Method for detecting surface defects of ceramic valve cores based on machine vision

A ceramic spool and machine vision technology, applied in the field of ceramic spool detection, can solve the problems of unsatisfactory manual detection efficiency, inability to guarantee the accuracy and efficiency of ceramic spools, increased labor costs and management costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

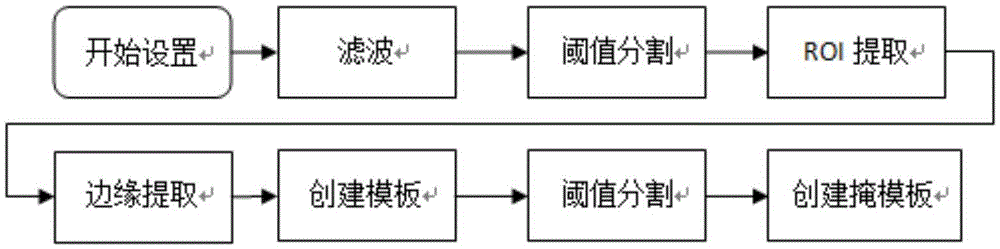

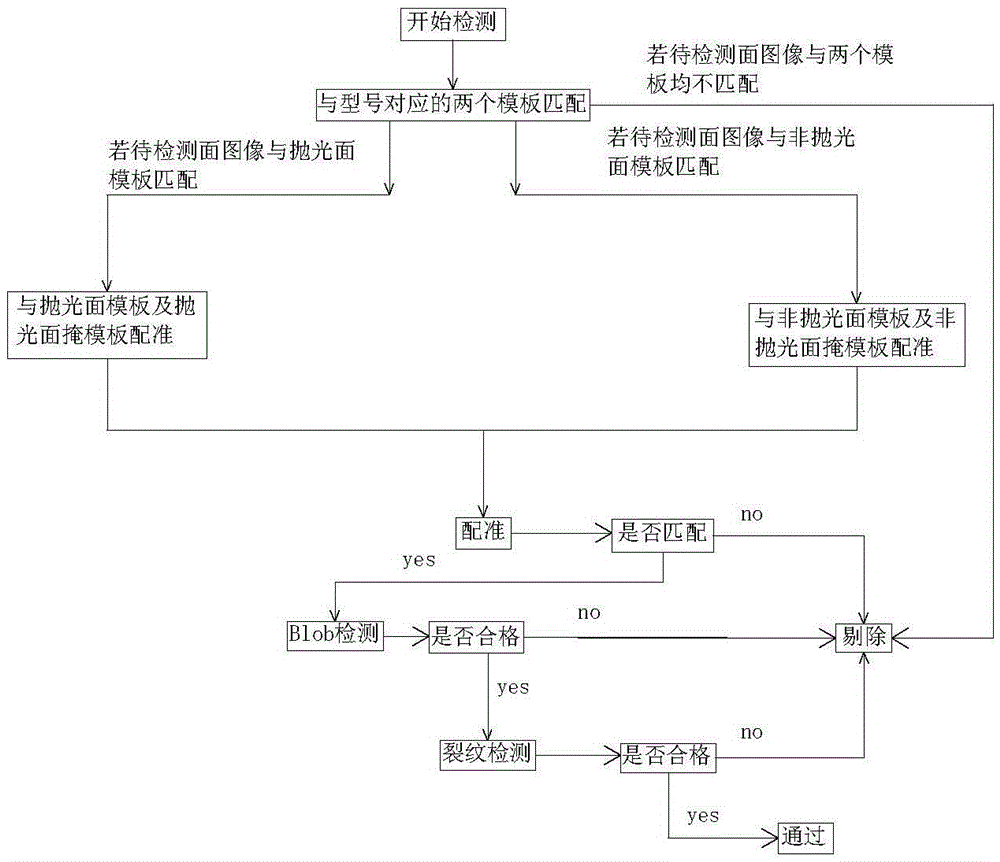

[0045] A method for detecting surface defects of ceramic valve cores based on machine vision, combined with figure 1 , figure 2 As shown, the detection method includes the following steps:

[0046] A. Before automatic detection, under manual intervention, templates and masks were established for different types of ceramic valve cores, among which: templates and masks of each type include polished surface templates, polished surface masks, and non-polished surface templates and non-polished masks;

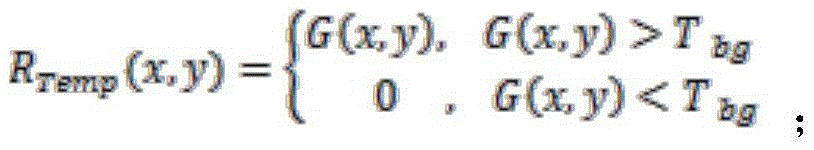

[0047] a1. Since the ceramic valve core is usually white, when designing, use black as the background to take pictures of the surface of the ceramic valve core to be tested, which is convenient for development; Holes or edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com