Igniting device and ignition method for sintering

The technology of an ignition device and an ignition furnace is applied in the direction of combustion ignition, a combustion method, and an igniter equipped with fuel, etc., which can solve the problems of cumbersome switching between burners and spare burners, short distance of flame elongation, and poor quality of sintered minerals. To improve the quality of sintered ore, reduce consumption, and avoid insufficient heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

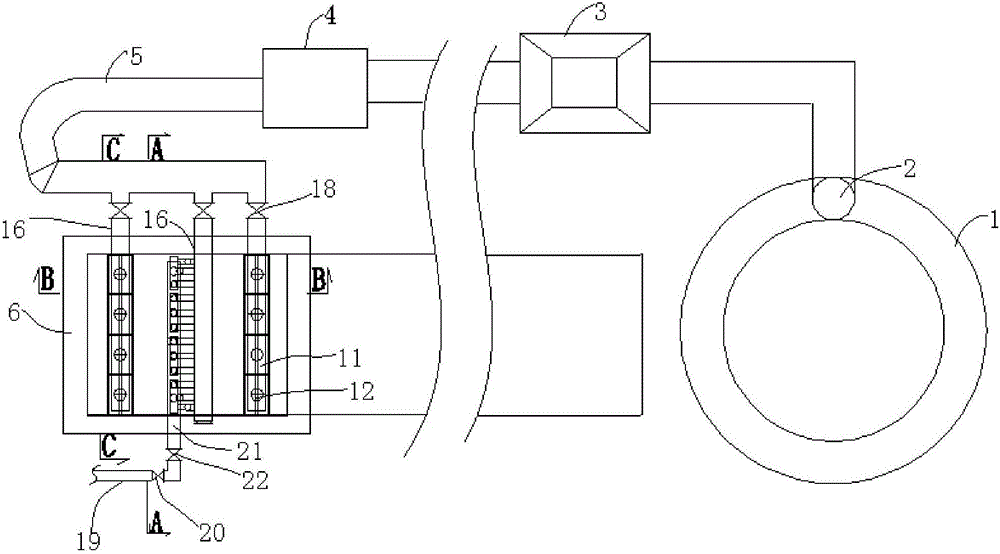

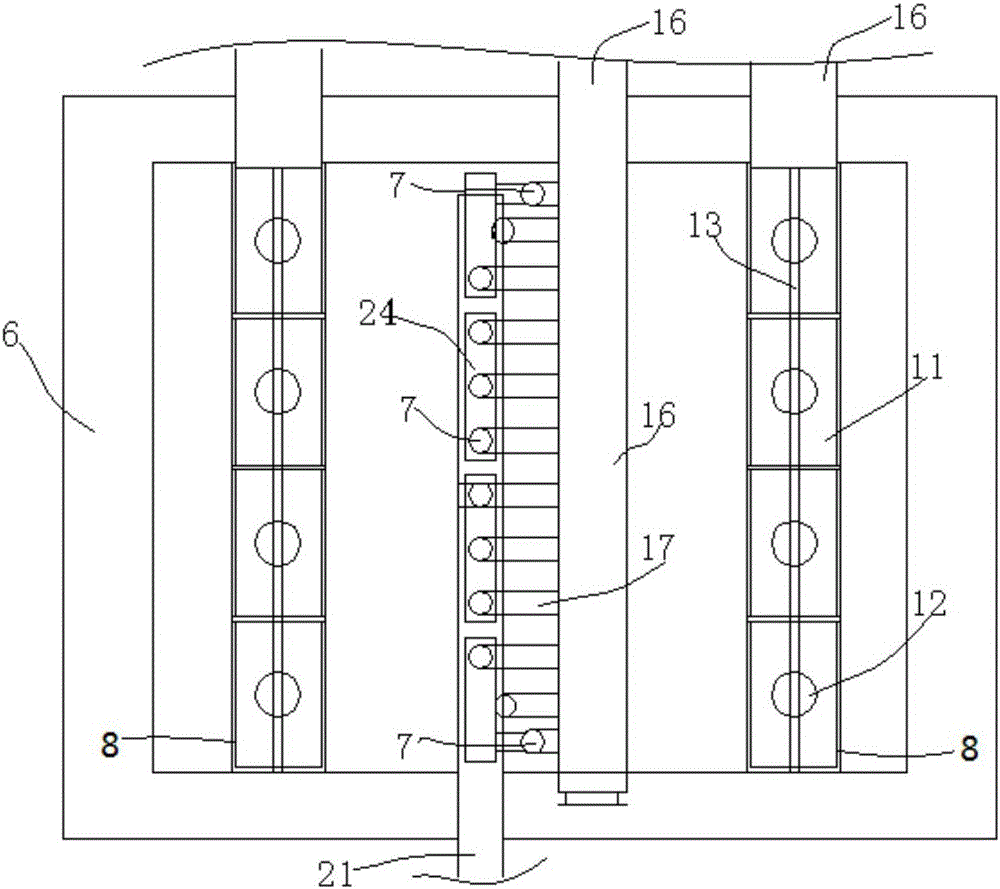

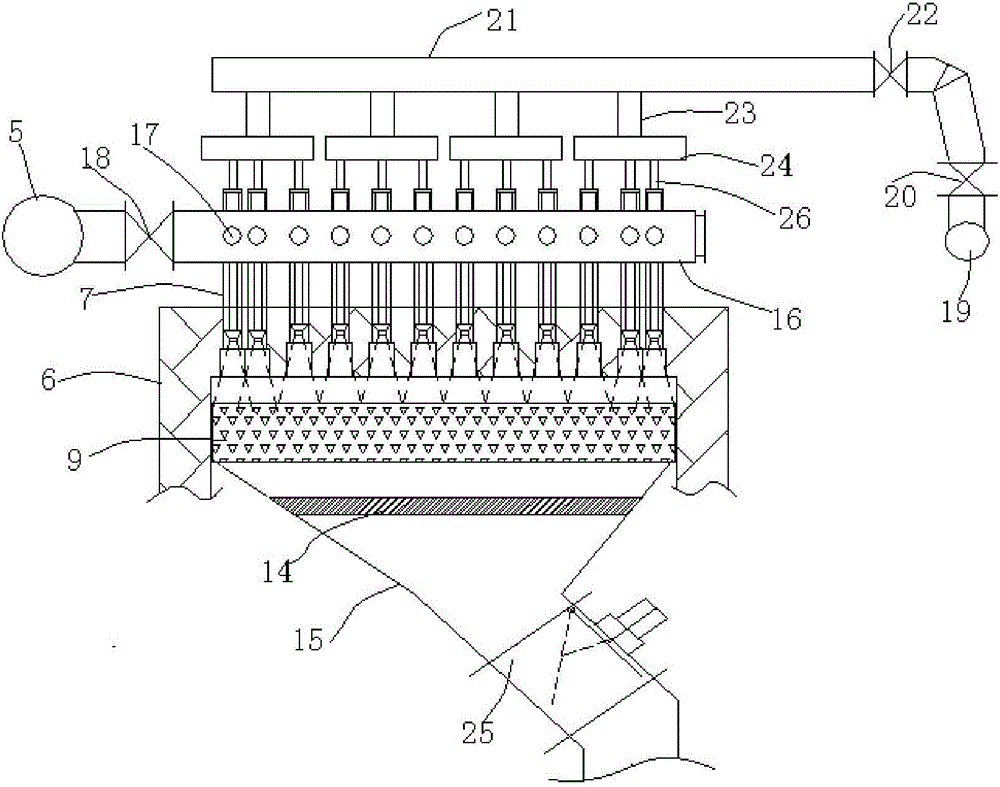

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a kind of sintering ignition device of the present embodiment comprises an ignition furnace 6, a gas inlet pipe and a hot air inlet pipe, and the ignition furnace 6 includes an ignition section and a heat preservation section, wherein the front and rear end furnace tops of the ignition section are respectively provided with An isolation chamber 8, which communicates with the hot air intake pipe. A row of burners 7 are vertically arranged on the top of the ignition furnace 6 ignition section, such as figure 2 As shown, there are 12 burners in total, the eight burners 7 in the middle are arranged in a straight line and evenly spaced, the last two burners 7 near the sides of the sintering machine trolley are arranged in an arc, and the burners 7 The height from the surface of the sintered material 9 is 10-20 mm lower than that of the middle burner 7 , specifically, in this embodimen...

Embodiment 2

