Low flow pulsation hydraulic pressure transformer

A technology of hydraulic transformer and small flow, applied in the field of hydraulic transformer, can solve the problems of poor stability, affecting application, output flow pulsation, etc., achieve the effect of structural optimization, improve working stability, and reduce flow pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

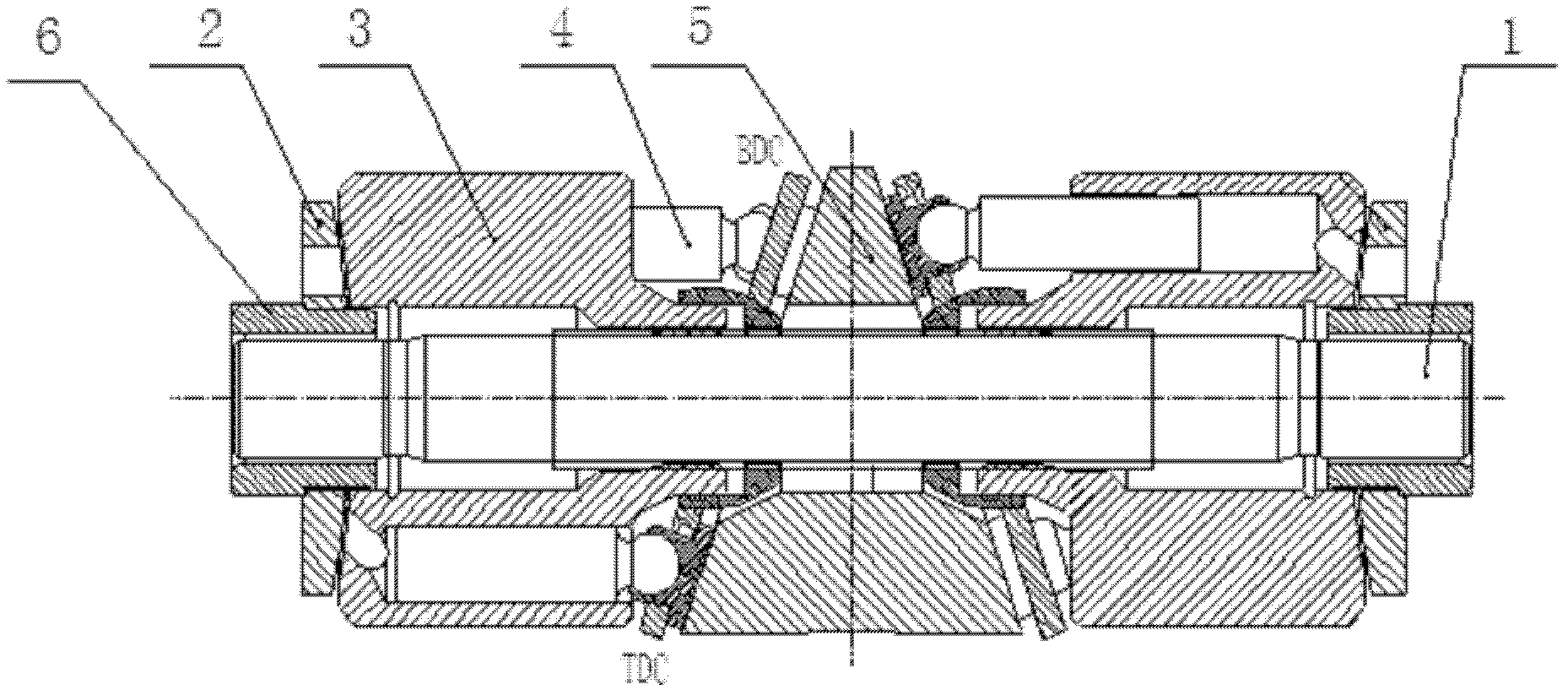

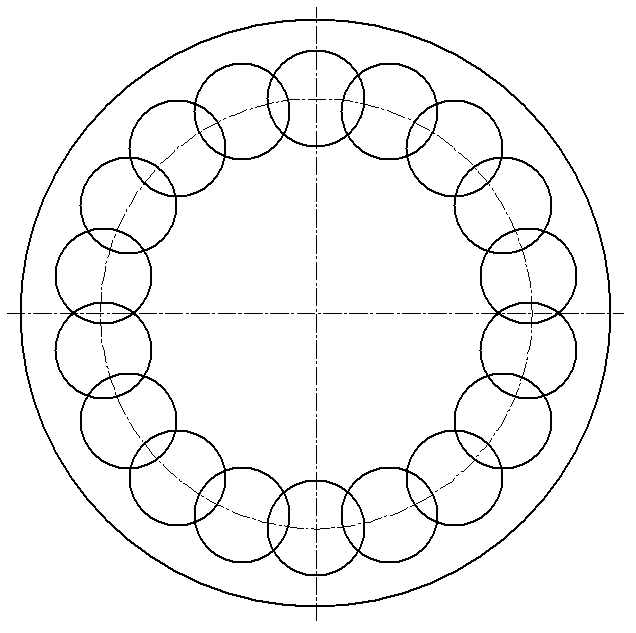

[0021] The small flow pulsation hydraulic transformer provided by the present invention is as figure 1 As shown, the transformer includes a main shaft 1, a swash plate 5, a left transformer component and a right transformer component. The hydraulic transformer adds a right transformer part symmetrical to the left transformer part on the traditional hydraulic transformer, and through the reasonable arrangement of the plunger, the flow pulsation of the hydraulic transformer is reduced, and the working stability of the system is improved.

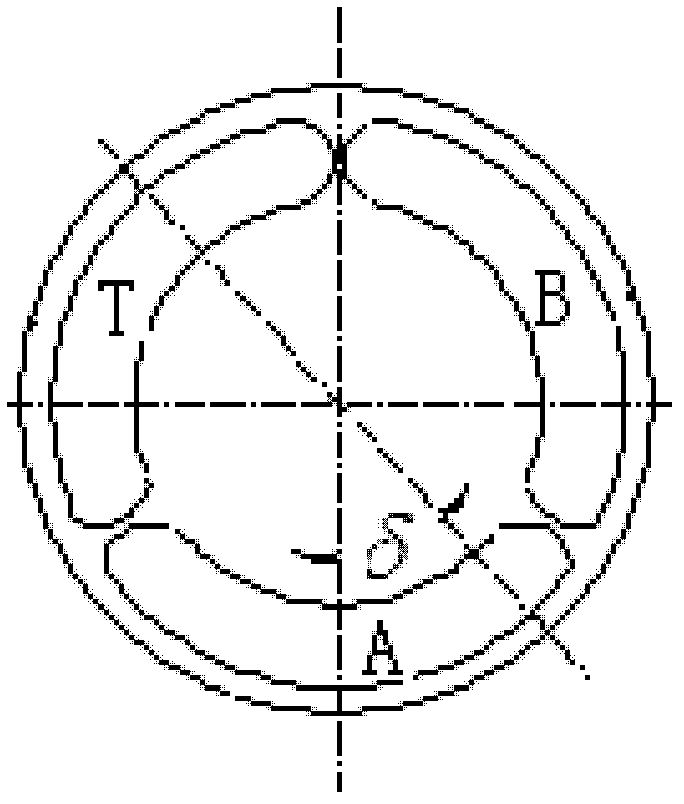

[0022] The swash plate 5 is a conical pedestal, such as Figure 4 As shown, the included angle between the busbar of the conical pedestal and the vertical direction is 15°, the center of the swash plate 5 is horizontally processed with a through hole, the main shaft 1 is installed in the through hole horizontally, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com