Low-noise axial plunger pump based on indexing angle of pumps in series

A technology of axial piston pump and indexing angle, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machines, etc., can solve noise pollution, limit application occasions, and increase the structural complexity and cost of axial piston pumps and other problems, to achieve the effect of reducing outlet flow pulsation and fluid noise excitation source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

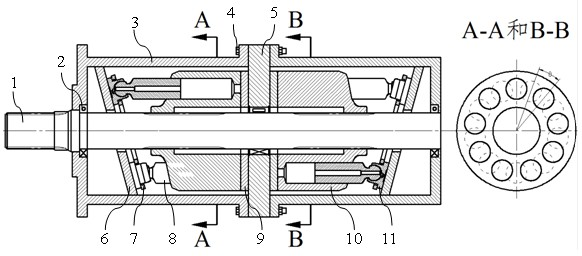

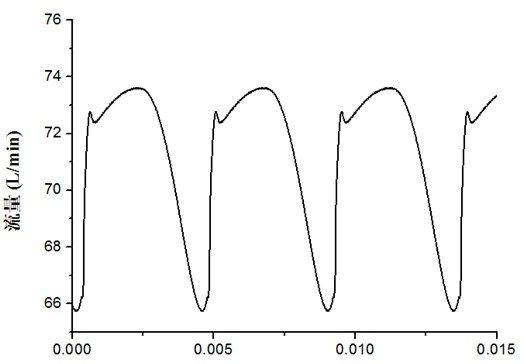

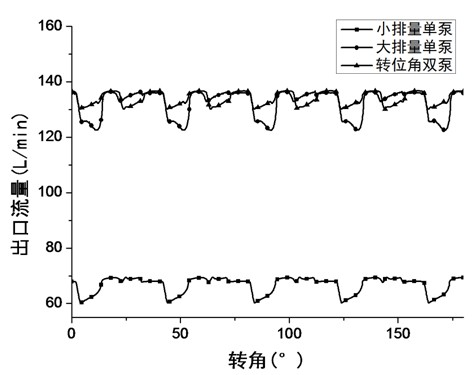

[0011] The dynamic change rule of the outlet flow of the axial piston pump is as follows figure 1 As shown, the peak and valley intervals are periodically distributed, and there is a large flow pulsation. The axial plunger pump of the present invention adopts two sets of rotor structures that perform the process of sucking and discharging oil. The rotor structure is composed of sliding shoes, plungers, cylinders and valve plates. Because the two cylinders are not in a mirror image relationship, they exist in the circumferential direction. Index angle, therefore, there is a fixed phase difference in the dynamic change curve of the oil displacement produced by the two sets of rotor mechanisms. When the two oil displacements merge at the outlet, the average effect will be produced, and the actual outlet flow pulsation of the axial piston pump will be greatly reduced. The noise level is reduced.

[0012] The present invention will be further described below in conjunction with the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com