Polishing device and chemical mechanical planarization equipment

A polishing device and polishing pad technology, applied in grinding/polishing equipment, grinding device, metal processing equipment, etc., can solve the problem of poor wafer surface uniformity, and achieve the effect of enhancing uniformity and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

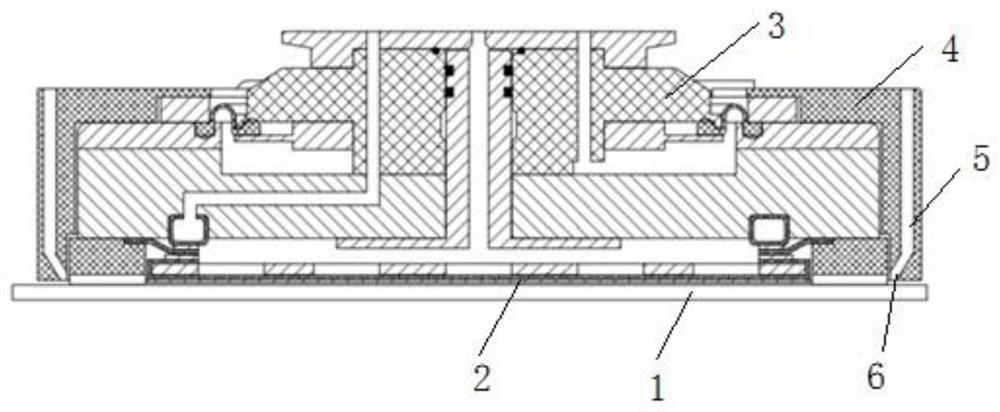

[0033] Such as Figure 1 to Figure 4 As shown, the present invention provides a polishing device, including a main body 3 and a protective cover 4 arranged outside the main body 3, an infusion set is located in the main body 3 and / or the protective cover 4, and the infusion set has at least one The liquid outlet 6 , the liquid ejected from the liquid outlet 6 is evenly distributed on the contact area of the polishing pad 1 .

[0034] The infusion set is communicated with an external liquid storage container (not shown in the figure) by a pipeline, and the liquid is delivered to the infusion set, and the liquid is polishing liquid. By setting the infusion unit inside the polishing device, the liquid can move with the movement of the polishing device, and when the liquid is sprayed on the contact area between the wafer 2 and the polishing pad 1, the liquid can evenly contact the wafer 2 , so that the chemical reaction between the wafer 2 and the liquid is more uniform and suf...

Embodiment 2

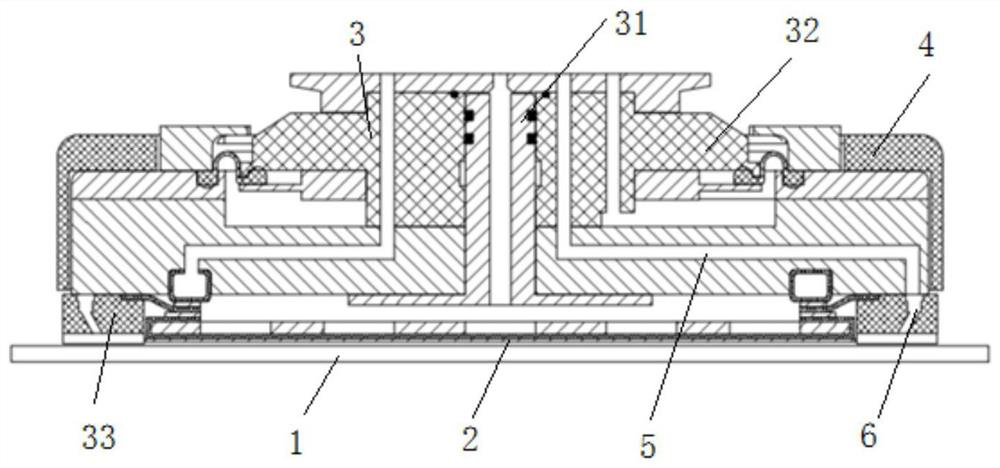

[0040] Such as figure 2 As shown, the infusion assembly can also be arranged in the main body 3, wherein the main body 3 includes a main shaft 31, a rotating assembly 32 sleeved on the main shaft 31, and a retaining ring 33 arranged at the bottom of the rotating assembly 32 to protect The cover 4 is sleeved on the outside of the rotating assembly 32 and the retaining ring 33, and the infusion channel 5 runs through the rotating assembly 32 and the retaining ring 33, so that the liquid is evenly sprayed on the contact area.

