Patents

Literature

43results about How to "No lateral force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

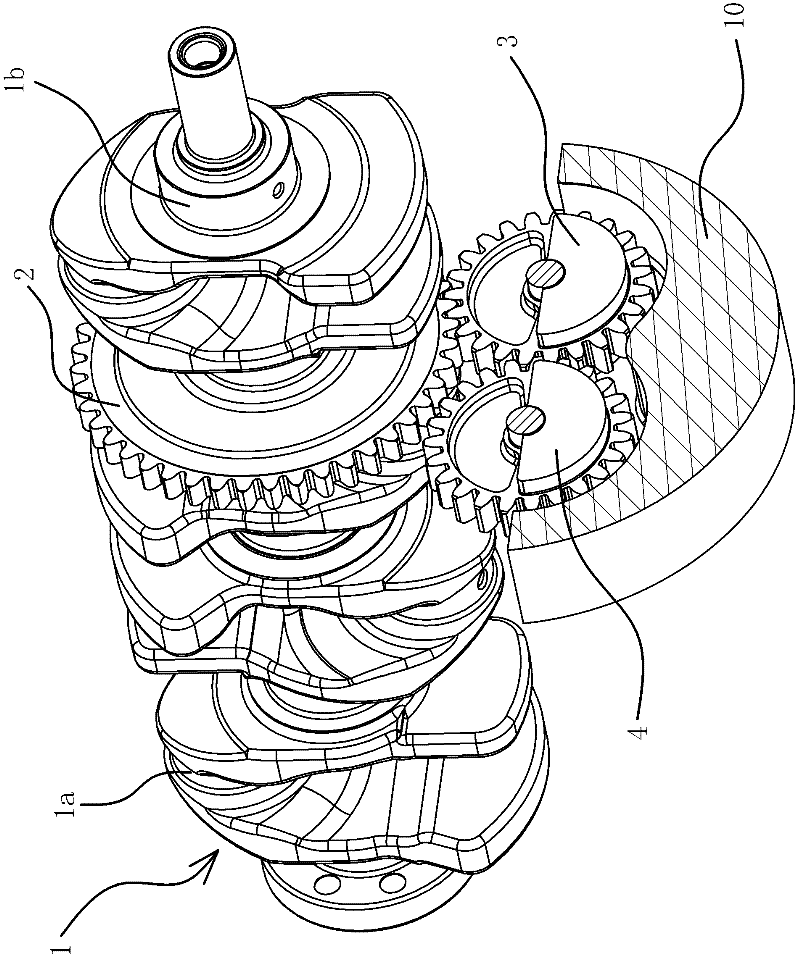

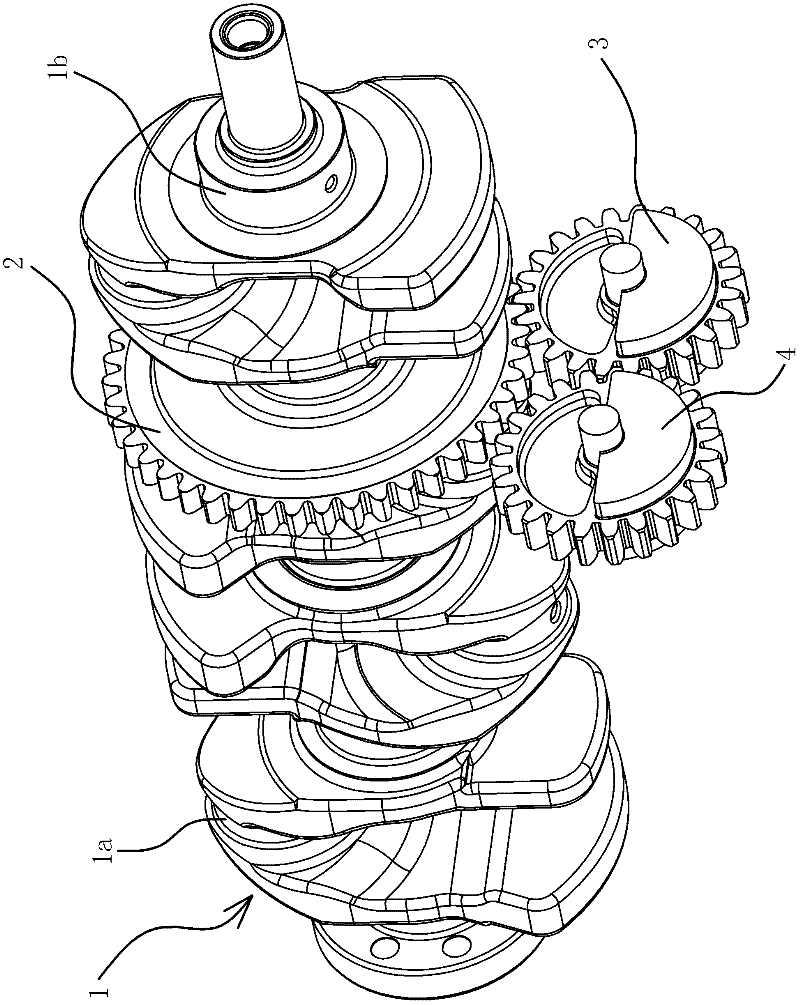

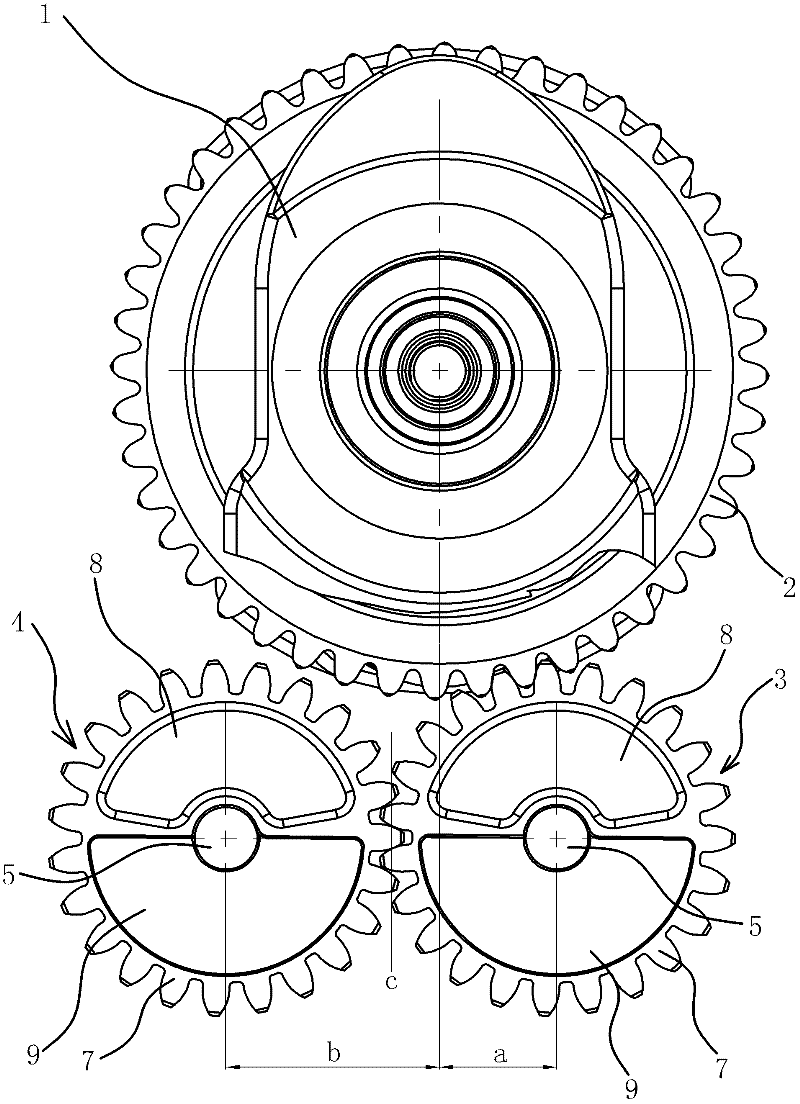

Double-shaft balance device of engine

InactiveCN102537205ANo lateral forceReduce axial sizeInertia force compensationMechanical engineering technologyEngineering

The invention provides a double-shaft balance device of an engine, which belongs to the technical field of mechanical engineering and resolves the technical problems of engine vibration and noise caused by vibration of the existing automobile. The double-shaft balance device of the engine comprises a driving gear fixed on a crank shaft and a first balance shaft and a second balance shaft which are arranged on the lateral side of the crank shaft and are parallel relative to a main journal of the crank shaft. The first balance shaft and the second balance shaft are respectively provided with a tooth portion, a shaft portion and a balance portion. The balance portion is arranged between the tooth portion and the shaft portion, and the weight of an area on one side of the balance portion relative to a radial line of the tooth portion is smaller than the weight of an area on the other side. The tooth portion of the first balance shaft is meshed with the tooth portion of the second balance shaft, and the tooth portion of the first balance shaft is meshed with the driving gear. The balance portion of the first balance shaft and the balance portion of the second balance shaft are symmetrically arranged relative to the meshing face of the first balance shaft and the second balance shaft. The double-shaft balance device facilitates integral machine arrangement and has the advantages of being compact in structure and small in size and saving cost.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

