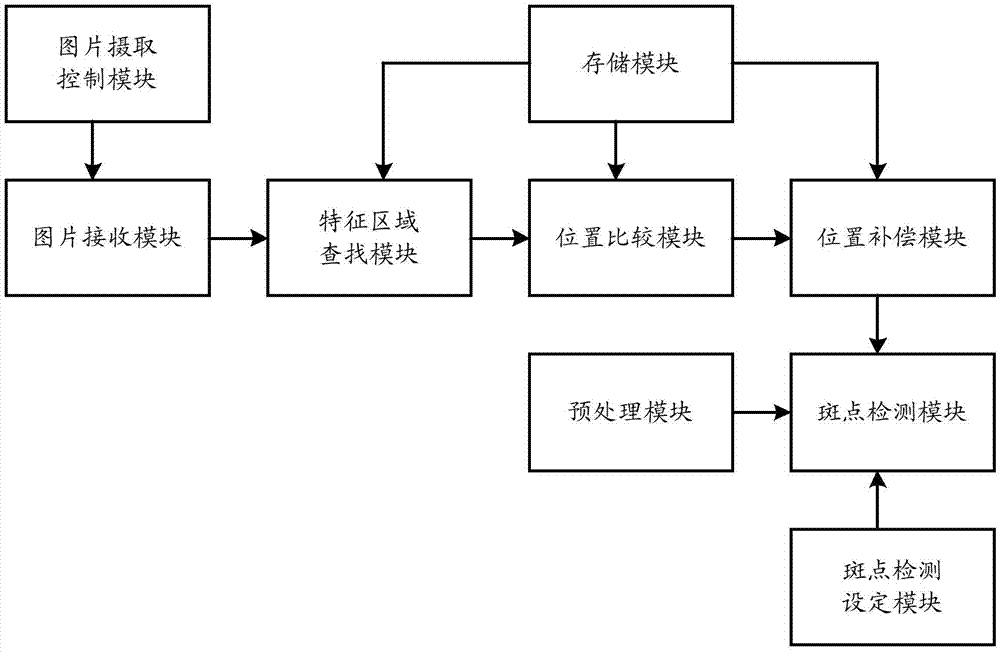

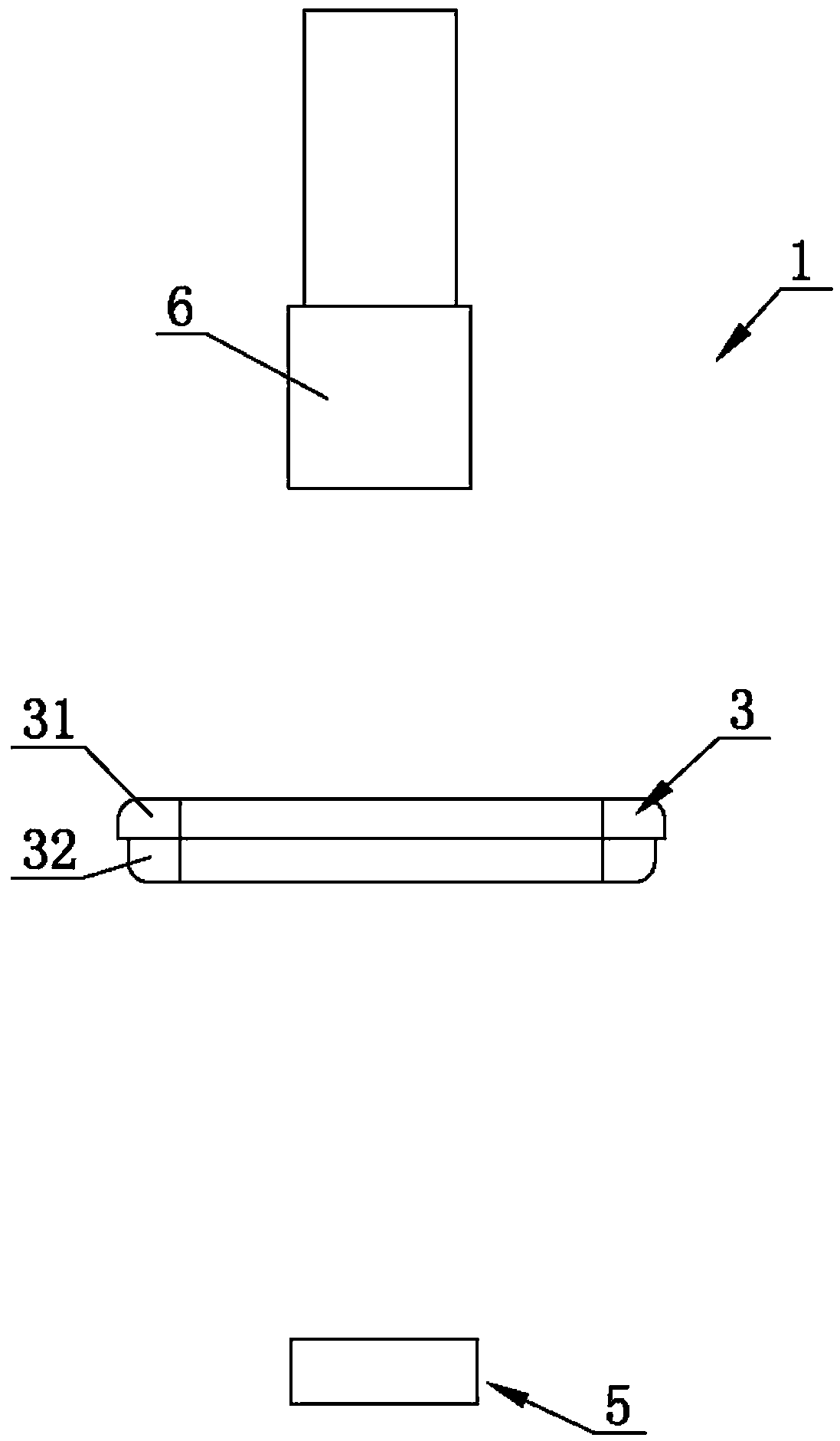

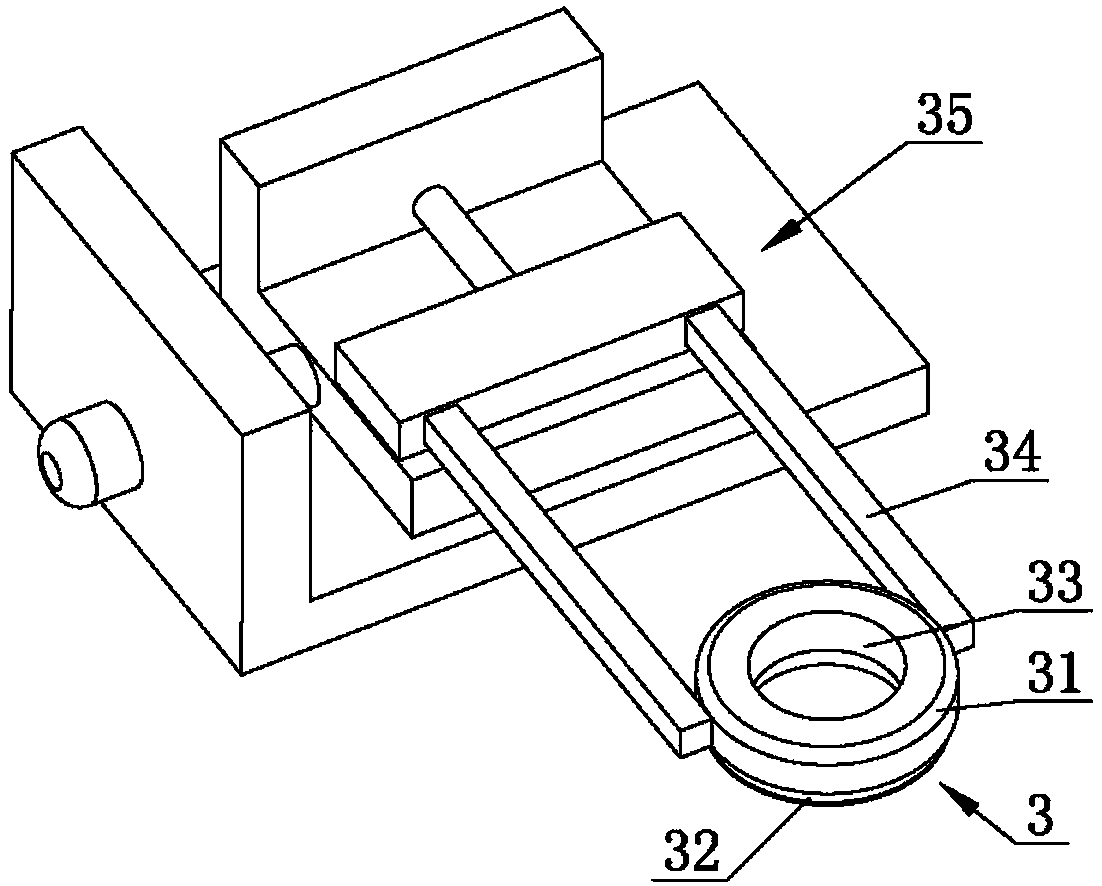

Visual detection method for screw on mobile terminal and control device

InactiveCN106937080AReduce labor costsReduce missed detectionOptical detectionClosed circuit television systemsPattern recognitionBlob detection

The invention discloses a visual detection method for a screw on a mobile terminal and a control device. The method comprises the following steps: taking a picture of a to-be-detected mobile terminal through a virtual detector; detecting a screw region on the picture taken currently through a spot detection method; if no screw head texture image is detected, judging that screw detection on the mobile terminal is abnormal; and if a screw head texture image is detected, judging that the mobile terminal passes screw detection. Through the method, the labor cost is lowered, the detection time is shortened, and the probability of missed detection and false detection is minimized.

