Surfactant for uncoated thermal transfer ink, uncoated thermal transfer ink and preparation method of surfactant

A surfactant, thermal transfer technology, applied in dyeing, textile and papermaking, etc., can solve the problems of ink penetration into paper, transfer rate, unclear transfer, unclear printing pattern, etc., and achieve excellent digital printing effect. , the effect of reducing the amount of use and reducing the consumption of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of described uncoated thermal transfer printing ink comprises the following steps:

[0047] a. First mix the organic solvent and water and stir to form an organic solution;

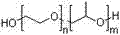

[0048] b. Surfactants are added to the organic solution, stirred for 30min to make it sufficiently uniform to form mixture A;

[0049] c. Add pH regulator, buffering agent, preservative, emulsifier, chelating agent to the mixture A, stir for 30min to make it fully uniform to form mixture B;

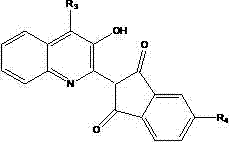

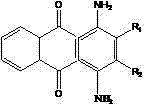

[0050] d. Add non-azo disperse dyes to the forming mixture B, stir for 2 hours to make it fully and uniformly form semi-finished thermal transfer printing ink;

[0051] e. Filter with a 1.0 μm filter membrane to obtain thermal transfer ink.

Embodiment 1

[0054] Mix and stir 10 parts of diethylene glycol, 5 parts of glycerin, 4 parts of polyethylene glycol, 5 parts of propylene glycol monobutyl ether, and 40 parts of water, then add 3 parts of DISPERBYK® 190 and 2 parts of BYK-348, and stir for 30 minutes to make it Mix well; add 0.4 part of pH regulator triethanolamine, 0.4 part of buffer EDTA salt, 0.2 part of preservative GXL, 0.2 part of emulsifier, 0.3 part of chelating agent, stir for 30 minutes to fully mix; add 30 parts of compound IV The color paste was stirred for 2 hours, and then filtered with a 1.0 μm filter membrane to obtain a yellow thermal transfer ink.

Embodiment 2

[0056] This example is roughly the same as Example 1, except that in this example, 30 parts of color paste containing compound IV was replaced with 30 parts of color paste containing compound I to prepare red thermal transfer printing ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com