Uniform motion pipeline pump

A technology for pipeline pumps and pump casings, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve problems such as inability to guarantee product quality, and achieve the effects of wide application range, small pressure pulsation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

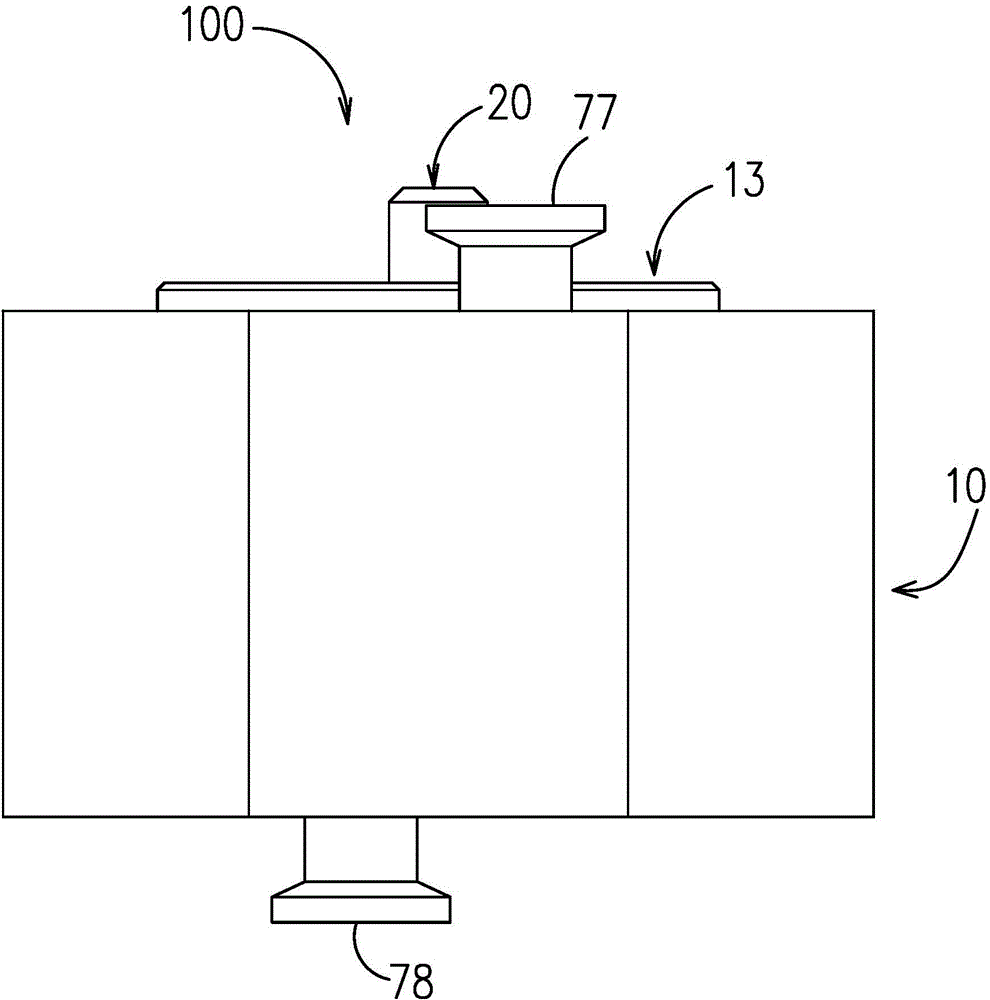

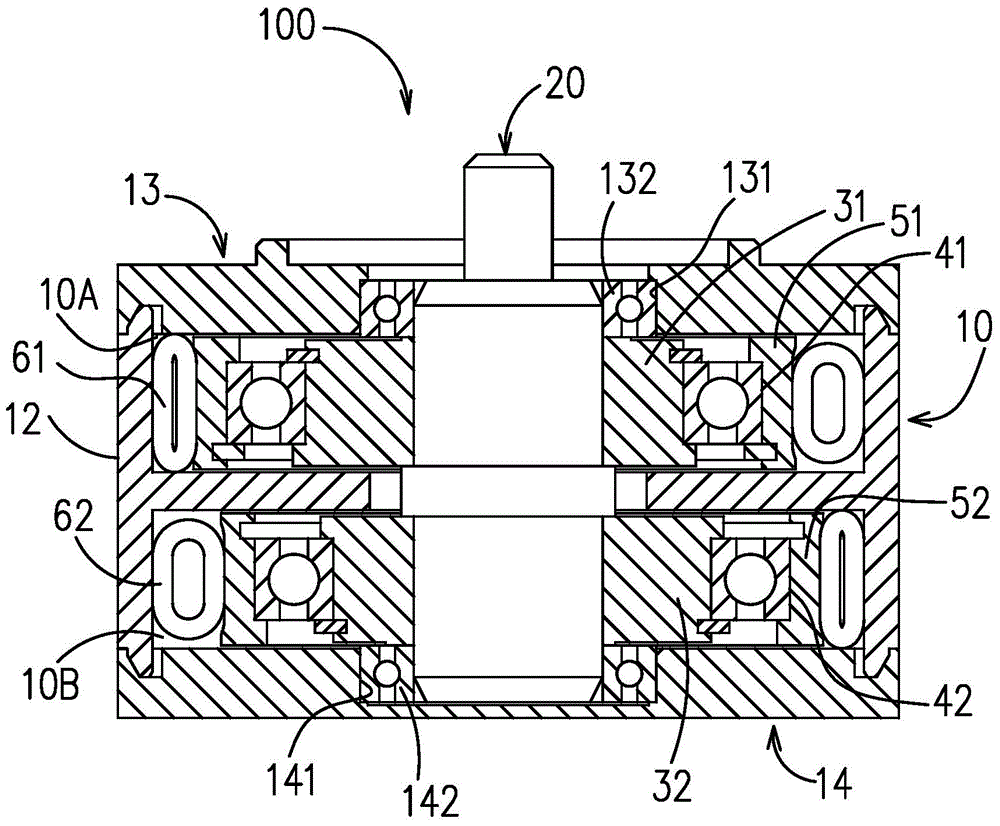

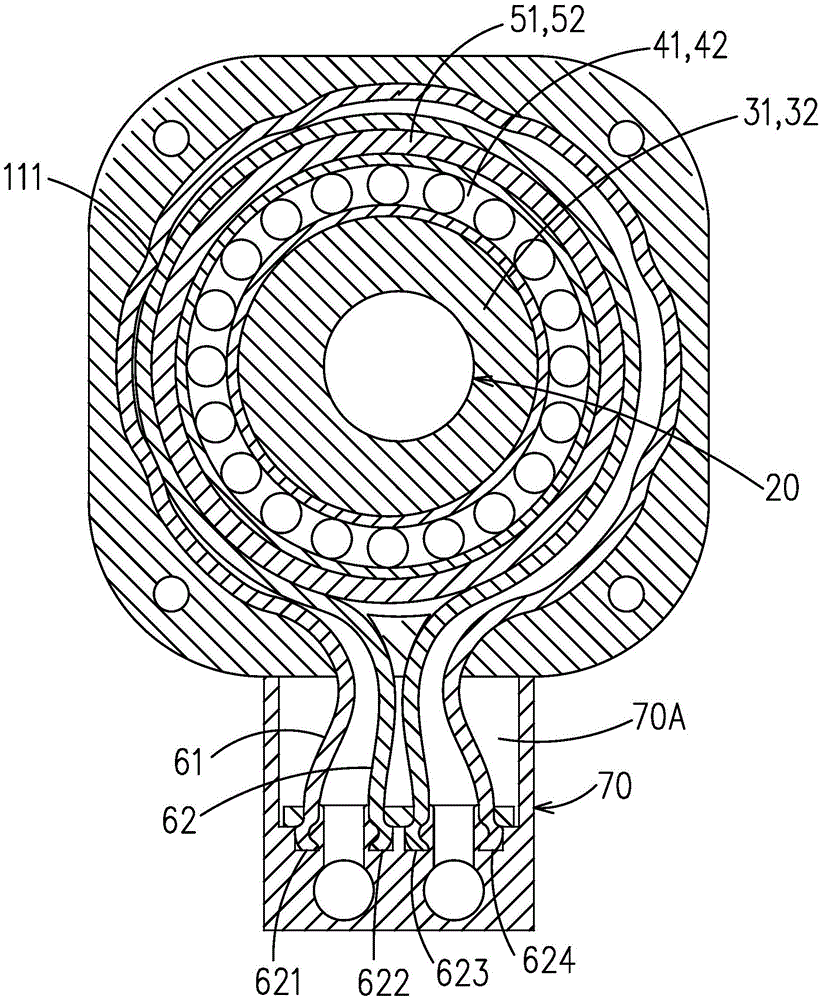

[0026] refer to Figure 1 ~ Figure 3 , The uniform motion pipeline pump 100 of the present invention includes a pump casing 10 , a central shaft 20 , eccentric wheels 31 , 32 , pressure wheels 51 , 52 , liquid pipes 61 , 62 and a filter joint 70 .

[0027] Such as Figure 1 ~ Figure 3 , the uniform motion pipeline pump 100 includes a steel pump casing 10. In this embodiment, the pump casing 10 is composed of a pump casing main body 12, a first end cover 13, and a second end cover 14. The structure of the first end cap 13 is as follows: Figure 10 As shown, there is a bearing hole 131 in its center, and a bearing 132 for supporting the central shaft 20 is fixed in the bearing hole 131, and a U-shaped groove 133 is arranged on the end surface of the opposite side of the pump casing main body 12, and O shaped seals,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com