Owner:SHANGHAI SIMCOM LTD

Self-adaptive detection method for spots of old movie

ActiveCN103279962AImproved method for finding pixel gray level difference between framesDrawbacks of change detectionImage analysisBlob detectionAlgorithm

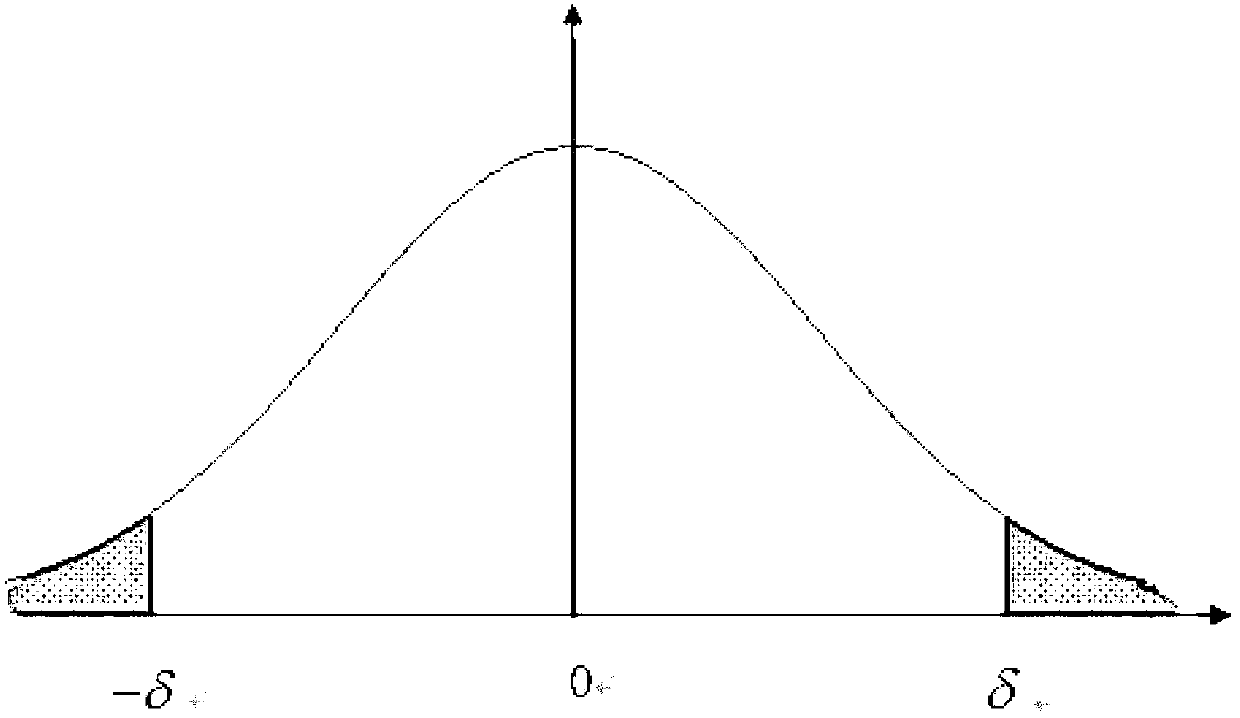

The invention discloses a self-adaptive detection method for spots of an old movie. The method comprises the steps that the local standard difference of different macro blocks of the current frame is estimated through an optimum matching block; spot detection is conducted on pixel points in the image of the current frame through an initial threshold, an initial detection result is recorded as M0, and the number of initial spot blocks is recorded as n0; an iteration step length delta epsilon is added to the initial threshold, a self-adaptive spot detection index is judged again, an iterative detection result is recorded as M1 and the number of iterative spot blocks is recorded as n1; whether the number n0 of the initial spot blocks is equal to the number n1 of the iterative spot blocks or not is judged, if n0 is equal to n1, the facts that new spots do not occur after the initial threshold is increased and M0 is equal to M1 are indicated, and then the previous step is executed; if n0 is not equal n1, the fact that a newly added area S0 which is not communicated with the initial detection result occurs in the iterative detection result is indicated, and then the next step is executed; and if the newly added area satisfies judgment conditions, the newly added area is a spot area, and if the newly added area does not satisfy the judgment conditions, the newly added area S0 is removed. Since proper thresholds are generated for the image of each frame by adopting a threshold iteration method, the self-adaptive detection method improves the detection accuracy and the self-adaptability.

Owner:天津渤化讯创科技有限公司

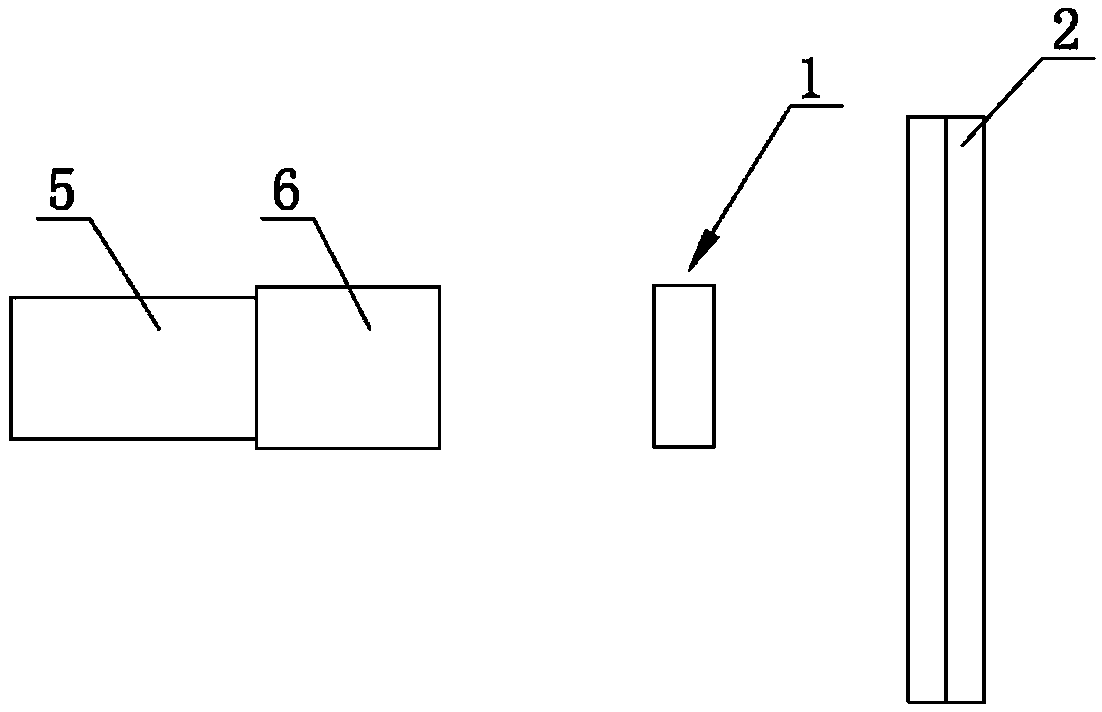

Size detection and identification method for plastic workpiece

InactiveCN109596058AHighlight contour featuresGuaranteed accuracyTelevision system detailsImage analysisBlob detectionData information

The invention relates to the technical field of visual detection, in particular to a size detection and identification method for a plastic workpiece. The method comprises the following steps of 1, sequentially moving the workpiece to a station I and a station II for carrying out image acquisition; 2, performing spot detection algorithm operation and circular detection algorithm operation on an image acquired by the station I, identifying and positioning the workpiece, and measuring the inner diameter and the outer diameter of the workpiece; 3, carrying out line segment detection algorithm operation and line-line measurement algorithm operation on an image acquired by the station II, identifying a line segment formed by the upper surface and the lower surface of the workpiece and measuringthe height of a product; and 4, converting identified inner diameter information, outer diameter information and height information of the workpiece into readable data information to be output. The two stations are set; and each station only carries out size detection on the workpiece, so that the accuracy of detection and identification is effectively guaranteed, the algorithm design difficultyis reduced, the operation time of a complex algorithm is shortened, and the production efficiency is improved.

Owner:东莞中科蓝海智能视觉科技有限公司

Devices and methods for sensing targets using photothermal speckle detection

A device, and corresponding method, can include a pump light source configured to be modulated at a pump modulation and to irradiate a target specimen. The device can also include a probe light source arranged to generate a speckle pattern from the target specimen, as well as a sensor configured to detect changes in at least one of position and intensity of one or more speckle lobes of the speckle pattern having correlation with the pump modulation. The device and method can be used for non-contact monitoring and remote sensing of surfaces, gases, liquids, particles, and other target materials by analyzing speckle pattern changes as a function of pump light irradiation. Advantages can include much higher sensitivity than existing methods; the ability to use visible probe wavelengths for uncooled, low-cost visible detectors with high spatial resolution; and the ability to obtain target material properties without detecting infrared light.

