Polymer emulsion and aqueous inkjet recording liquid containing the polymer emulsion

A polymer emulsion, water-based inkjet technology, applied in the direction of ink, copy/marking method, application, etc., can solve problems such as inability to meet, and achieve the effect of improving clogging and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

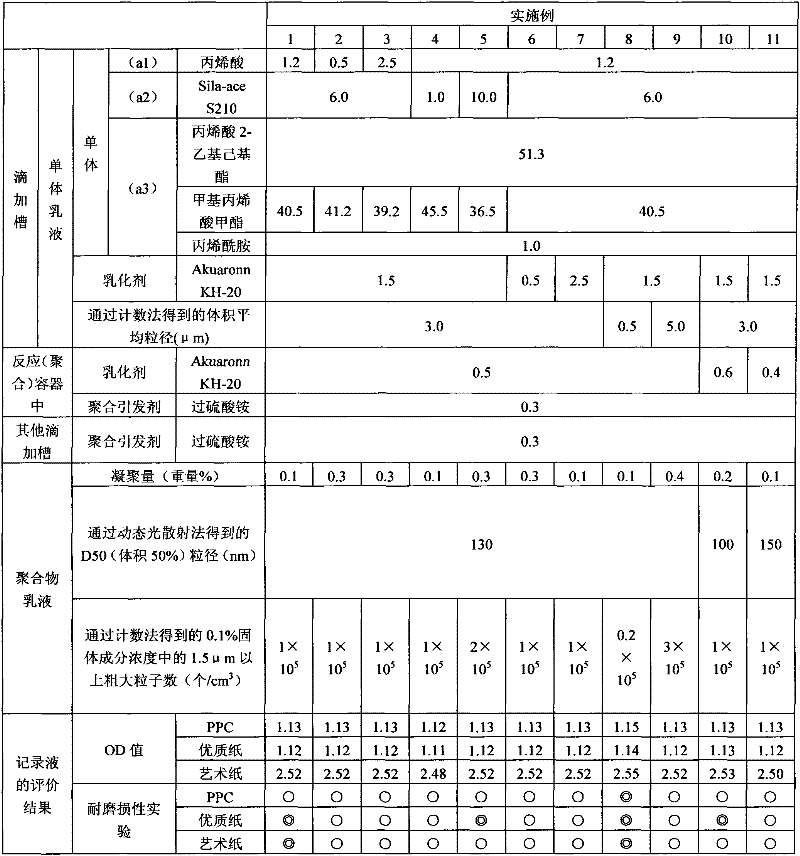

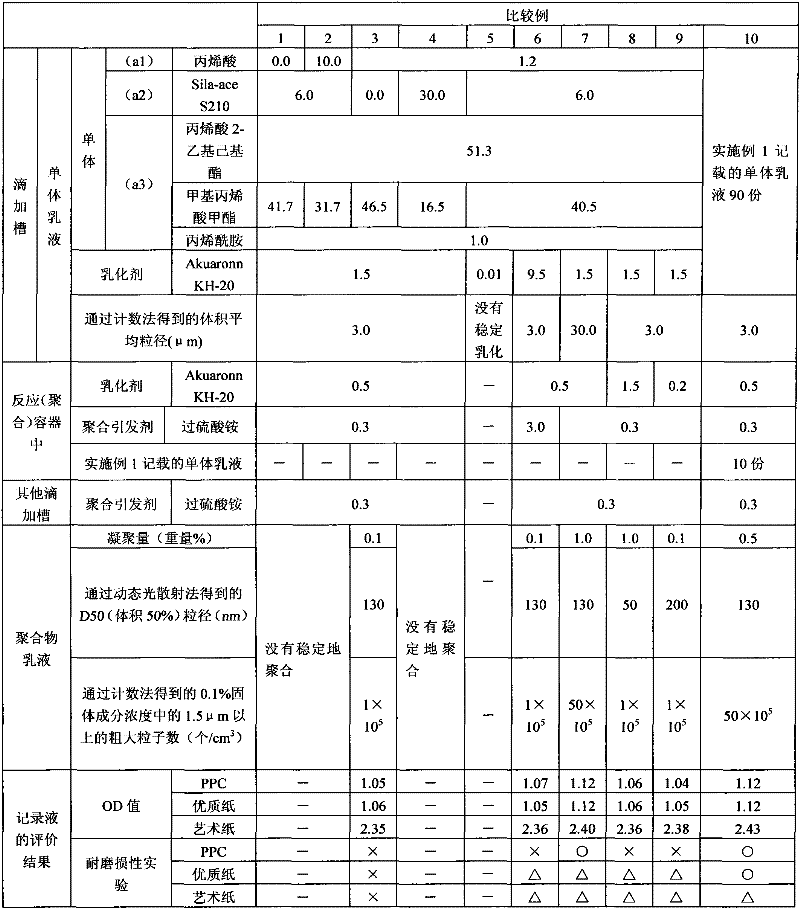

Embodiment 1

[0159]

[0160] 1.2 parts of acrylic acid as the monomer (a1), 6 parts of Sila-ace 210 (サイラエース210, registered trademark) (vinyltrimethoxysilane, manufactured by CHISSO CORPORATION) as the monomer (a2), 40.5 parts as Monomer (a3) of methyl methacrylate, 51.3 parts of 2-ethylhexyl acrylate, 1.0 parts of acrylamide, 1.5 parts of akualong KH-20 (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) as an emulsifier Sexual emulsifier), and the mixture of 53.1 parts of ion-exchanged water were emulsified by a batch homomixer to prepare monomer pre-emulsion, and put into the dropping tank.

[0161] In addition, in order to maintain the measurement accuracy, distilled water was used to dilute the monomer pre-emulsion with a monomer concentration of about 60%, so that the number of particles larger than 0.5 μm reached about 5000 / cm3. For diluents with a monomer concentration of about 0.002%, use an Accusizer manufactured by PARTICLE SIZING SYSTEMS, USA, and calculate the volume a...

Embodiment 2~5

[0175] A polymer emulsion was obtained in the same manner as in Example 1, except that the composition of the monomers which were added to the dropping tank and constituted the monomer pre-emulsion was changed to the composition shown in Table 1. Using the obtained polymer emulsion, it carried out similarly to Example 1, and obtained the aqueous inkjet recording liquid, and performed the same evaluation.

Embodiment 6~7

[0177] The amount of the emulsifier Akuaronn KH-20 that is added to the dropping tank and that constitutes the monomer pre-emulsion is changed to the amount shown in Table 1, and the stirring conditions of the batch homomixer are changed to make the D50 grains of the monomer pre-emulsion Diameter (volume average particle diameter) was the same as that of Example 1 to obtain a polymer emulsion. Using the obtained polymer emulsion, it carried out similarly to Example 1, and obtained the aqueous inkjet recording liquid, and performed the same evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com