Uncooled dual-color polarization infrared bolometer and manufacture method thereof

A technology of infrared detector and manufacturing method, which is applied in the directions of electric radiation detector, radiation pyrometry, manufacturing microstructure device, etc. , reduce optical components, the effect of good image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

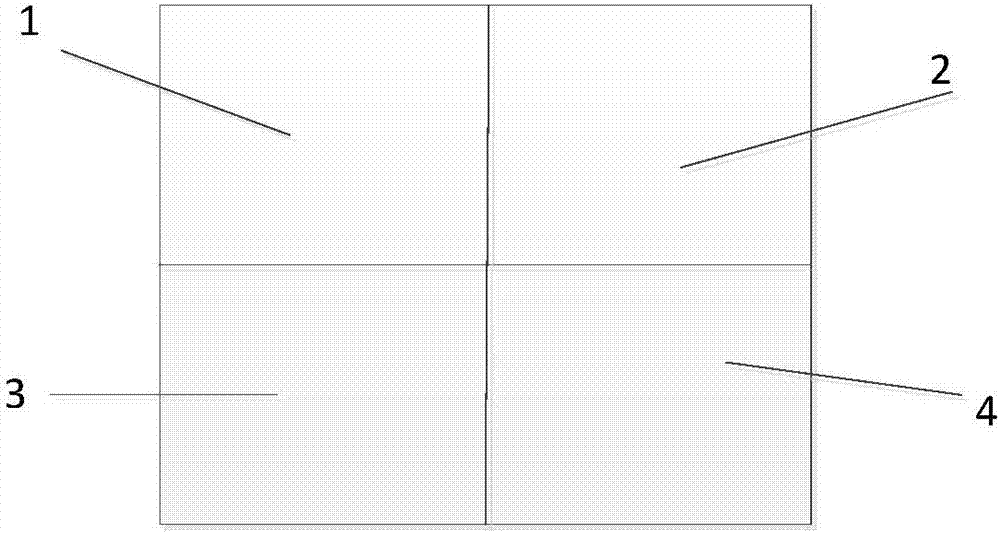

[0095] A method for manufacturing an uncooled two-color polarized infrared detector, first preparing an uncooled two-color infrared detector without sacrificial layer release, comprising the following steps:

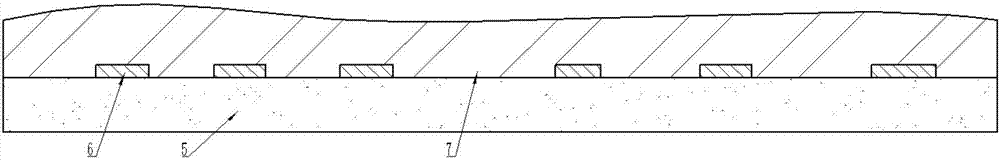

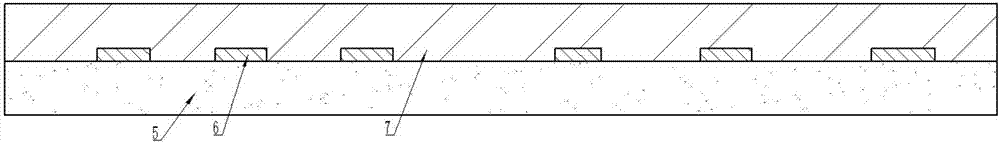

[0096] (1) Deposit one layer of metal reflective layer 6 on the substrate comprising ASIC circuit, and carry out patterning process to described metal reflective layer 6, the metal reflective layer 6 after patterning process comprises the metal block of matrix arrangement;

[0097] (2). Deposit an insulating dielectric layer 7 on the metal reflection layer 6, the insulating dielectric layer 7 is silicon dioxide, and the thickness of the insulating dielectric layer 7 is Such as figure 2 As shown, and carry out CMP treatment to described insulating medium layer 7, remove thickness is Such as image 3 shown;

[0098] (3) Utilize the method for photolithography and etching, in the first and third areas, etch connection holes at the corresponding positions of the detect...

Embodiment 2

[0117] The difference from Example 1 is that in step (19), when preparing the metal grating structure on the grating support layer, the photoresist or PI is first spin-coated on the grating support layer, and the photoresist coating or PI is coated by photolithography technology. A grating pattern is obtained on the PI coating with a grating interval of 10-500nm. Then, a metal film is deposited or sputtered on the photoresist or PI coating by physical vapor deposition or sputtering. Finally, the light is removed by a lift-off process. Resist or PI coating, and the excess metal film is peeled off, the metal film is gold, copper, aluminum, titanium, cadmium or chromium, and the thickness is 10-500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com