Owner:MASSACHUSETTS INST OF TECH

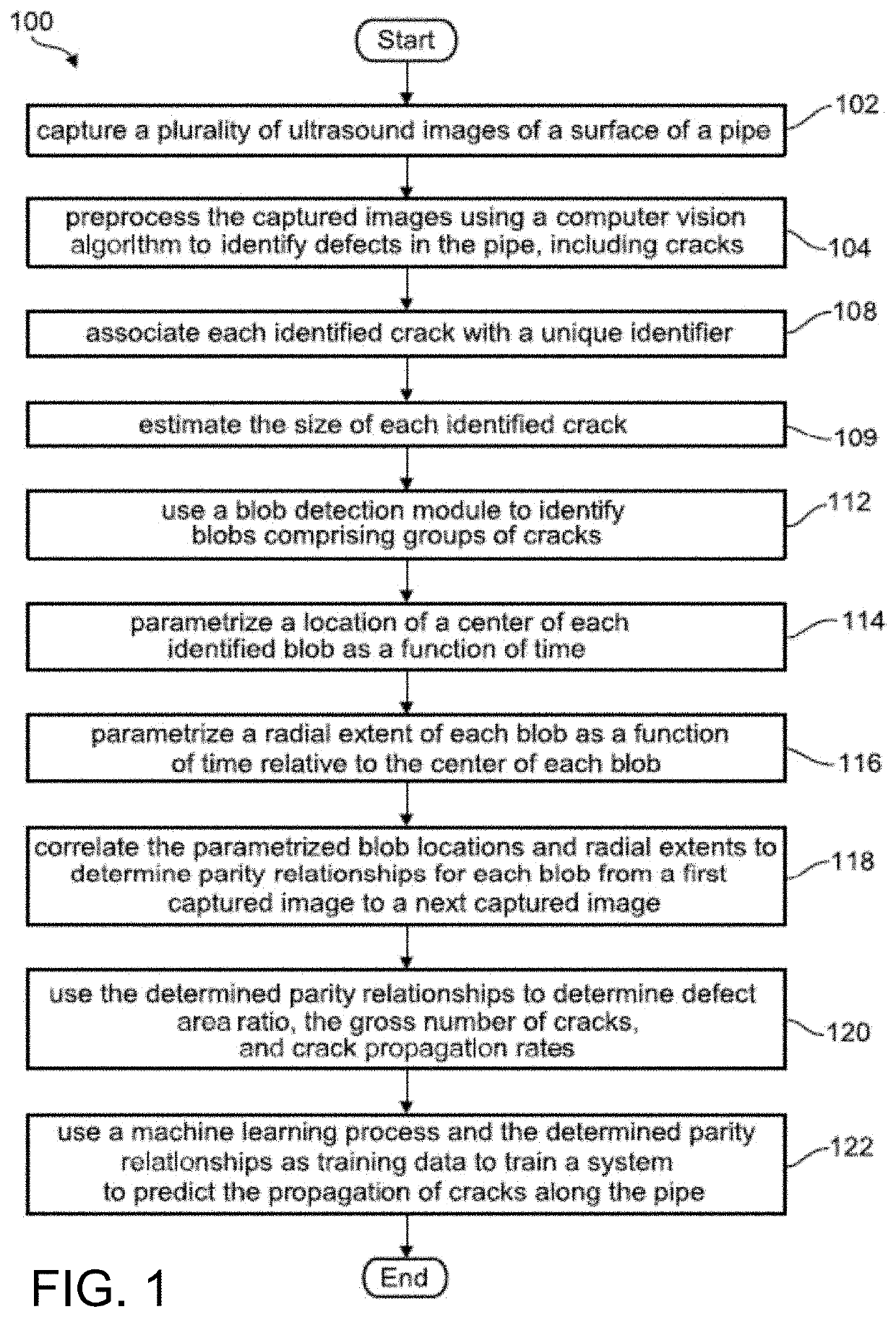

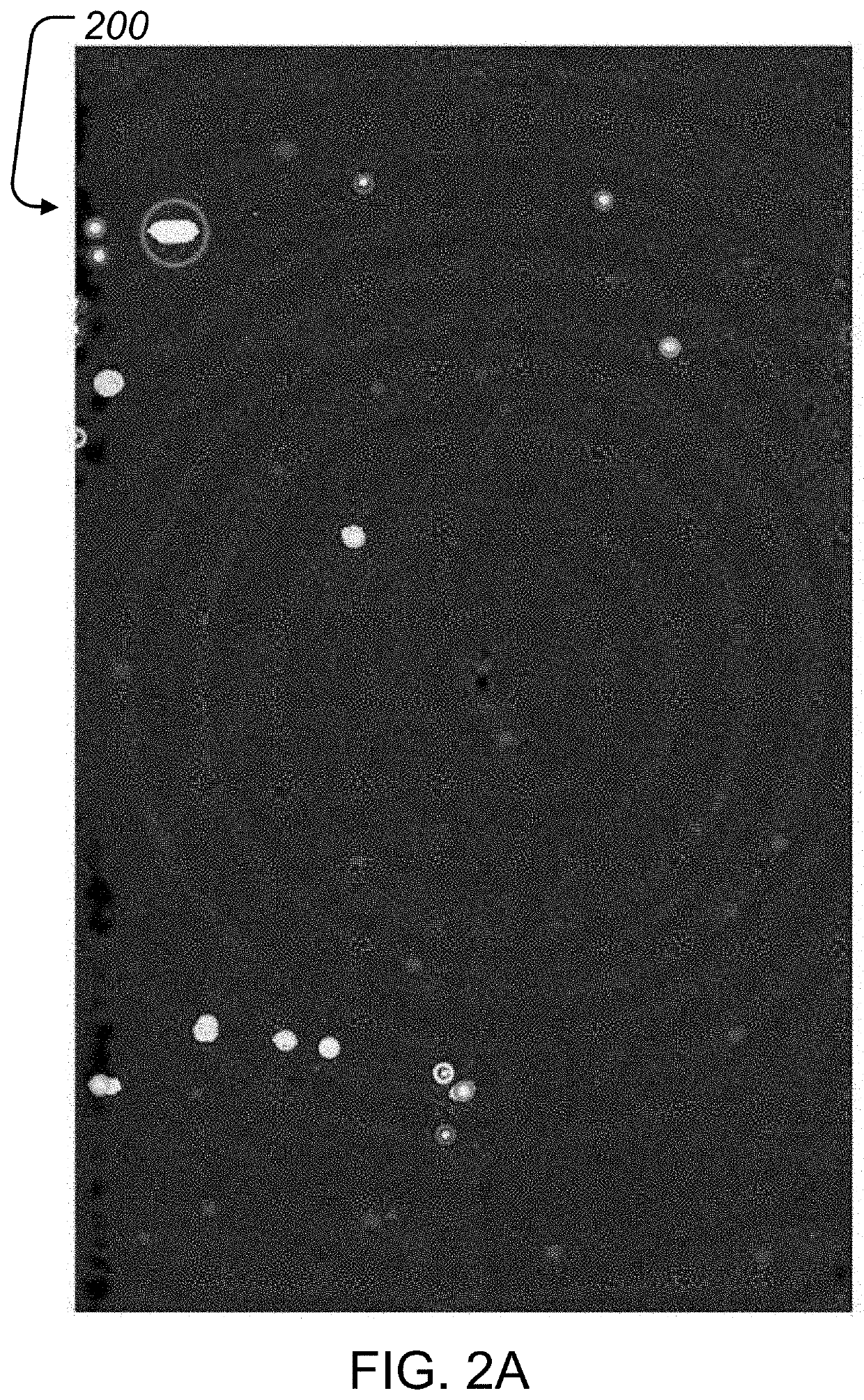

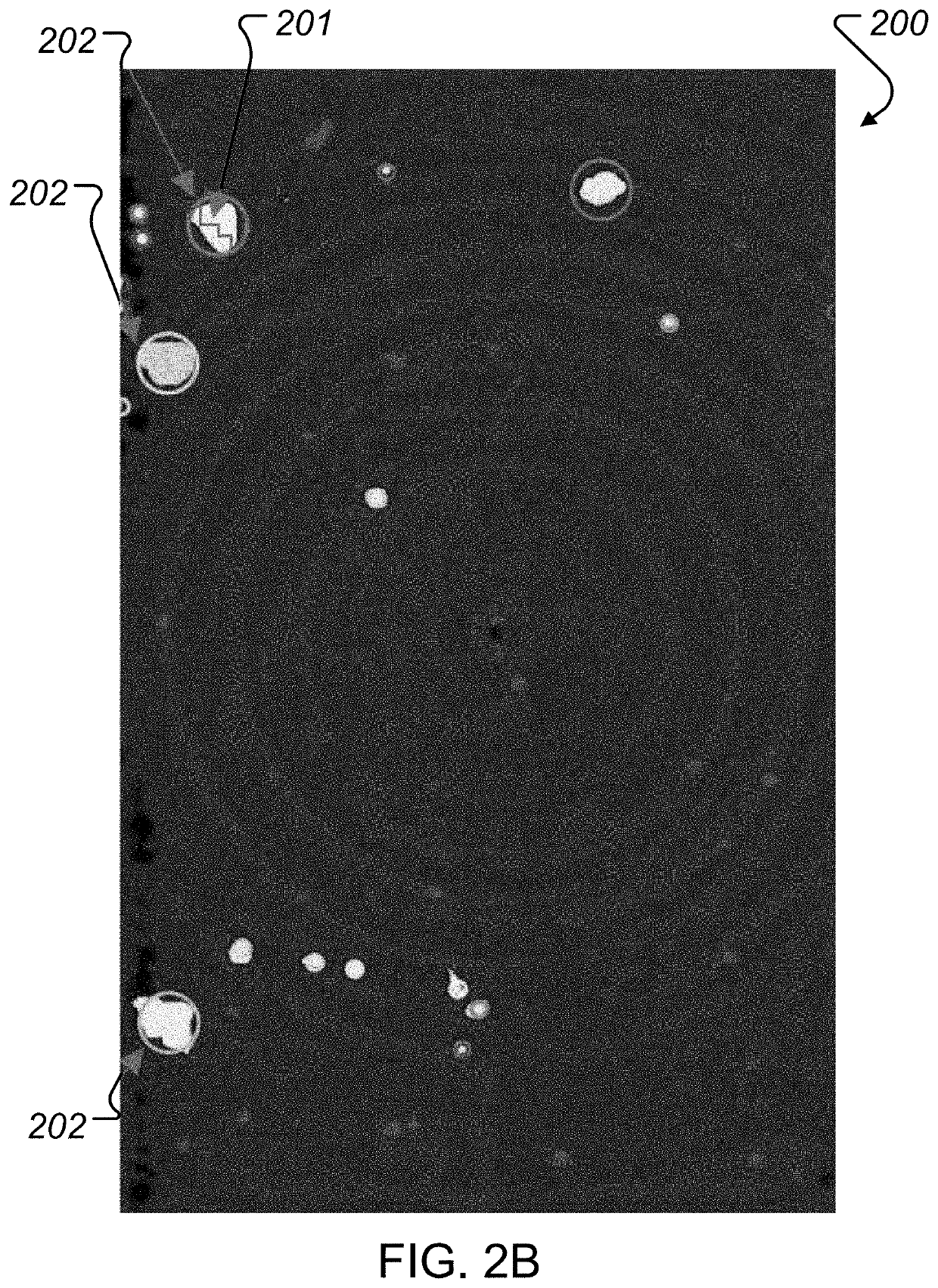

Method for automated crack detection and analysis using ultrasound images

ActiveUS20210340857A1Image enhancementMaterial analysis using sonic/ultrasonic/infrasonic wavesDigital dataStress concentration

A computer-based method and system for predicting the propagation of cracks along a pipe is provided, wherein successive time-indexed ultrasound images of a pipe surface are captured and digitized. A computer vision algorithm processes the images to identify defects in the pipe, including cracks. At least one blob detection module is used to identify groups of cracks on the pipe surface that have created detectable areas of stress concentration or a prescribed likelihood of crack coalescence or crack cross-influence. The center locations and radial extents of respective blobs are each parametrized as a function of time and pipe surface location by determining parity relationships between successive digital data sets from successive captured images. The determined parity relationships are then used as training data for a machine learning process to train a system implementing the method to predict the propagation of cracks along the pipe.