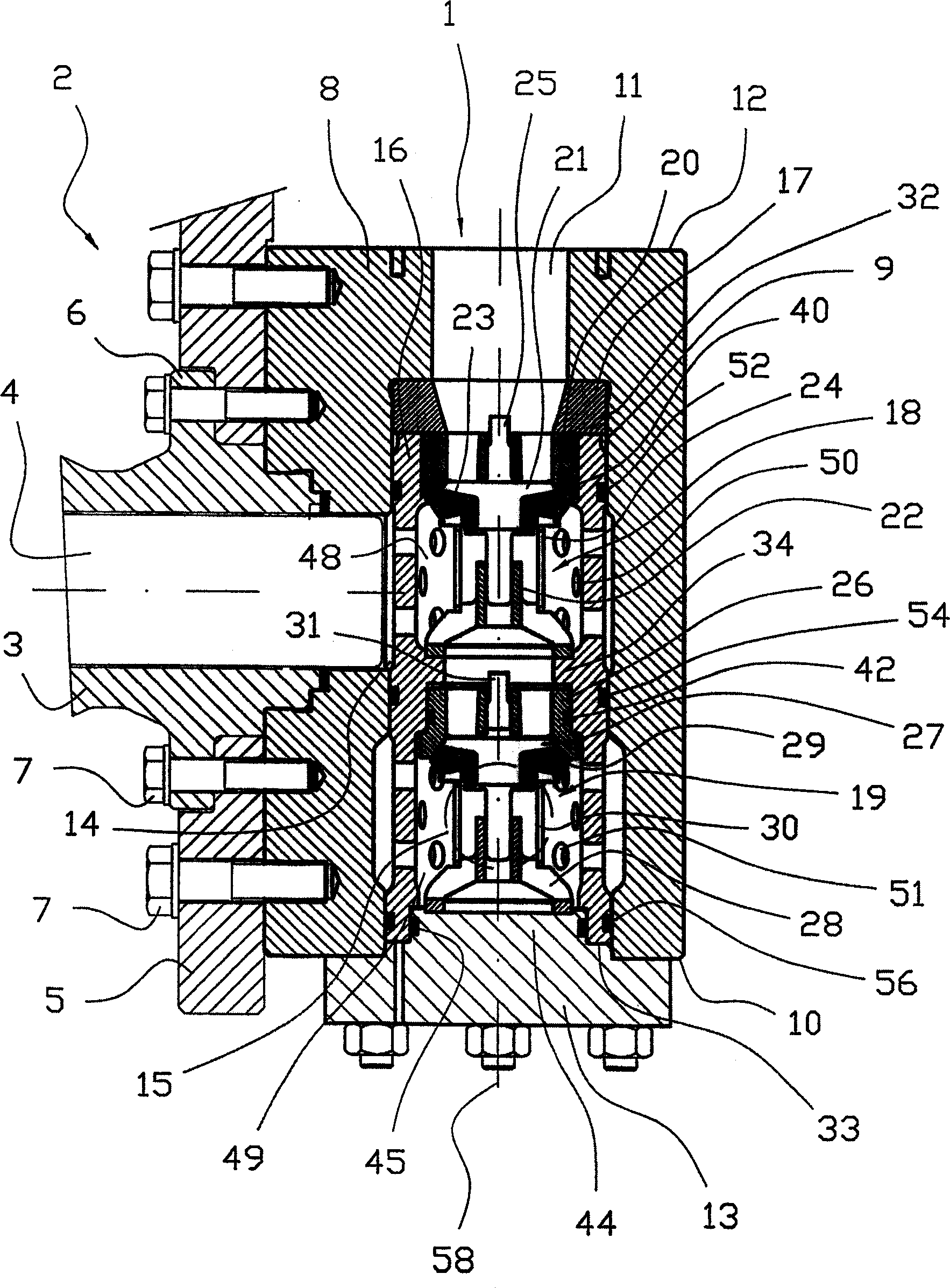

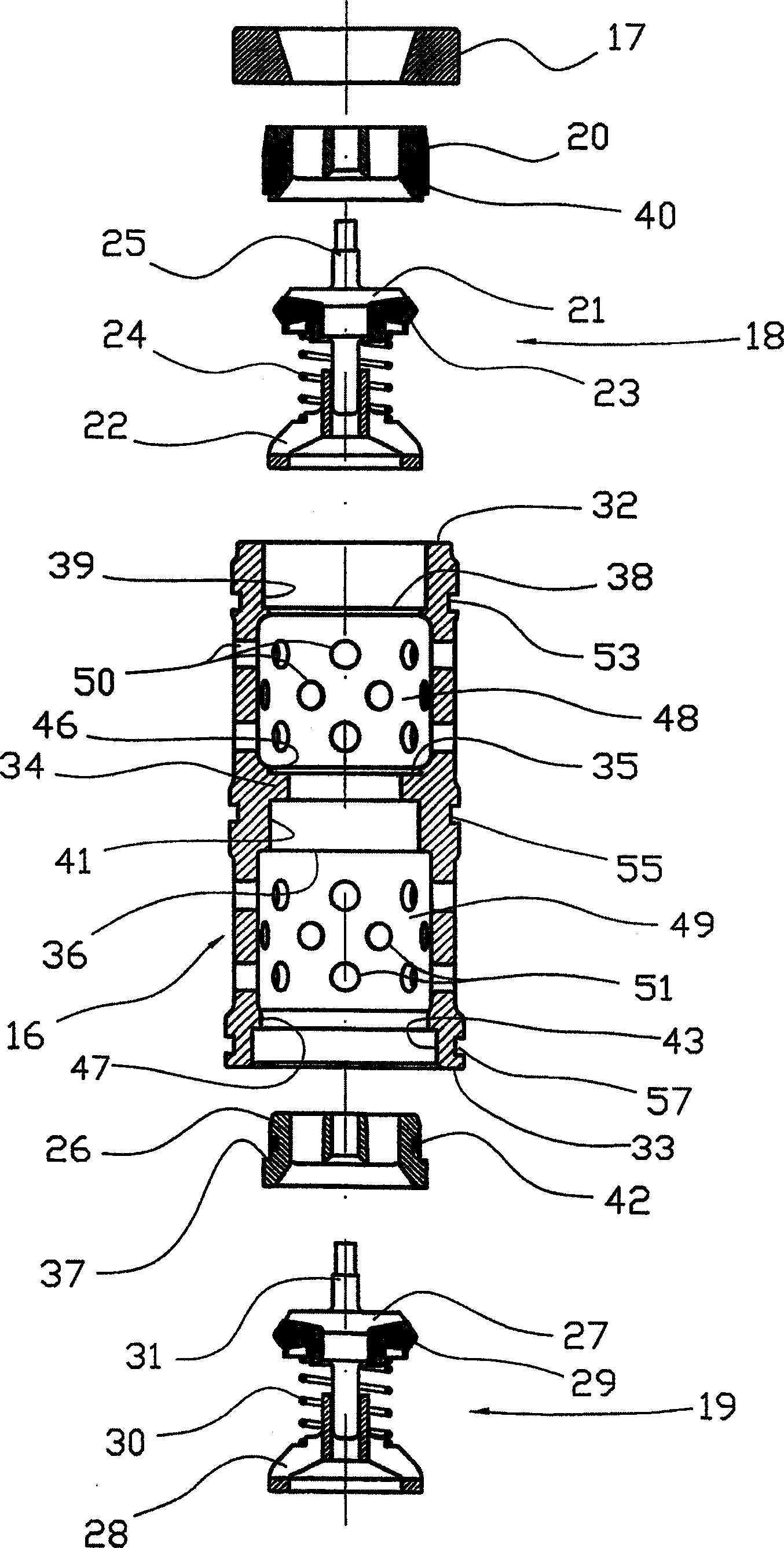

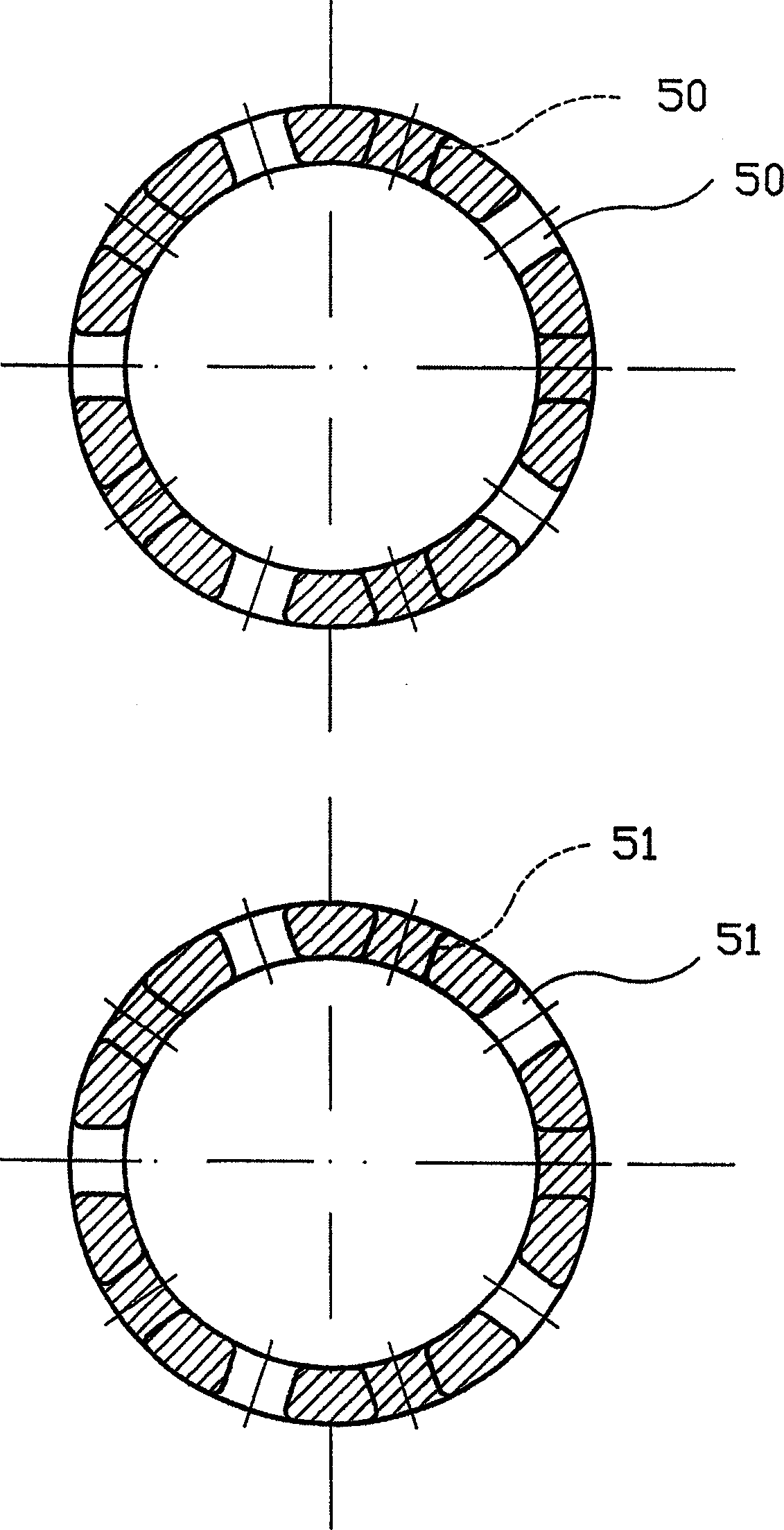

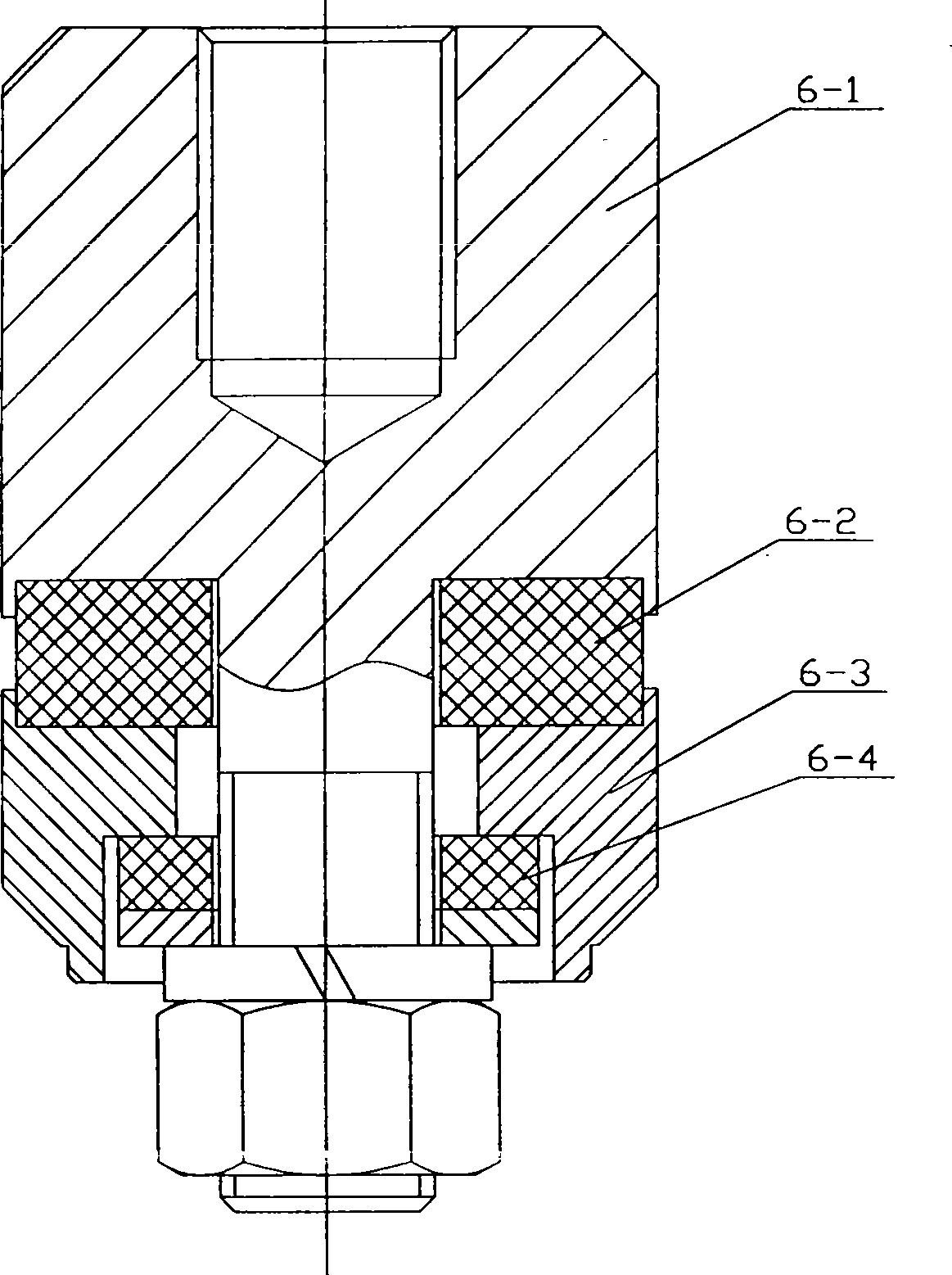

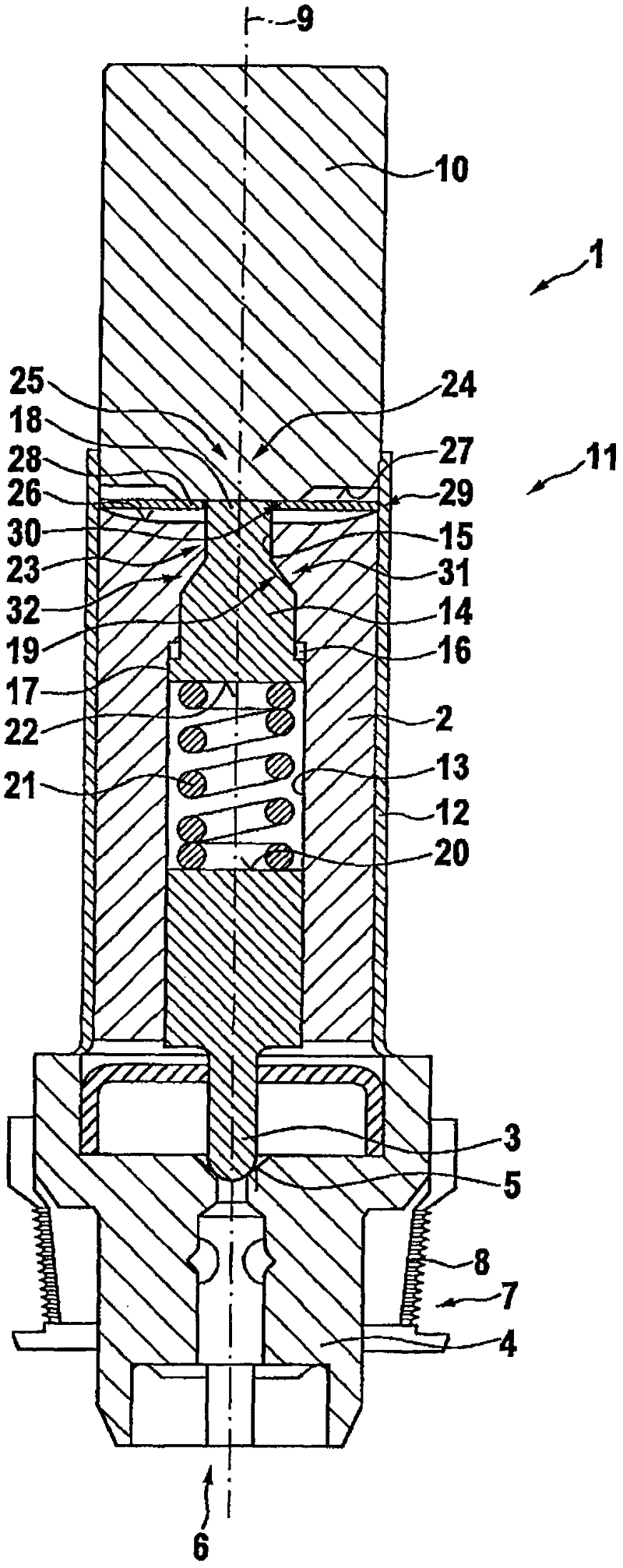

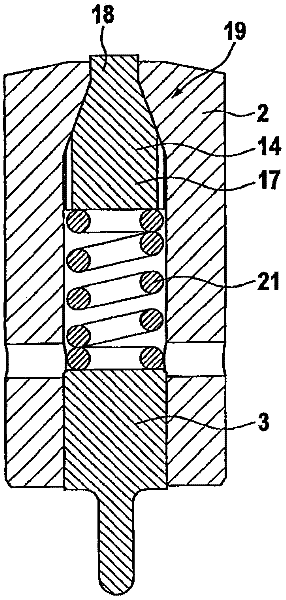

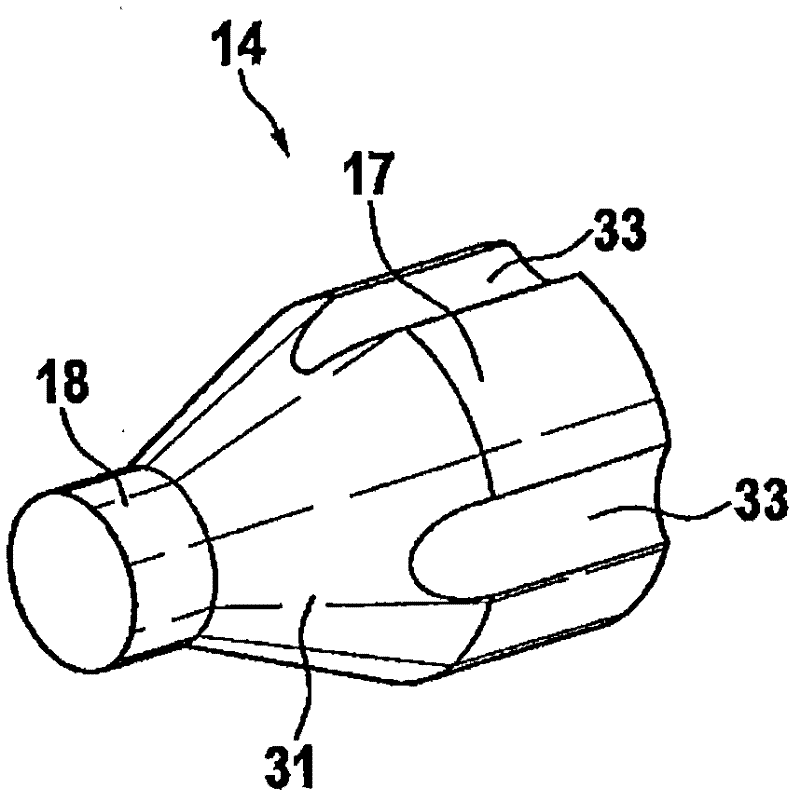

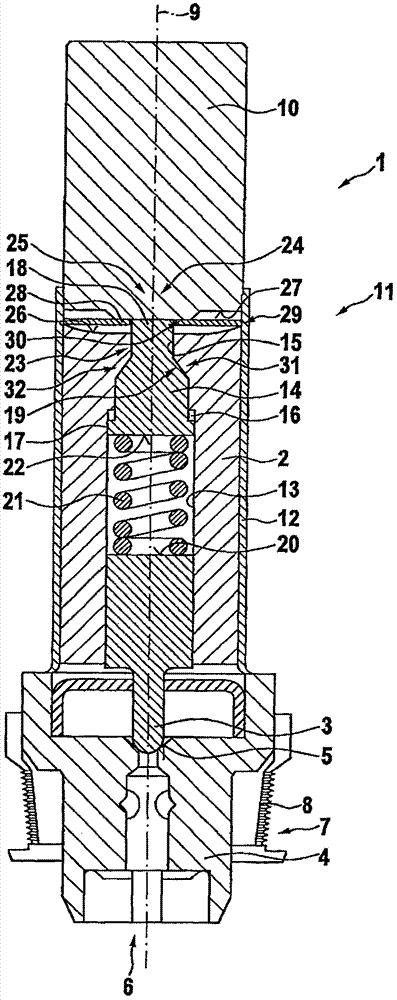

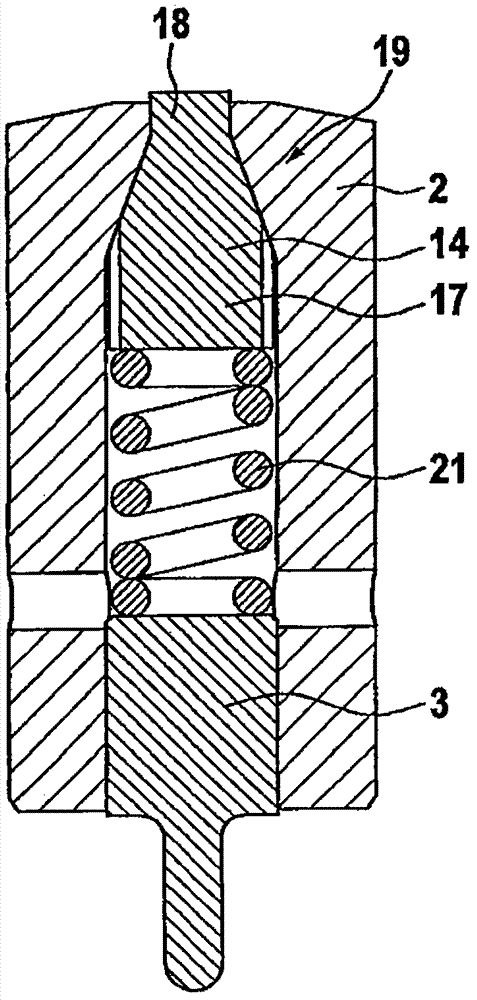

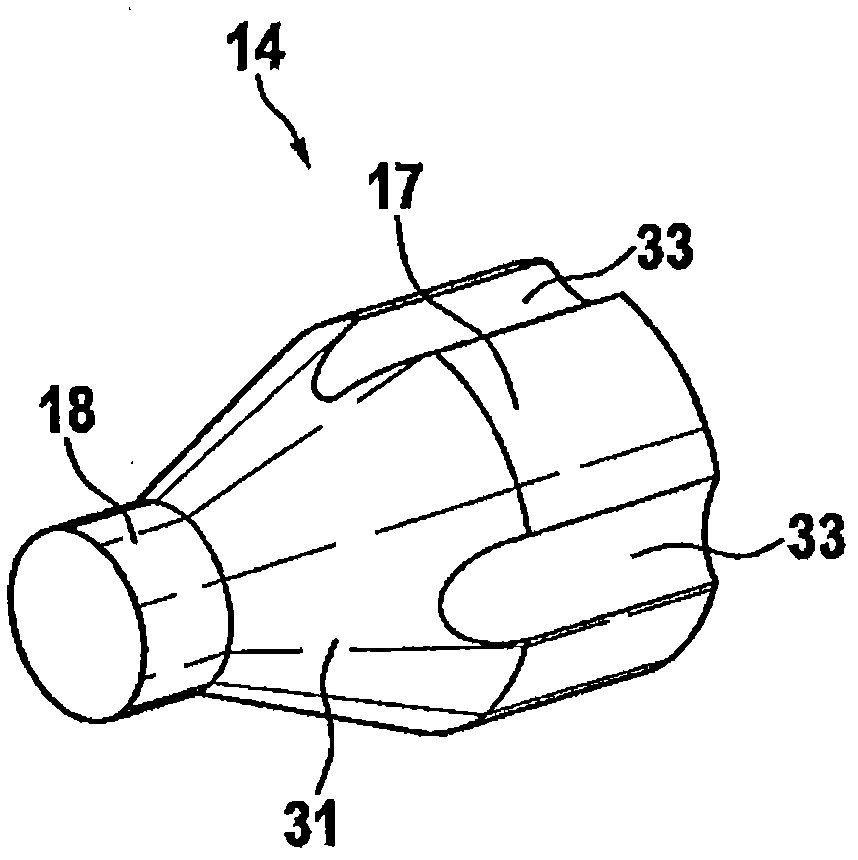

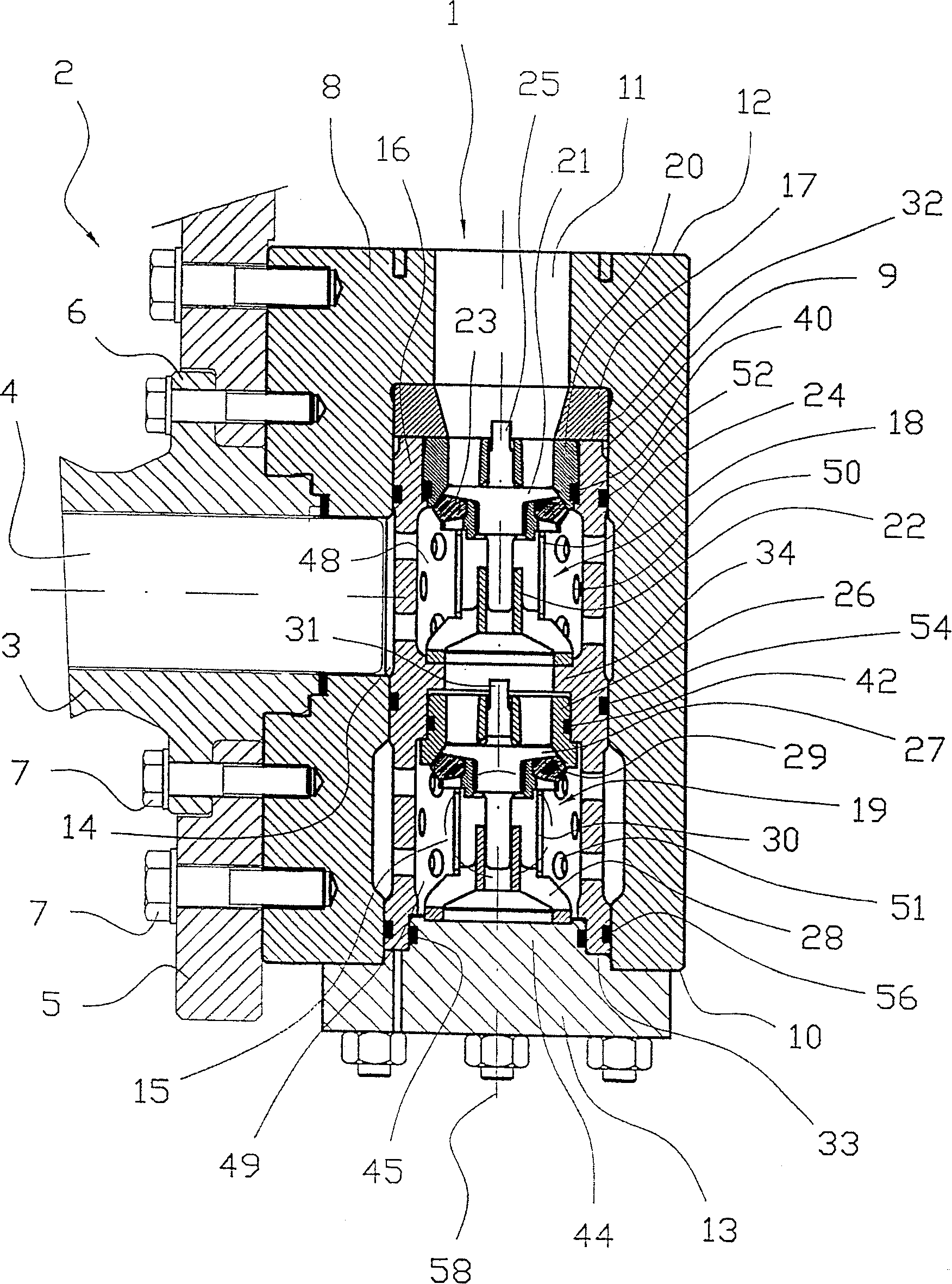

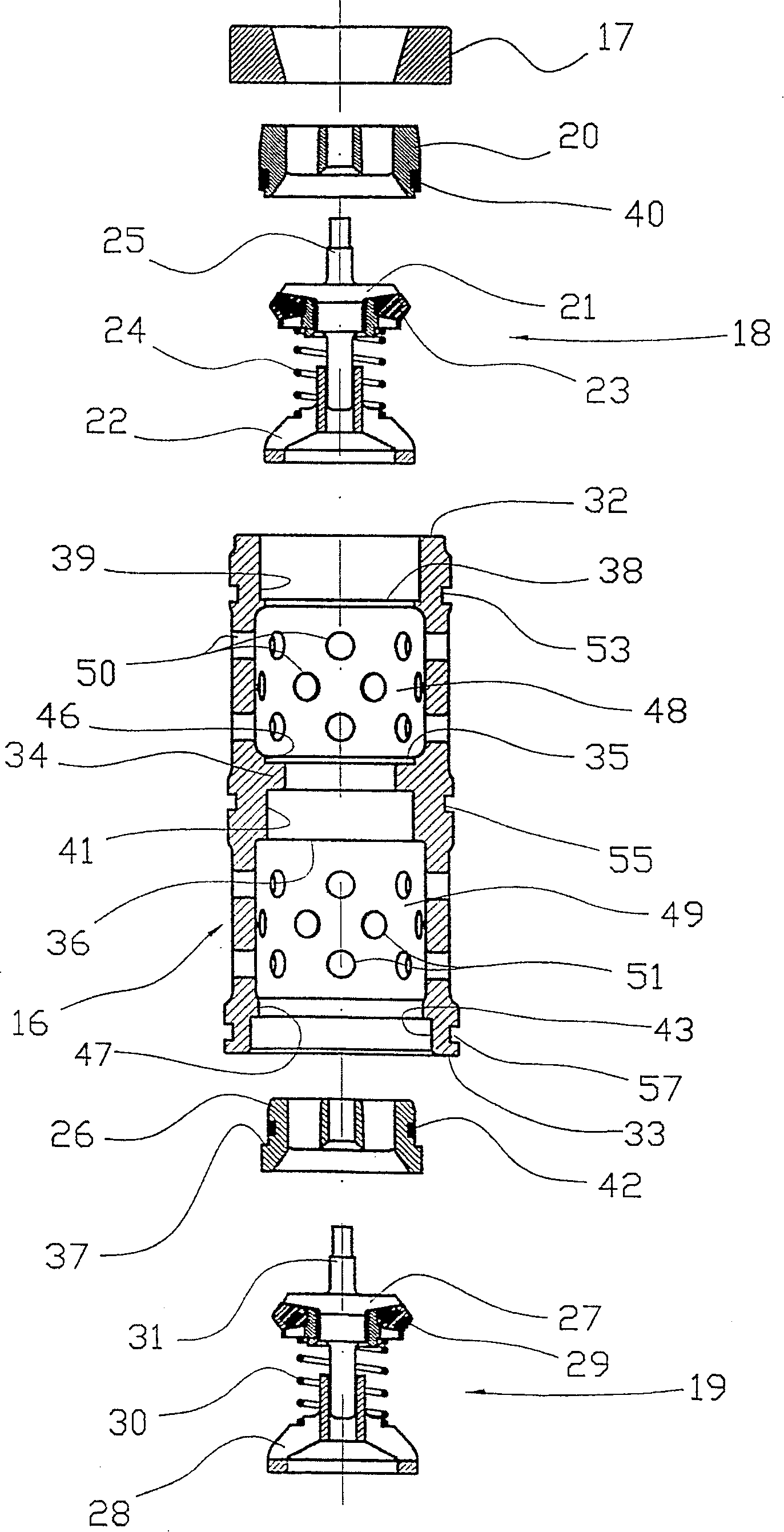

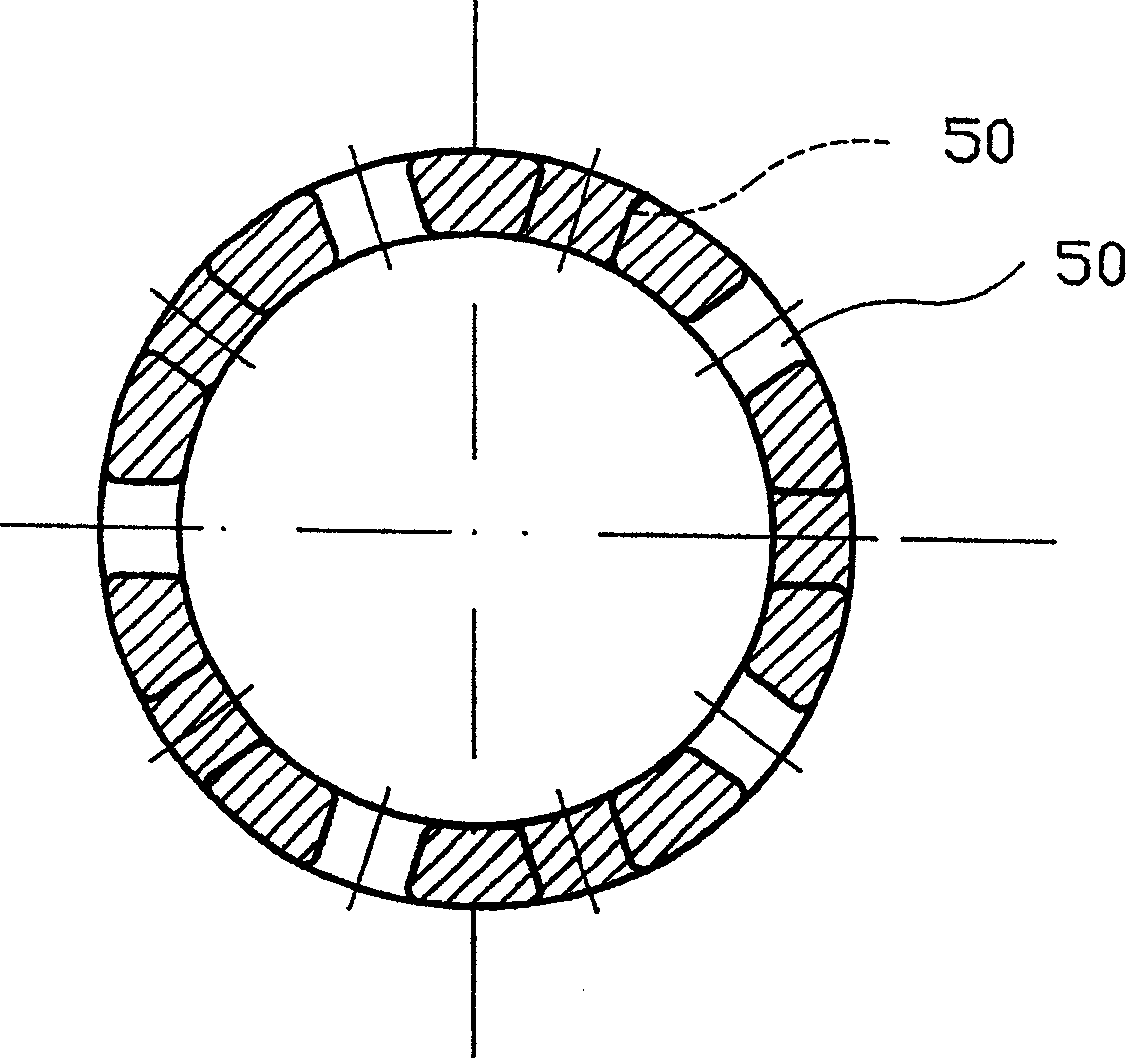

Valve arrangement for reciprocating machinery such as a pump and a compressor

InactiveCN1643257AEasy to installEasy to removePositive displacement pump componentsCheck valvesCylinder headEngineering

A valve arrangement for reciprocating machine, where the arrangement (1) comprises an in-valve (18) and an out-valve (19), each valve (18), (19) being a springloaded one-way valve designed to open for flow when the pressure differential in the direction of flow provides a force that exceeds the spring tension, wherein the valves (18, 19) are mounted in a casing (8) that forms or is connected to the cylinder head of the reciprocating engine (2). The in-valve (18) and the out-valve (19) are mounted in a sleeve (16) designed to be fitted in a bore (9) in the casing (8), and where fluid may flow to the sleeve (16) from an inlet (11) in the casing (8) and into the sleeve (16) via the in-valve (18), and where the sleeve (16) is provided with at least one perforated area where fluid may flow radially out of or into the sleeve (16) via holes (50, 51), thereby flowing to or from a passage (14, 15) that forms a perpendicular or near perpendicular connection with the bore (9).

