Visual detection method of reflective circular ring piece

A technology for visual inspection and ring parts, applied in the field of visual inspection, can solve the problems affecting the operation efficiency and operation quality of visual inspection equipment, unfavorable for ordinary technicians to routinely change parameters, and complex algorithm steps, so as to reduce hardware configuration requirements and ensure Detect the effect of recognition quality, guarantee accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

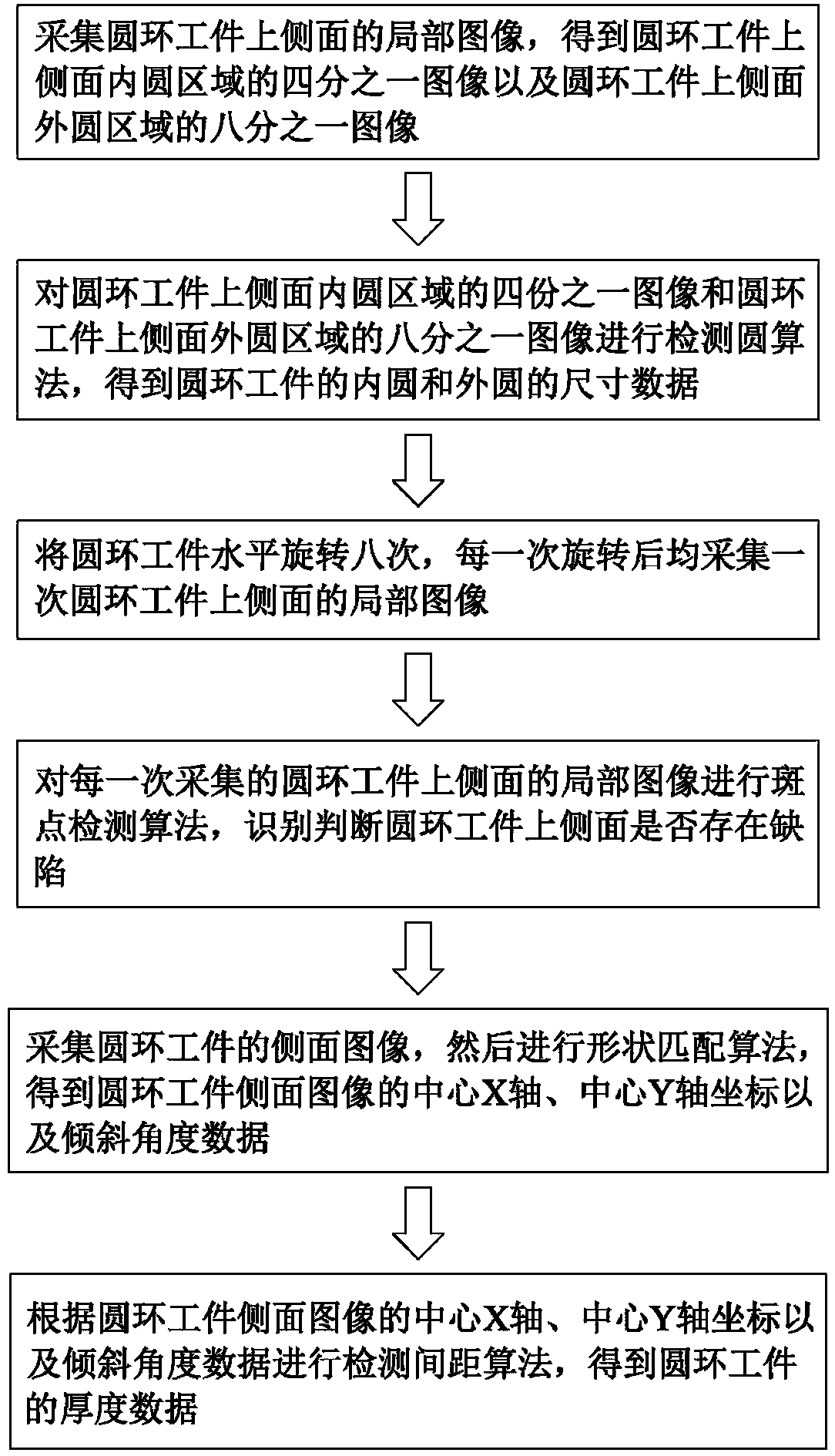

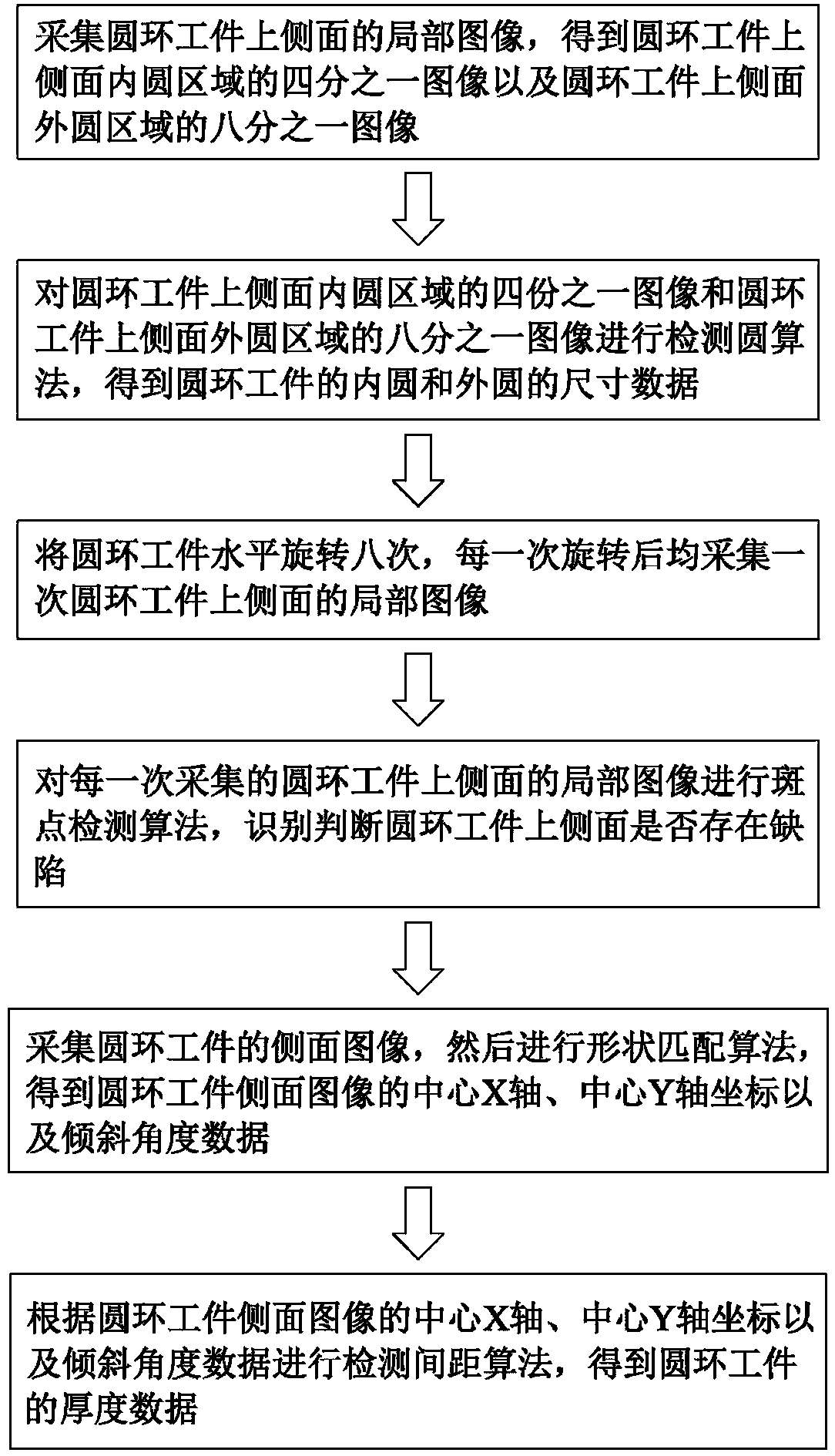

[0018] Such as figure 1 As shown, a visual detection method of a reflective circular ring includes the following steps: Step A: collecting a quarter of the image of the upper side of the circular ring workpiece, obtaining a quarter of the image of the inner circle area on the upper side of the circular ring workpiece and One-eighth image of the outer circle area on the side surface of the ring workpiece;

[0019] Step B: Perform a detection circle algorithm on the one-fourth image of the inner circle area on the side surface of the ring workpiece and the one-eighth image of the outer circle area on the side surface of the ring workpiece to obtain the dimensions of the inner circle and outer circle of the ring workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com