Steel tube counting method by combining support vector machine threshold statistics and spot detection

A technology of support vector machine and blob detection, applied in computing, image data processing, computer parts and other directions, which can solve the problems of low algorithm implementation complexity, reduced recognition accuracy, and difficulty in sub-region screening thresholds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

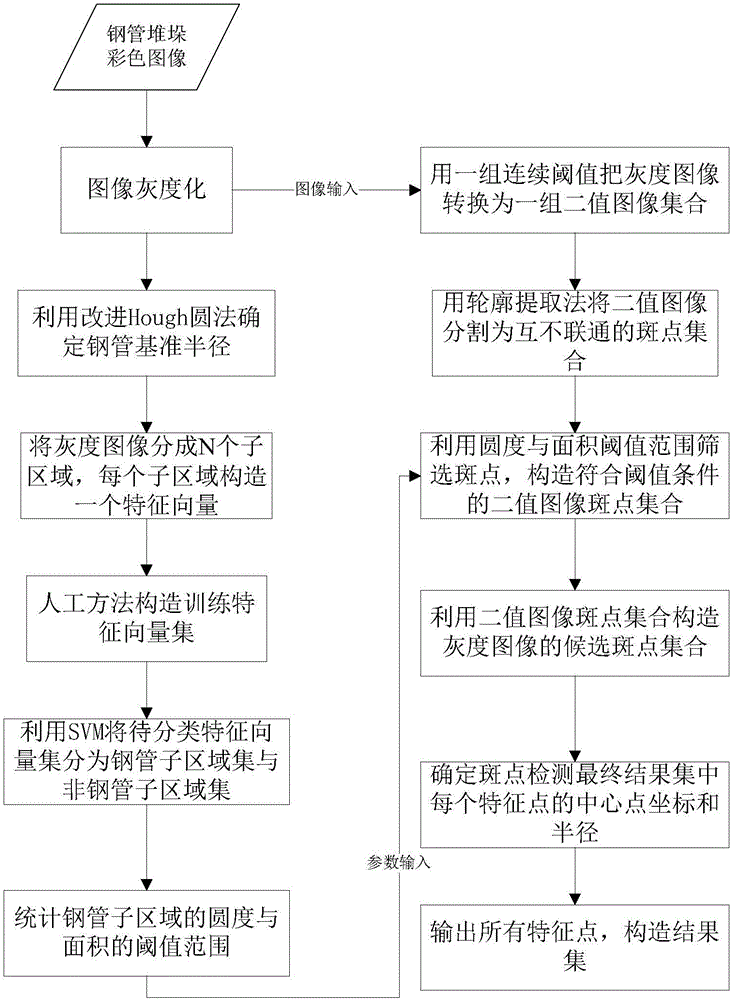

[0041] Such as figure 1 As shown, the present invention provides a steel pipe counting method combining support vector machine threshold statistics and spot detection, comprising the steps of:

[0042] Step 1, using the image grayscale method to process the two-dimensional image of the cross section of the steel pipe stack to be identified into a grayscale image of the stack cross section;

[0043] Step 2, use the SVM algorithm to classify the target sub-region and non-target sub-region in the gray image, and then use the statistical method to perform threshold statistics on the roundness characteristic parameters and area characteristic parameters of the target subregion, and then generate circles according to the threshold statistical results Degree threshold range and area threshold range, the specific steps are:

[0044] Step 2.1, use the gradient Hough transform method to detect all target circles in the gray image of the stacking cross section, statistically calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com