Owner:NAT OILWELL NORWAY

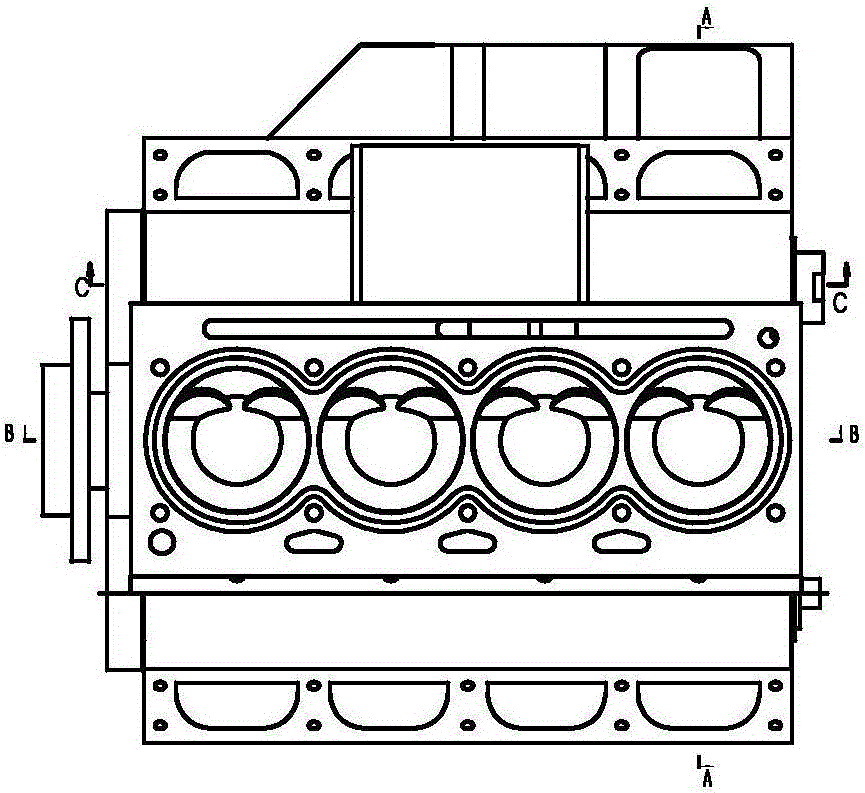

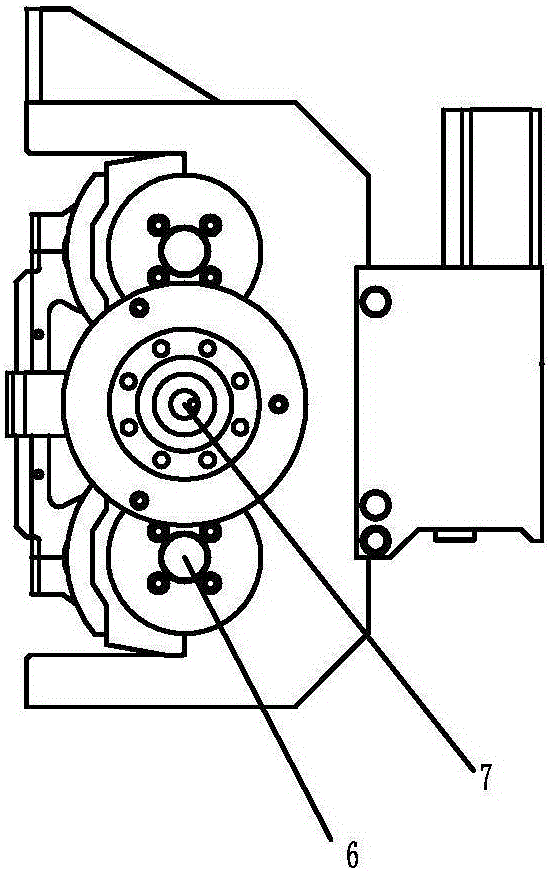

Double-crankshaft engine

ActiveCN105927380AReduce toughnessReduce manufacturing costCasingsConnecting rodsPiston GuideCylinder block

The invention discloses a double-crankshaft engine and belongs to the technical field of engines. The double-crankshaft engine comprises a piston and two crankshafts forming a double-crankshaft mechanism, and further comprises a cylinder block. The cylinder block comprises an air cylinder block part and a crankshaft supporting part. A piston guide rod is arranged at the lower end of the piston, the cylinder block is internally provided with a piston rod guide groove, the lower end of the piston is open and is provided with a piston end cover, and the piston end cover and the piston guide rod are detachably and fixedly connected; and the piston is a skirt-free piston with the piston guide end and the piston seal end separated, the piston seal end is a piston head, and the piston guide end is provided with the piston guide rod and the piston rod guide groove. The double-crankshaft engine is good in manufacturability, the piston is designed through isostress, strength is increased, abrasion-resisting design is adopted in a connecting part of a connecting rod and the piston, and the abrasion resisting performance and the reliability of the whole engine are improved.