Owner:SAUDI ARABIAN OIL CO

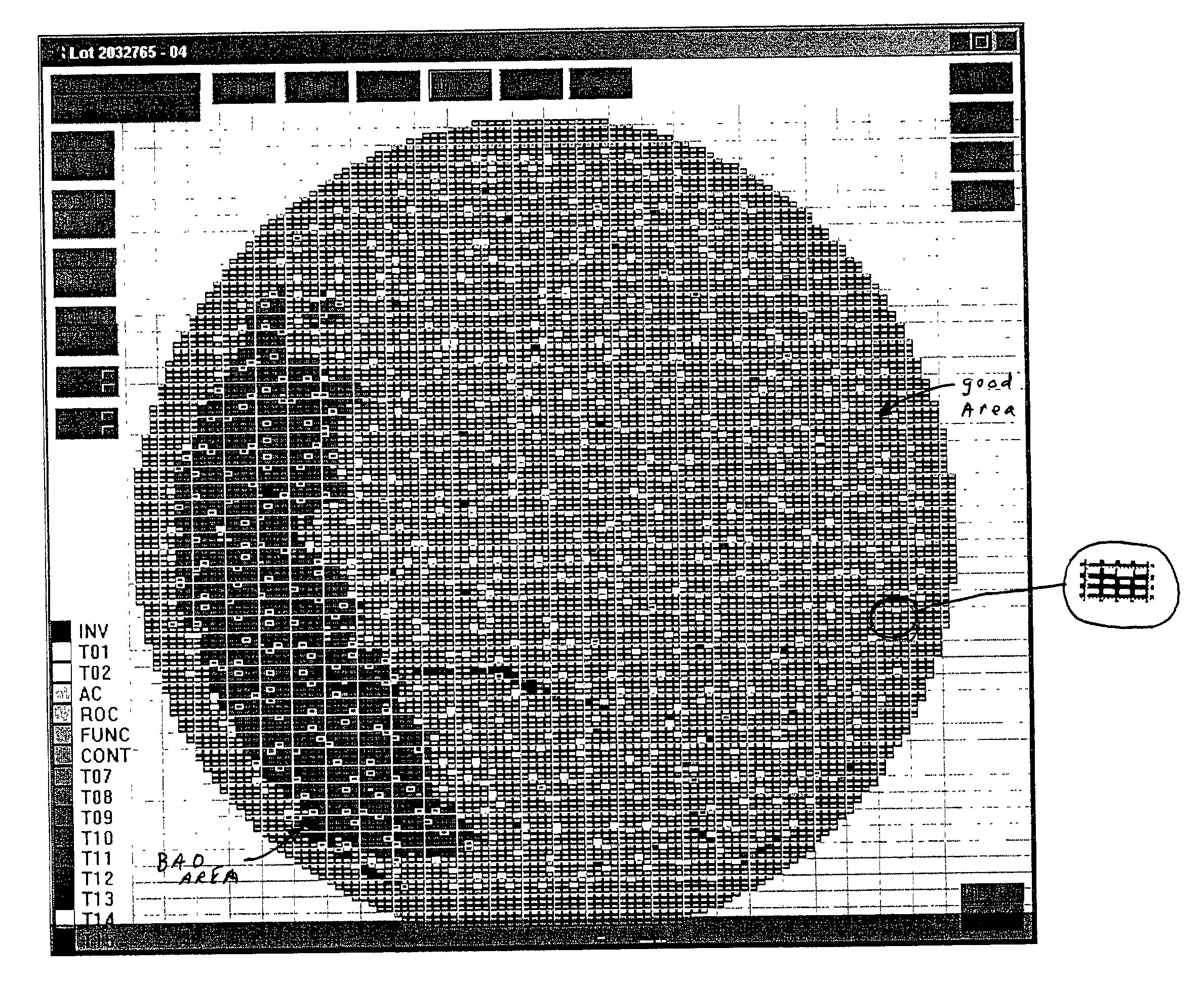

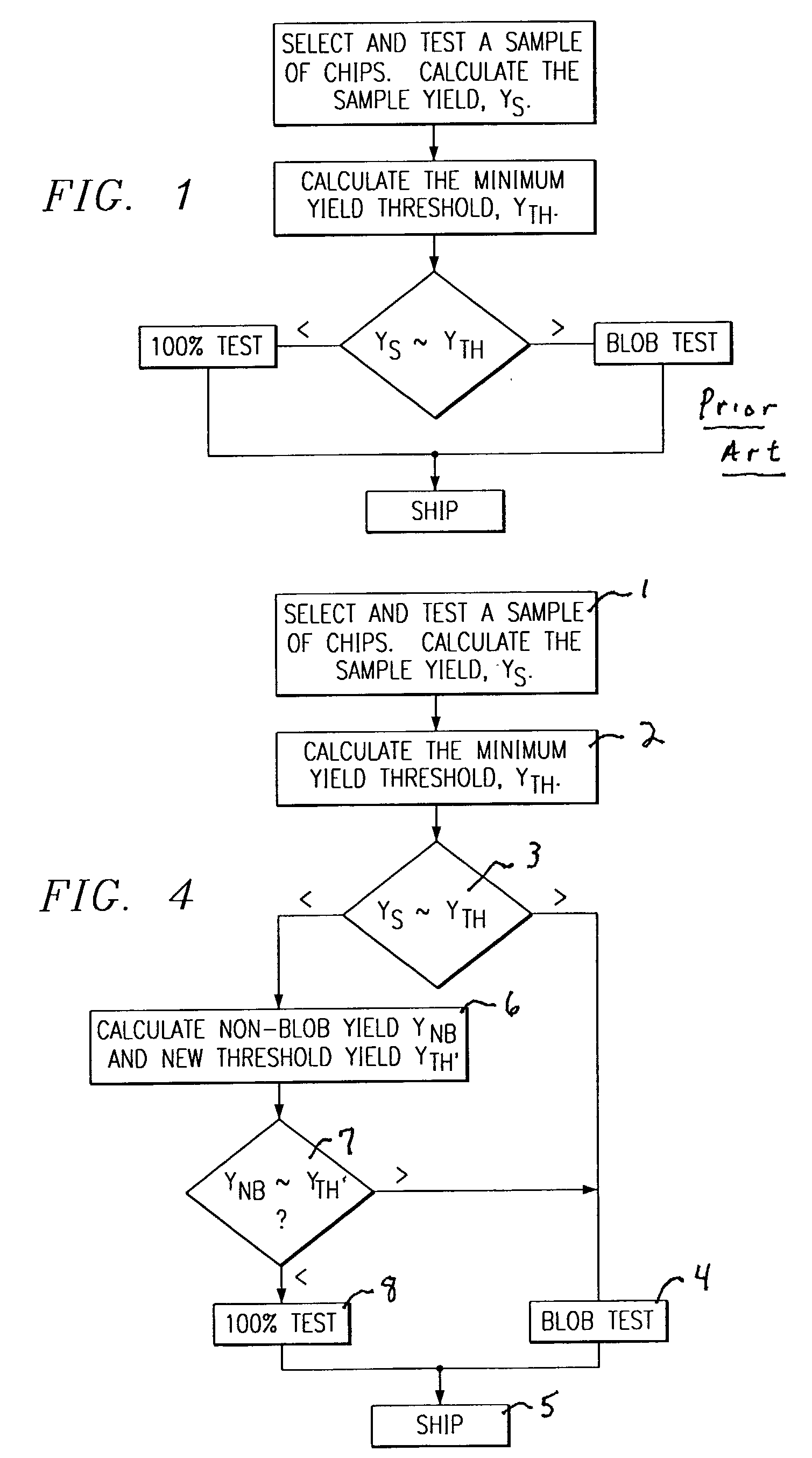

Multiprobe blob test in lieu of 100% probe test

InactiveUS20040034493A1Semiconductor/solid-state device testing/measurementNuclear monitoringBlob detectionStatistical physics

A method of predicting the effect of blob test in GSP sample testing is disclosed. The method includes extracting failure density maps from sample test results, where the density of any failed cell is expressed as the number of adjacent failing sample cells; determining the existence of local concentration of bad chips (blobs) as the occurrence of a detection density value above a threshold which can be adjusted to control the sensitivity of blob detection; determining the extent of such identified blobs as the occurrence of adjacent cells with density values above an inclusion threshold, which can be adjusted to control the sensitivity of blob extent determination; calculating a residual sample yield YNB for the areas outside blob regions using the total sample cell count NS, the passing cell count NG, and the count of cells in blobs NB by equation: <math-cwu id="MATH-US-00001"> <NUMBER>1< / NUMBER> Y NB = N G N S - N B ; <mathematica-file id="MATHEMATICA-00001" file="US20040034493A1-20040219-M00001.NB" / > <image id="EMI-M00001" wi="216.027" he="18.96615" file="US20040034493A1-20040219-M00001.TIF" imf="TIFF" ti="MF" / > < / MATH-CWU> and re-evaluating the decision of whether 100% probe test is required or if the cost savings can still be realized by performing only blob test.

