Tool cleaning device

A technology for cleaning devices and tools, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as reduced processing accuracy, inability to locate, and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

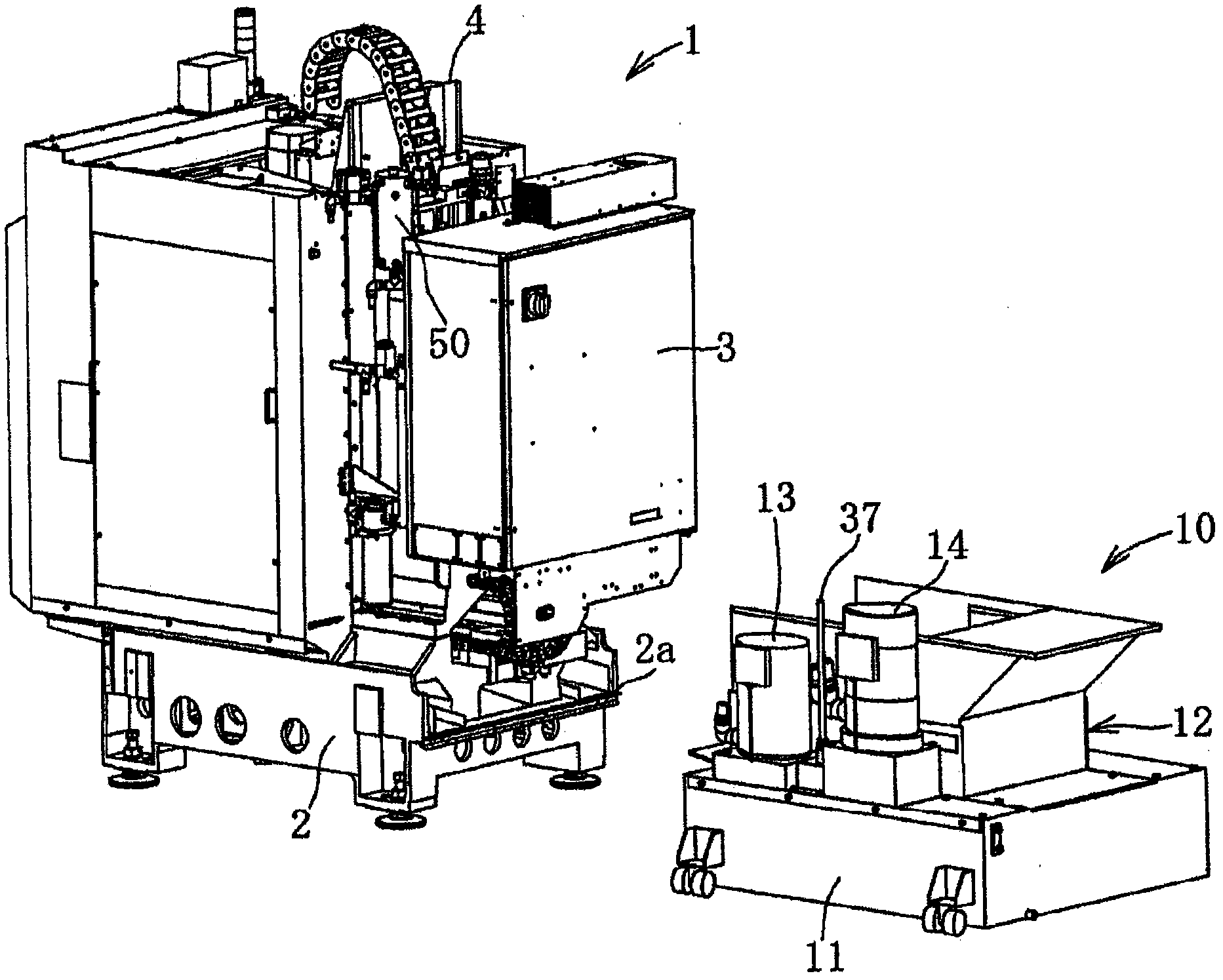

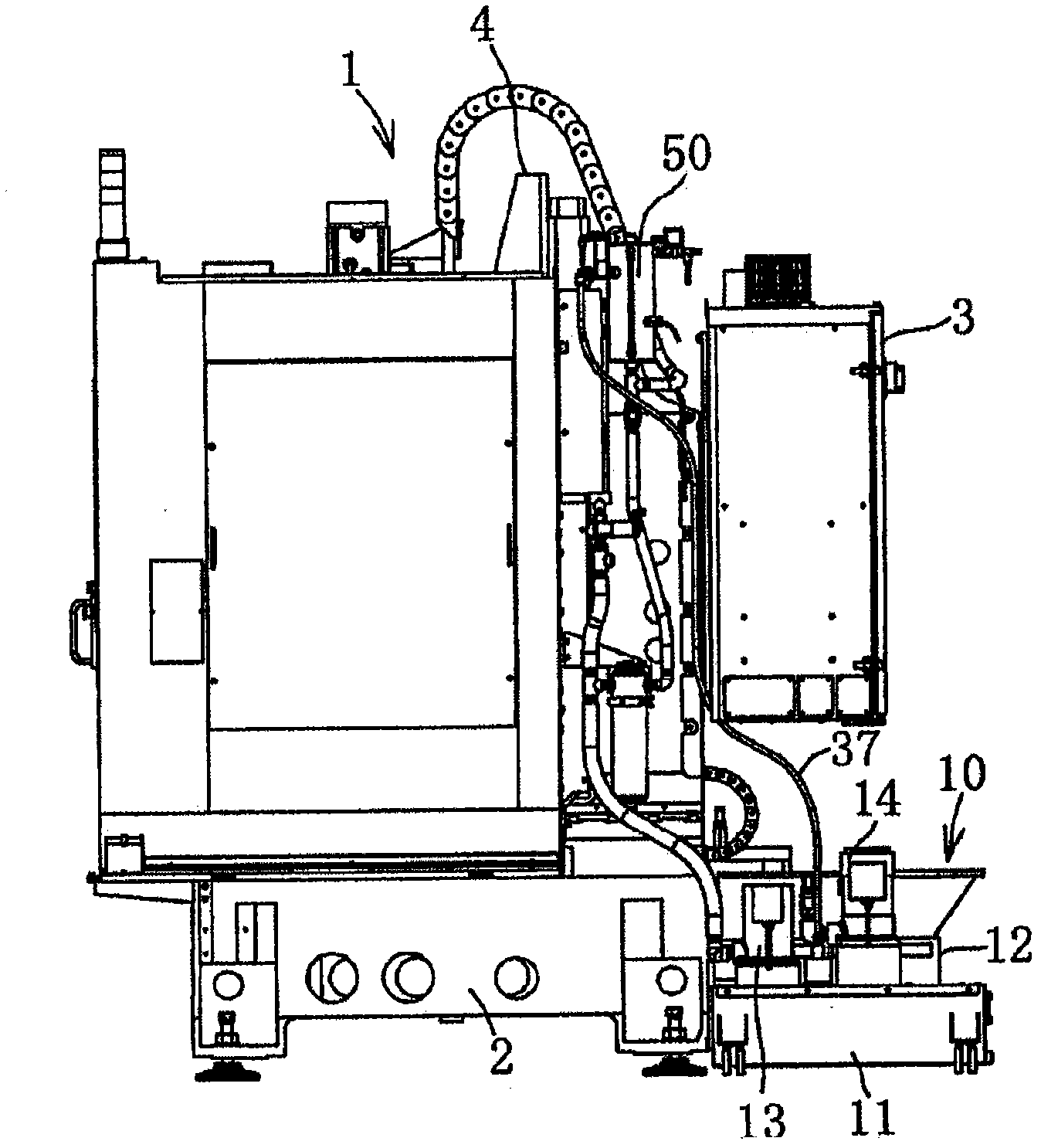

[0034] Such as Figure 1 ~ Figure 3 As shown, the machine tool 1 comprises a control box 3 and a column 4 on its base 2 supported on the floor. machine tool 1 figure 2 The left side of is the front (front). An operator operates machine tool 1 from the front (front). The column 4 is a support vertically erected at the center of the base 2 in the left-right direction and at the rear of the base 2 . Machine tool 1 includes being located at column 4 front side ( figure 1 , figure 2 on the left side) of the processing chamber. The processing chamber includes a processing table (not shown) movable in the front-rear direction and the left-right direction inside the processing chamber. The machine tool 1 processes the workpiece on the processing table inside the processing chamber.

