Size detection and identification method for strip-shaped workpiece

A recognition method and size detection technology, applied in the field of visual inspection, can solve problems affecting the operating efficiency and quality of visual inspection equipment, high cost of use, unfavorable parameter changes, etc., and achieve the needs of improving operation efficiency, stable detection accuracy, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

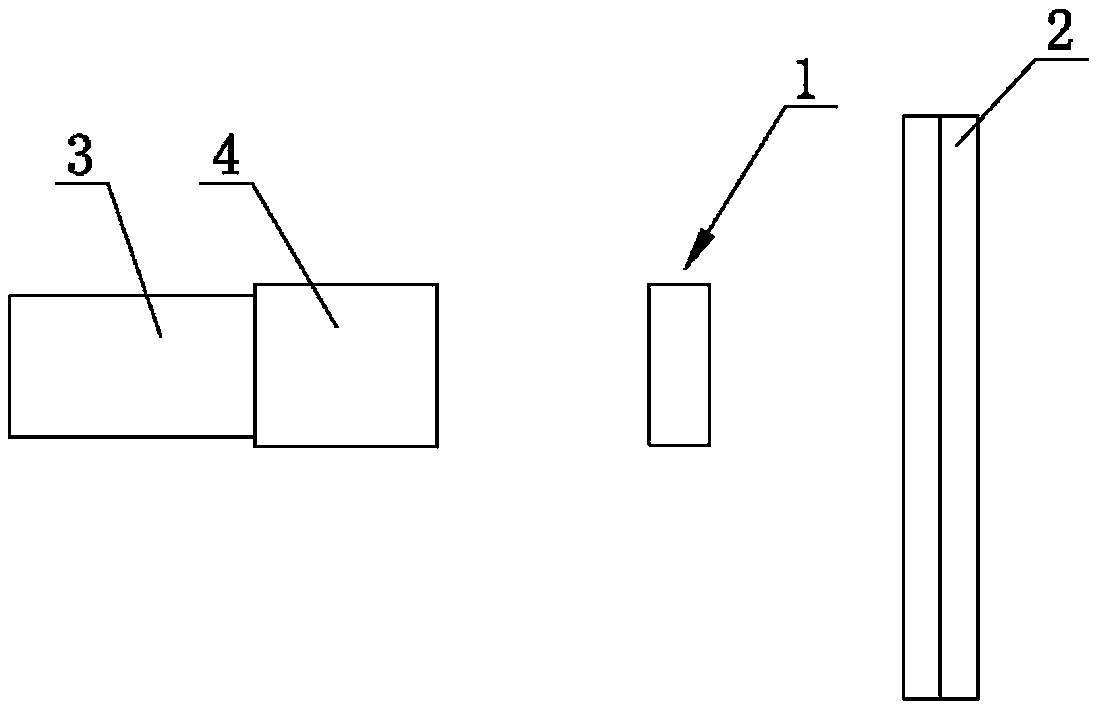

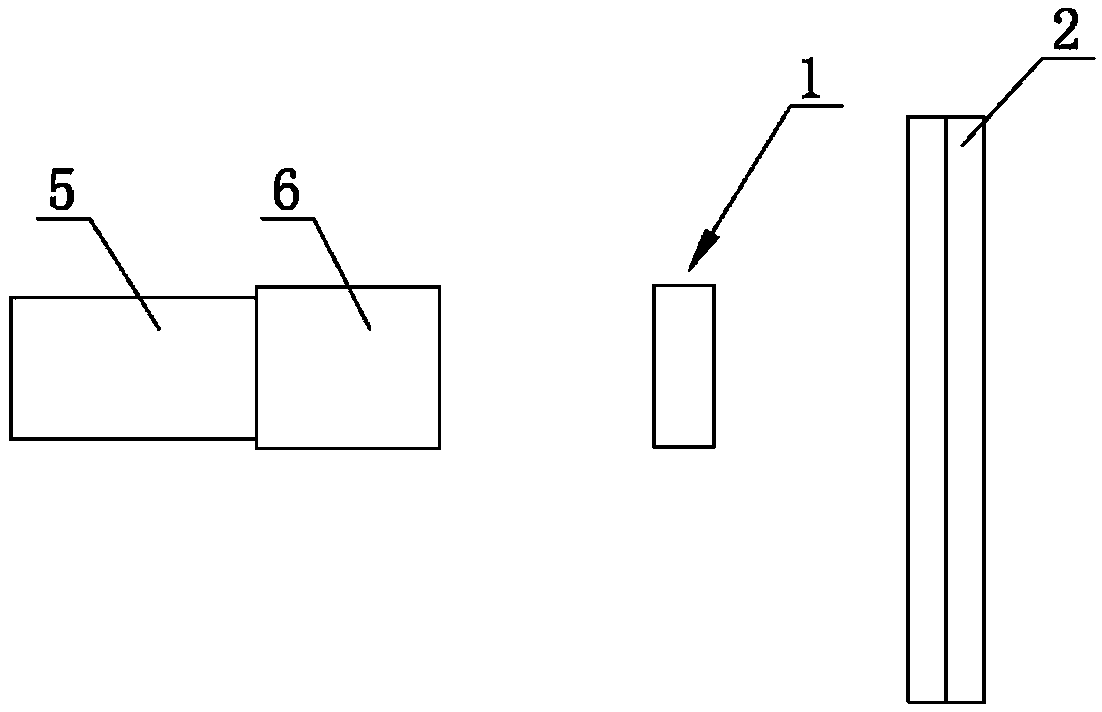

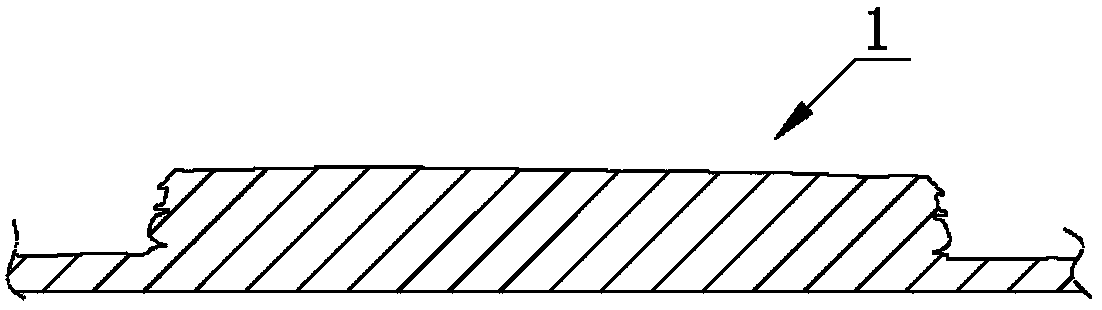

[0021] like Figure 1 to Figure 3 As shown, a method for detecting and recognizing the size of a strip-shaped workpiece includes the following steps. Step 1: Collect an image of the workpiece 1, use a 1.3 million-pixel industrial camera 3 with a 25mm fixed-focus lens 4 to shoot, and use a flat surface The light source 2 performs backlighting to assist image shooting, and takes multiple images of a workpiece 1 and then merges them to obtain the final image of the workpiece 1, wherein the horizontal distance between the plane light source 2 and the workpiece 1 is 100 mm, and the fixed-focus lens 4 and The horizontal distance between the workpieces 1 is 250 mm, or use a 2048 resolution line scan camera 5 with a 60 mm line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com