Owner:TEXAS INSTR INC

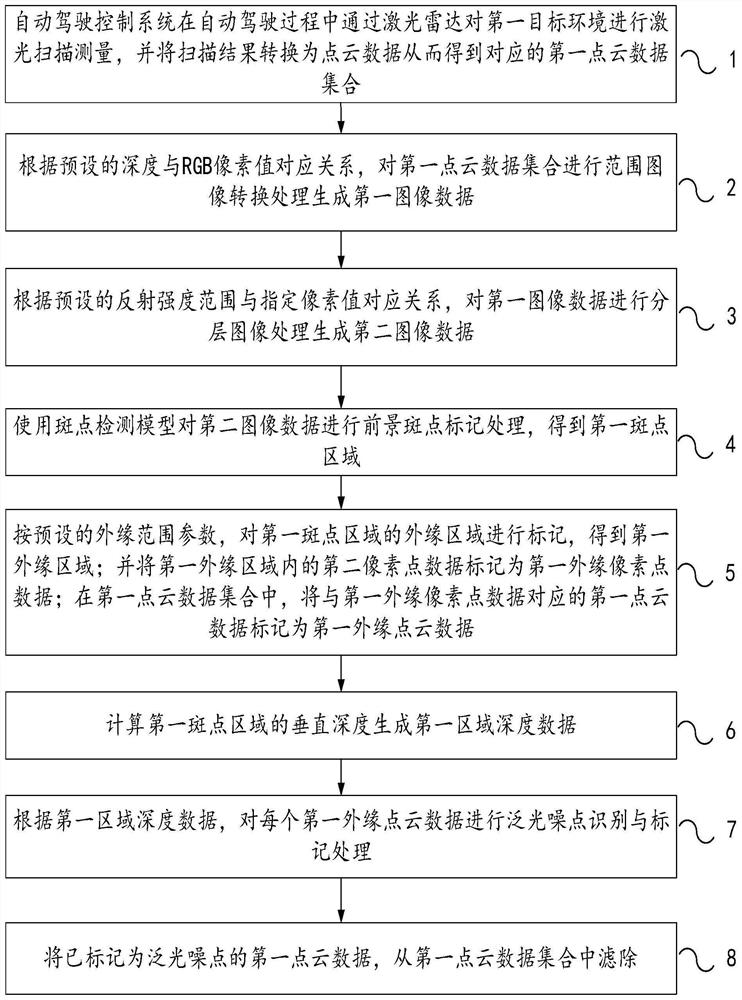

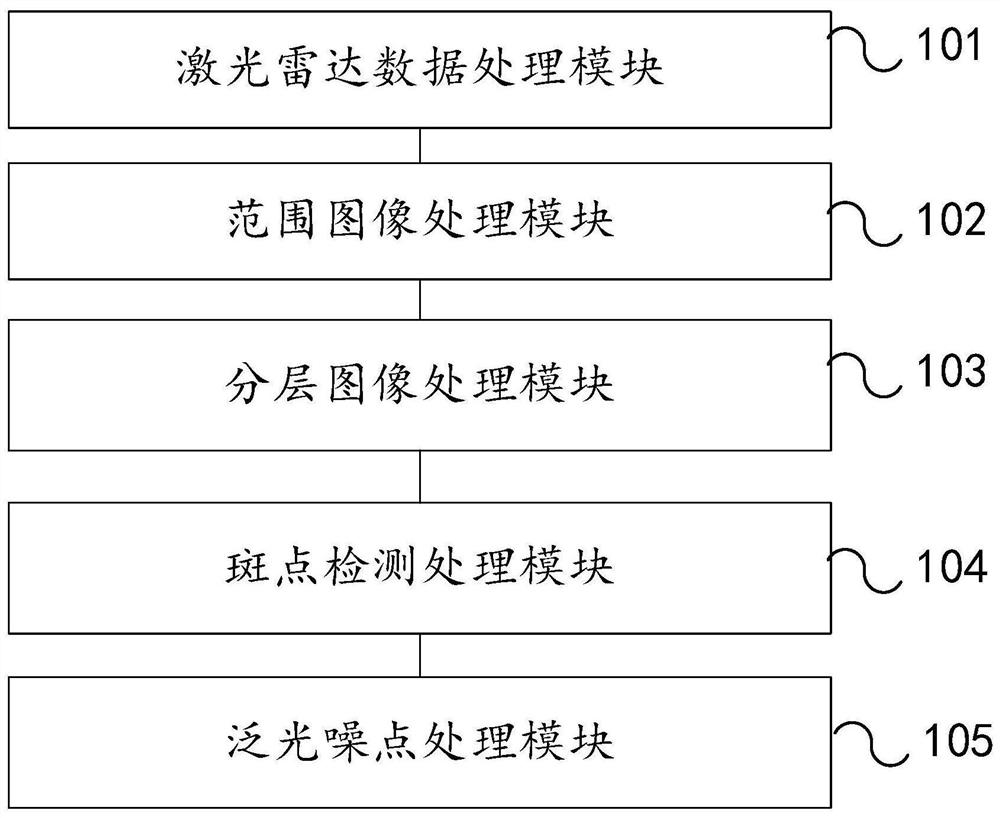

Method and device for filtering floodlight noisy points of laser radar in automatic driving

InactiveCN113325388ALow resolution accuracyImprove environmental adaptabilityElectromagnetic wave reradiationData setImaging processing

The embodiment of the invention relates to a method and a device for filtering floodlight noisy points of a laser radar in automatic driving. The method comprises the steps of performing laser scanning measurement on a first target environment through the laser radar in an automatic driving process to obtain a first point cloud data set; performing range image conversion processing on the first point cloud data set to generate first image data; performing layered image processing on the first image data to generate second image data; performing foreground spot marking processing on the second image data by using a spot detection model to obtain a first spot area; marking the outer edge area of the first spot area to obtain a first outer edge area; marking first outer edge point cloud data; calculating first area depth data; carrying out floodlight noisy point identification and marking processing; and filtering the first point cloud data marked as the floodlight noisy points from the first point cloud data set. According to the invention, the problem that the accuracy of laser radar measurement data is reduced in a humid / raining weather state can be solved.

