Externally-engaged spherical gear pump

An external meshing and spherical tooth technology, applied in the field of hydraulic pumps, can solve the problems of unsatisfactory flow pulsation performance, small inter-tooth load, and low flow pulsation of involute gear pumps, so as to achieve small inter-tooth load and high gear meshing degree. , the effect of large output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

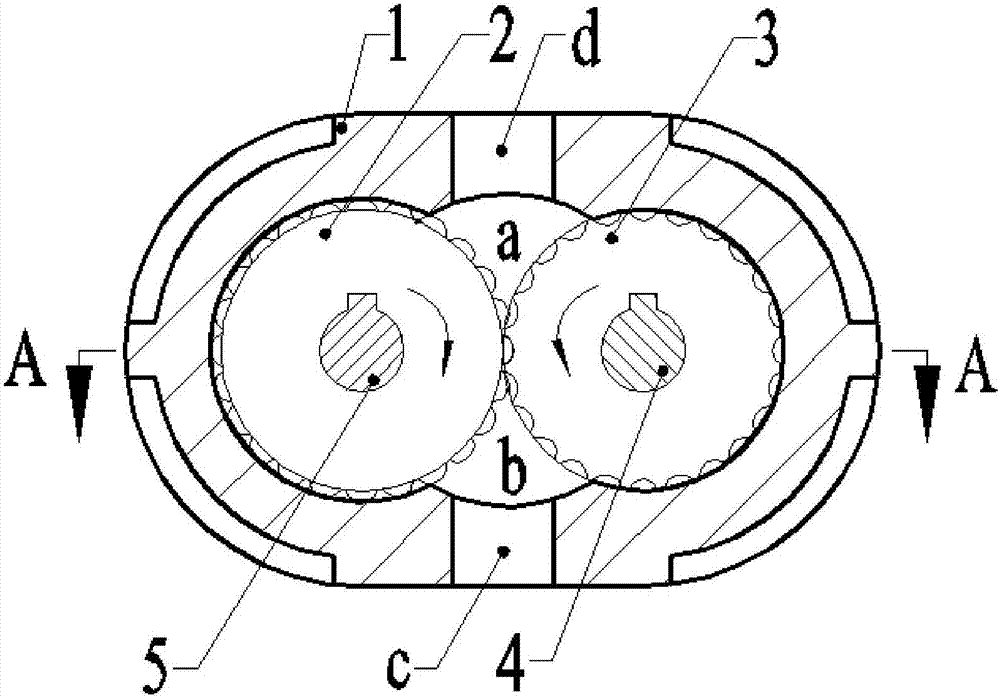

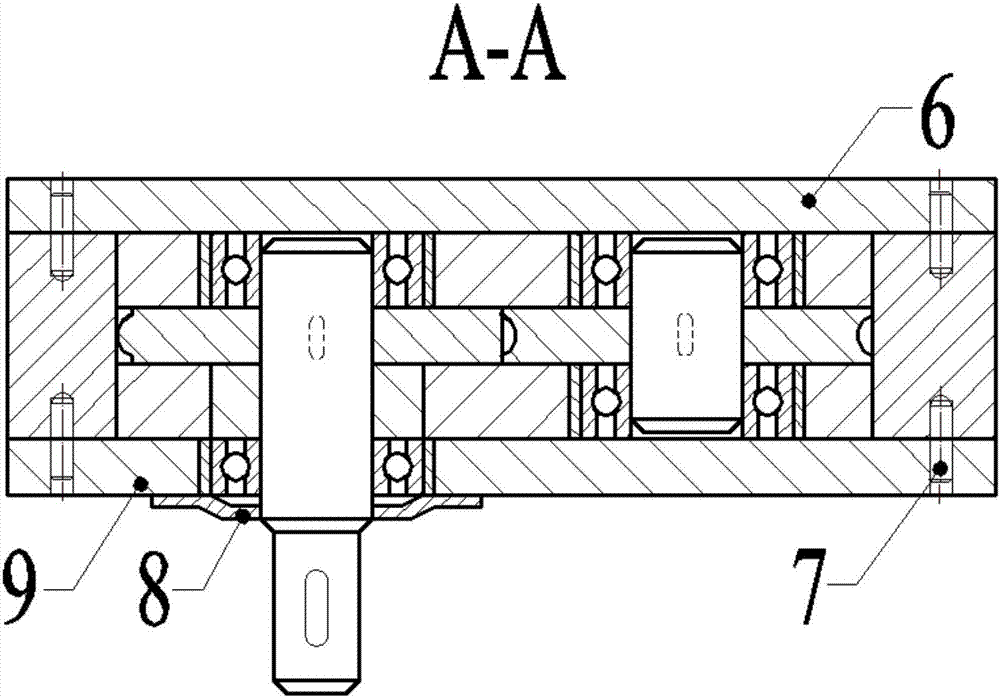

[0018] figure 1 with figure 2 One embodiment of the present invention is shown. The external meshing ball-tooth pump of the present invention consists of a pump body 1, a male gear 2, a female gear 3, a driven shaft 4, a driving shaft 5, a rear pump cover 6, a positioning pin 7, a bearing cover 8, a front pump cover 9, etc. composition. The main points of the structure are: the tooth profile of the male gear 2 is a convex spherical tooth, the tooth profile of the female gear 3 is a concave spherical tooth that meshes with the convex spherical tooth of the male gear 2, and the driving shaft 5 passes through the male The toothed gear 2 drives the male gear 2 to rotate through a key connection, and the driven shaft 4 passes through the female gear 3.

[0019] The outer shape of the pump body 1 is elliptical. The male gear 2 and the female gear 3 mesh wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com