Engine cleaning oil

A technology for cleaning oil and engine, which is applied in the field of engine cleaning oil, which can solve problems such as easy fire, incompleteness, and impact on safe driving, and achieve the effects of improving anti-rust and anti-wear functions, increasing protection functions, and extending the overhaul period

Active Publication Date: 2009-01-07

孙国中

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] During the use of engine lubricating oil, due to long-term working friction, high temperature oxidation will produce metal powder, colloid, impurities, moisture, fuel oil mixing and lubricating oil dilution, etc., so that the quality of lubricating oil will deteriorate and cannot be used

The long-term friction and wear of the engine will cause extremely serious losses to the engine. If it is not cleaned for a long time, it will cause damage to the engine and greatly affect the safe driving.

[0003] At present, there are several ways to clean the engine in China: 1. Clean with kerosene and diesel oil, which is easy to catch fire and is very dangerous; 2. Chemical cleaning. Chemical cleaning agents are corrosive to the engine and have a decomposition effect on lubricating oil; 3. Mechanical cleaning, not Thoroughly; 4. Disassemble the engine for cleaning, which takes a long time and costs a lot

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

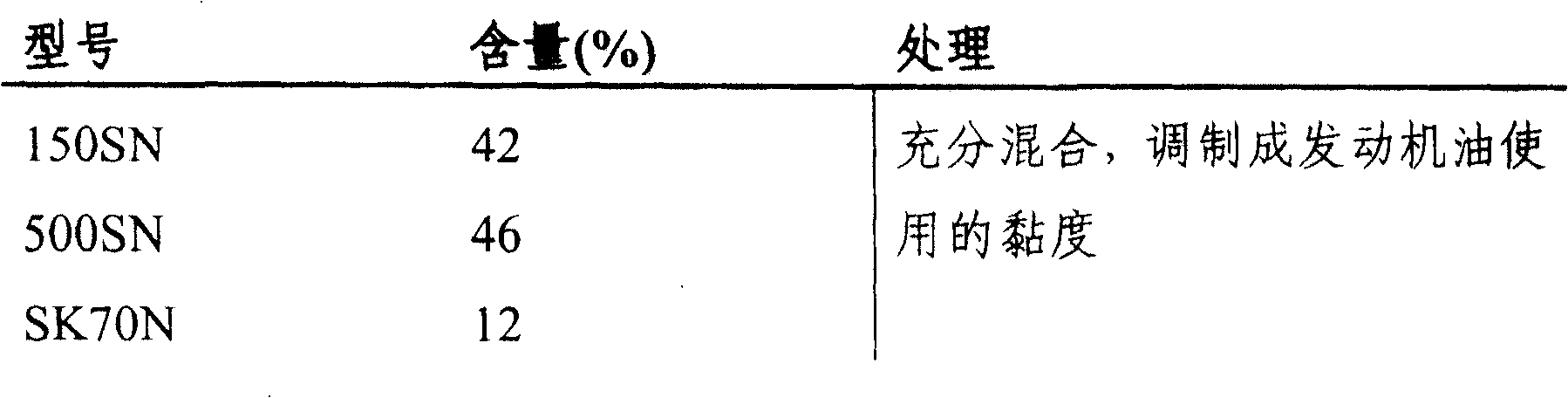

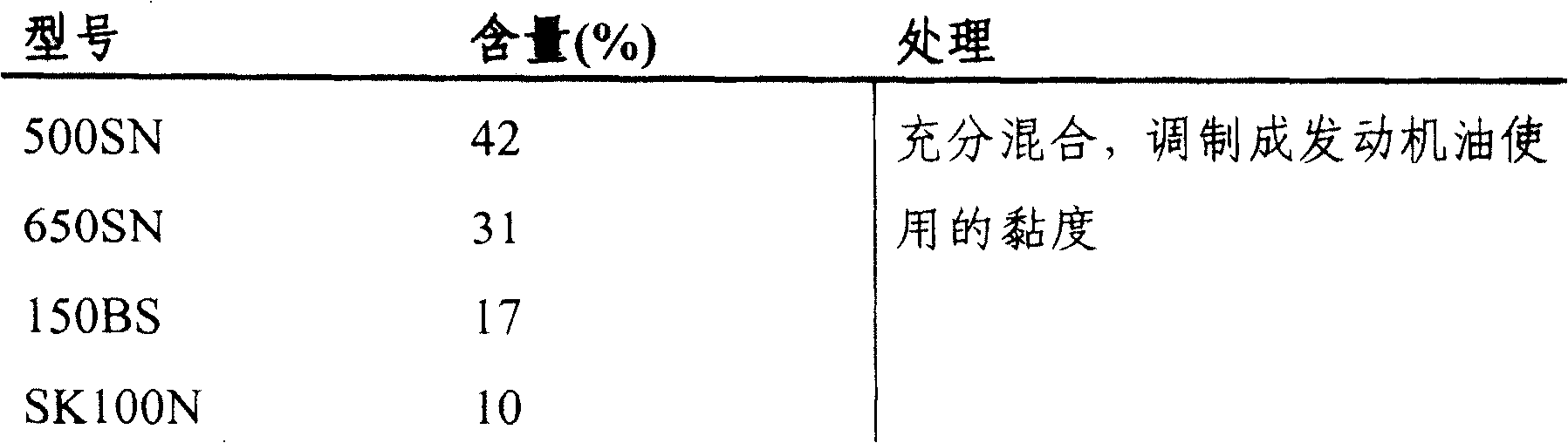

[0029] 1) Preparation of base oil

[0030]