Owner:BEIJING QINGZHOUZHIHANG TECH CO LTD

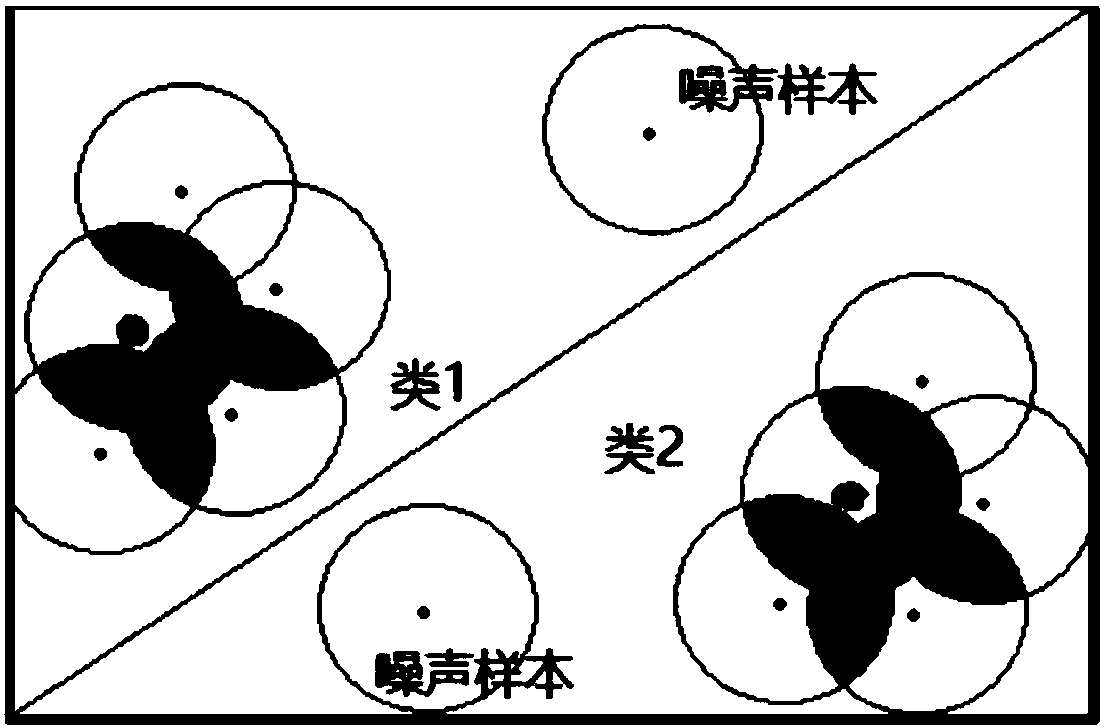

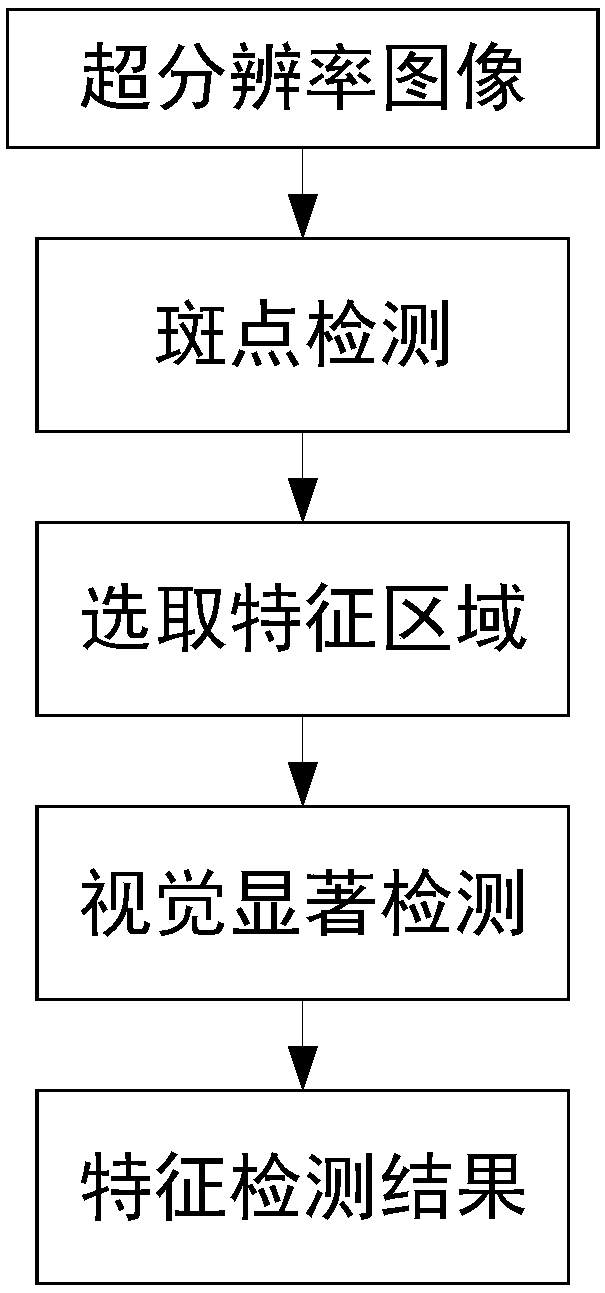

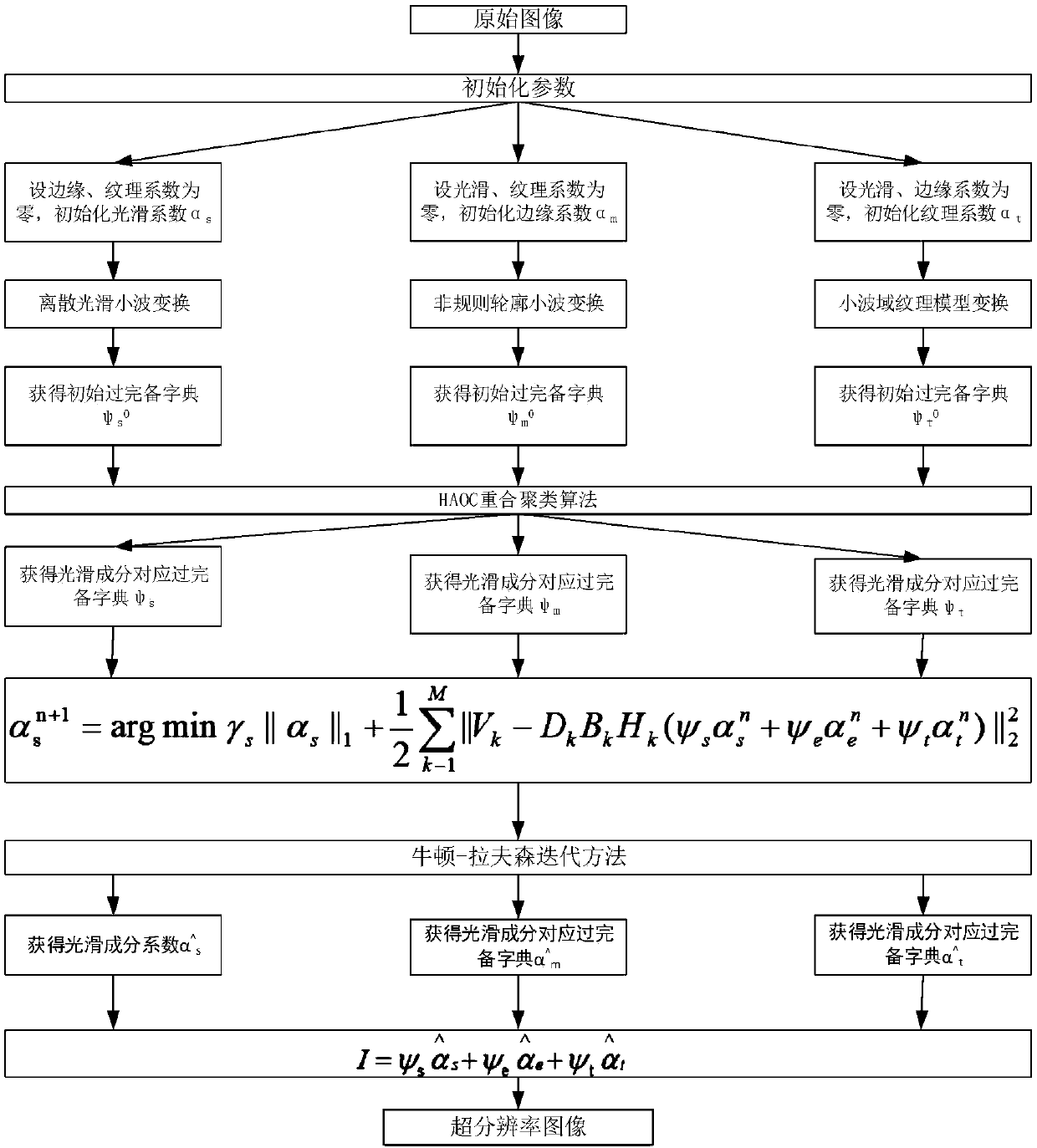

Sonar image super-resolution reconstruction target tracking and detection method based on compressed sensing

The invention provides a sonar image super-resolution reconstruction tracking and detection method based on compressed sensing. Based on the existing underwater sonar image target tracking method, a traditional clustering method and dictionary training method are improved. Spot detection and visual saliency detection are combined to track and detect a target. The method is more accurate in the aspect of dictionary training, and the image resolution is improved. The target is tracked step by step. After the relative position of the target is found, saliency detection is carried out to ensure that tracking and detection are real-time and accurate.

