Digital jet printing system with pre-detection device

A digital jet printing and pre-detection technology, applied in printing devices, printing and other directions to achieve the effect of improving quality, simple structure and accurate overprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

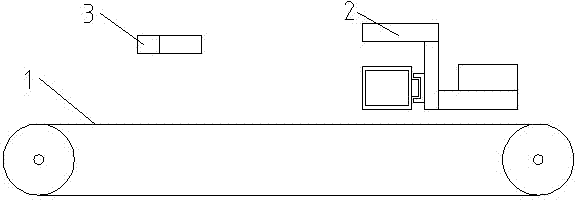

[0029] see Figure 1 to Figure 7 , the digital jet printing system with pre-detection device in the present embodiment comprises jet printing medium delivery device 1, inkjet printing head device 2, ink supply device, printing control device, digital camera device 3 and frame, wherein, jet printing medium Conveying device 1, inkjet printing head device 2, ink supply device, printing control device and frame are all the same as or similar to the prior art, and the jet printing medium conveying device 1, inkjet printing head device 2, printing control device and The ink supply devices are all installed on the digital jet printing system by the installation method of the prior art.

[0030]The digital camera 3 in the present embodiment comprises a camera 31 and a camera bracket 32, wherein the camera bracket 32 is fixed on the frame, the camera 31 is fixed on the camera bracket 32, and the camera 31 is positioned at the inkjet printing of the printing medium delivery device 1. ...

Embodiment 2

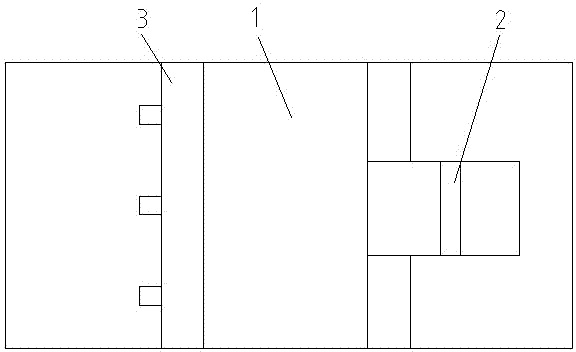

[0037] see Figure 8 to Figure 12 , the digital jet printing system with pre-detection device in the present embodiment comprises jet printing medium delivery device 1, inkjet printing head device 2, ink supply device, digital camera device 3, printing control device and frame, wherein, jet printing medium Conveying device 1, inkjet printing head device 2, ink supply device, printing control device and frame are all the same as or similar to the prior art, and this jet printing medium conveying device 1, inkjet printing head device 2, ink supply device and The printing control devices are all installed on the digital jet printing system by the installation method of the prior art.

[0038] The inkjet print head device 2 in the present embodiment comprises a nozzle 21, a nozzle frame 22, a slider 23, a linear guide rail 24 and a crossbeam 25, wherein the crossbeam 25 is fixed on the frame, and the linear guide rail 24 is fixed on the crossbeam 25. Block 23 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com