Owner:XUZHOU XIAN BO ENGINE MACHINERY TECH CO LTD

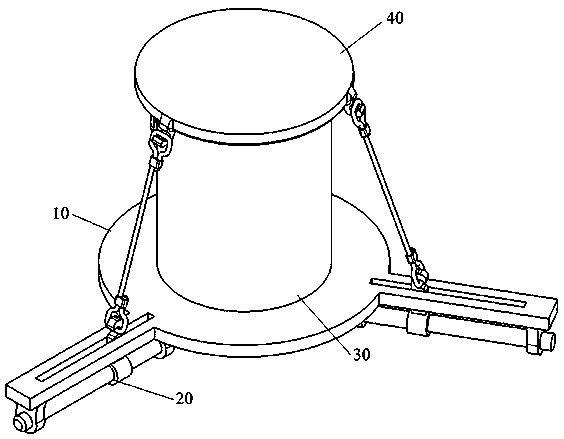

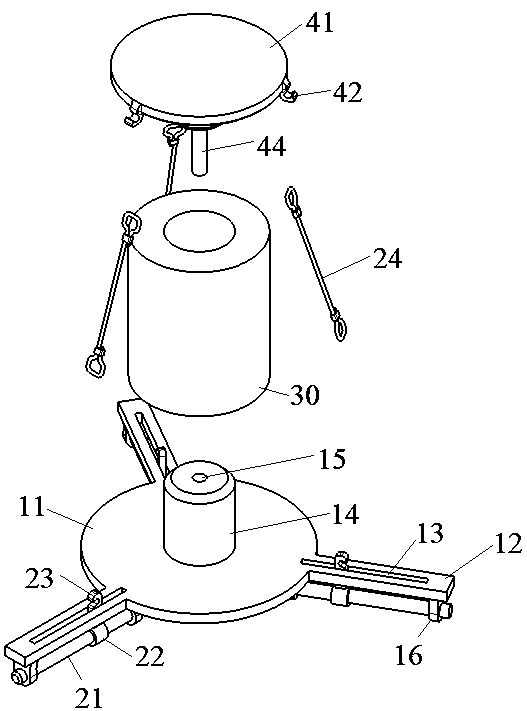

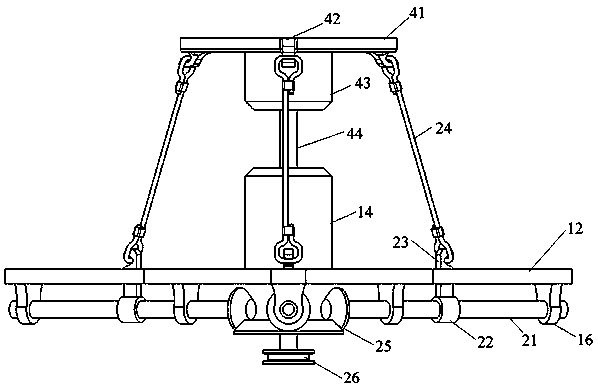

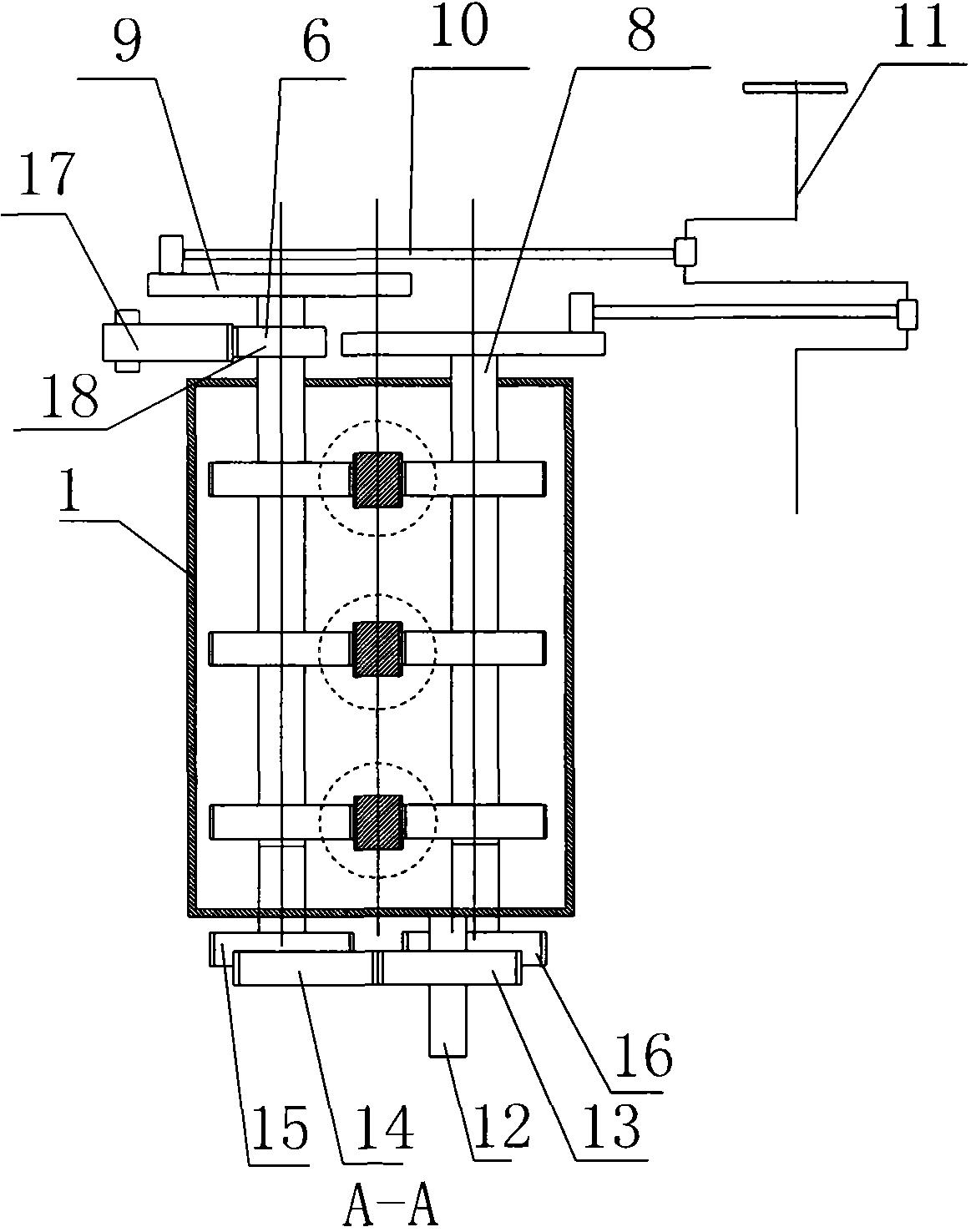

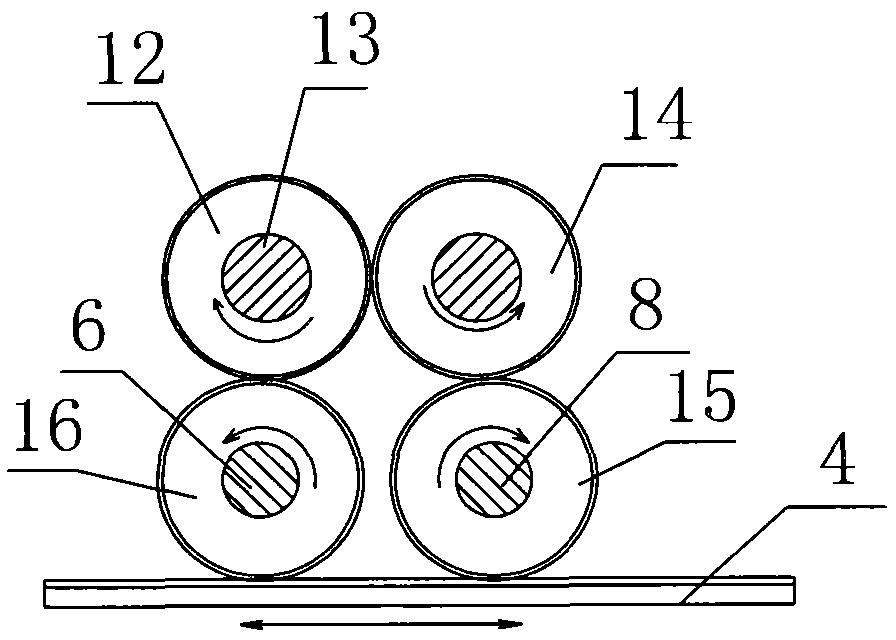

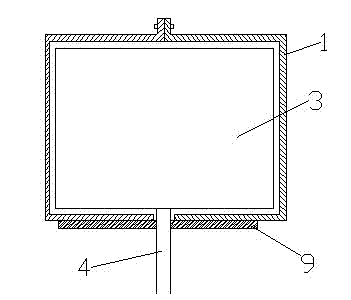

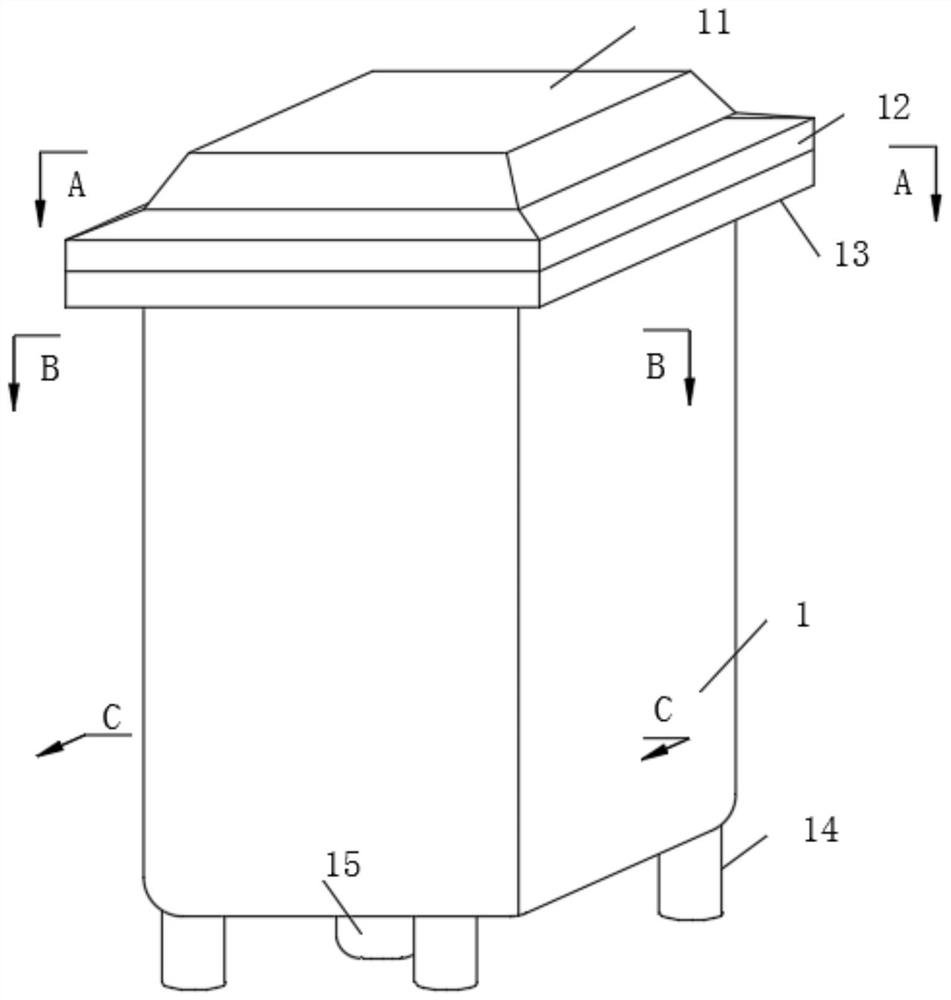

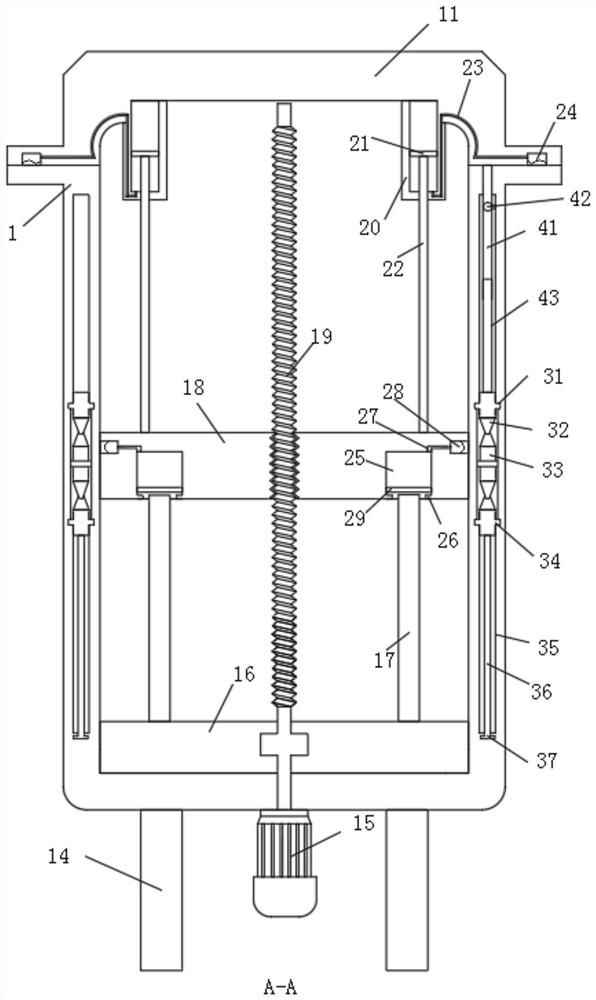

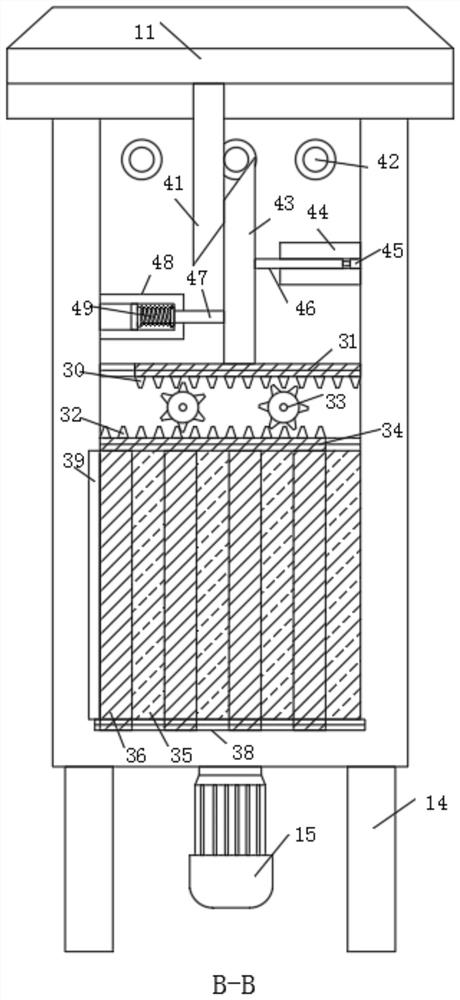

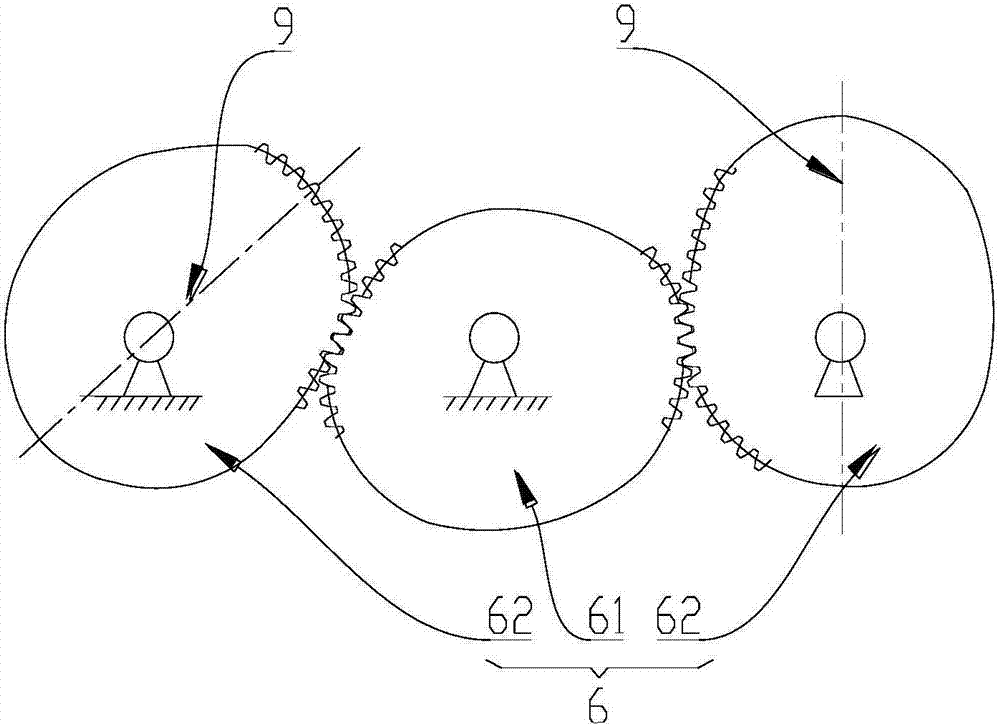

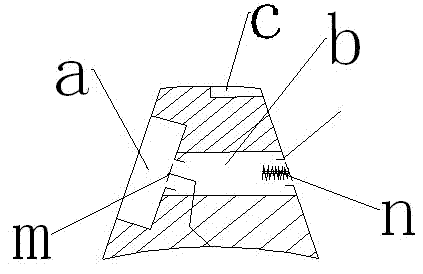

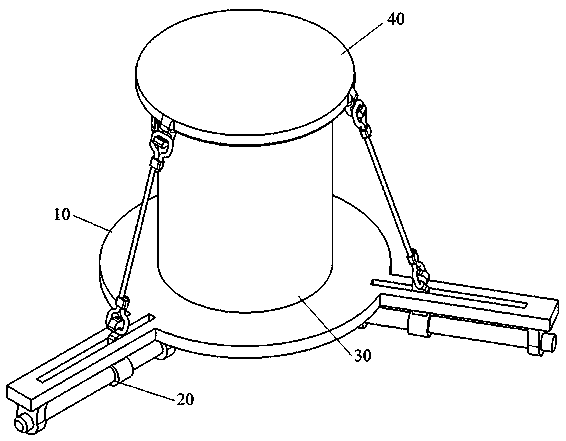

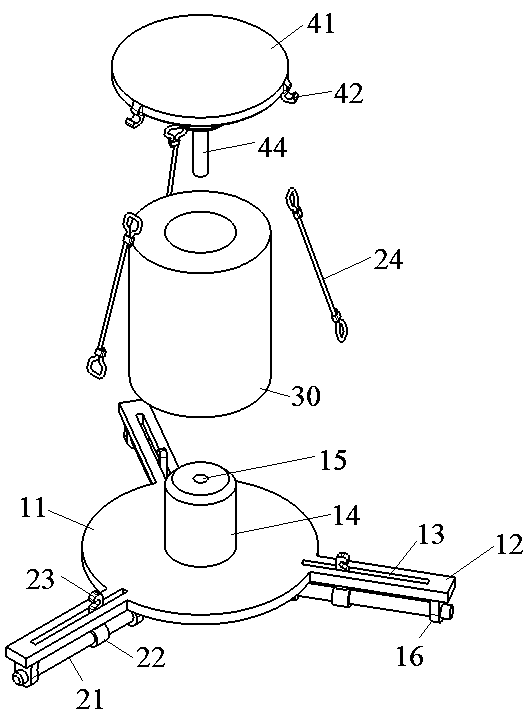

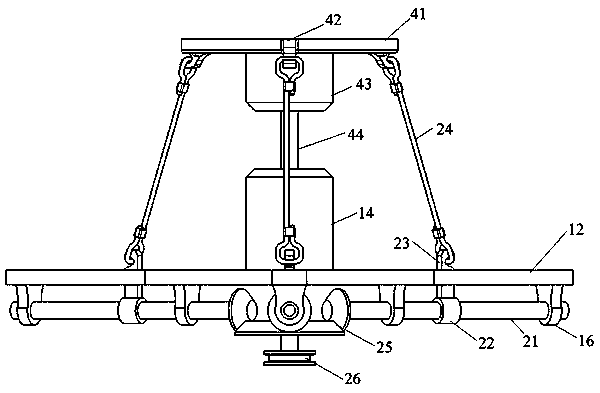

Coil-pressing device

The invention discloses a coil pressing device, and belongs to the technical field of transformer production, which includes a support portion, a drive portion and a pressing portion; The support portion includes a base, a cross beam, a chute and a lug; a lateral beam extends circumferentially outwardly of that base, the cross beam is provided with a sliding groove penetrating the cross beam, a pair of lugs are arranged below the cross beam, and the transmission part comprises a screw, a sliding block, a lower hook, a steel cable, a bevel gear and a pulley; the screw is installed on the lugs of the support part, a sliding block is installed on the screw, the sliding block and the screw are threadably matched, the sliding block is connected with the lower hook, and the lower hook is exposedabove the cross beam through the sliding groove of the support part. The steel cable is connected to the lower hook and the upper hook of the pressing part, the screw extends to the center below thebase, the inner side end of the screw has a bevel gear, the pressing part includes a top cover and an upper hook, the top cover is installed above the coil, and the top cover peripheral ring has an upper hook.