Owner:SHANGHAI MARITIME UNIVERSITY

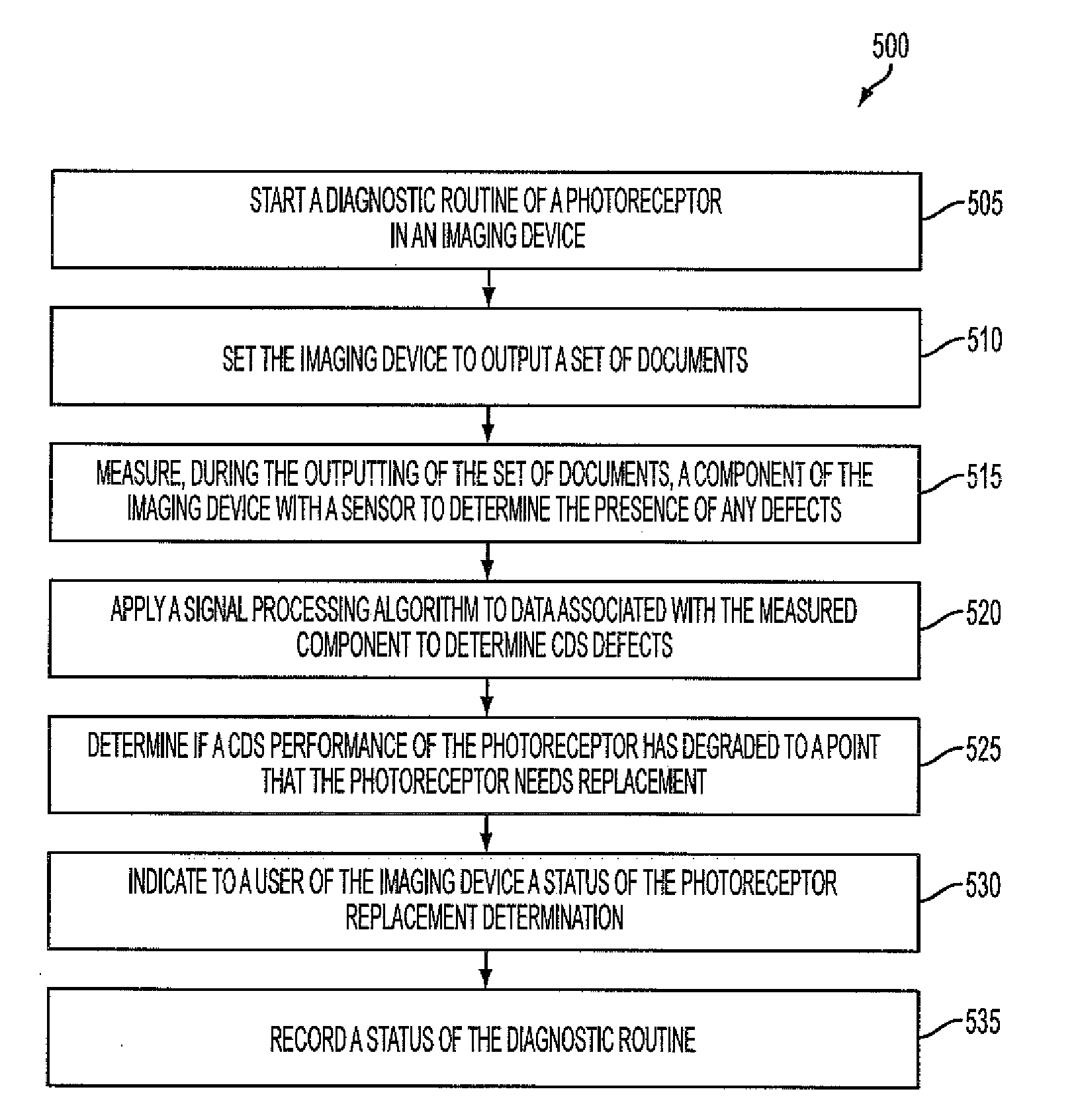

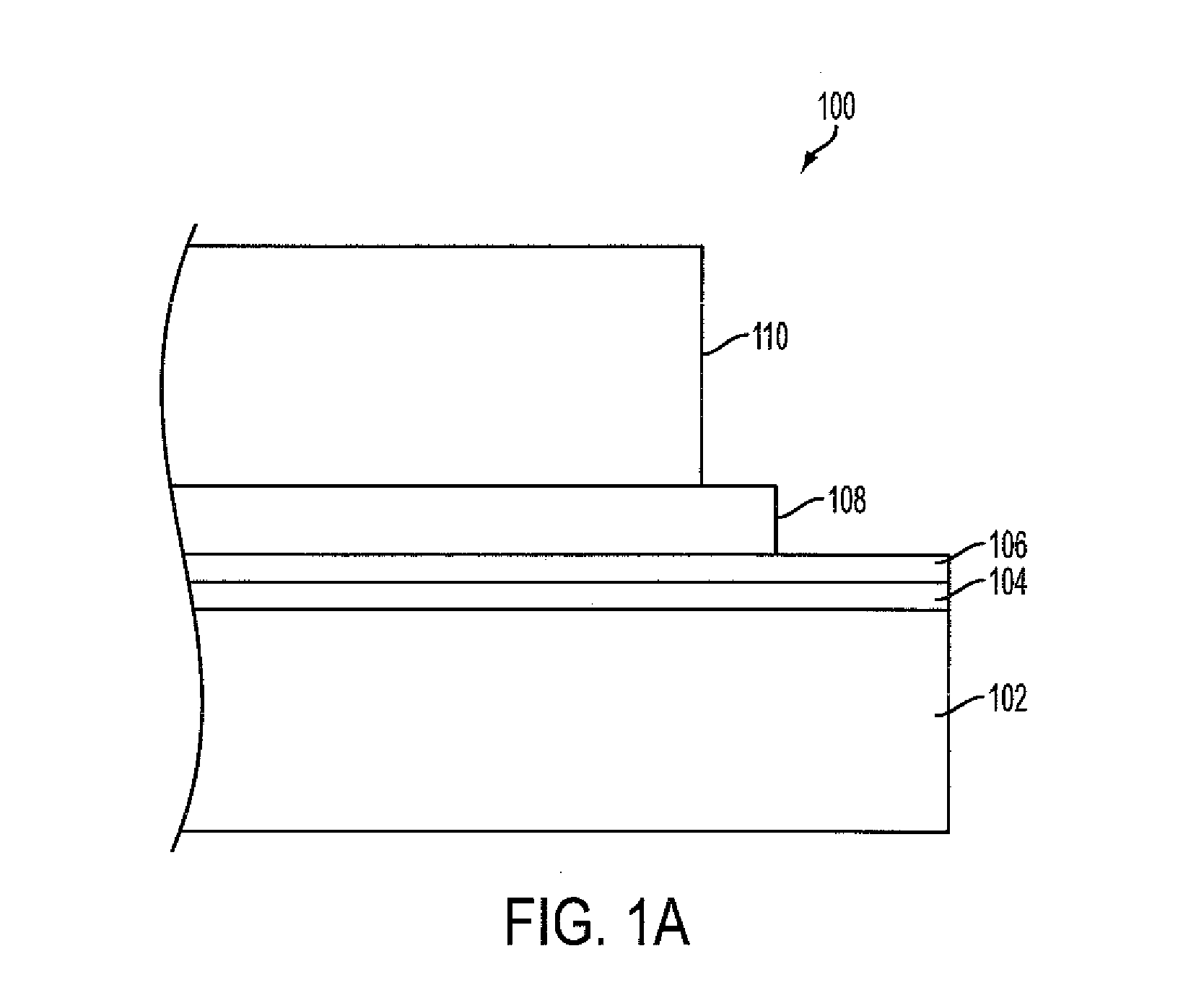

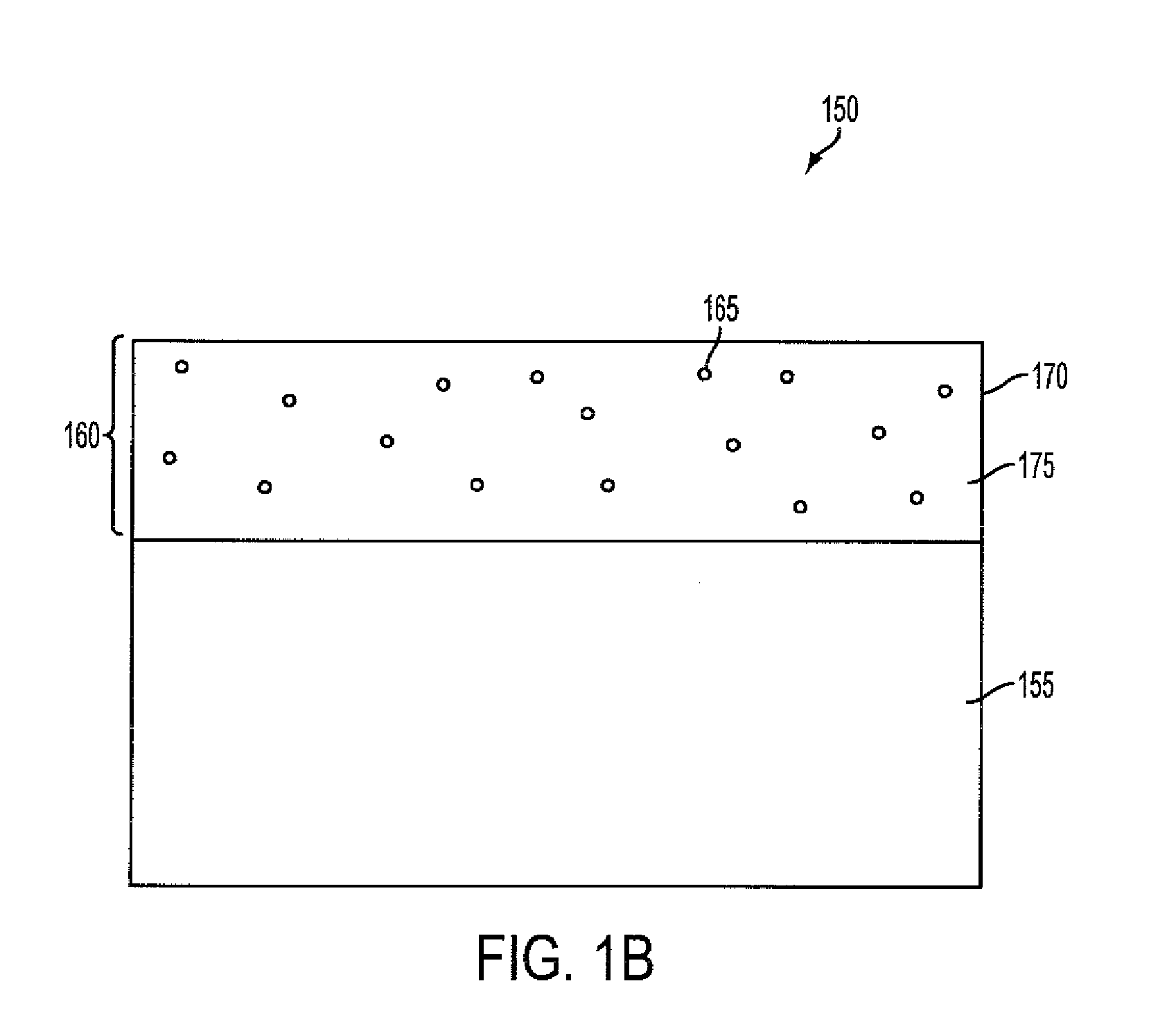

Photoreceptor diagnostic method based on detection of charge deficient spots

Systems and methods of diagnosing a photoreceptor associated with an imaging device. The photoreceptor is configured to enter into a diagnostic cycle to complete a set number of cycles. A sensor or array is configured to a scan a component associated with the imaging device during each of the set of cycles to establish defect data. The defect data is analyzed to filter one or more charge deficient spots (CDS) from background noise in the defect data. The systems and methods determine whether the photoreceptor needs replacement based on the determined one or more CDS. The systems and methods are further configured to output a report of the determination. The determination is conducted at fixed or variable intervals throughout the life of the photoreceptor and / or imaging device.

Owner:XEROX CORP

Size detection and identification method for strip-shaped workpiece

InactiveCN109596054AImprove detection accuracyConvenient follow-up work needsImage enhancementImage analysisBlob detectionData information

The invention relates to the technical field of visual detection, in particular to a size detection and identification method for a strip-shaped workpiece. The method comprises the following steps ofcarrying out image acquisition on the workpiece; performing a linear detection algorithm and a spot detection algorithm on acquired images, identifying and locating the workpiece, and identifying andmeasuring the length of the workpiece; judging the identified and measured length of the workpiece; and converting total number information of identifying and measuring the workpiece, total number information of judging qualified times, total number information of judging unqualified times and the corresponding identified and measured length information of the workpiece into readable data information to be output. The acquired images are subjected to multiple data acquisition and summarization, so that the follow-up operation is greatly facilitated; and meanwhile, summarization information canbe transmitted to a computer and exported as a table, so that processing conditions are clear to working personnel at a glance, the operations of modifying a processing scheme and the like can be quickly made according to the conditions, and the operation efficiency is improved.