[0041] Specifically, there are multiple at least one liquid outlet 6 , which is arranged at the bottom of the retaining ring 33 and arranged at intervals along the axial direction of the retaining ring 33 . The liquid outlets 6 can be evenly arranged on the retaining ring 33 , of course, they can also be unevenly arranged on the retaining ring 33 .

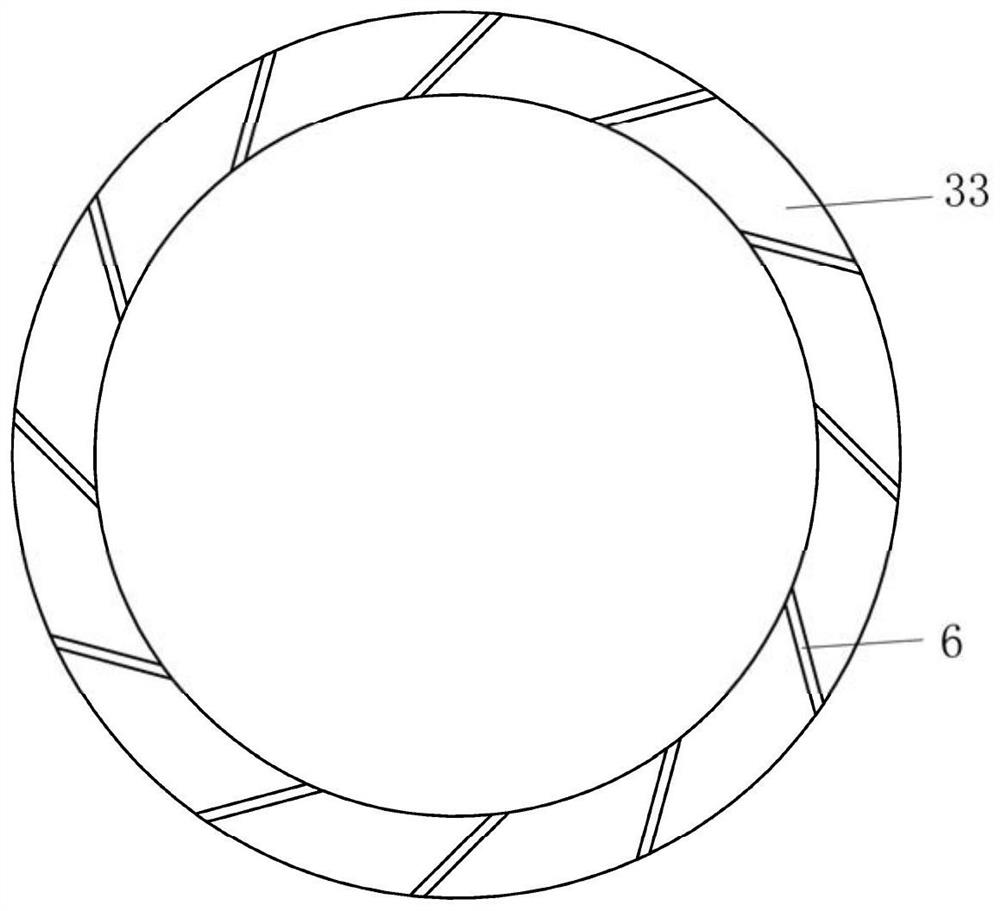

[0042] Such as image 3 As shown, specifically, the projections of the plurality of liquid outlets 6 on th...

Embodiment 3

[0045] It is also possible to arrange the infusion set in the main body 3 and the protective cover 4 together to ensure the output of the liquid. When the infusion set in the main body 3 is blocked, the liquid can also be sprayed out through the infusion set in the protective cover 4; When the infusion set in the protective cover 4 is blocked, the liquid can also be ejected through the infusion set in the main body 3 .

[0046] The present invention also provides a chemical mechanical planarization device, including the polishing device.

[0047] The specific working process: use the polishing device to absorb the wafer 2, place the wafer 2 on the polishing pad 1, and apply a certain pressure to the wafer 2 to start polishing. The liquid port 6 sprays the liquid in the liquid container evenly on the contact area of the polishing pad 1 through the infusion channel 5 and the liquid outlet 6, thereby ensuring the uniformity of the distribution of the liquid on the polishing pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com