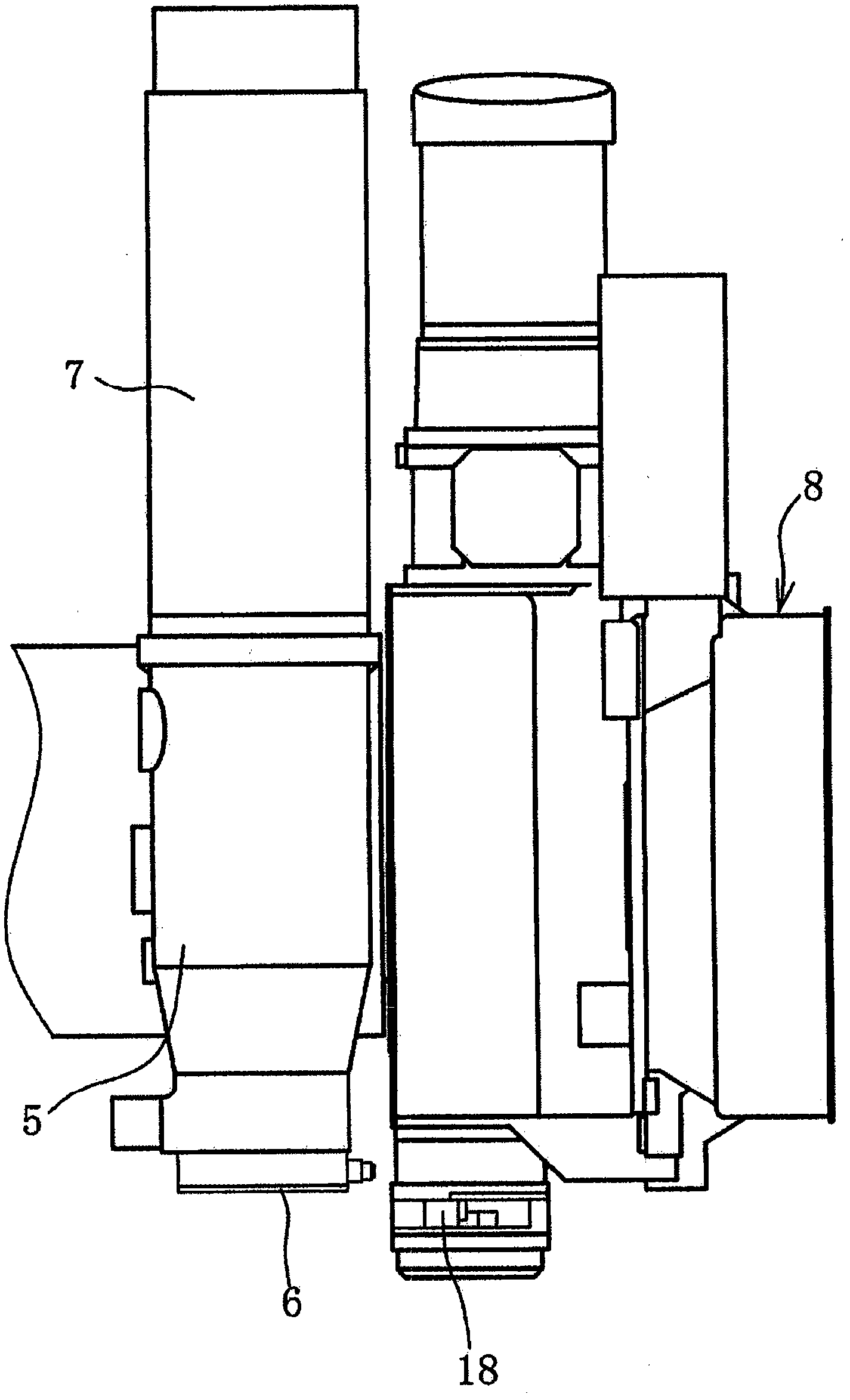

[0035] The column 4 supports a headstock 5 at its front (cf. image 3 ). The headstock 5 ascends and descends along the column 4 inside the machining chamber. The control box 3 is installed on...

Embodiment approach 2

[0087] Refer below Figure 10 , the tool cleaning device according to Embodiment 2 will be described. In the tool cleaning device according to Embodiment 2, the air passage 40 is branched into two air passages 60 and 62 on the downstream side of the first electromagnetic valve 43 . The air passage 60 is connected to the liquid supply valve 35 through a speed regulator 61 . The air passage 62 is connected to the pressurizing valve 45 . The speed regulator 61 includes a variable throttle valve 61a and a check valve 61b connected in parallel. The variable throttle valve 61 a provides resistance to the airflow in the air passage 60 . The one-way valve 61b allows the air flow to the liquid supply valve 35 in the air passage 60 to pass, and blocks the air flow to the first solenoid valve 43 .

[0088] During the cleaning operation, the control unit 9 opens the first electromagnetic valve 43 . The liquid supply valve 35 is opened by the air pressure applied through the air passa...

Embodiment approach 3

[0092] Refer below Figure 11 , the tool cleaning device according to Embodiment 3 will be described. In the tool cleaning device according to Embodiment 2, the air passage 40 is branched into two air passages 63 and 64 on the downstream side of the first electromagnetic valve 43 . The air passage 63 is connected to the pressurizing valve 45 . The air passage 64 is connected to the liquid supply valve 36 . Such as Figure 11 As shown, the length of the air passage 64 is much longer than the length of the air passage 63.

[0093] During the cleaning operation, the control unit 9 opens the first electromagnetic valve 43 . The pressurizing valve 45 is opened by the air pressure applied through the air passage 63 . The liquid supply valve 35 is opened by the air pressure applied through the air passage 64 . When the cleaning operation ends, the control unit 9 closes the first electromagnetic valve 43 . The first solenoid valve 43 discharges the air in the air passages 63 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com