Dust collection box and steam vacuum cleaning machine using the same

A technology for vacuum cleaning and dust collection box, applied in the field of dust collection box, can solve the problems of unreasonable layout, steam inhalation, inconvenient use of wires, etc., and achieve the effect of preventing splashing or reverse flow, preventing splashing and reverse flow, and improving the filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The following are examples to illustrate the present invention with reference to the accompanying drawings.

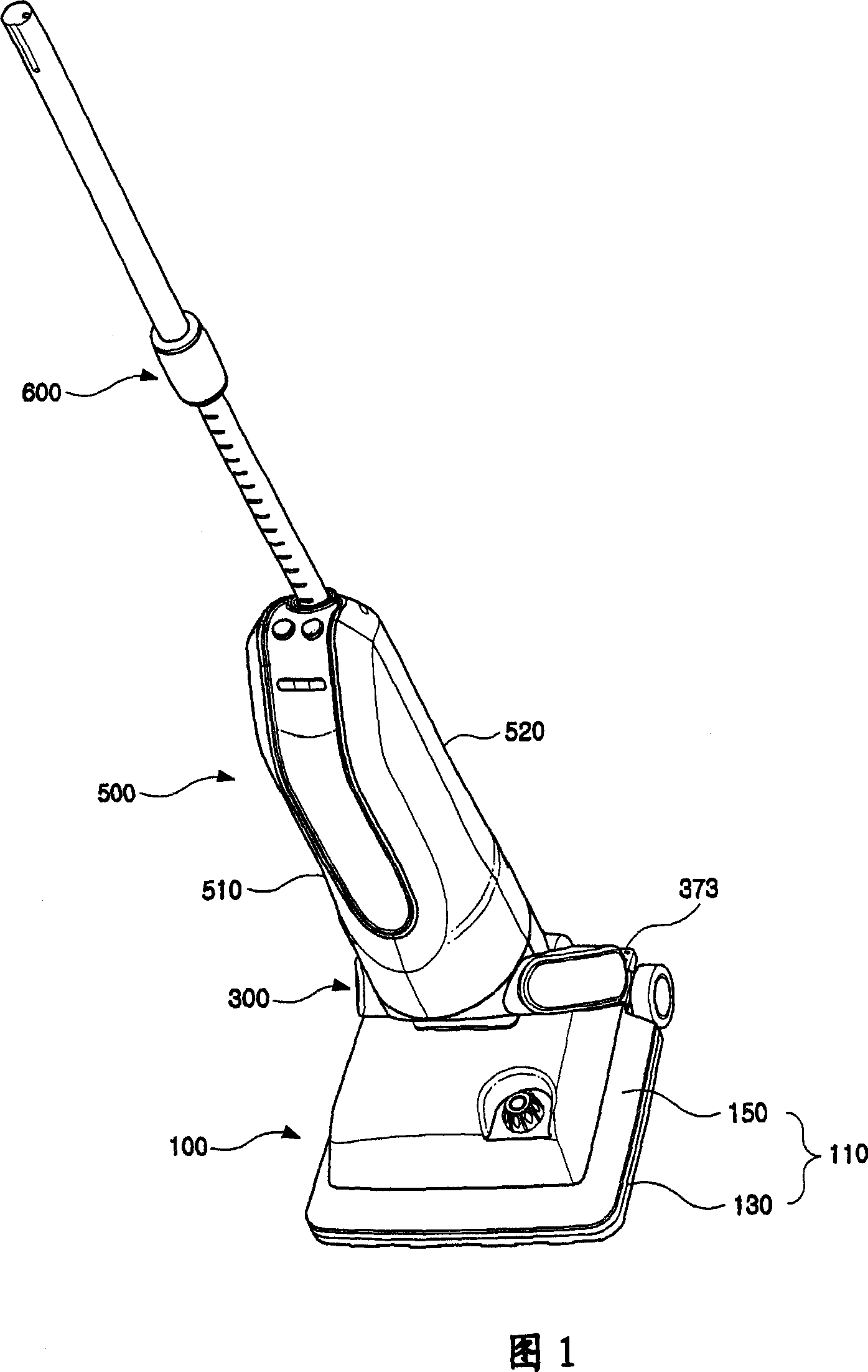

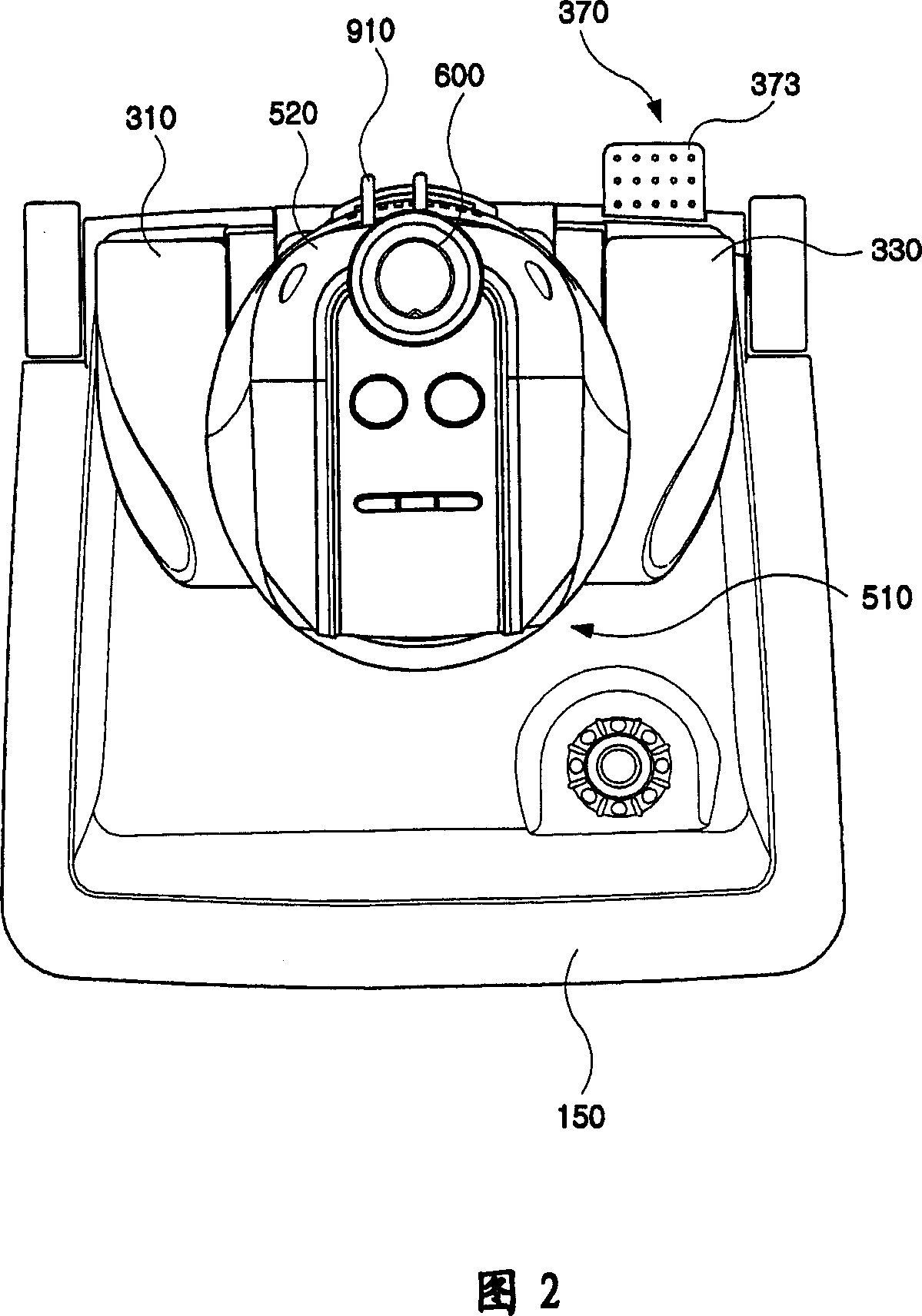

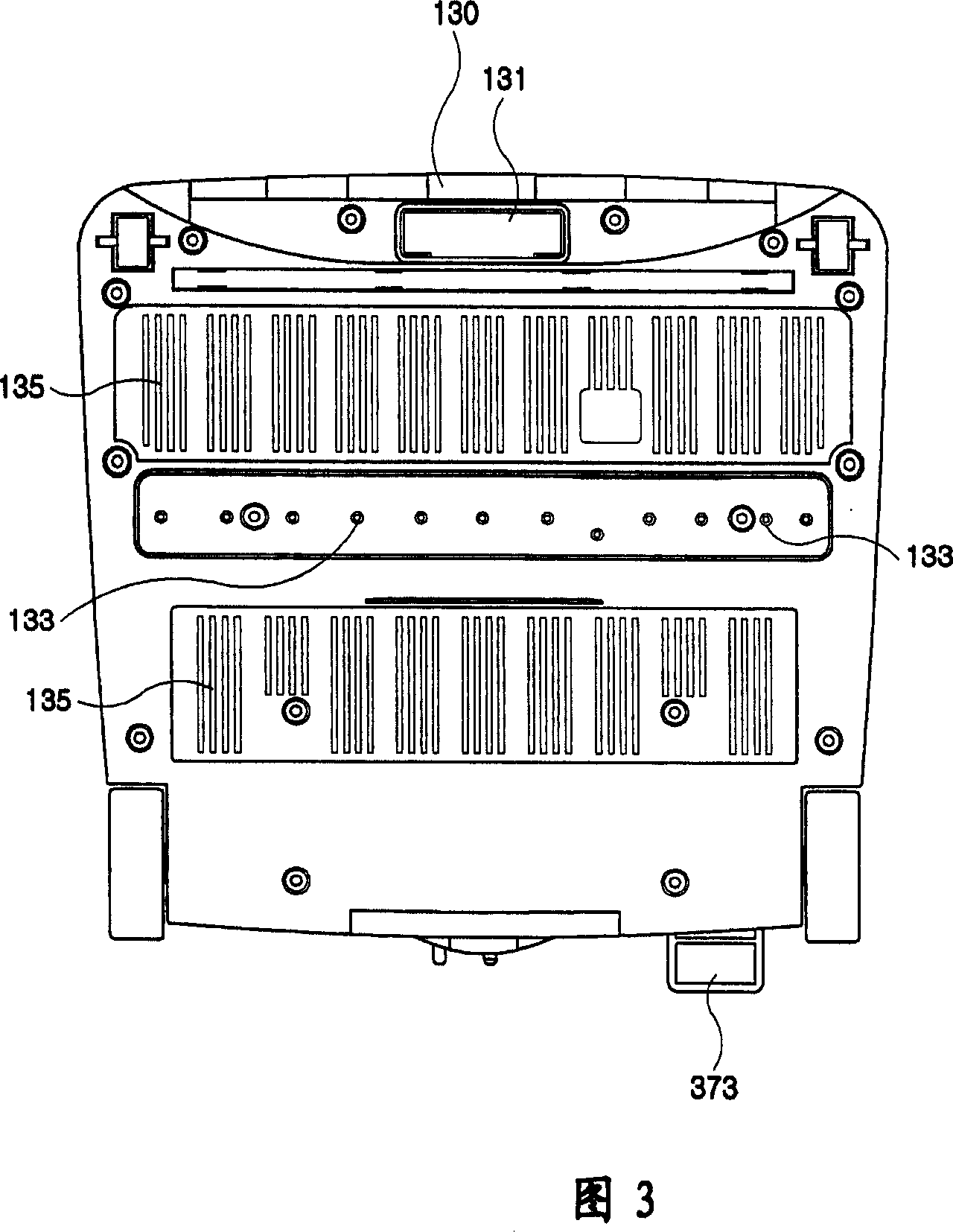

[0078] 1 is a front perspective view of a steam vacuum cleaner according to an example of the present invention, and FIGS. 2 to 4 are a plan view, a bottom view and a rear view of FIG. 1 .

[0079] As shown in FIG. 1 and FIG. 4 , the steam vacuum cleaner in this example is generally composed of a base 100, an operating body 500, and a neck 300 connecting the base 100 and the operating body 500. At the same time, the operating body There should be a handle bar 600 with an adjustable length on the 500, and the handle bar 600 is detachably mounted on the tube 550 to be described below.

[0080] As shown in FIG. 5 , the base 100 is composed of a main body 110 composed of a bottom plate 130 and an upper cover 150 , a steam generating part 170 mounted on the bottom plate 130 , and a dust collecting box 200 mounted on the back of the main body 110 .

[0081] As shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com