Valve core of vane hydraulic motor controller

A hydraulic motor and controller technology, applied in the hydraulic field, can solve the problems of hydraulic reversing impact, large hydraulic clamping force, unreasonable matching clearance between valve core and valve body, and low control accuracy, so as to achieve balanced radial Effects of hydraulic pressure, prevention of reversing hydraulic clamping, and control of fluid noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

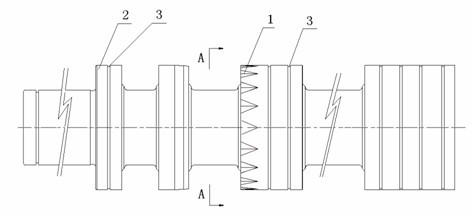

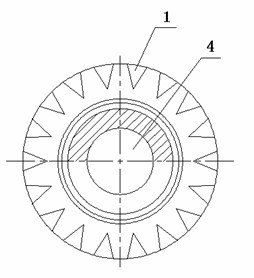

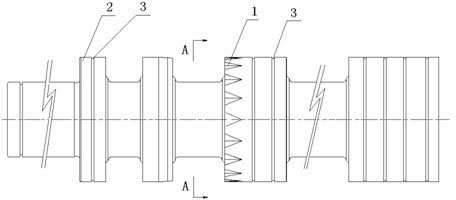

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] see figure 1 , the vane hydraulic motor controller spool of the present invention, the outer surface of the spool is provided with a triangular groove 1 along the radial direction, and the slope angle of the triangular groove 1 is 45 to 75 o , the number is 12 to 16. The triangular groove 1 is arranged on the controller spool, which can effectively reduce flow pulsation and control fluid noise. As the number of triangular grooves 1 increases, its functions of reducing flow pulsation and controlling fluid noise gradually increase, but when the number of triangular grooves 1 increases to a certain amount, the enhancement of its effect is very limited, and at the same time, the processing of the valve core is difficult And the structural cost is significantly increased, therefore, it is very important to set a reasonable number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com