Detection and identification method for circular high-reflection workpieces

A recognition method and high-reflection technology, applied in the field of visual inspection, can solve the problems of high cost of use, complex algorithm steps, unfavorable parameter changes, etc., to improve work efficiency, the overall steps are simple, and it is easy to quickly master the effect of skilled employment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

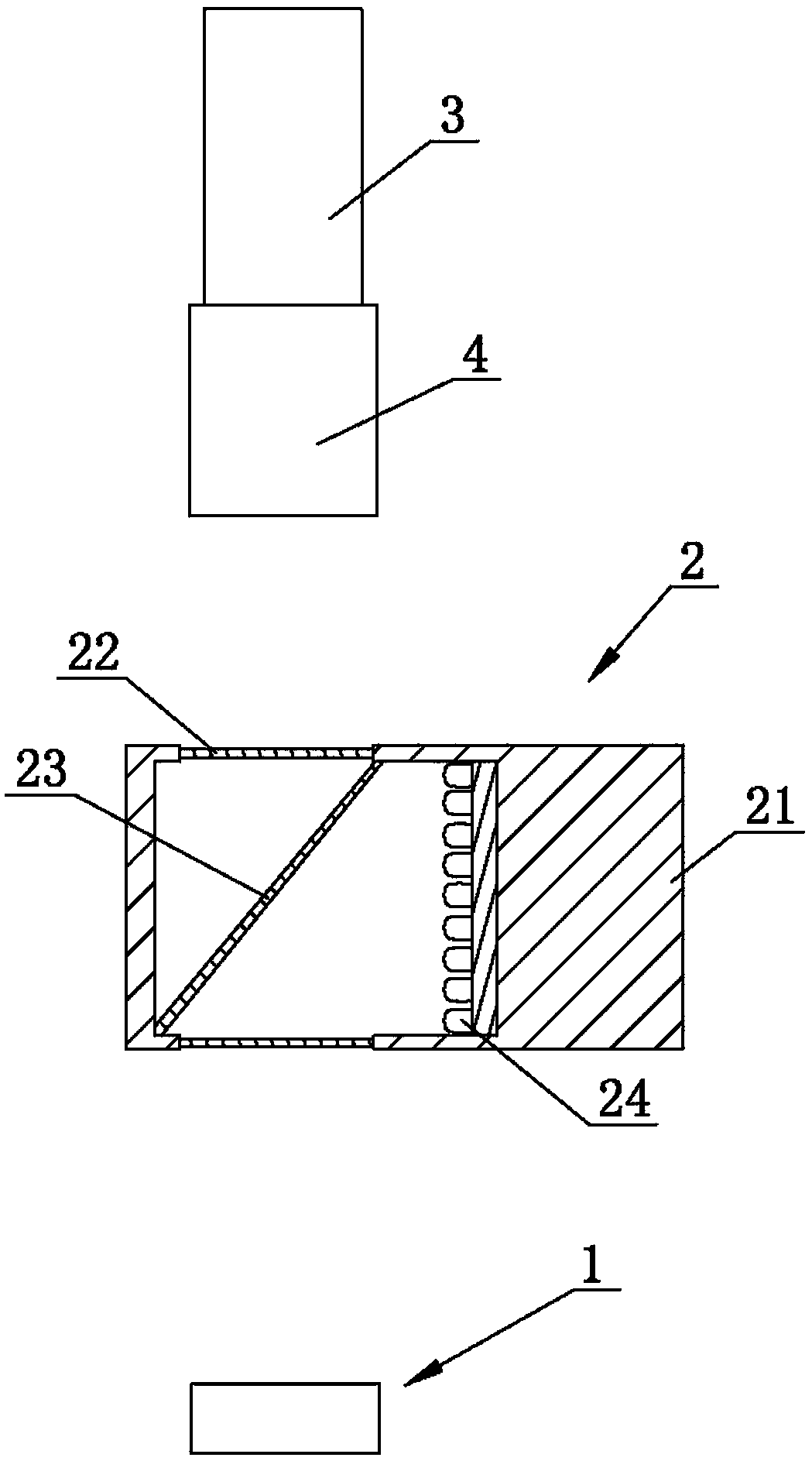

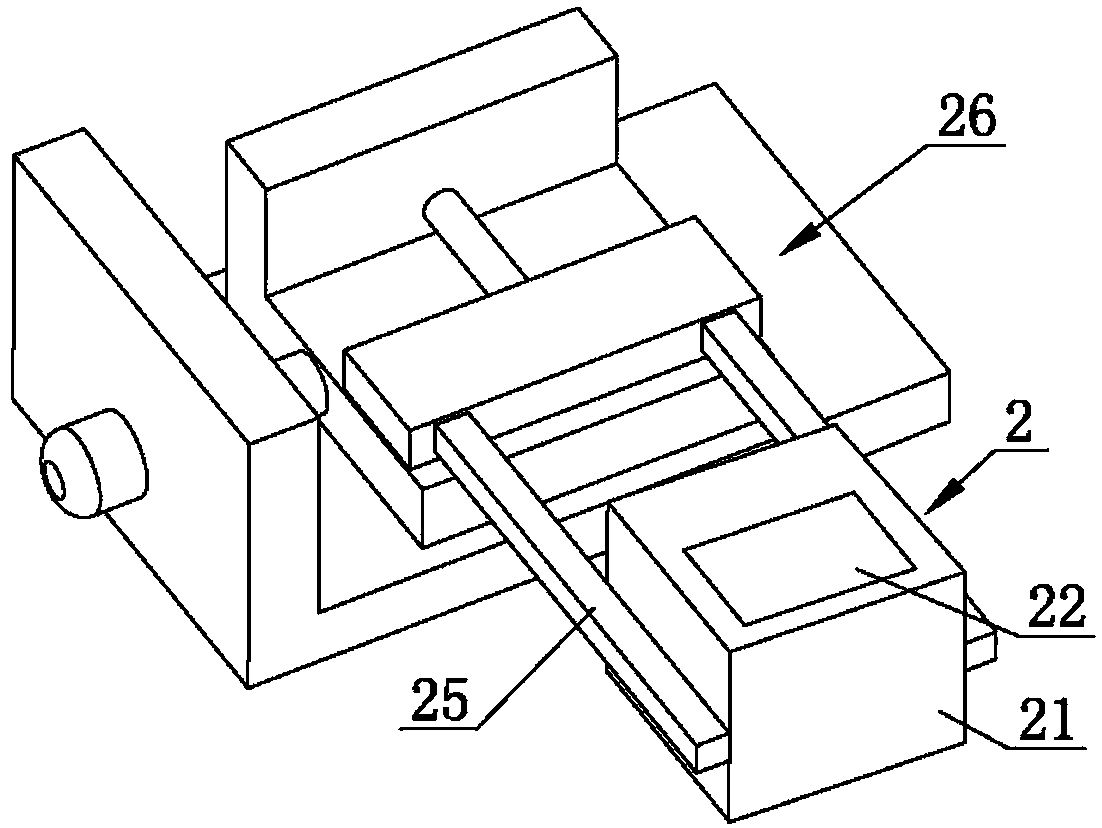

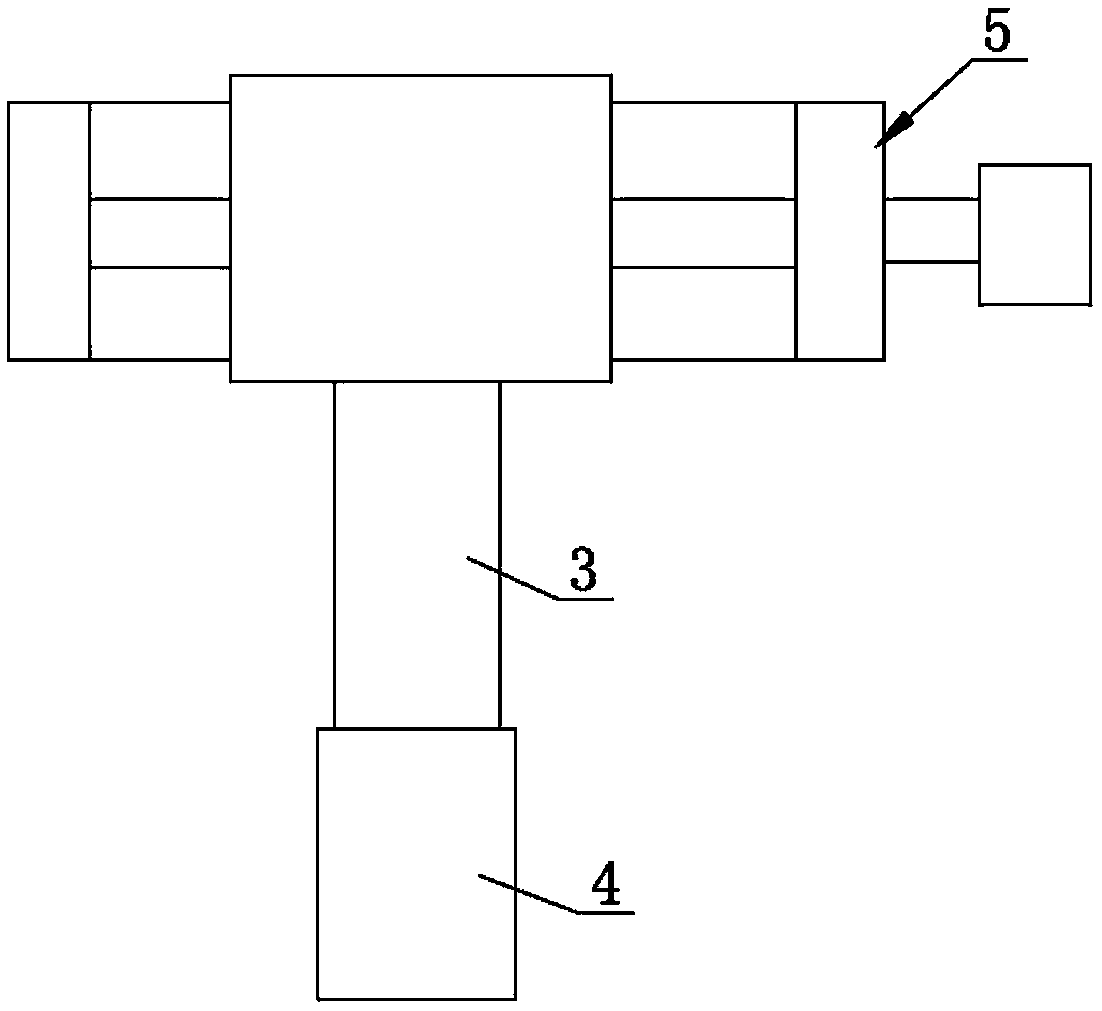

[0022] Such as Figure 1 to Figure 4 As shown, a detection and recognition method for a circular highly reflective workpiece includes the following steps. Step 1: Carry out image acquisition on the workpiece 1, and use a coaxial light source 2 to assist in completing the image acquisition. The coaxial light source 2 includes a box body 21, a penetrating The shooting channel 22 provided in the box body 21, the refractor 23 extending upward from the inner corner of one side of the box body 21 through the shooting channel 22 abutting against the upper wall of the box body 21, and the light-emitting lamp group 24 installed on the inner wall of the box body 21, the box body The outer wall of the body 21 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com