Horizontal type spatial multiphase crank pump

A multi-phase, crankshaft pump technology, applied in the direction of multi-cylinder pumps, variable capacity pump components, pumps, etc., can solve the problems of flow pulsation, large volume, machine wear, etc., achieve reduced volume and weight, compact and stable structure, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The horizontal space multi-phase crankshaft pump provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

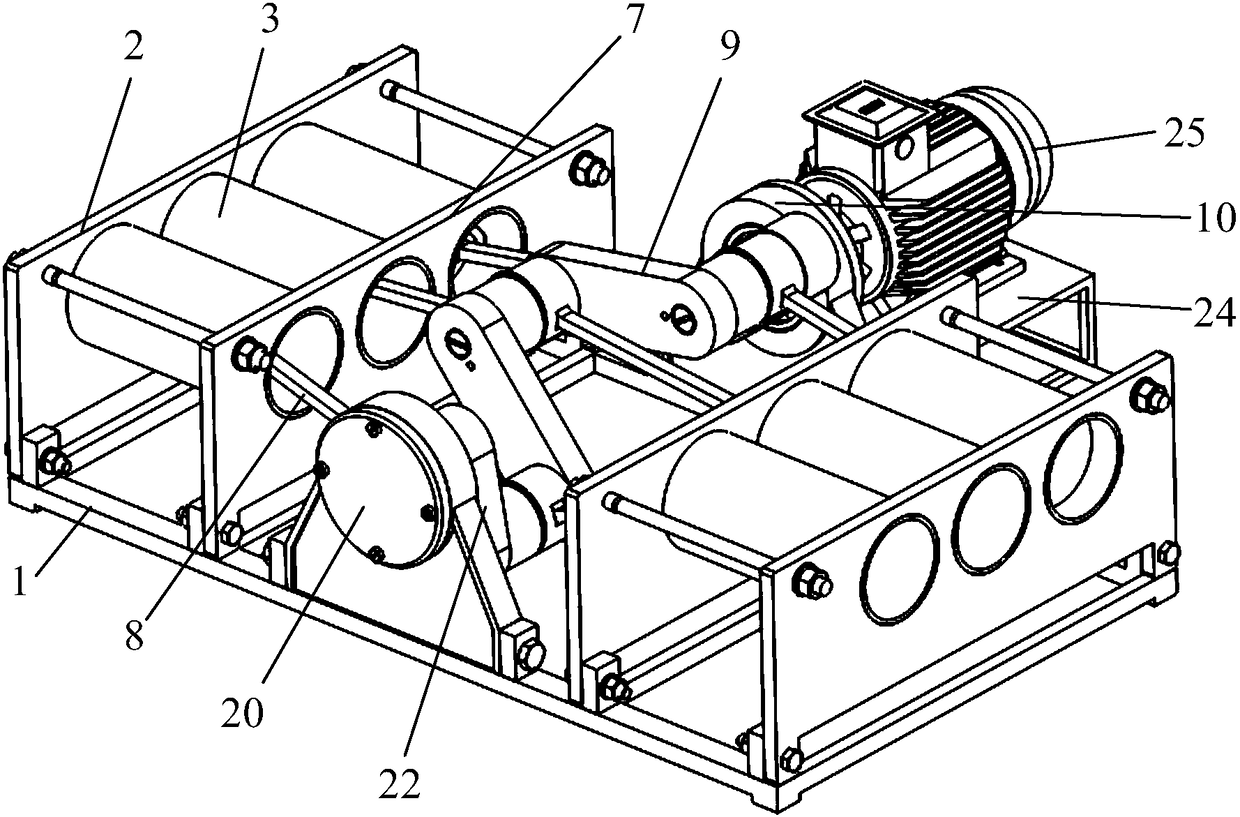

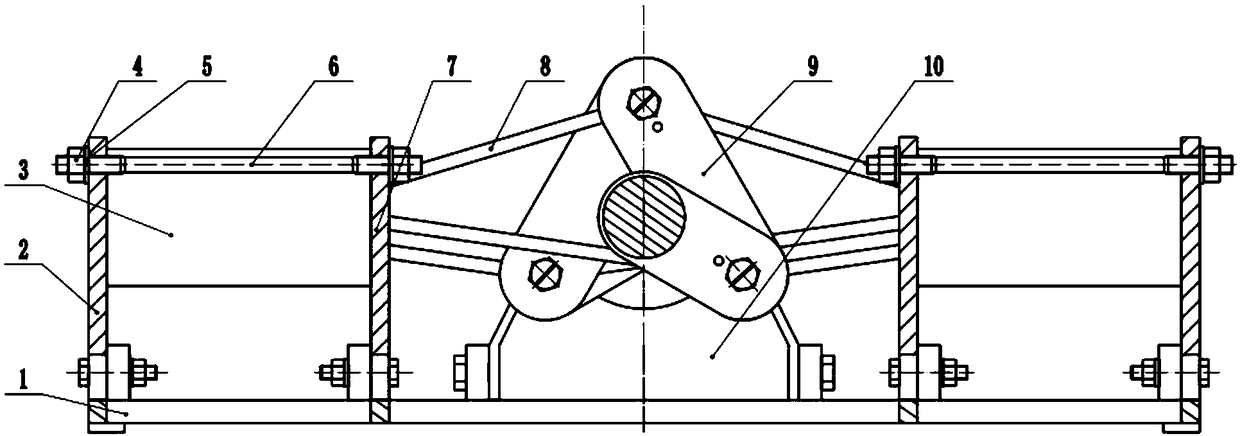

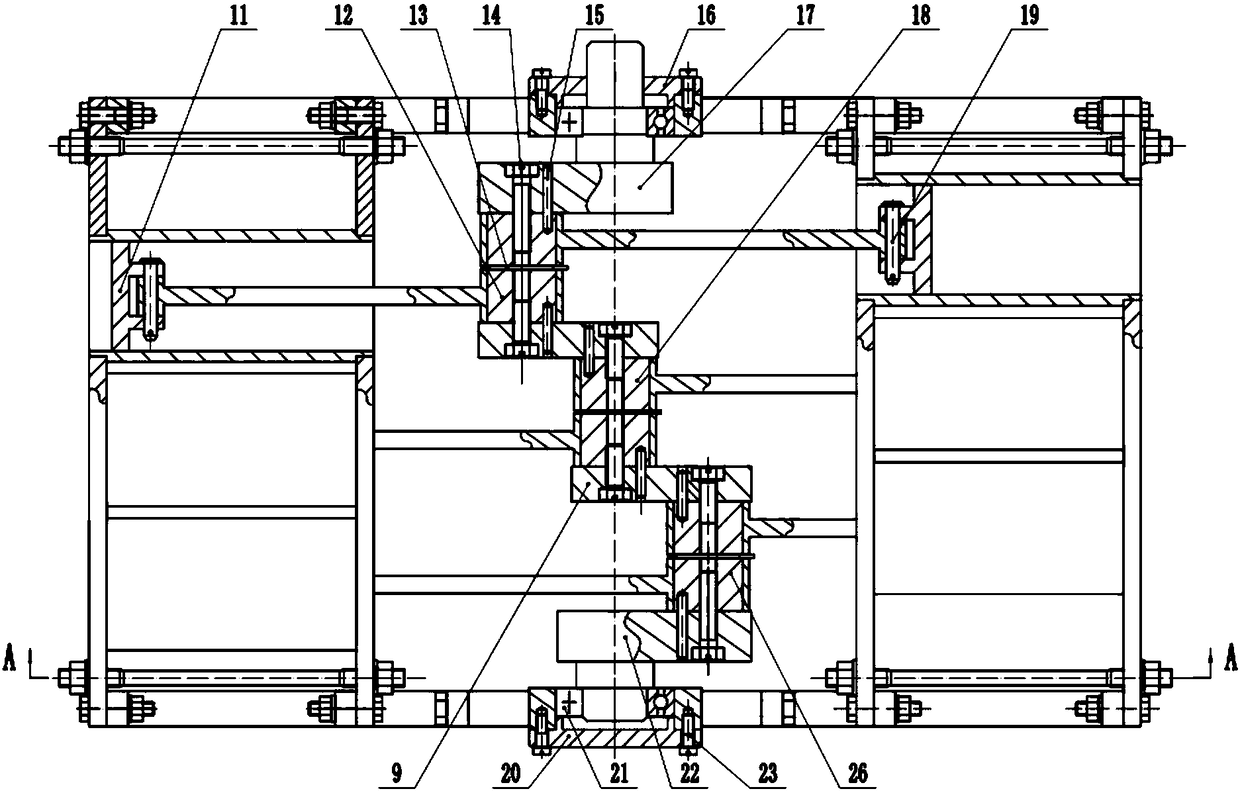

[0019] like figure 1 — image 3 As shown, the horizontal space multiphase crankshaft pump provided by the present invention includes a bottom plate 1, an outer baffle 2, a hydraulic cylinder 3, an inner baffle 7, a connecting rod 8, a second crank 9, a bearing housing 10, a piston 11, a first Crank pin 12, bearing through cover 16, first crank 17, second crank pin 18, bearing end cover 20, bearing 21, the 3rd crank 22, the 3rd crank pin 26, motor frame 24 and motor 25; Wherein bottom plate 1 is Rectangular plate, placed horizontally; two outer baffles 2 are vertically fixed on both sides of the surface of the bottom plate 1 in parallel; each outer baffle 2 is provided with an inner baffle in parallel on the bottom plate 1 at the inner side 7. Each outer baffle 2 and the two ends of the adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com