Gasoline engine

A gasoline engine and fuel oil technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of power reduction, difficult exhaust gas emission, waste of energy, etc., to achieve improved power conversion efficiency, reasonable piston movement, and reduced operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail with reference to the accompanying drawings, but are not limited by the embodiments.

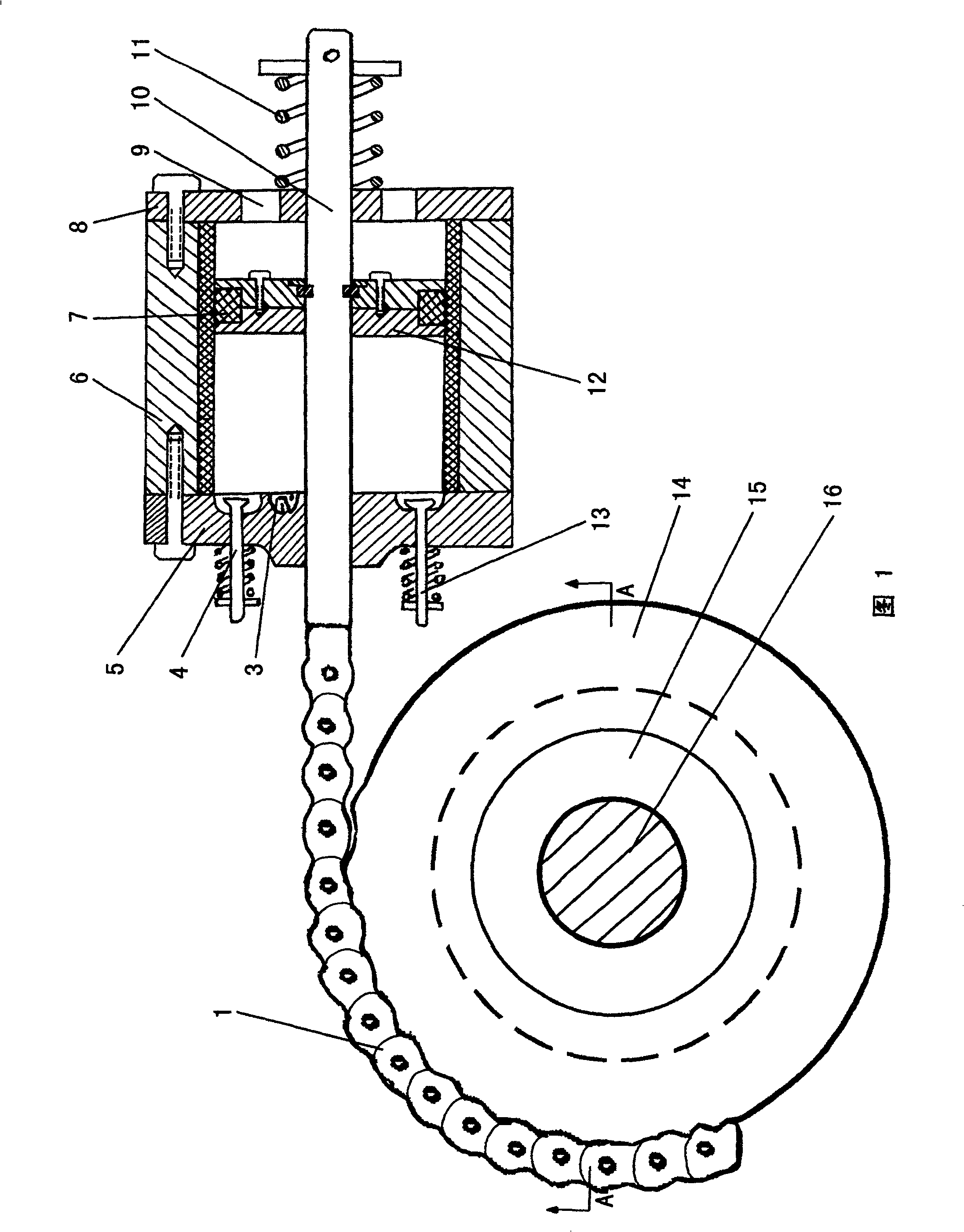

