A light irradiator and a printer using the light irradiator

A technology of light irradiation and printing, applied in refractors, typewriters, printing devices, etc., can solve the problems of ink viscosity increase and hardening, and achieve the effect of preventing low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

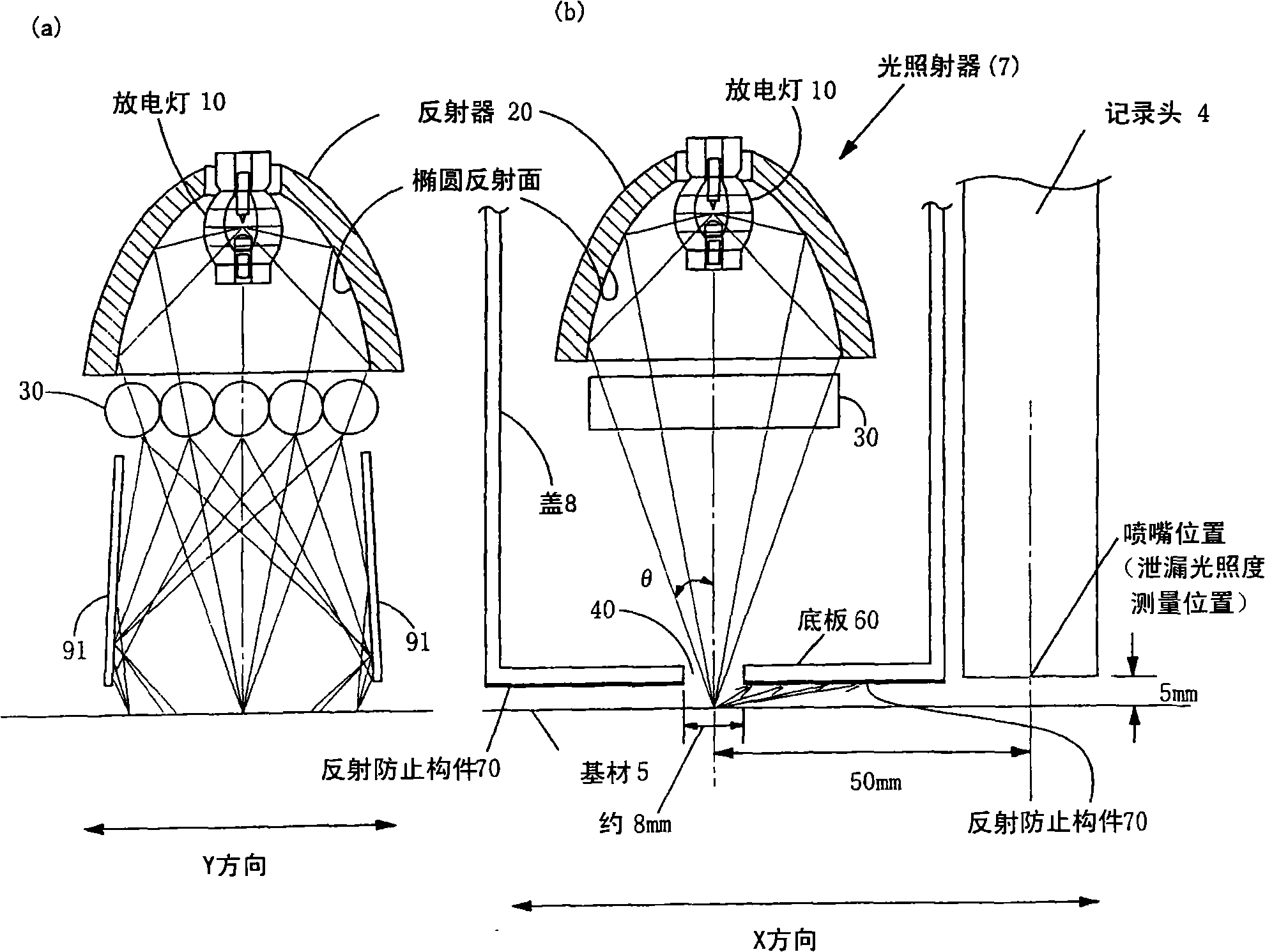

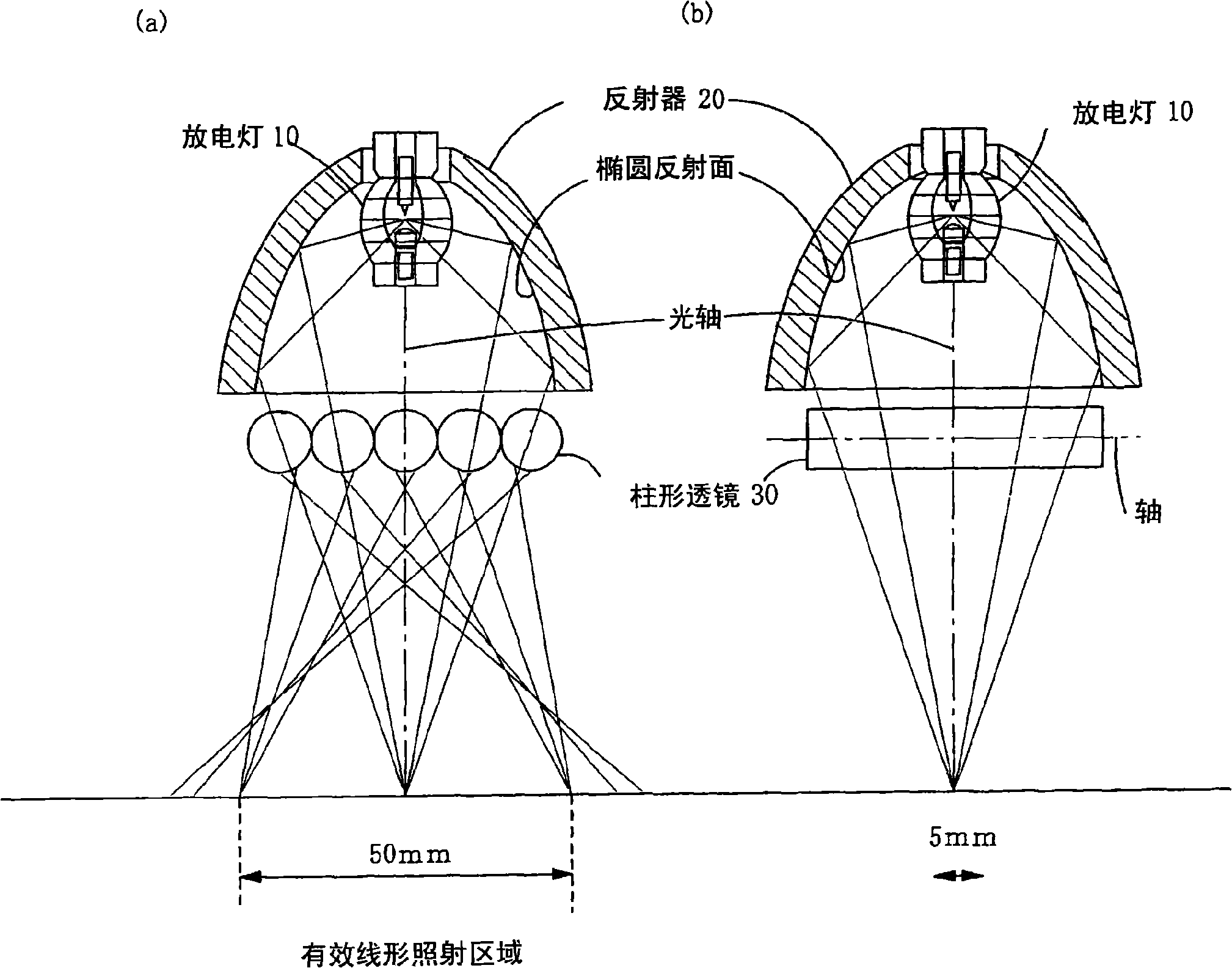

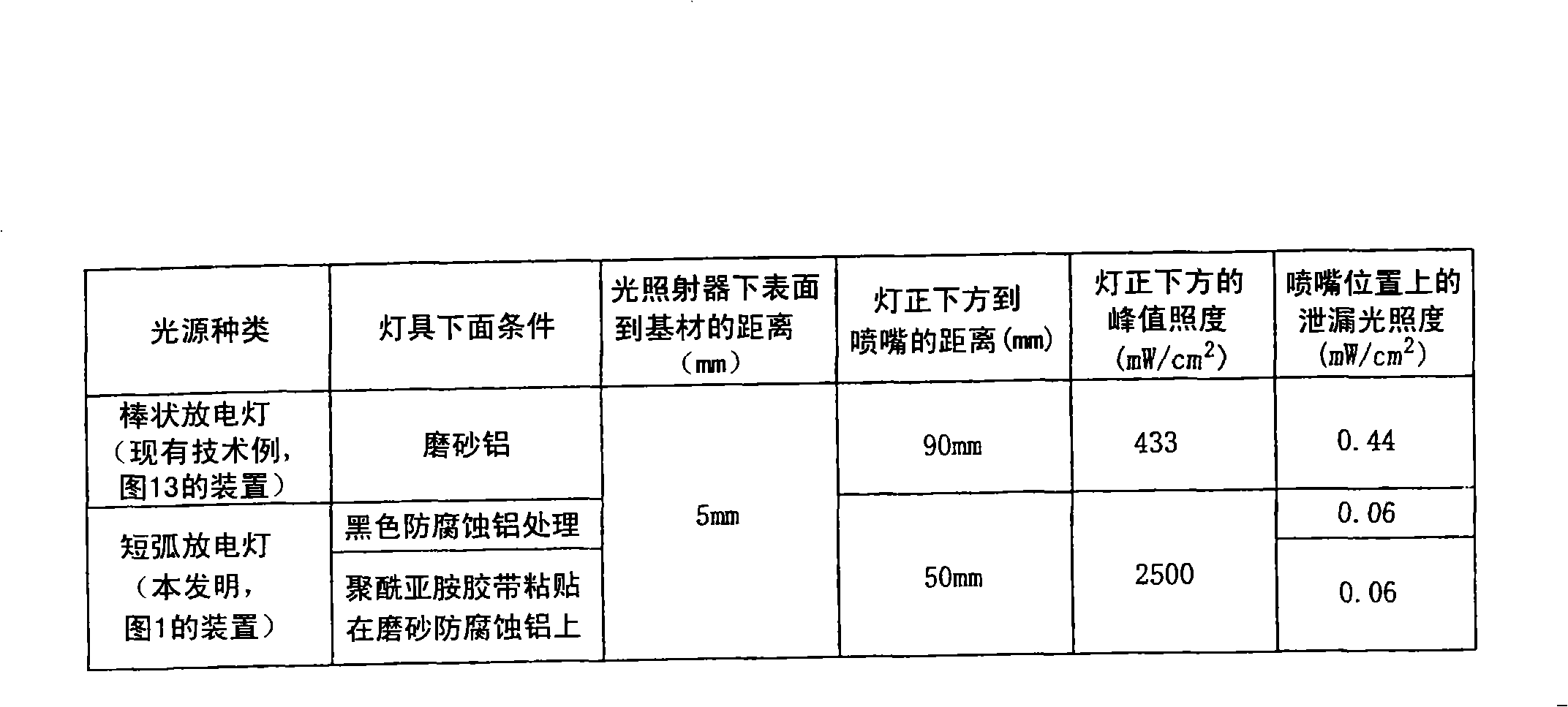

[0074] figure 1 The structure of the first embodiment of the light irradiator of the present invention is shown. This figure is an enlarged view of the head part, figure 1 (a) is a cross-sectional view in the Y direction (direction orthogonal to the head moving direction), figure 1 (b) is a cross-sectional view in the X direction (direction along the moving direction of the head).

[0075] figure 1 Among them, 10 is a short-arc discharge lamp that radiates light of a wavelength that hardens the ink (liquid material) ejected from the recording head 4 . 20 is a reflector which reflects and condenses the light from the lamp 10, and has a reflective surface in the shape of an ellipsoid of revolution.

[0076] The short-arc discharge lamp 10 is composed of an ultra-high pressure mercury lamp capable of efficiently emitting ultraviolet light with a wavelength of, for example, 300 to 450 nm, and a pair of electrodes are arranged oppositely in the discharge vessel with a dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com