Flexible linkage reciprocating pump

A reciprocating pump, flexible technology, applied to pumps with flexible working elements, pumps, components of pumping devices for elastic fluids, etc., can solve the vibration of wafer cleaning nozzles, unfavorable fluid flow rate adjustment and control, and affect cleaning Efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

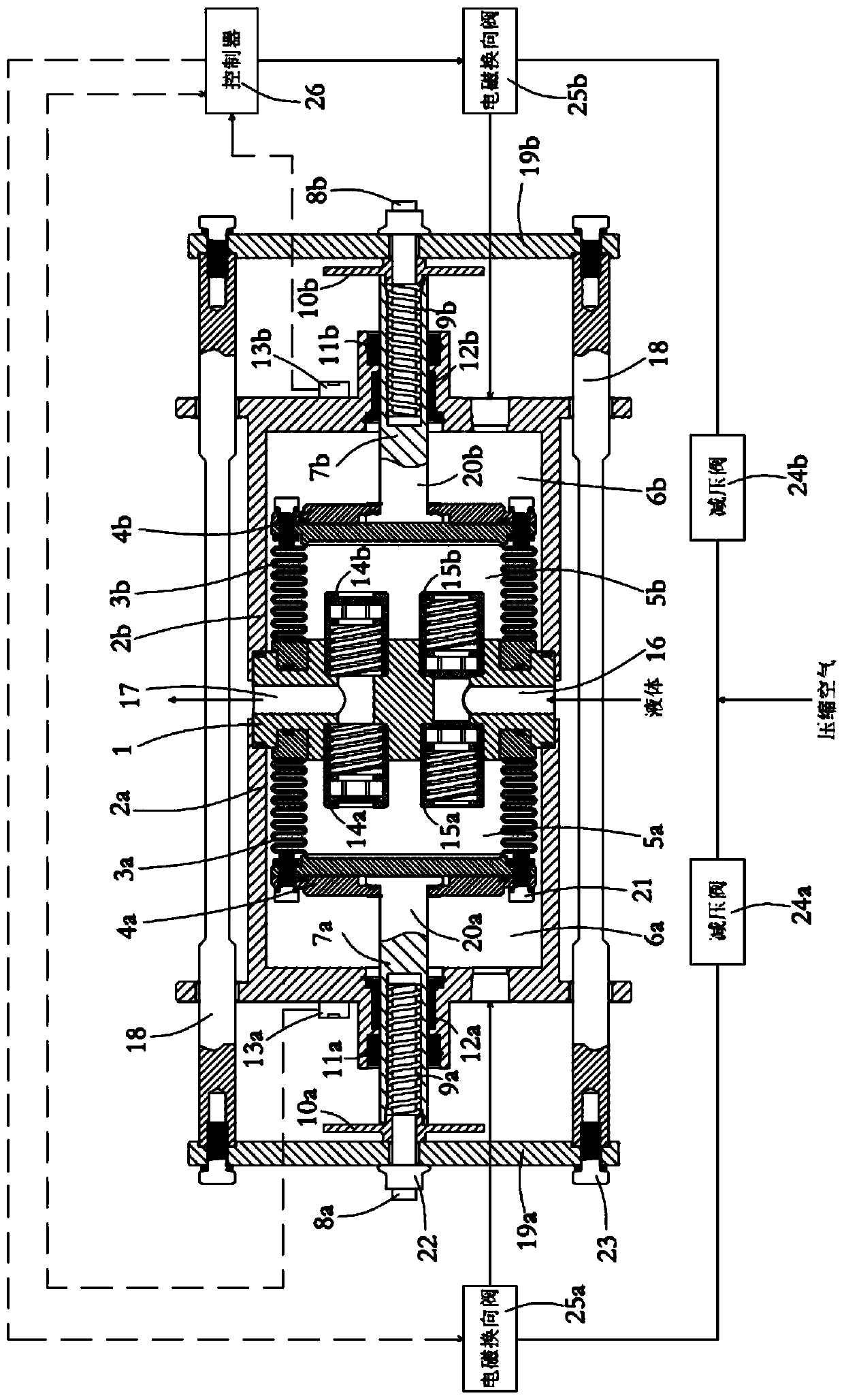

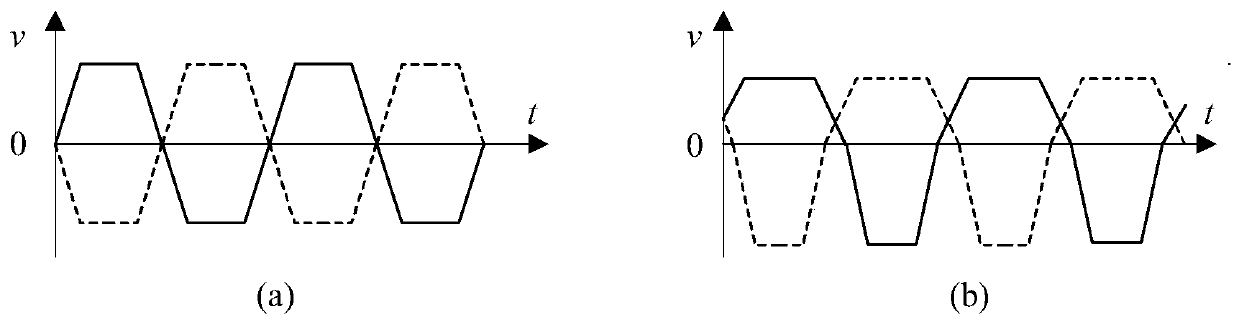

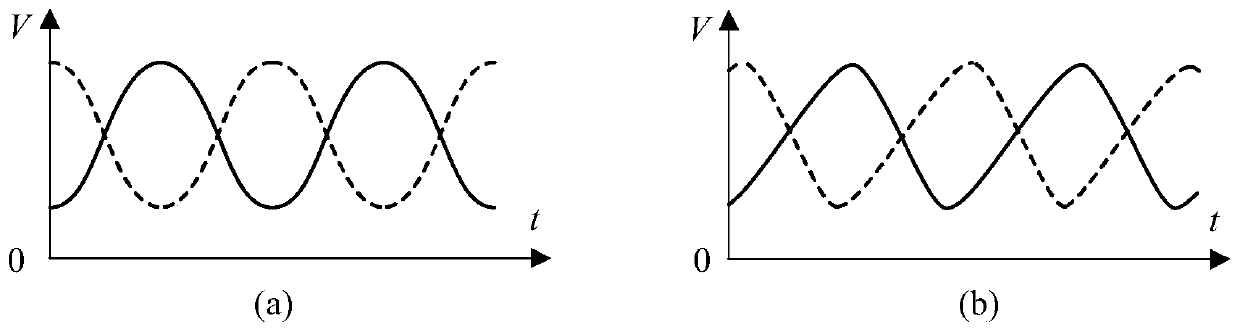

Method used

Image

Examples

no. 2 approach

[0037] In the previous embodiments, the flexible telescoping part of the pump shaft is located inside the pump shaft. Such as Figure 5 As shown, in this embodiment, the flexible telescoping part of the pump shaft is located outside the pump shaft. This embodiment, like the first embodiment, can achieve the effect of flexible linkage, and can realize the partial overlap of the contraction sequence of the left and right bellows, thereby achieving the effect of reducing output flow pulsation.

no. 3 approach

[0039] In the previous embodiments, the flexible linkage reciprocating pump has a pair of left and right symmetrical flexible telescopic parts. Such as Figure 6 As shown, in this embodiment, there is not necessarily a pair of symmetrical flexible telescopic parts on the left and right, and they can be asymmetrical, or even have flexible telescopic parts on the left and no flexible telescopic parts on the right. This embodiment can also achieve the effect of flexible linkage, and can realize the partial overlap of the contraction sequence of the left and right bellows, thereby achieving the effect of reducing output flow pulsation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com