Owner:JIANGXI YAWEI ELECTRIC

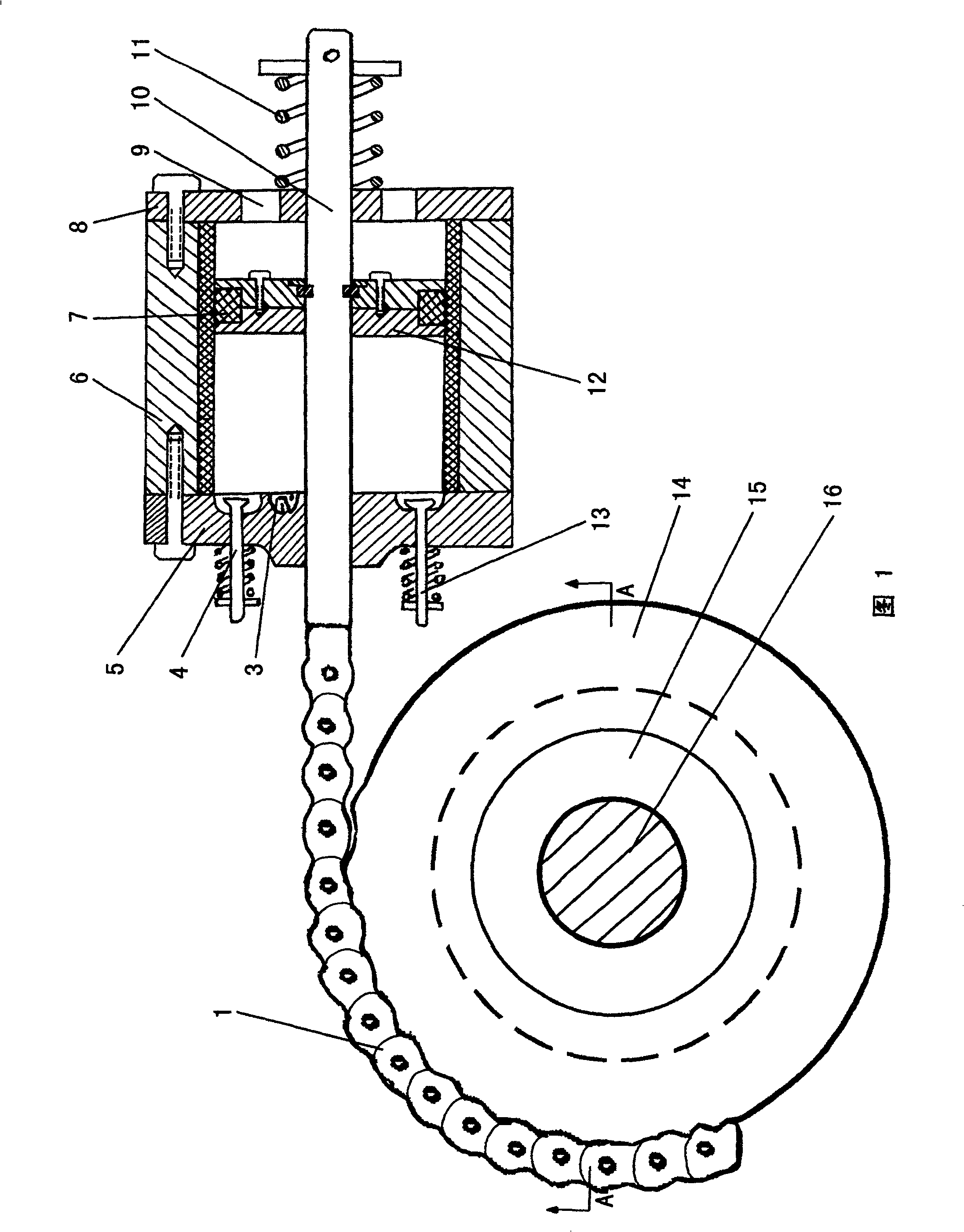

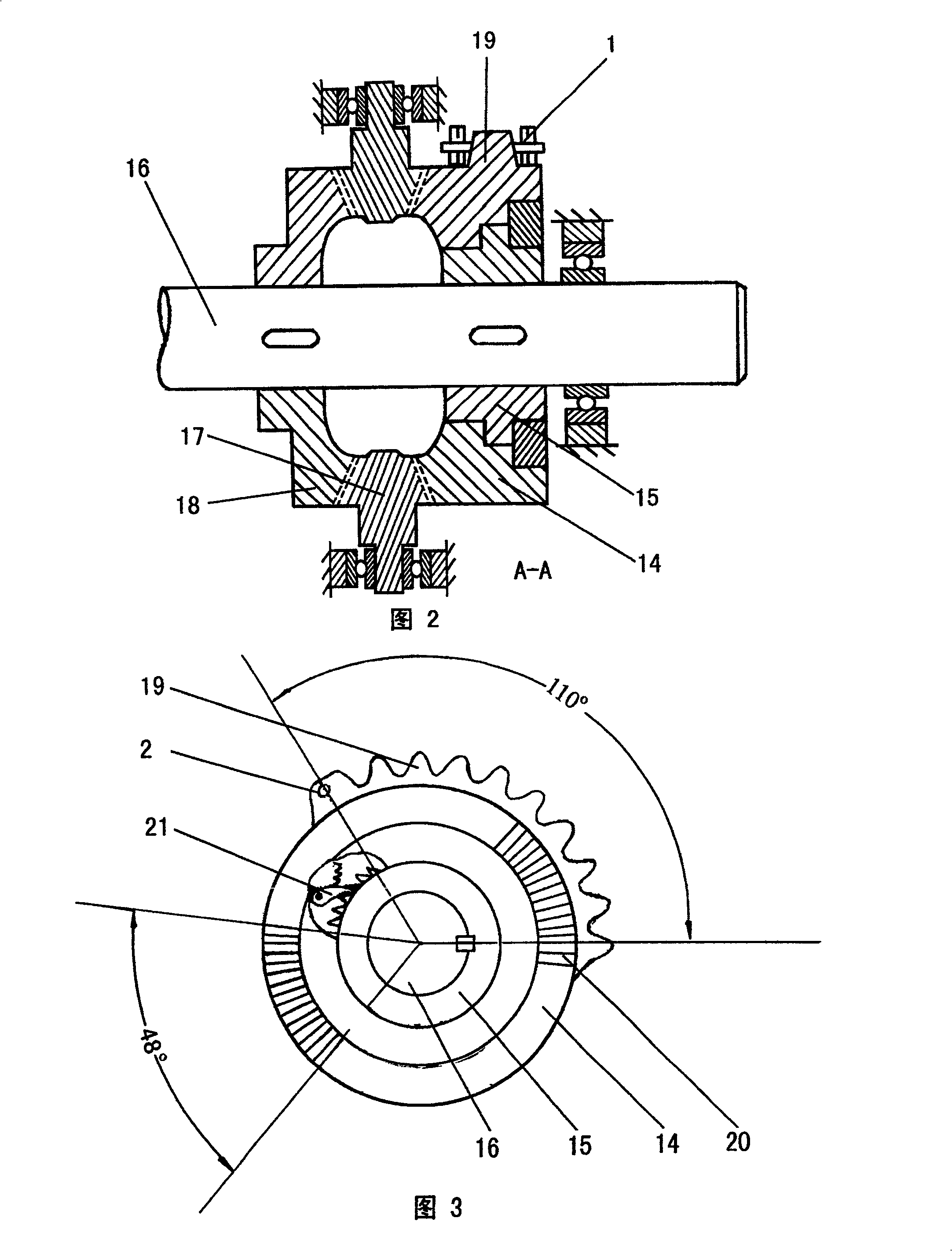

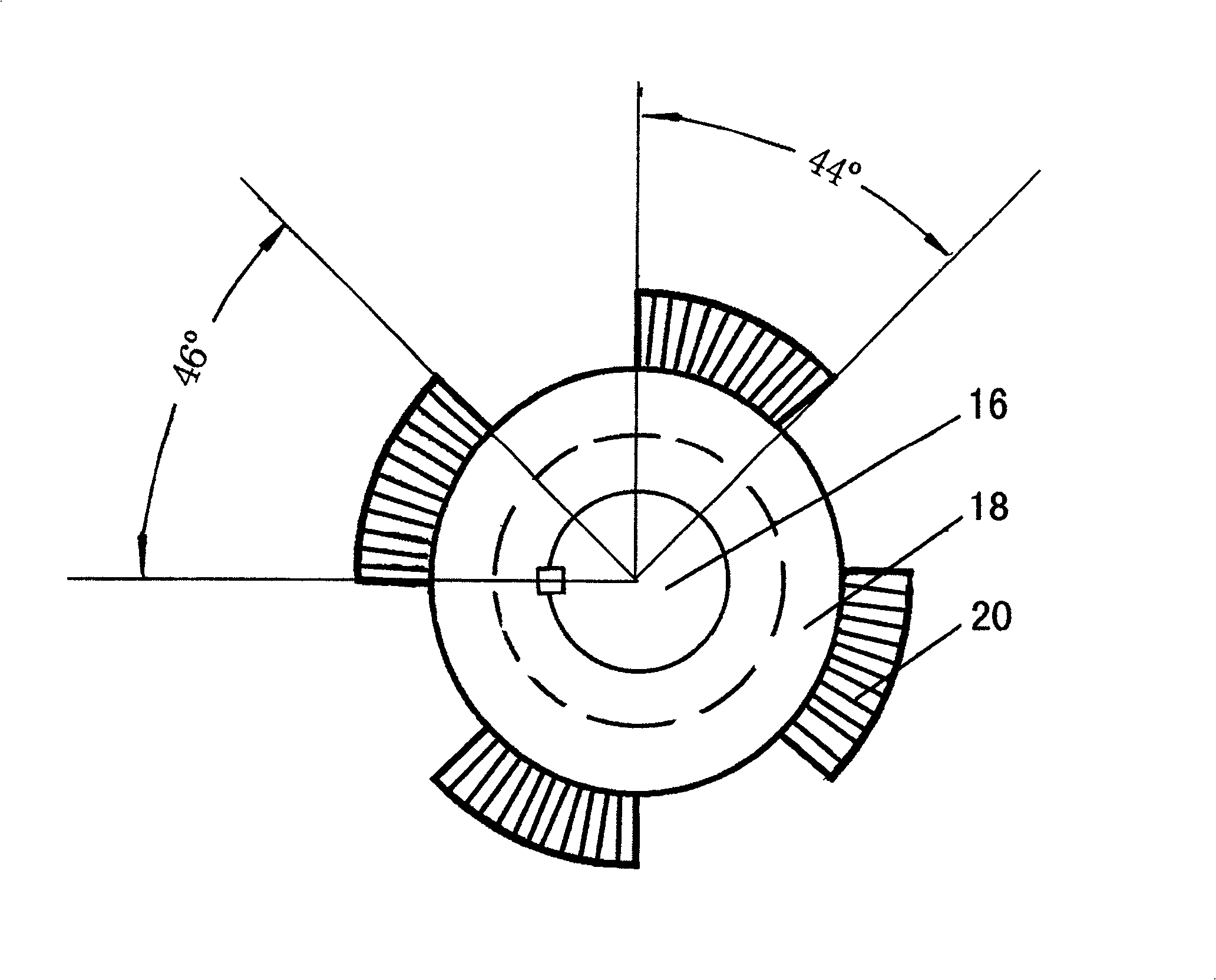

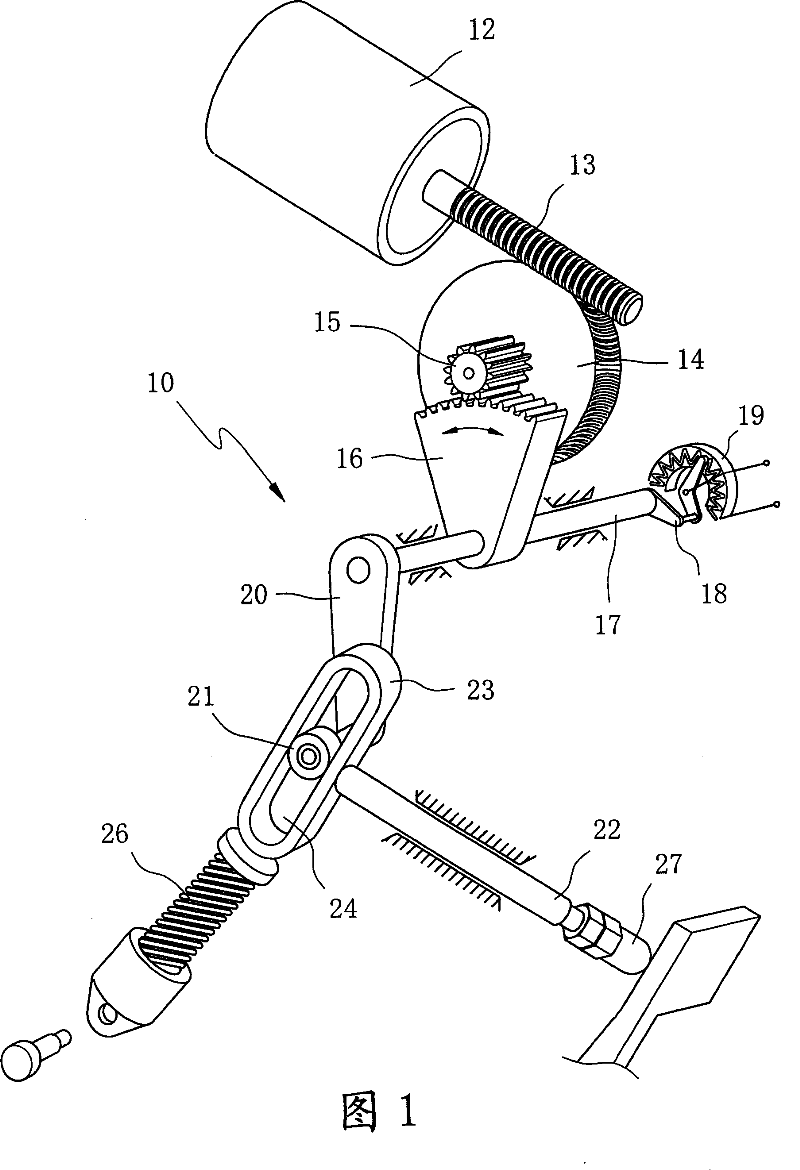

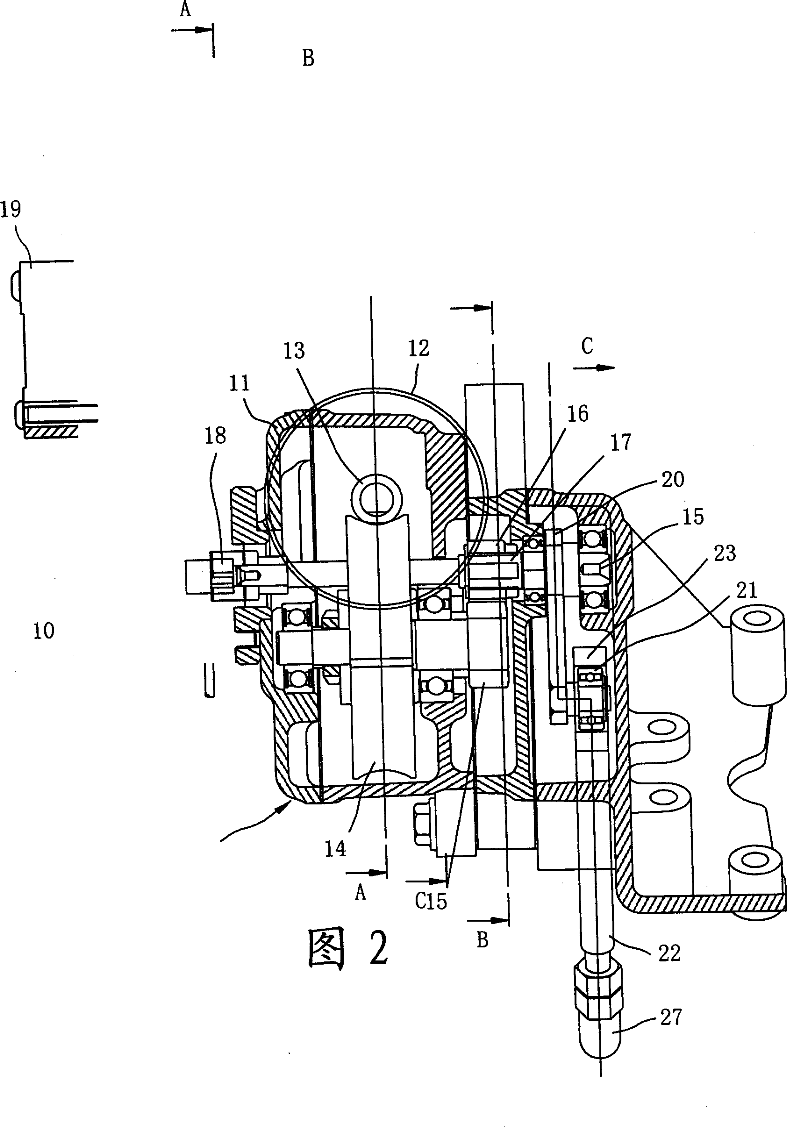

Gasoline engine

InactiveCN100419234CSimple preparation processReasonable exerciseValve arrangementsCylinder headsPower exchangeGasoline

The invention discloses a motor, especially providing a petrol motor with reasonable operation, energy-saving, high exchange efficiency and non-side force component. It is formed by a fuel fire system and a boss axle, wherein, it comprises at least one main axle of main transmission wheel element and a horizontal power cylinder relative to the main transmission wheel element; and one end of piston rod of power cylinder is hinged with the chain on the edge of main transmission wheel element. Compared with present technique, it has more reasonable operation of piston, non-side force component, less abrasion between sleeve and cylinder, and prolonged maintenance period. The tension arm for transmitting torque to the main axle is always in the longest position without dead point to improve the power exchange efficiency, save energy, simplify producing process, and reduce cost. The invention can apply variable fuels as mechanical motor.

