Size detection and identification method for plastic workpiece

A technology of size detection and identification method, applied in the field of visual inspection, can solve the problems of complex algorithm steps, unfavorable parameter changes, high use costs, etc., to improve production efficiency, facilitate analysis and processing, and ensure the effect of accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the following examples, and the content mentioned in the embodiments is not a limitation of the present invention.

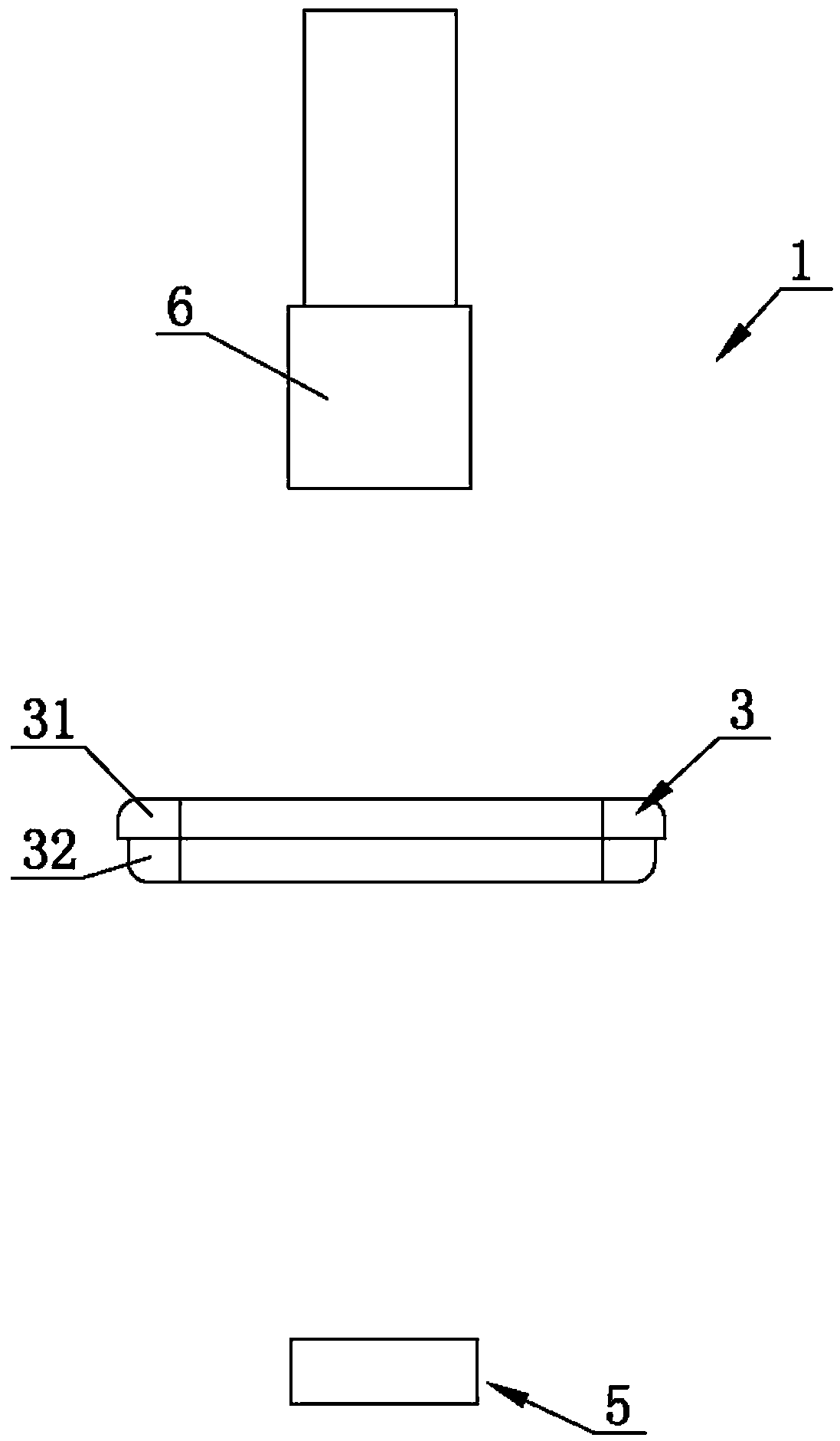

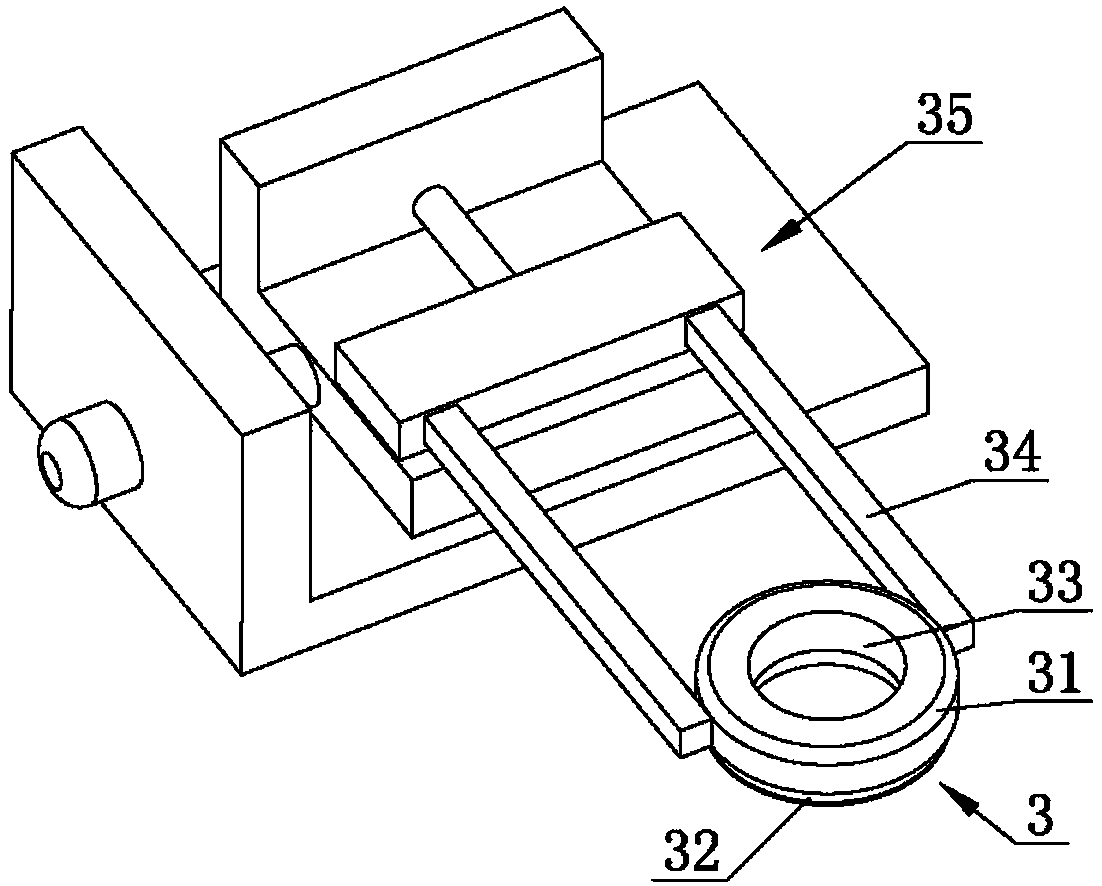

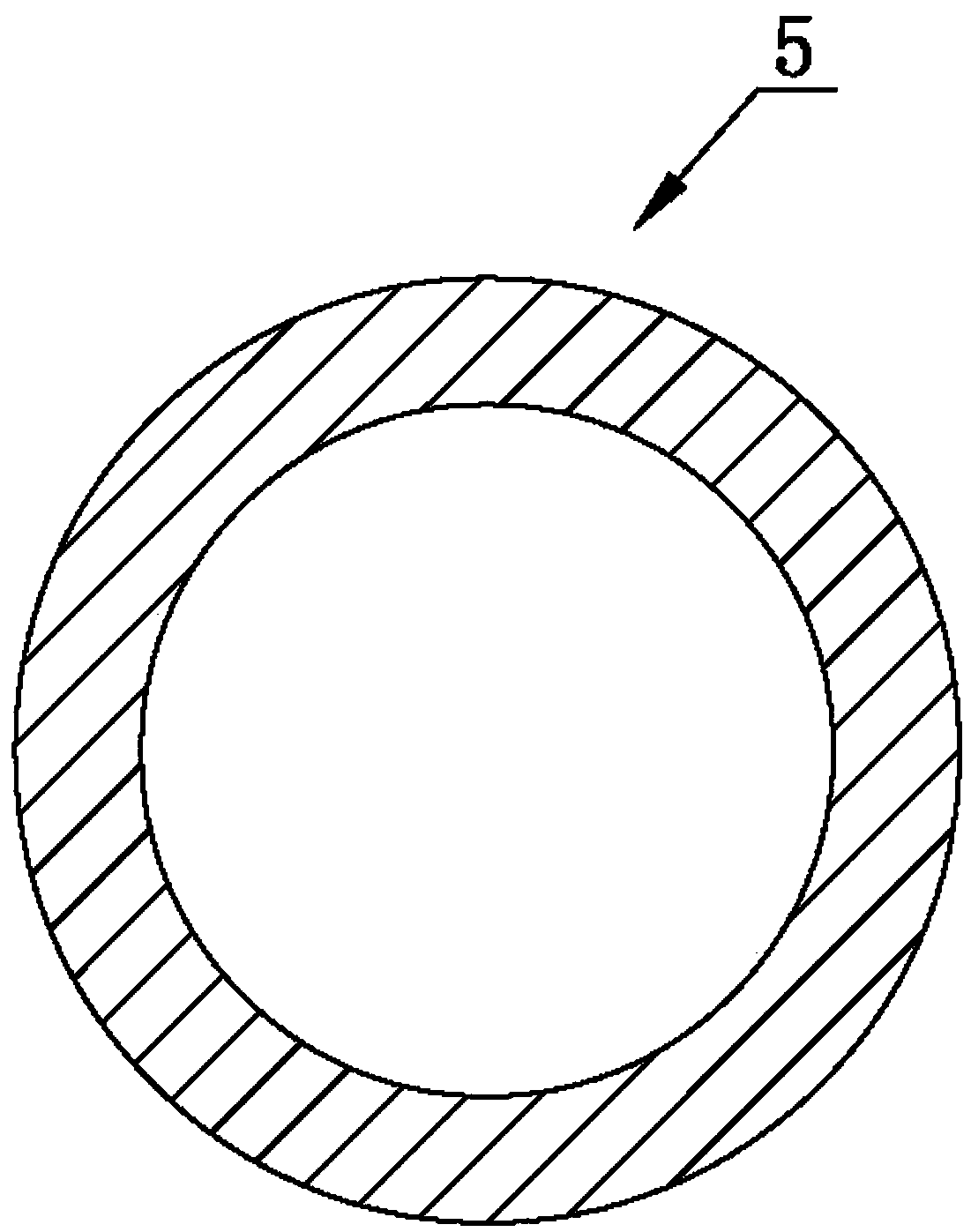

[0025] Such as Figure 1 to Figure 5 As shown, a method for detecting and recognizing the size of a plastic workpiece includes the following steps. Step 1: Move the workpiece 5 to station 1 and station 2 for image acquisition. Station 1 uses ring light source 3 for red light. The illumination assists to complete the image acquisition. The vertical separation distance between the ring light source 3 and the workpiece 5 is 230 mm. The ring light source includes a circular housing 31 and a circular light 32 mounted on the lower side of the circular housing 31 And the shooting hole 33 penetrating the circular housing 31 and the circular light 32. The circular housing 31 is fixedly connected with the adjusting arm 34 and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com