Owner:中珂湳海(佛山)智能科技有限公司

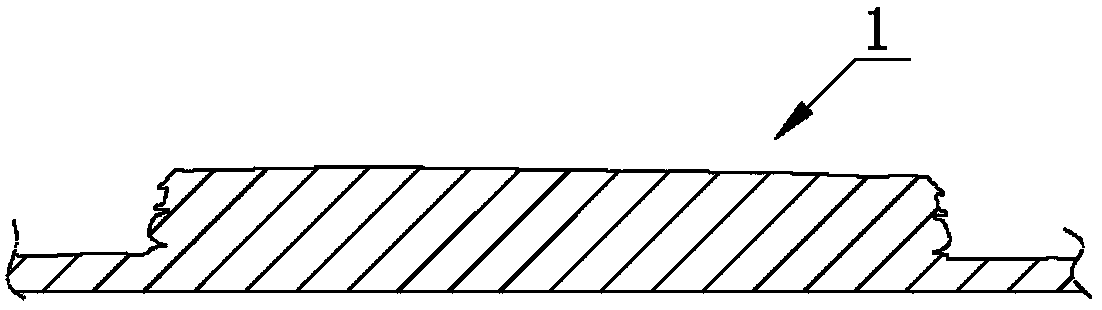

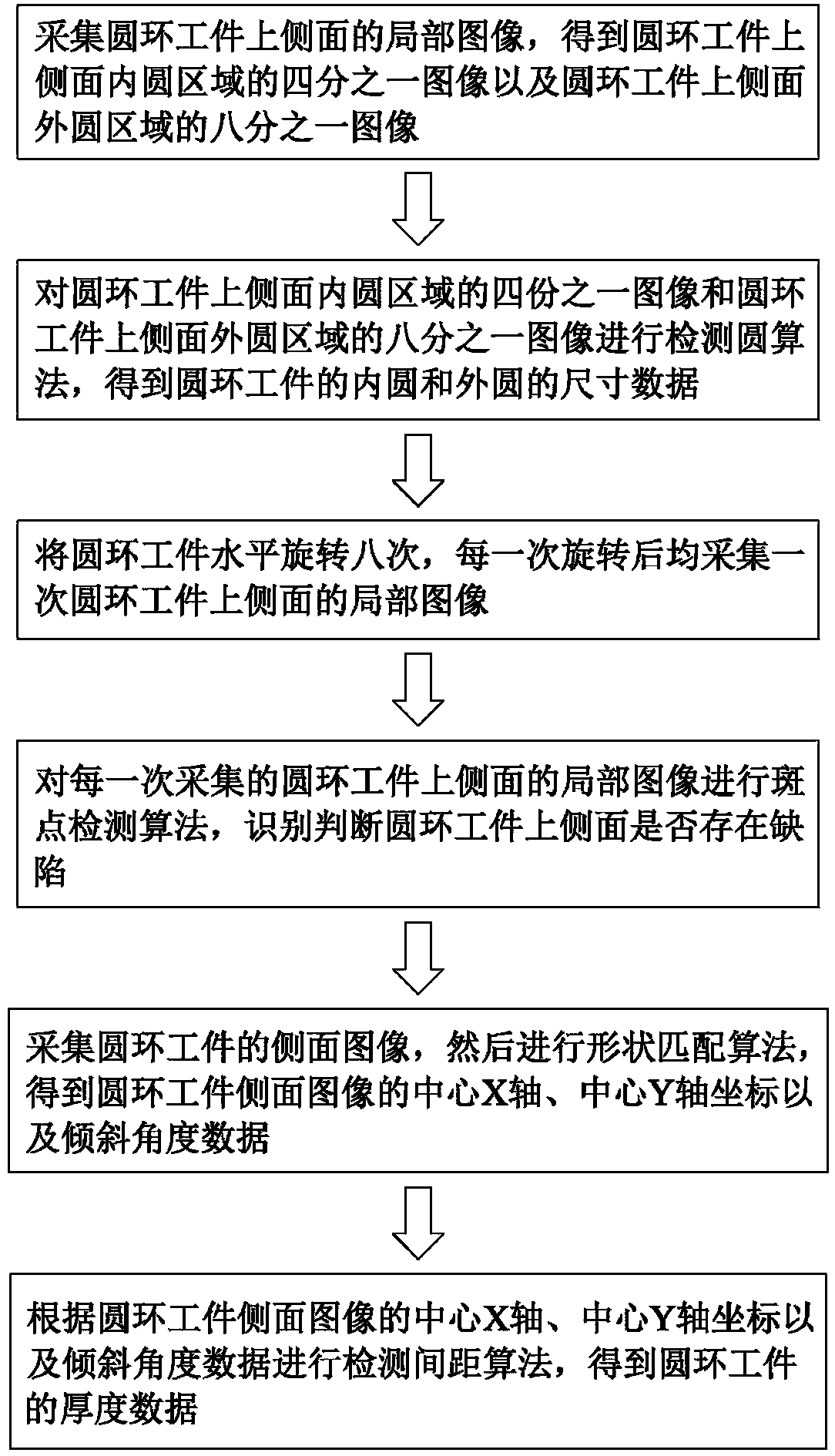

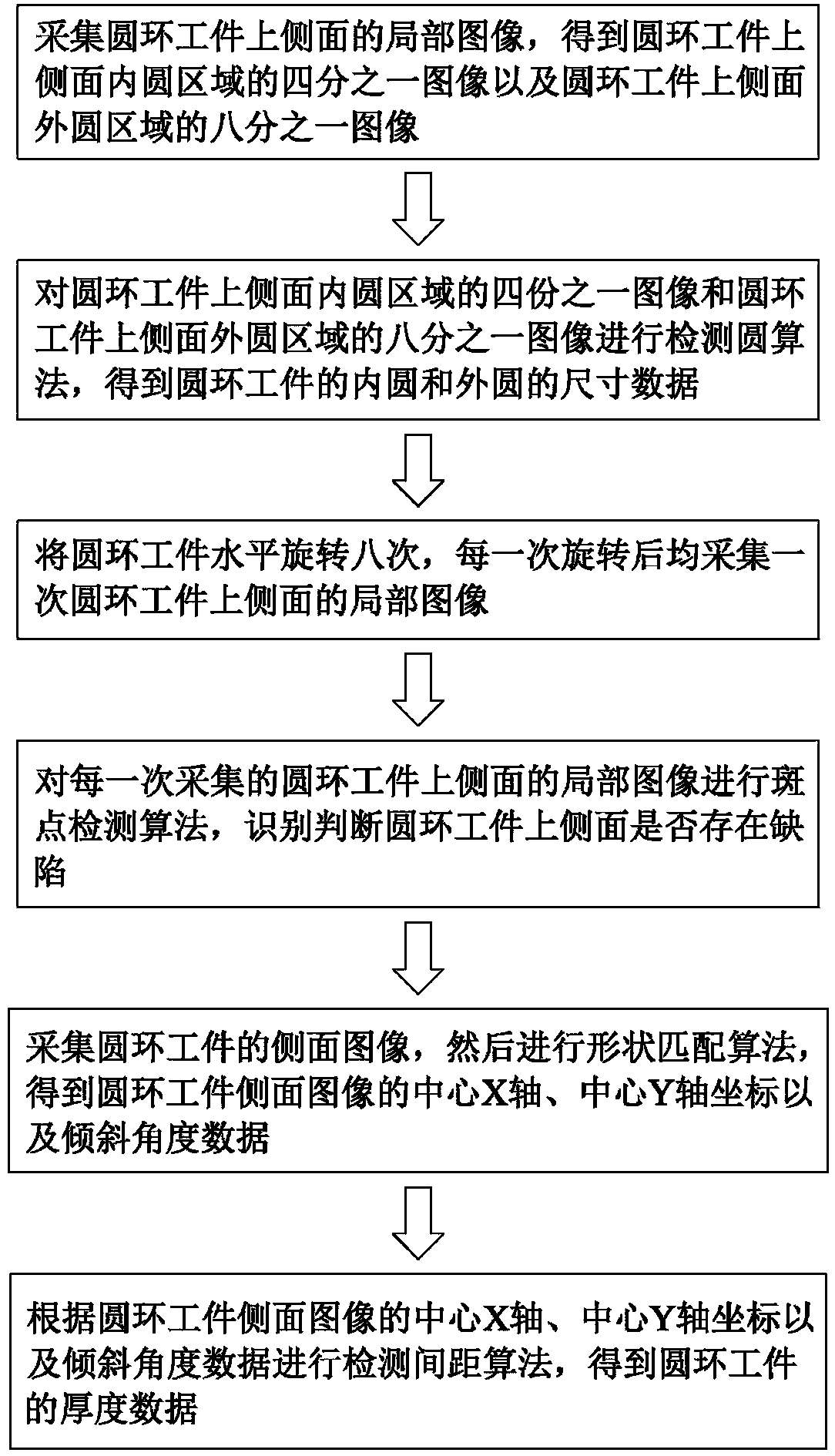

Visual detection method of reflective circular ring piece

InactiveCN110038822AReduce configuration requirementsGuaranteed accuracySortingBlob detectionImage detection

The invention relates to the technical field of visual detection, in particular to a visual detection method of a reflective circular ring piece. The visual detection method comprises the following steps that a quarter image of the upper side surface of the circular ring workpiece is collected; a circle detection algorithm is detected on the quarter image of the inner circle area and an eighth image of the outer circle area of the upper side surface of the circular ring workpiece to obtain size data of an inner circle and an outer circle of the circular ring workpiece; the circular ring workpiece is horizontally rotated for M times, and a local image on the upper side surface of the circular ring workpiece is collected once after rotation each time; and a spot detection algorithm is carried out on the local image on the upper side surface of the circular ring workpiece collected every time, and whether the defects exist on the upper side surface of the circular ring workpiece or not isidentified and judged. The multiple rotating shooting mode is adopted, and algorithm parameter setting which is accumulated by a manufacturer for a plurality of years is adopted, so that the accuracyand the stability of image detection and the identified data are effectively ensured, the use cost is reduced, and meanwhile, the detection and identification quality is ensured.

Owner:东莞中科蓝海智能视觉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com