Owner:李鱼飞

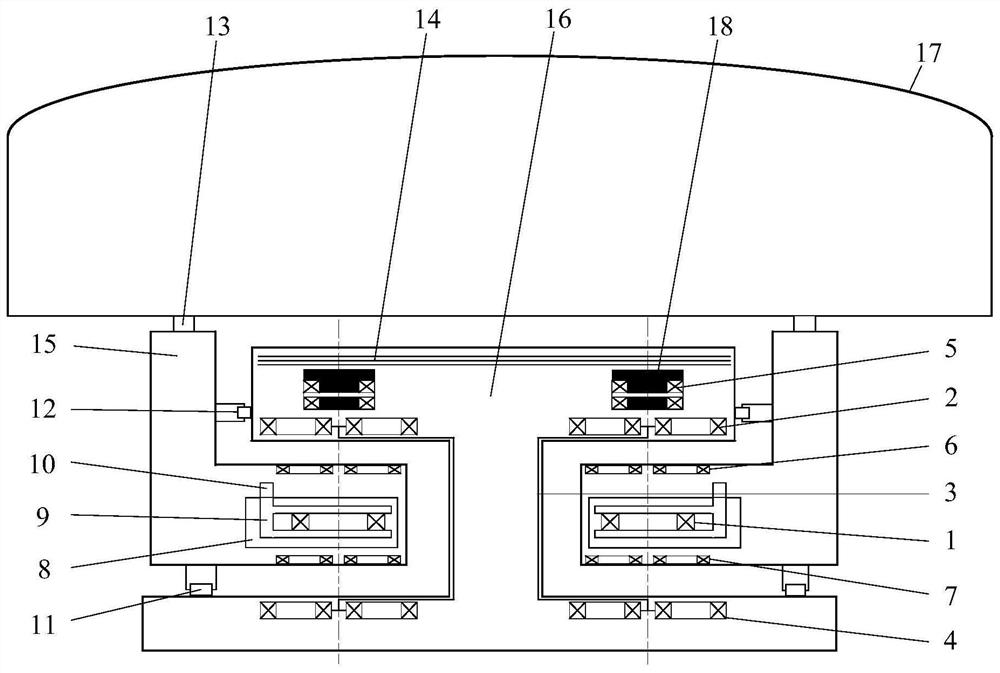

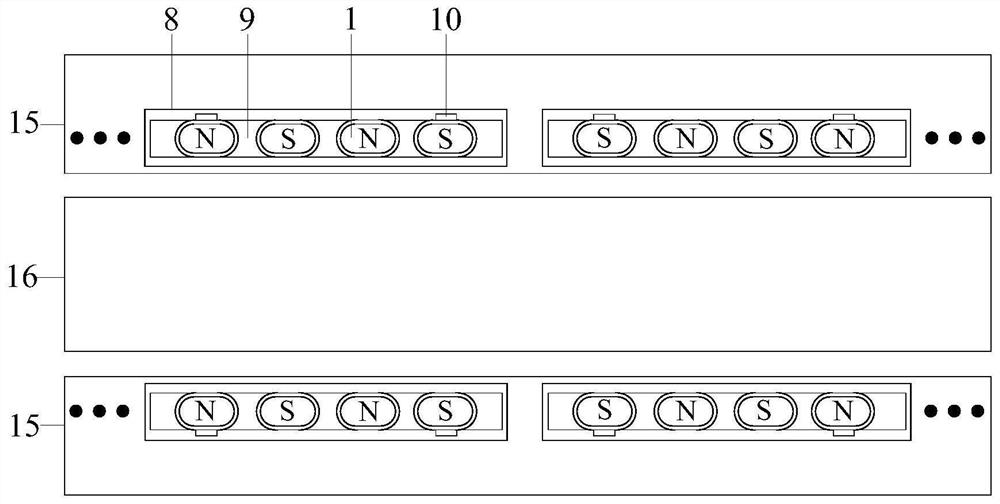

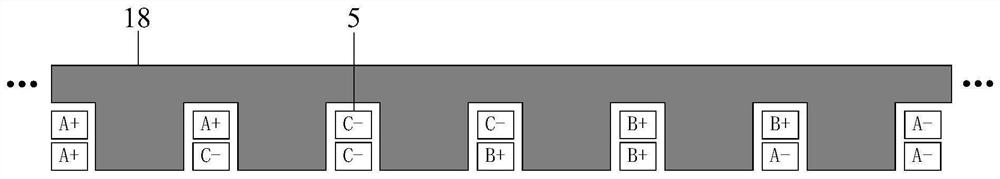

Superconducting electric-electromagnetic hybrid maglev train

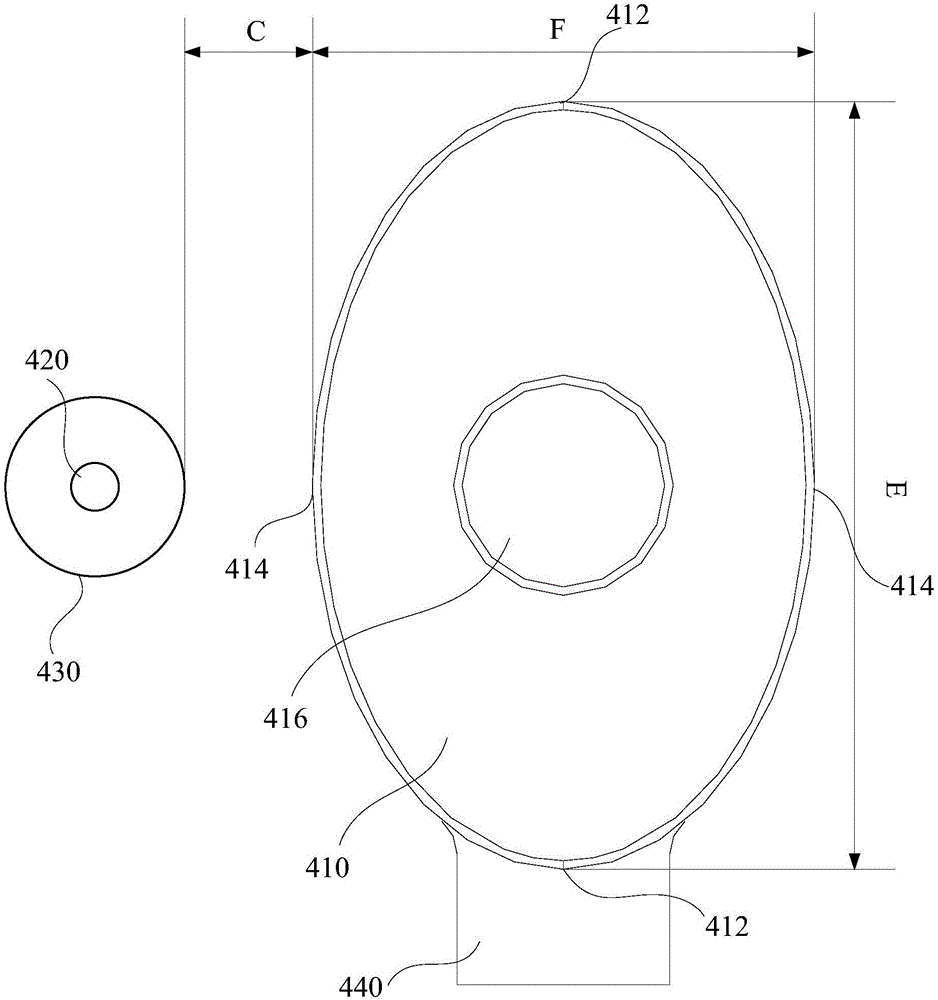

PendingCN111873808ALarge operating air gapGood self-stabilityRailway vehiclesElectric propulsionAir springSuperconducting Coils

The invention discloses a superconducting electric electromagnetic hybrid maglev train, which comprises L-shaped suspension frames and an I-shaped ground rail, and is characterized in that the upper end of each suspension frame is connected with a train body through an air spring; the suspension frames are arranged on the two sides of the ground rail, and the suspension frames and the ground railare arranged at intervals. A plurality of superconducting magnets is arranged at the lower end of each suspension frame. An 8-shaped upper-layer suspension coil and an 8-shaped lower-layer suspensioncoil are arranged at the upper end and the lower end of the ground rail respectively, an upper-layer power generation coil and a lower-layer power generation coil are arranged at the lower end of thesuspension frame, and the upper-layer suspension coil is electrically connected with the lower-layer suspension coil; and a propelling coil is arranged above the upper-layer suspension coil. The invention has the advantages of large operation air gap, self-stabilization, good suspension guiding dynamic performance, better curve passing capacity, higher superconducting magnet magnetic field utilization rate and lower track construction cost.

