A method for manufacturing a selective emitter cell with precise overprinting

A manufacturing method and selective technology, applied in the field of solar cells, can solve problems such as inability to ensure metal grid lines, and achieve the effects of improving overprinting accuracy, improving printing efficiency, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present invention is a method for manufacturing a selective emitter battery with precise overprinting, which includes the following steps in sequence:

[0031] S1. The silicon wafer is subjected to conventional cleaning, texturing and growth masking treatments.

[0032] S2. Position the silicon wafer on the first printing table through the positioning rods fixed on the first printing table. Here, a first screen is provided above the first printing table, and the first printing table can be positioned relative to the first printing table. The screen plate moves freely, and the positioning rod can be a positioning screw or a screw rod; after the first printing station and the first screen plate are superimposed, the etchant is printed on the silicon wafer, and the pattern printed by the etchant is consistent with the pre-printed positive electrode grid line pattern. Correspondingly, after the silicon dioxide layer under the etchant is fully etched away, the silicon wa...

Embodiment 2

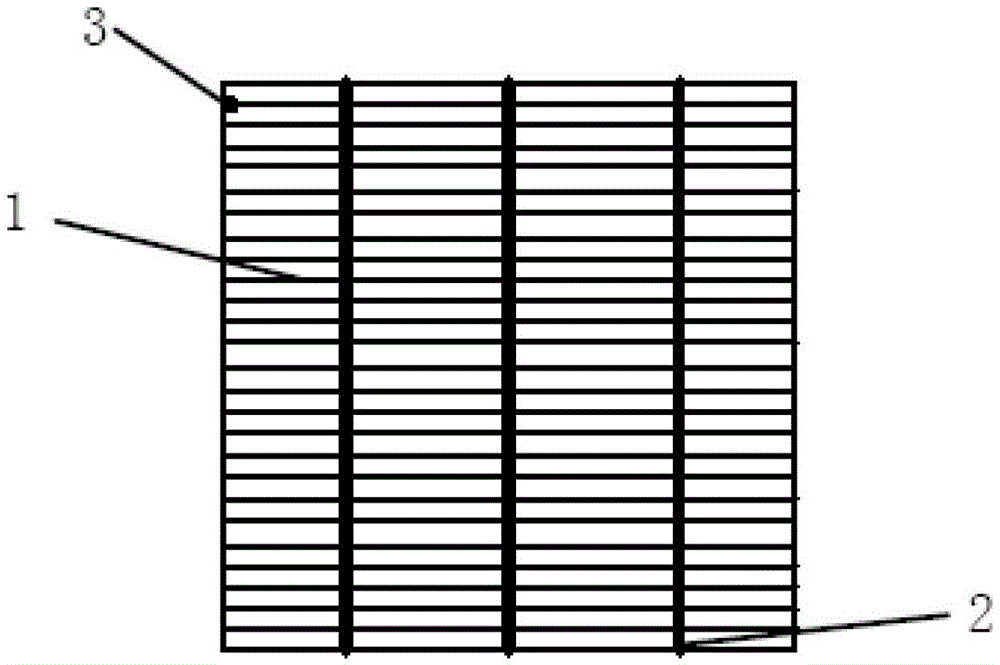

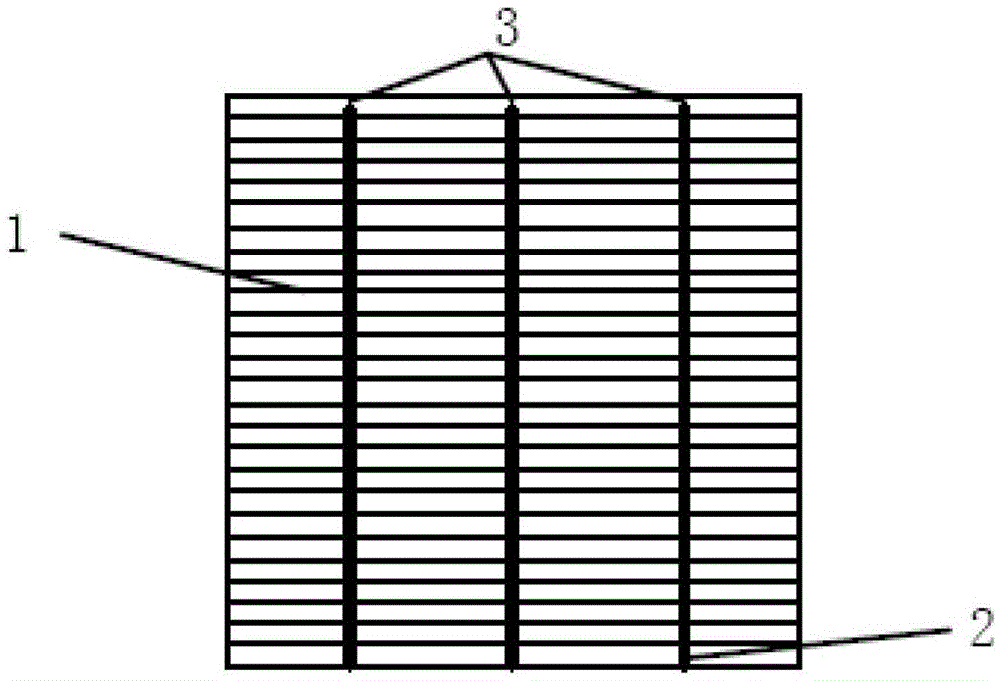

[0039] On the basis of Embodiment 1, a preferred embodiment of the present invention is: the first and second screens have directionality. Such as figure 1 and figure 2 As shown, the first and second screen plates can realize the directivity of the first and second screen plates by setting feature points at the ends of the fine grid and / or the main grid. Such as figure 1 As shown, the feature points can be the ends of the fine grid roughening. figure 2 In , the feature points are the ends of the main grid refinement.

Embodiment 3

[0041] On the basis of Embodiment 2, a preferred embodiment of the present invention is: the second optical imaging device is a three-dimensional imaging device capable of obtaining a three-dimensional image of the silicon wafer; the image analysis and recognition system is provided with a three-dimensional image analysis module, The three-dimensional image of the silicon chip transmitted from the three-dimensional camera device is identified and analyzed by the three-dimensional image analysis module, and the average depth of the groove on the silicon chip is calculated, and the average depth of the groove is calculated. transmitted to the controller of the grouting machine; the grouting machine is used to sizing the second screen, the controller is connected with the motion actuator for adjusting the sizing amount of the grouting machine, and according to the groove The average depth controls the motion of the motion actuator. The motion actuator here may be the piston actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com