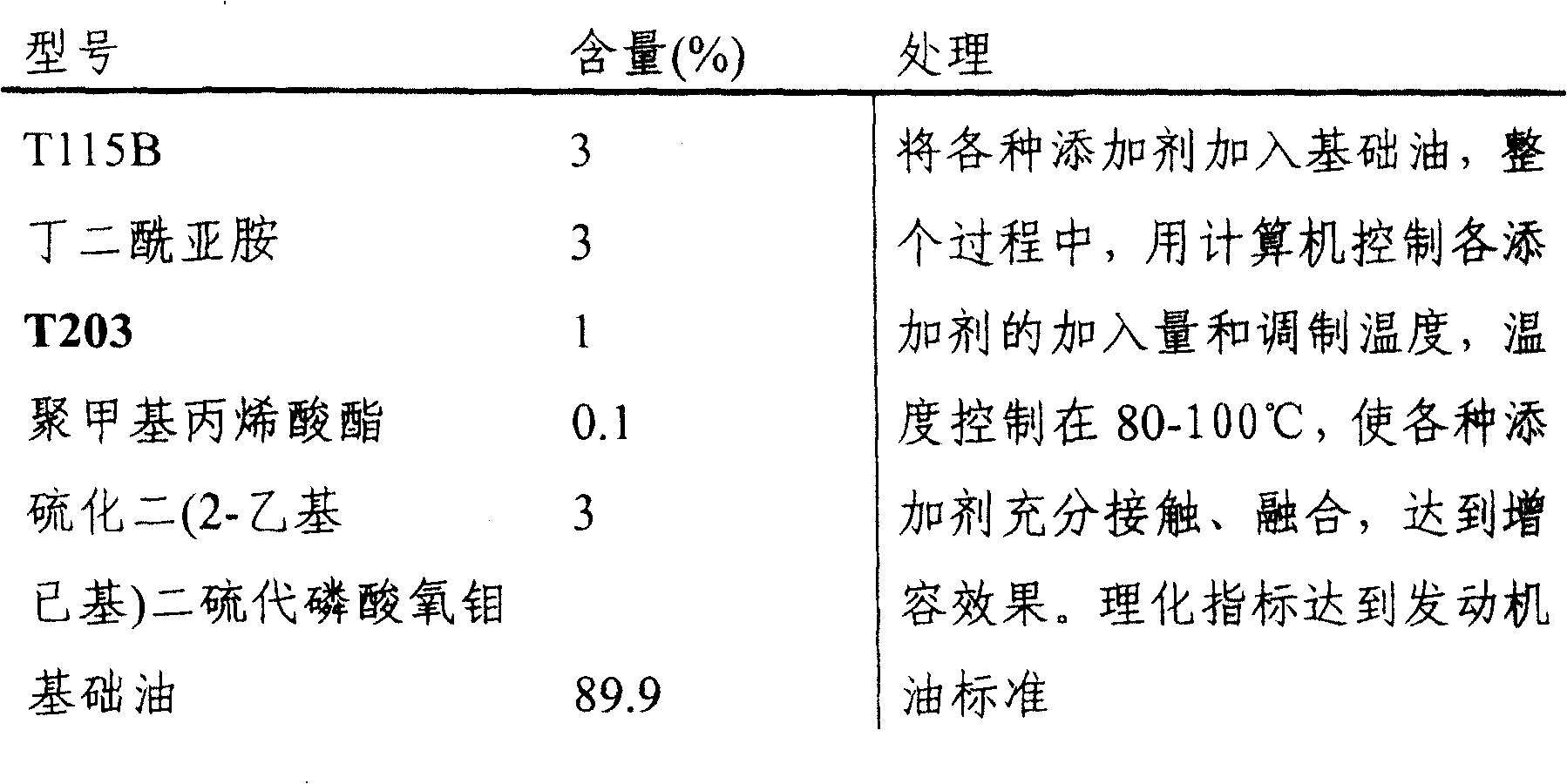

[0031] 2) Prepare finished cleaning oil

[0032]

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

This invention relates to new cleaning oil for engines, which is composed of one or many of ordinary motor-oils as the basic oil: 150SN, 500SN, 650SN, 150BS and advanced motor-oil from south Korea: SK70n, SK150N, and SK100N, anticorrosive, oxidation inhibitor, antiwear agent, detersive pour-point depressant and freely selected defoamer agent. In preparation, a computer is used to control the volume of the additives and the regulation temperature so that, they can fully contact with each other and interfuse with each other to get the target of the engine oil standard.

Description

【Technical field】 [0001] The invention relates to an engine cleaning oil. 【Background technique】 [0002] During the use of engine lubricating oil, due to long-term working friction, high temperature oxidation will produce metal powder, colloid, impurities, moisture, fuel oil mixing and lubricating oil dilution, etc., so that the quality of lubricating oil will deteriorate and cannot be used. The long-term friction and wear of the engine will cause extremely serious losses to the engine. If it is not cleaned for a long time, it will cause damage to the engine and greatly affect safe driving. [0003] At present, there are several ways to clean the engine in China: 1. Clean with kerosene and diesel oil, which is easy to catch fire and is very dangerous; 2. Chemical cleaning. Chemical cleaning agents are corrosive to the engine and have a decomposition effect on lubricating oil; 3. Mechanical cleaning, not Thoroughly; 4. Disassemble the engine for cleaning, which takes a long...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23G5/02

Inventor 孙国中

Owner 孙国中

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com