Owner:SOUTHWEST JIAOTONG UNIV

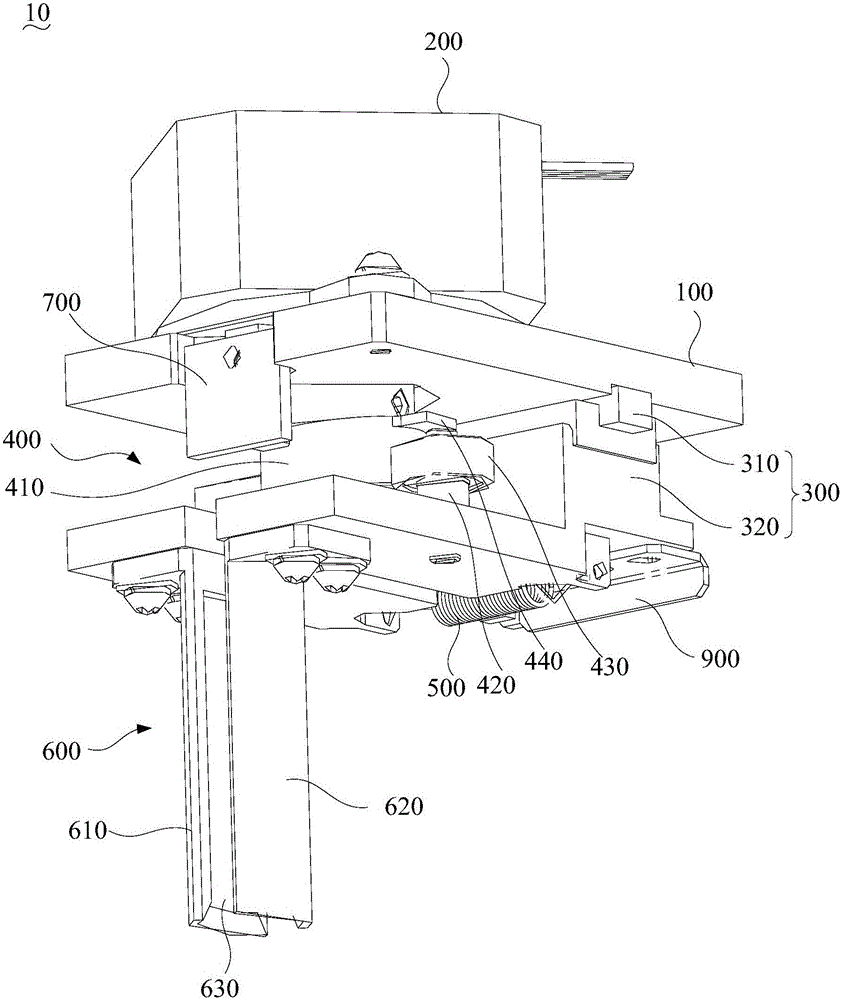

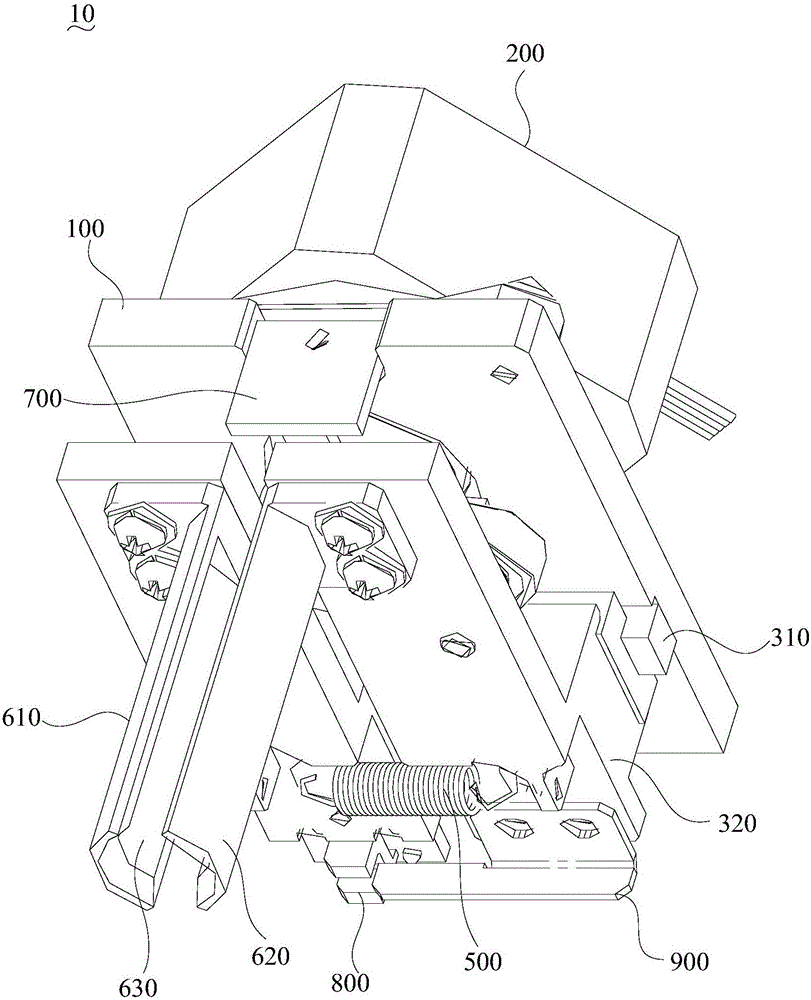

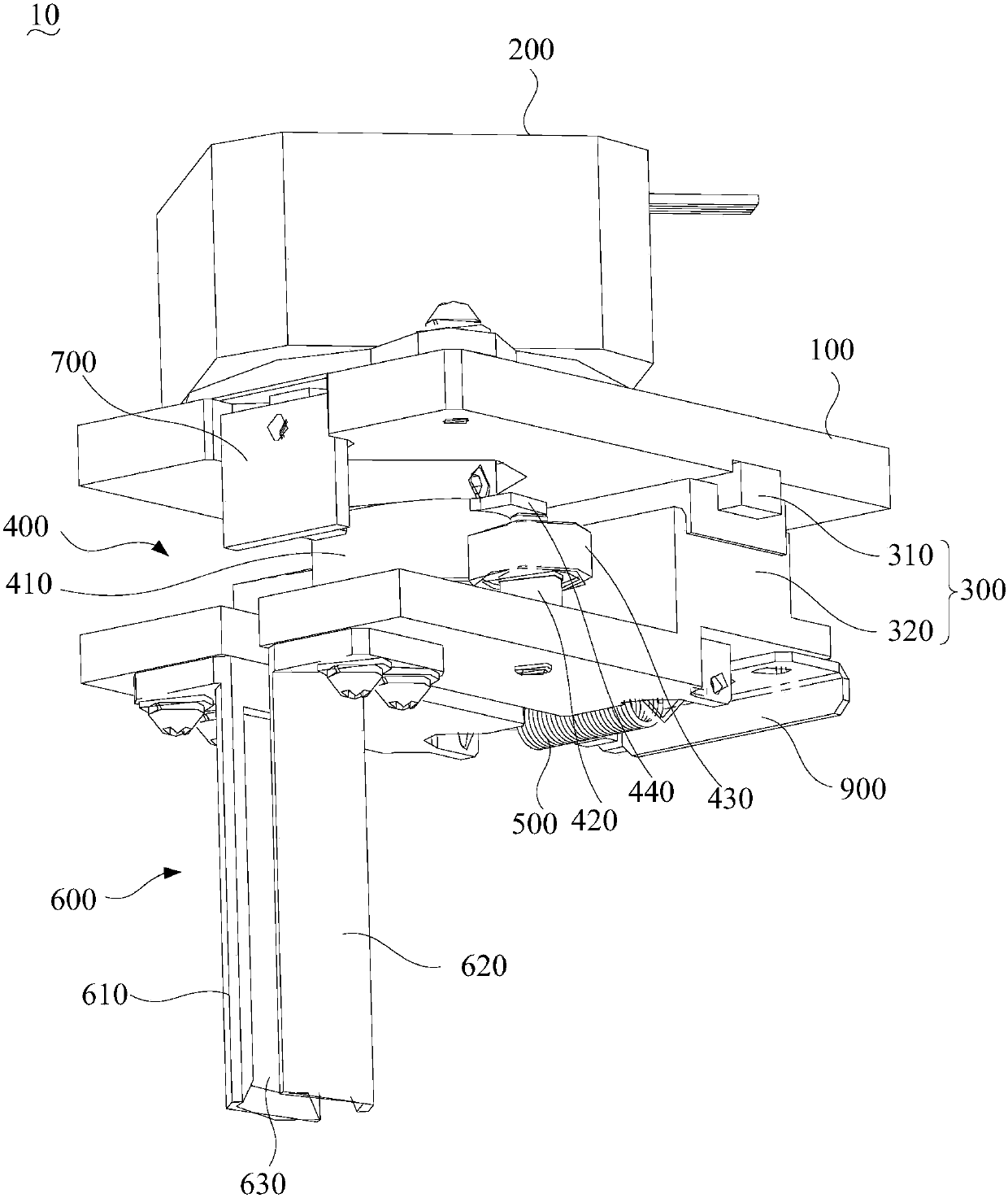

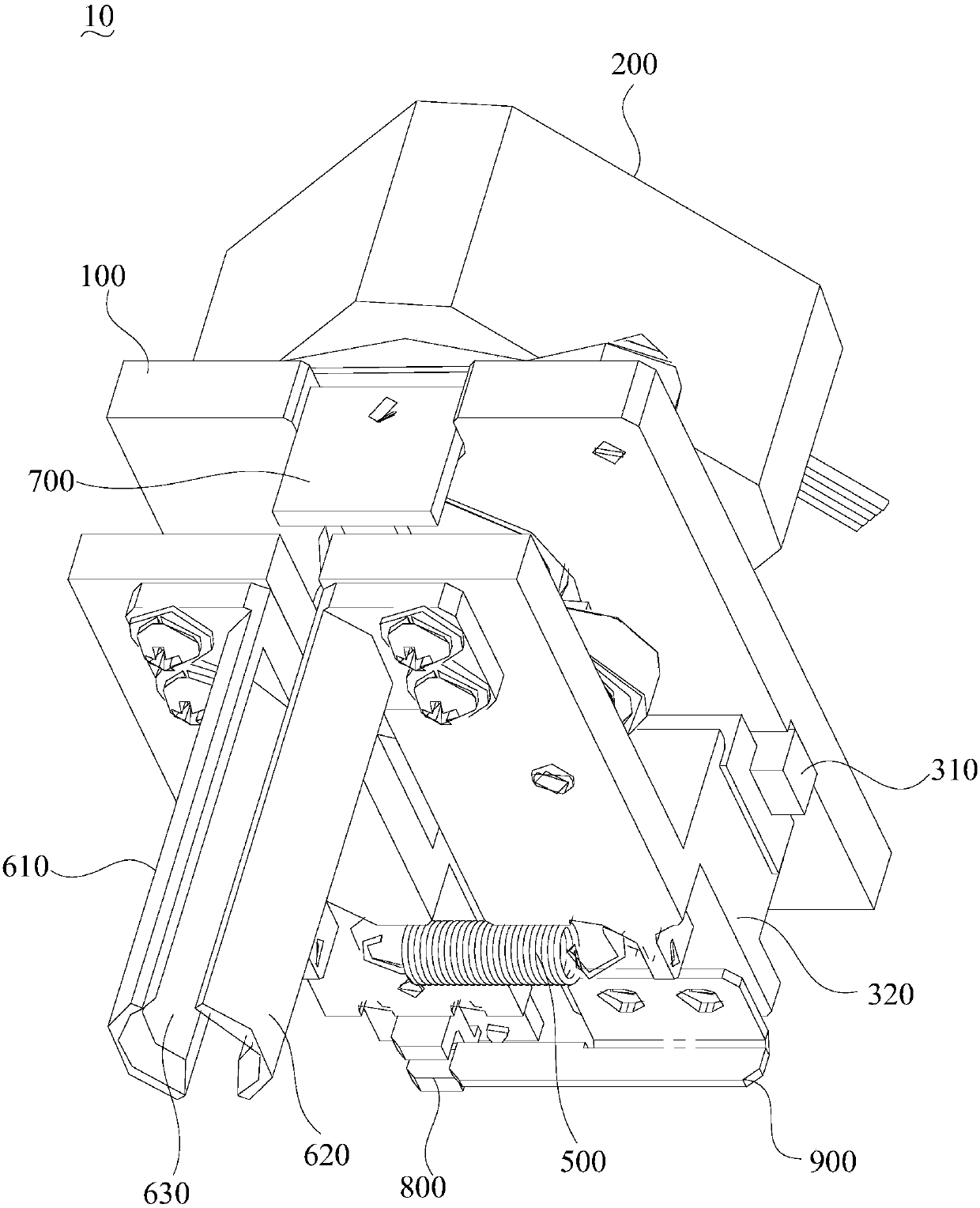

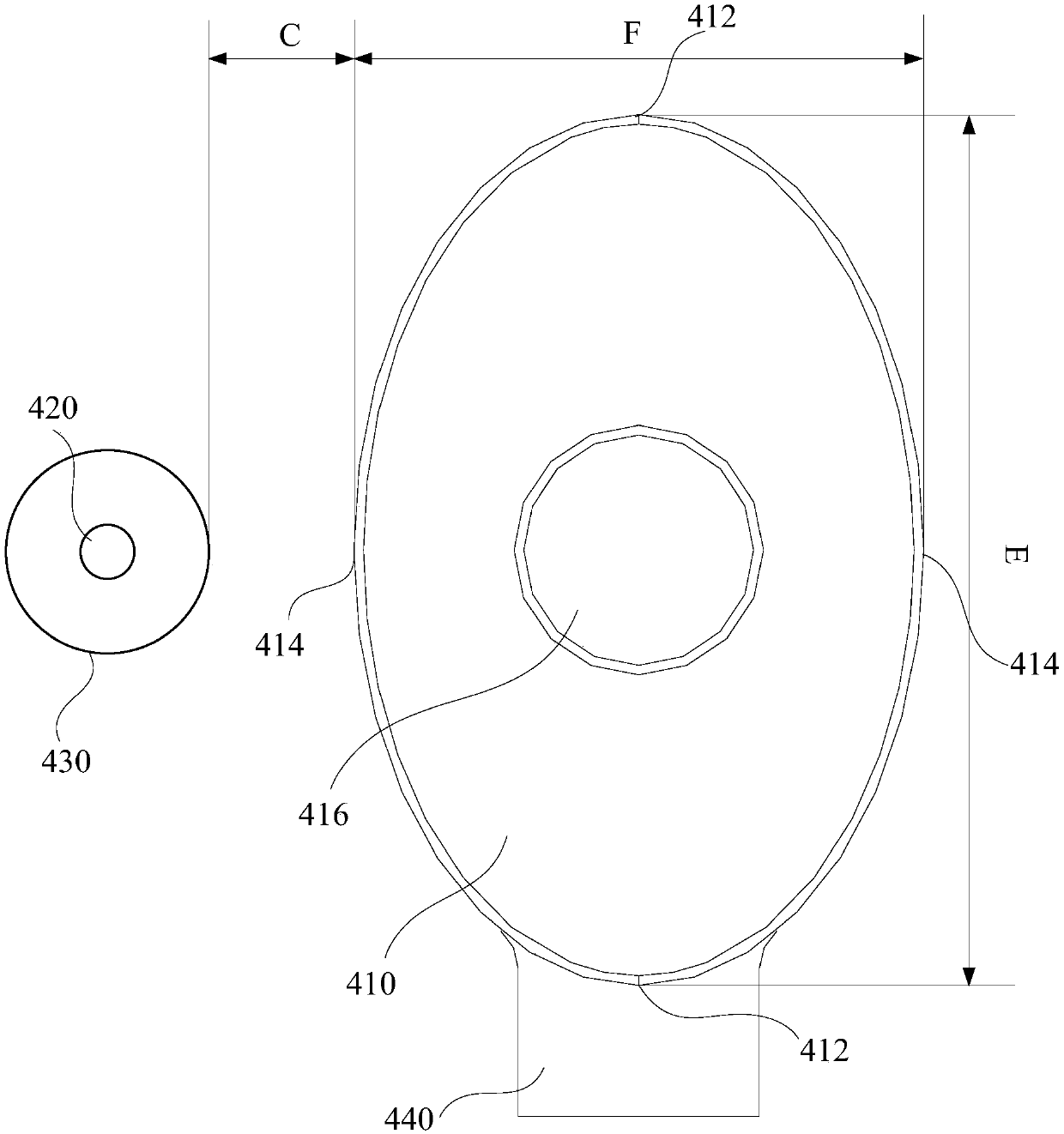

Object grabbing device

ActiveCN106002997AWith self-adjusting functionAvoid wear and tearProgramme-controlled manipulatorGripping headsCentre of rotationSelf adjusting

The invention relates to an object grabbing device. The object grabbing device comprises a base, a driving device, a slide rail assembly, an adjusting assembly, an elastic part and a gripper, wherein the slide rail assembly is mounted on the side, opposite to the driving device, of the base, and comprises a guide rail and two sliding blocks capable of moving along the guide rail relative to each other; a rotary part of the adjusting assembly is connected with the driving device; two support pillars are vertically arranged on the two sliding blocks; the rotation center of the rotary part and the axes of the two support pillars are in the same plane; the two ends of the elastic part are connected with the two sliding blocks; a first clamping part and a second clamping part of the gripper are oppositely arranged on the sides, opposite to the support pillars, of the two sliding blocks; and when the gripper grabs an object, the rotary part is not in contact with the two support pillars. According to the object grabbing device, a self-adjusting function is achieved, and when the gripper and the object deviate from each other, the gripper can be automatically adjusted along the guide rail according to the position of the object to align to the object, so that the purpose that the gripper can successfully grab the object is guaranteed, and the abrasion of the gripper and the object is reduced.

Owner:SHENZHEN YHLO BIOTECH

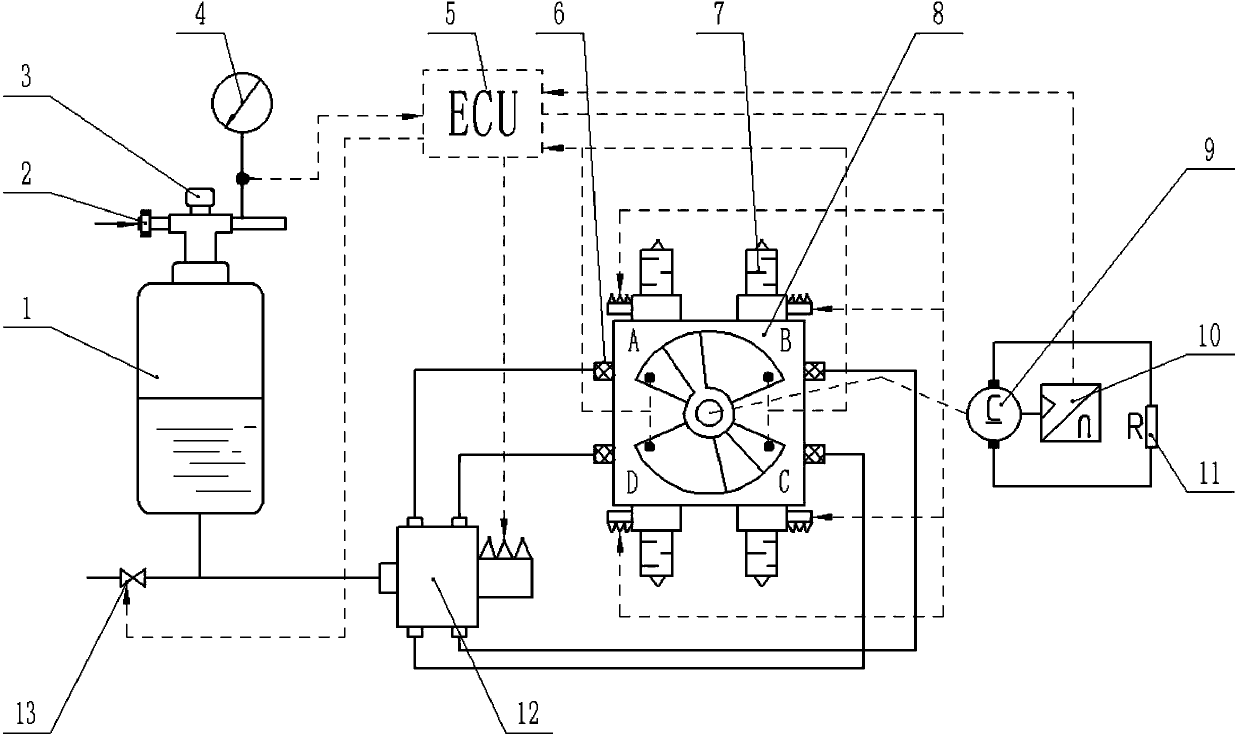

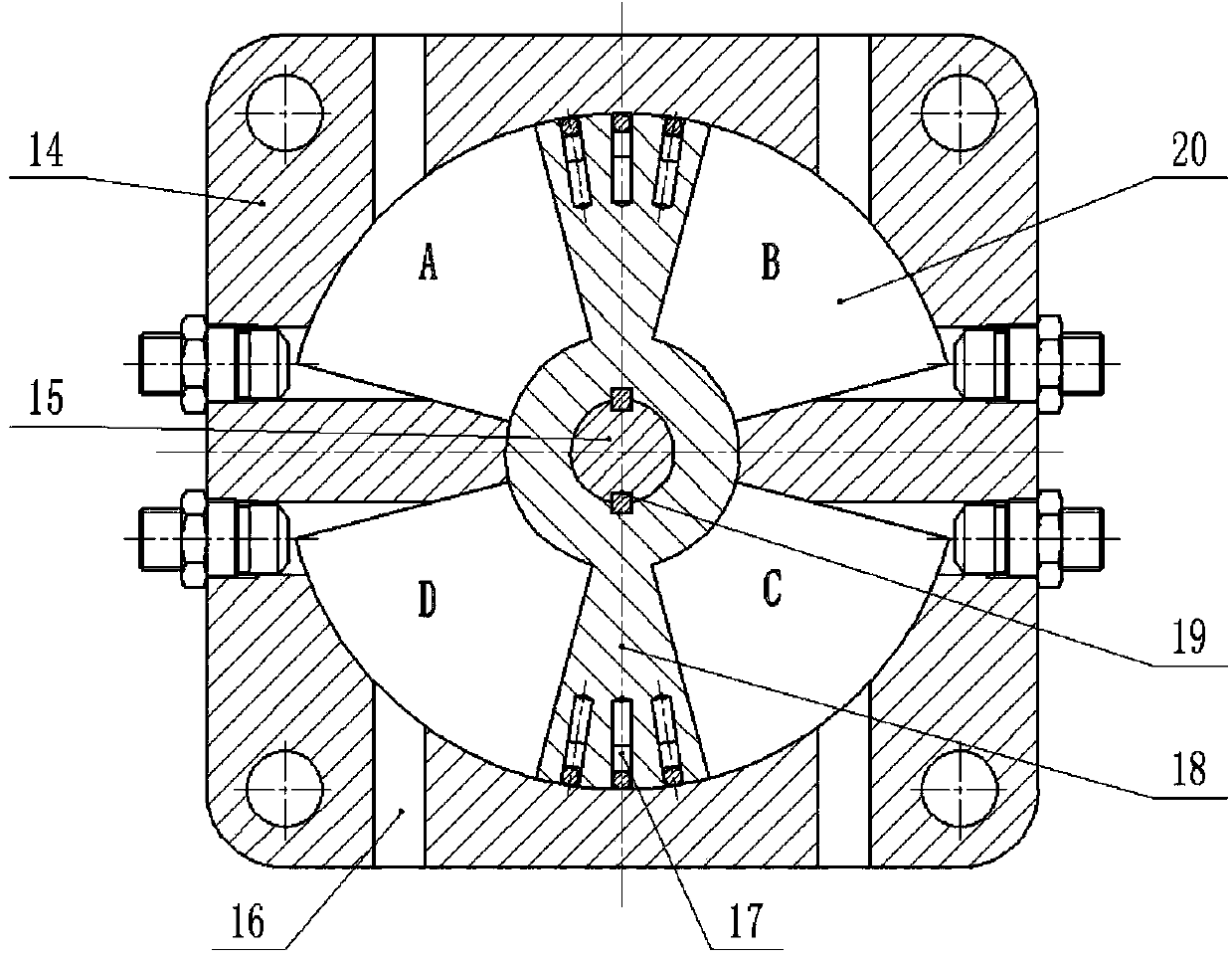

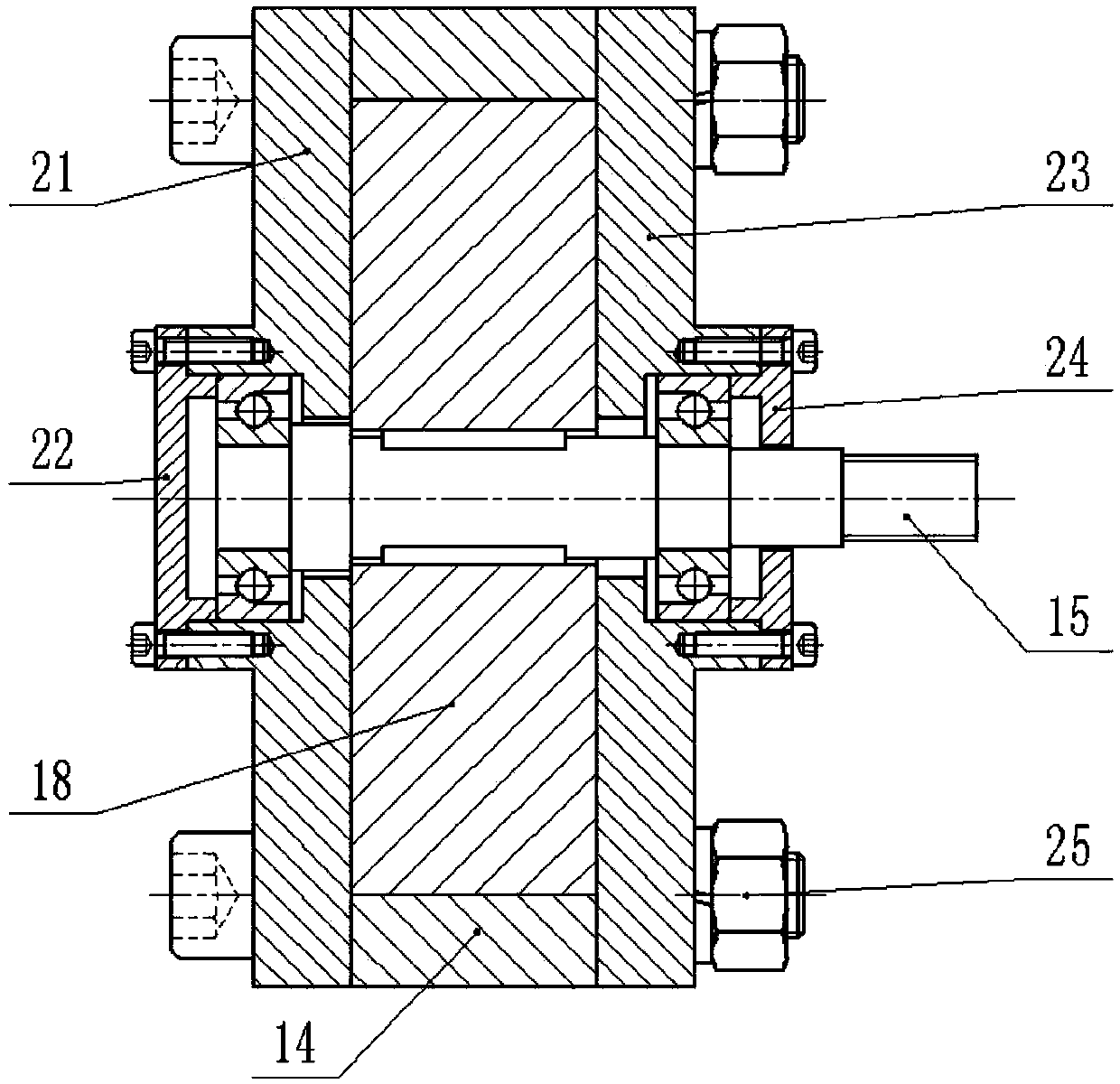

Micro swing type monopropellant engine

InactiveCN103742198ASimple structureThe overall structure is simple and reliableOscillating piston enginesEngine componentsHigh concentrationHigh energy

The invention provides a micro swing type monopropellant engine, which comprises a fuel tank, an electronic control unit, a catalytic device, a swing type engine, a fuel distributing valve, a gas exhausting check valve and a muffler, wherein a hydrogen peroxide solution of high concentration is used as a fuel, the electronic control unit controls the fuel flow valve to provide the fuel to the specified catalytic device, high temperature and high pressure gas is generated by decomposing the fuel through catalytic reaction and acts upon a central swing of the swing type engine, so that direct output or electric energy output of swing power is realized. The micro swing type monopropellant engine provided by the invention has the advantages of high integration of work modes, simple structure, convenience in control, high energy density and the like and is applicable to energy supply devices in various anoxic or oxygen-free environments such as outer space, polar regions, plateaus, drilling platforms or underwater.