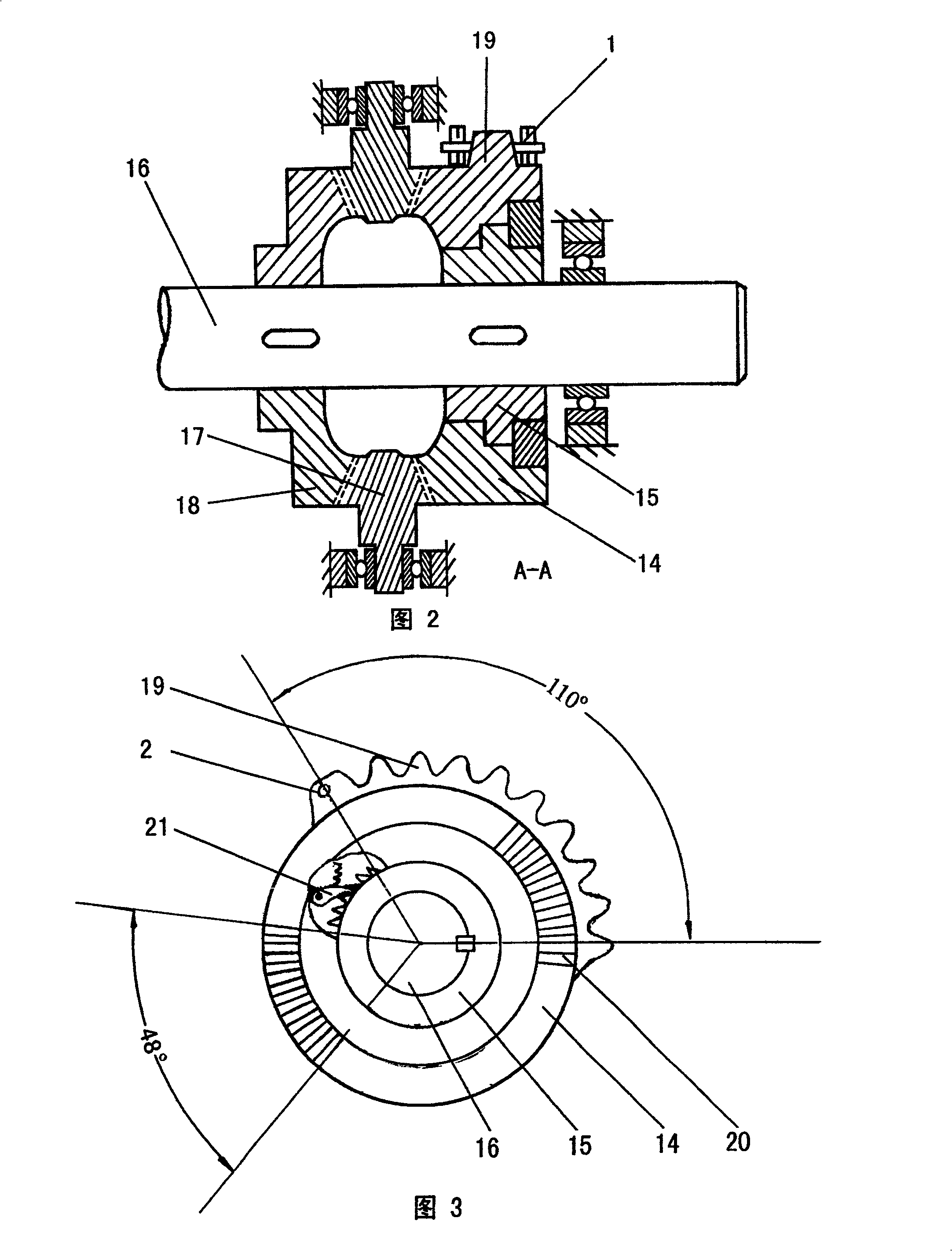

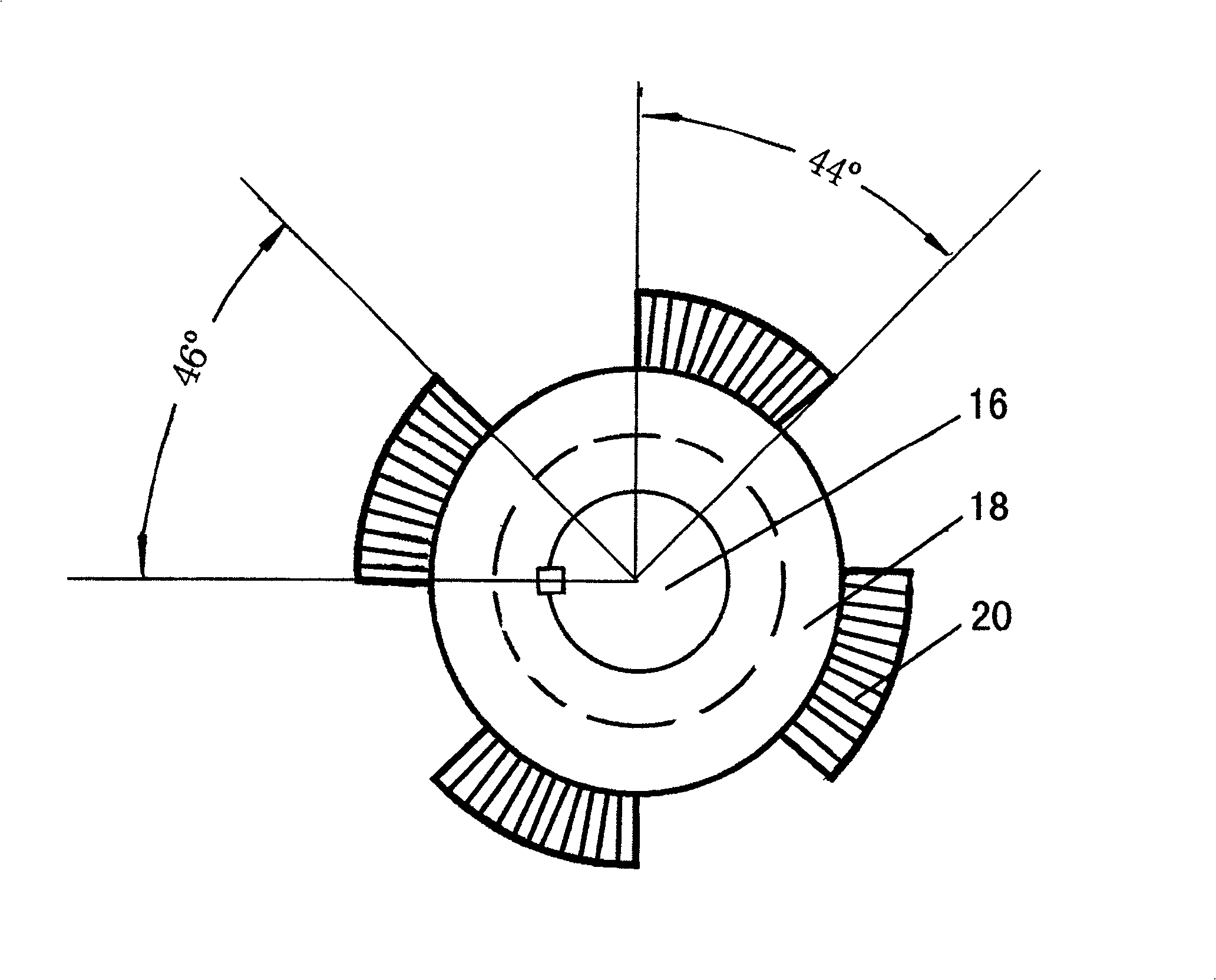

[0022] As shown in Fig. 1, it is a schematic diagram of the front view of the combination of the single cylinder and the main shaft in the present invention. The structure of the present invention is as follows: it is made up of fuel ignition system and camshaft, and one or four main transmission wheel assemblies and corresponding power cylinder 6 with main transmission wheel assembly are fixedly installed on the main shaft 16, and described main transmission wheel assembly passes through One end of the chain 1 fixed on the chain holder 2 is hinged with the piston rod 10 protruding from the power cylinder 6, and the power cylinder 6 is lined with a cylinder sleeve made of wear-resistant material, which is integrated with the piston rod 10 and has a piston ring The piston 12 of 7, one end is the cylinder head A5 that is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com