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a sintering ignition device of this embodiment has the same basic structure as that of Embodiment 1, the difference is that the length of the ignition furnace 6 in this embodiment accounts for 14% to 20% of the length of the sintering machine body, and the ignition section furnace The height from the top to the surface of the sintered material 9 is 800-900mm, and the distances between the front and rear isolation chambers 8 and the central burner 7 are 800-1000mm and 1300-1500mm respectively.

[0056] Isolation chamber 8 among the present embodiment comprises the ventilation hole 12 that is connected with hot blast branch pipe 16, and this ventilation hole 12 extends to the stove top inner wall of ignition furnace 6, and the bottom of ventilation hole 12 is provided with buffer chamber 11, and the buffer chamber 11 The bottom is provided with a strip-shaped nozzle 13, which forms a...

Embodiment 3

[0069] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a kind of sintering ignition device of this embodiment has the same basic structure as that of Embodiment 2, the difference is that the height of the arc-shaped burners 7 in this embodiment from the surface of the sintered material 9 is lower than that of the middle burner 7 20mm; the gas outlet end of the burner 7 is embedded in the insulation layer, and the embedding depth is 25mm; the cross-sectional area of the bellows 15 at the installation position of the baffle 14 is S, and the upper surface area of the baffle 14 is 60% S, That is, the wind blocking area of the spoiler 14 accounts for 60% of the ventilation area of the bellows 15; the isolation chamber 8 is made of heat-resistant stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com