Inkjet recording device

An inkjet recording and recording head technology, applied in printing and other directions, can solve the problems of inability to effectively suppress residual vibration and unstable continuous ink ejection, and achieve the effects of preventing residual vibration, preventing ink penetration, and stably ejecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

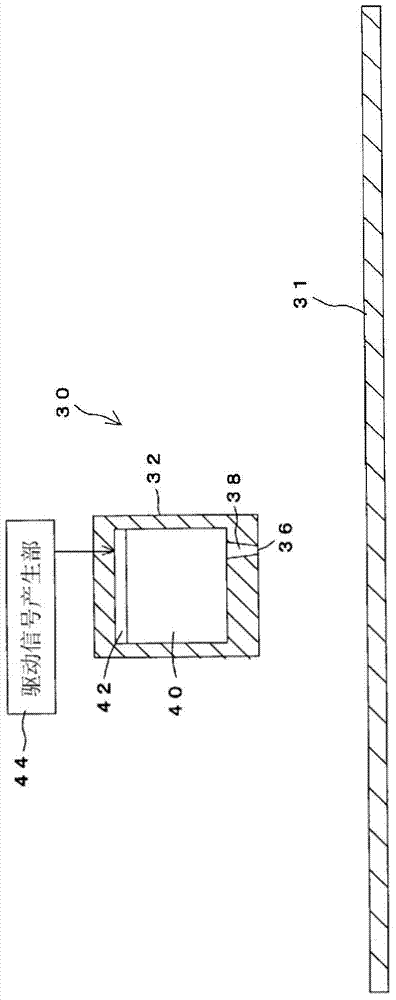

[0046] exist figure 1 A schematic diagram of an inkjet recording apparatus is shown in .

[0047] The inkjet recording device 30 is a device that performs printing on a medium 31 by jetting ink, and includes a recording head 32 that ejects ink to the medium 31 , and an ink tank (not shown) that stores ink supplied to the recording head 32 .

[0048] The recording head 32 includes a nozzle 38 formed with an opening 36 for ejecting ink, and a pressure chamber 40 for accommodating ink. In addition, a part of the wall surface constituting the pressure chamber 40 is formed by the piezoelectric element 42 . The piezoelectric element 42 is deformed by applying a predetermined voltage, and the deformation of the piezoelectric element 42 changes the volume of the pressure chamber 40 so that the ink contained in the pressure chamber 40 can be ejected from the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com