Visual detection method for screw on mobile terminal and control device

A mobile terminal and visual inspection technology, applied in the field of visual inspection, can solve problems such as complex process and unsuccessful application, and achieve the effects of reducing labor costs, reducing the probability of missed detection and false detection, and shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

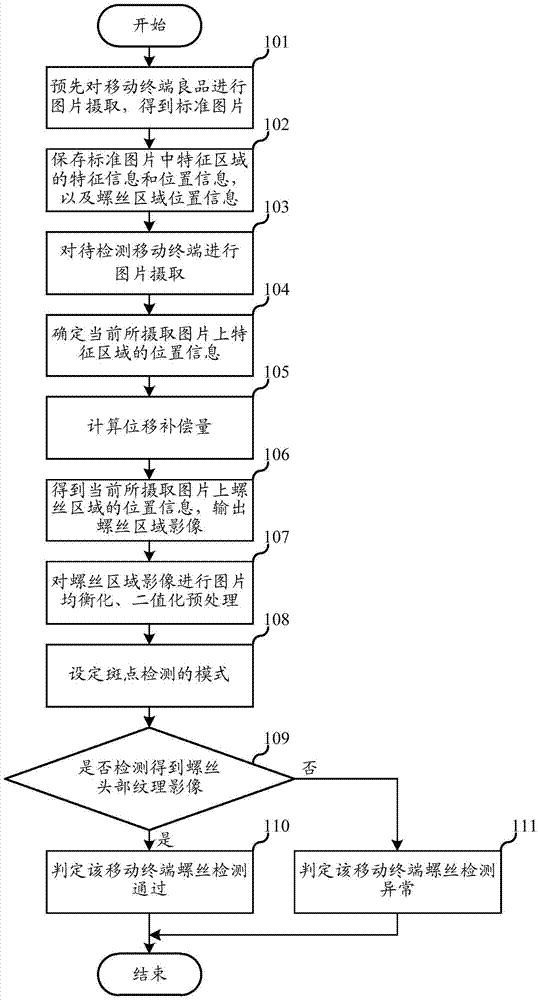

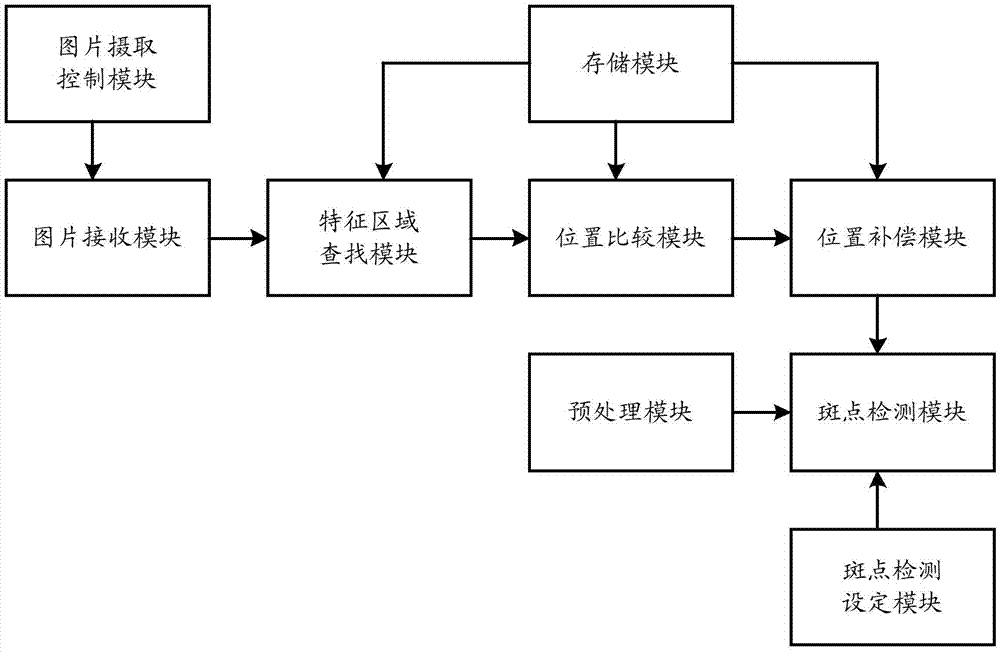

[0035] The first embodiment of the present invention relates to a visual inspection method for screws on a mobile terminal, such as figure 1 shown.

[0036] In step 101, the visual inspection machine is used to capture a picture of a mobile terminal that has no abnormality detected manually (that is, a good product) to obtain a standard picture. Usually, when the mobile terminal moves into the sensing range of the sensor installed in the visual inspection machine, the camera on the visual inspection machine is triggered to take pictures of the mobile terminal to obtain a standard picture.

[0037] In step 102, a feature area is selected from the captured standard picture, where the feature area refers to a uniquely identifiable area, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com