Owner:INNER MONGOLIA UNIV OF TECH

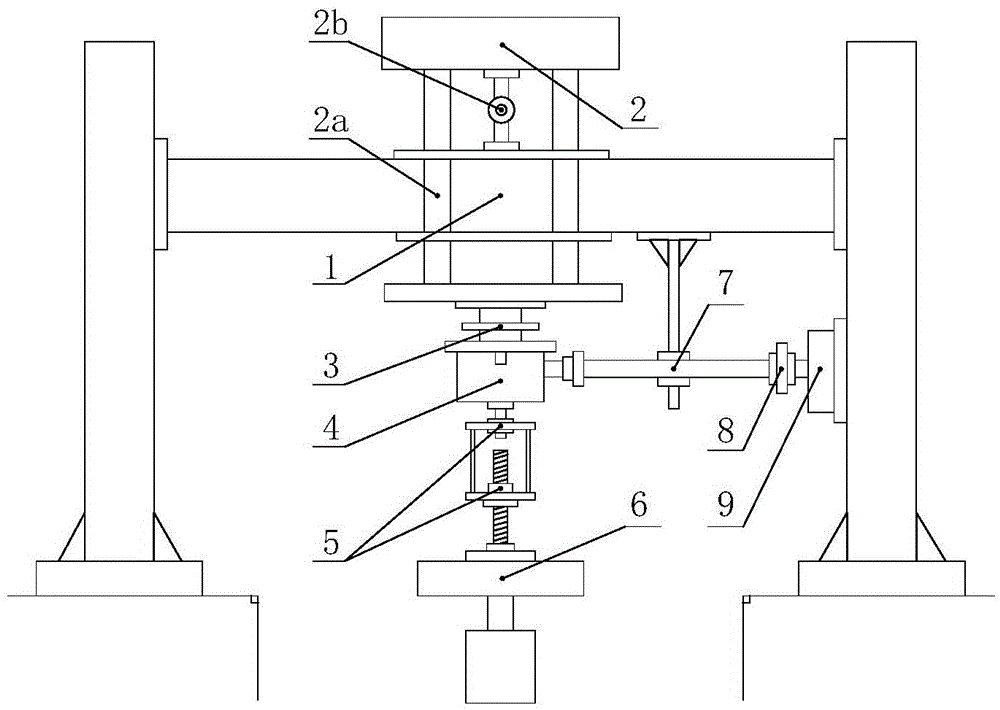

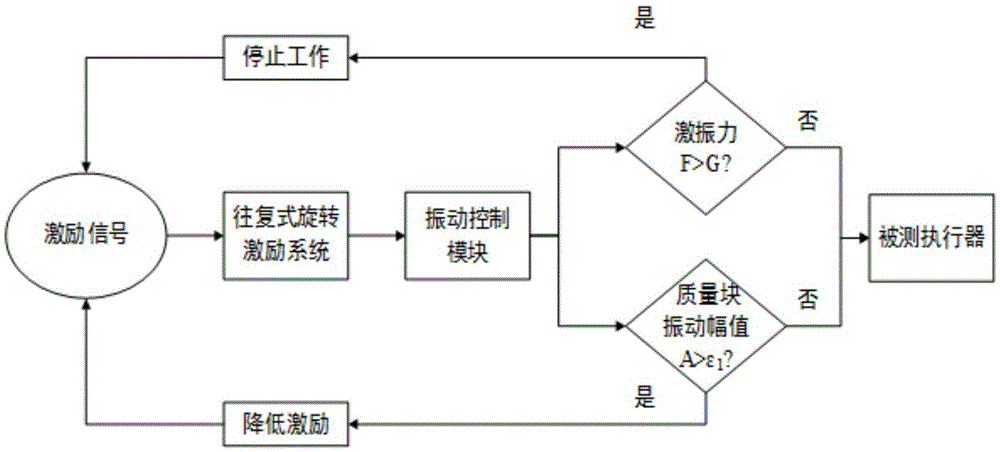

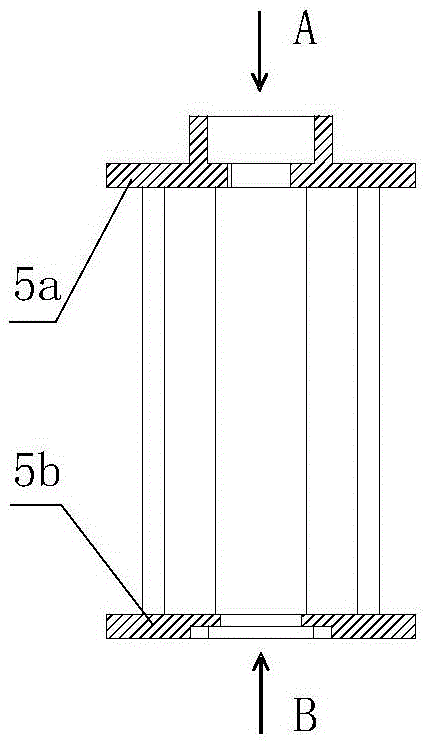

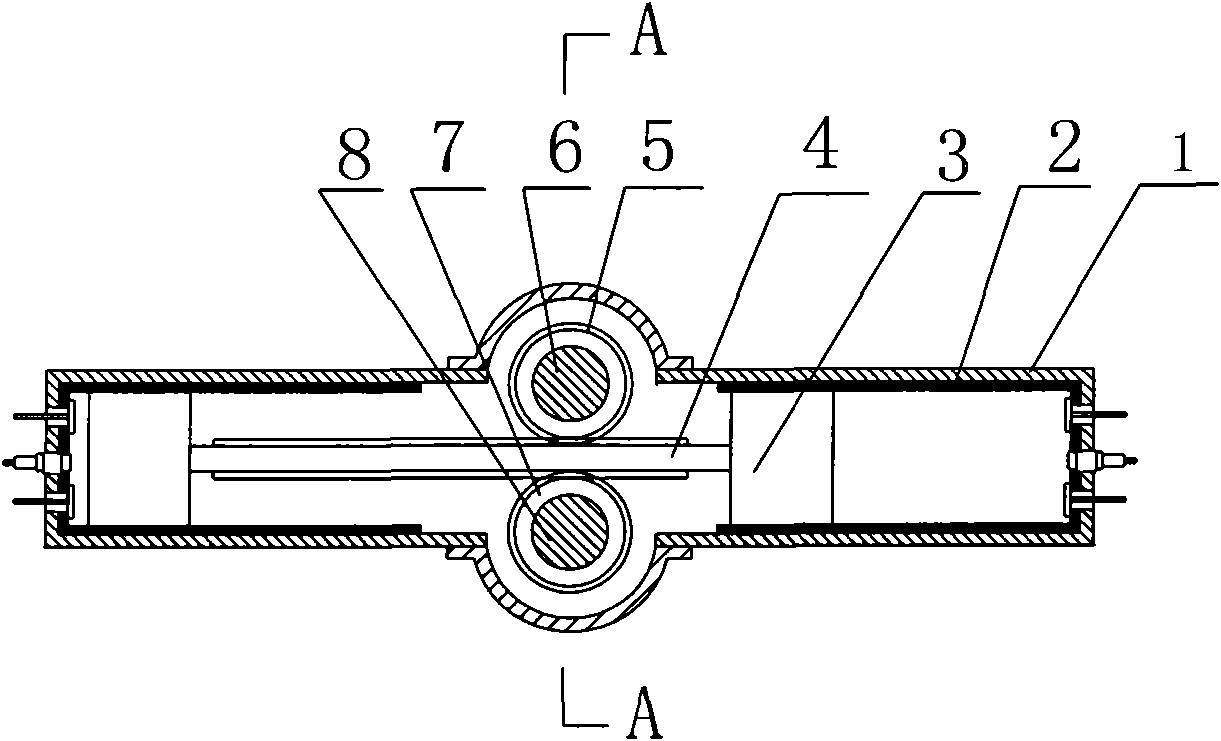

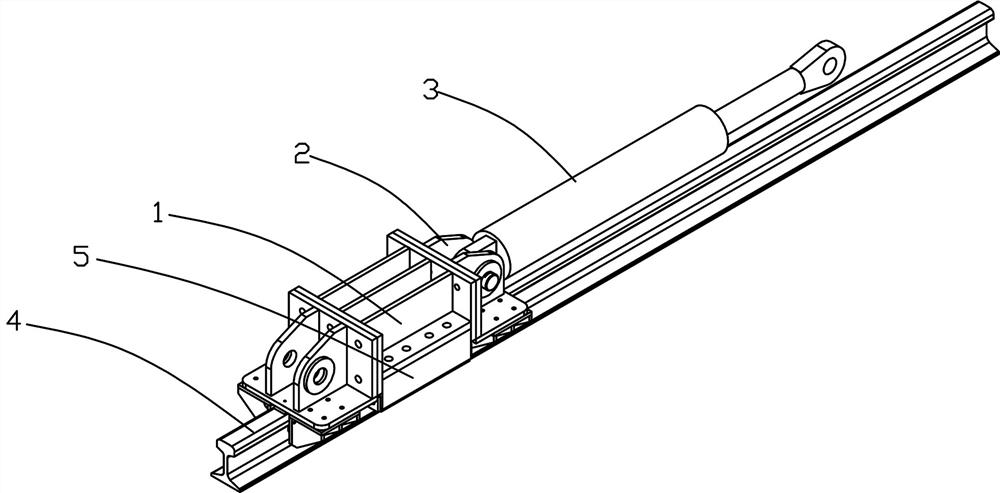

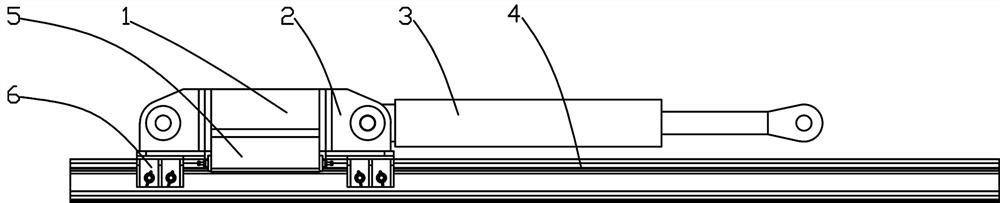

Reciprocating rotation excitation stand system

ActiveCN105486502AAvoid excessive vibrationPrevent overloadMachine gearing/transmission testingRotary actuatorTurn angle

The invention discloses a reciprocating rotation excitation stand system which is characterized in that a reciprocating rotation excitation system is composed of a linear actuating vibration table, a motion conversion device, and a turning torque rising device, the motion conversion device converts the vertical reciprocating linear excitation formed by the linear actuating vibration table into vertical reciprocating rotation excitation, the turning torque rising device converts the vertical reciprocating rotation excitation into horizontal reciprocating rotation excitation, the torque and the rotation travelling of the horizontal reciprocating rotation excitation can be increased and reduced in the turning torque rising device, and an excitation control module measures the vibration amplitude and the linear exciting force of the reciprocating rotation excitation system at the same time. The reciprocating rotation excitation stand system is suitable for the characteristic test of a large-torque limited angle actuator and can perform the vibration control experiment test based on passive / active / half-active rotary actuator.

Owner:合肥庐阳科技创新集团有限公司

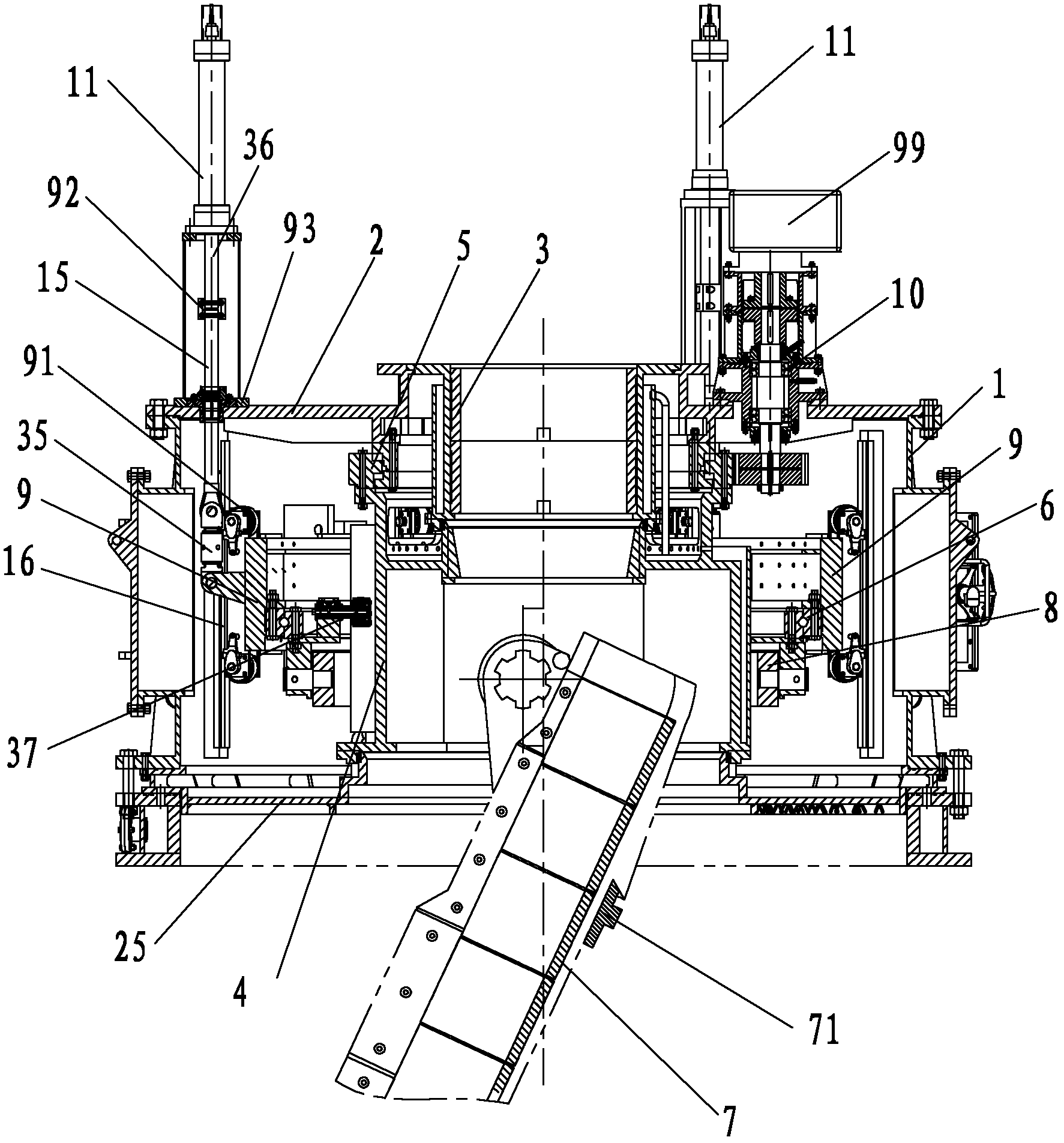

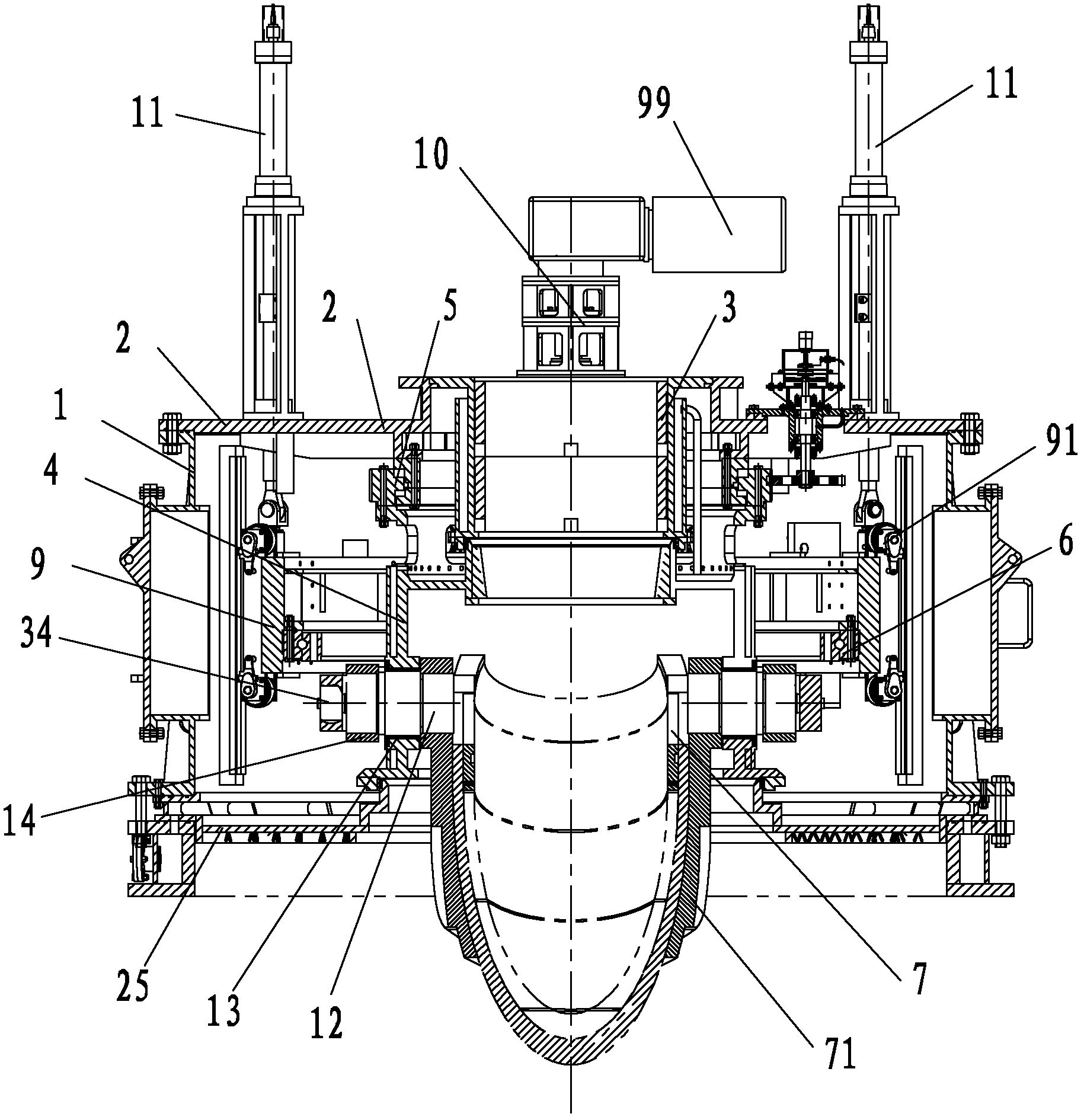

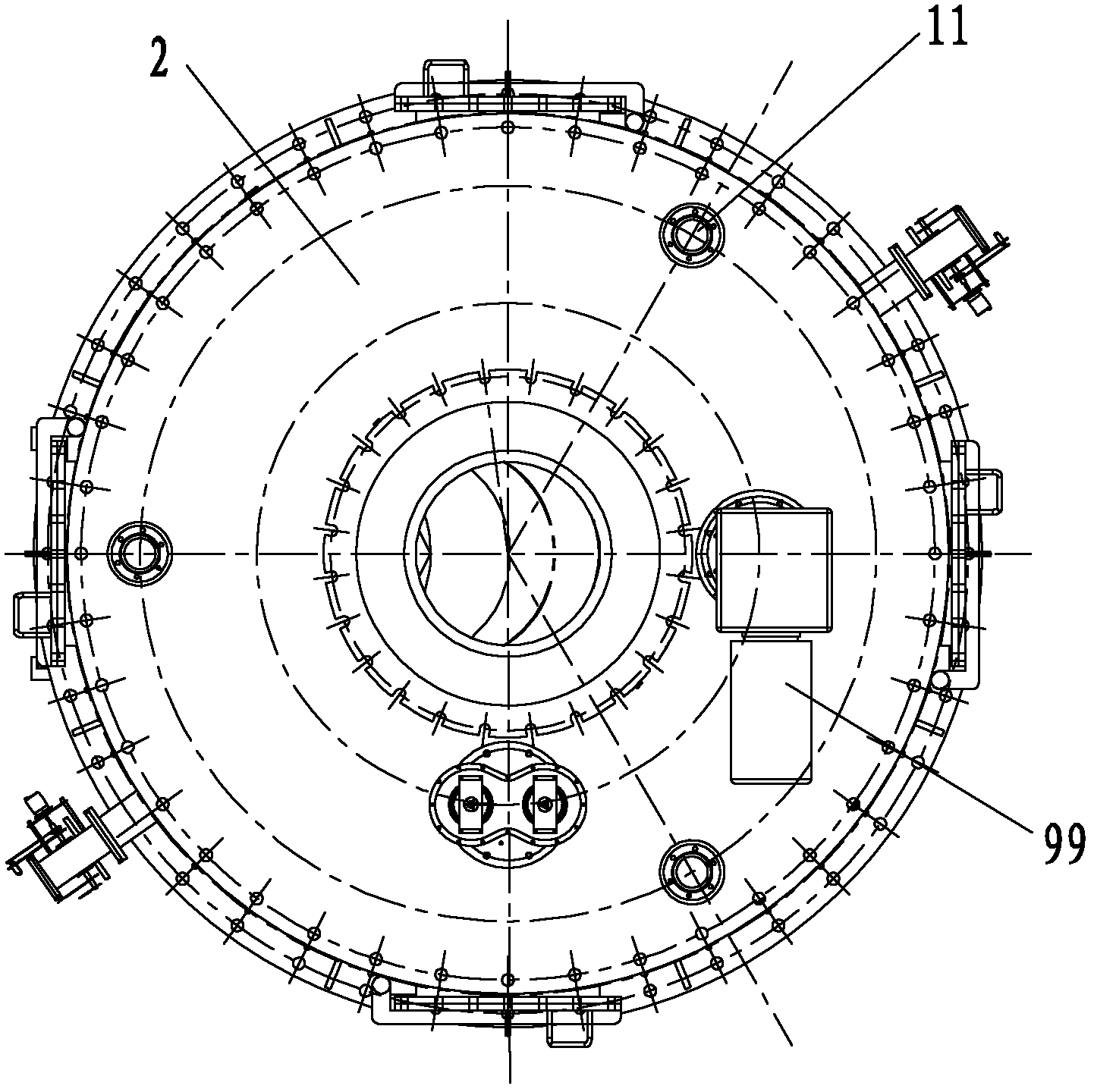

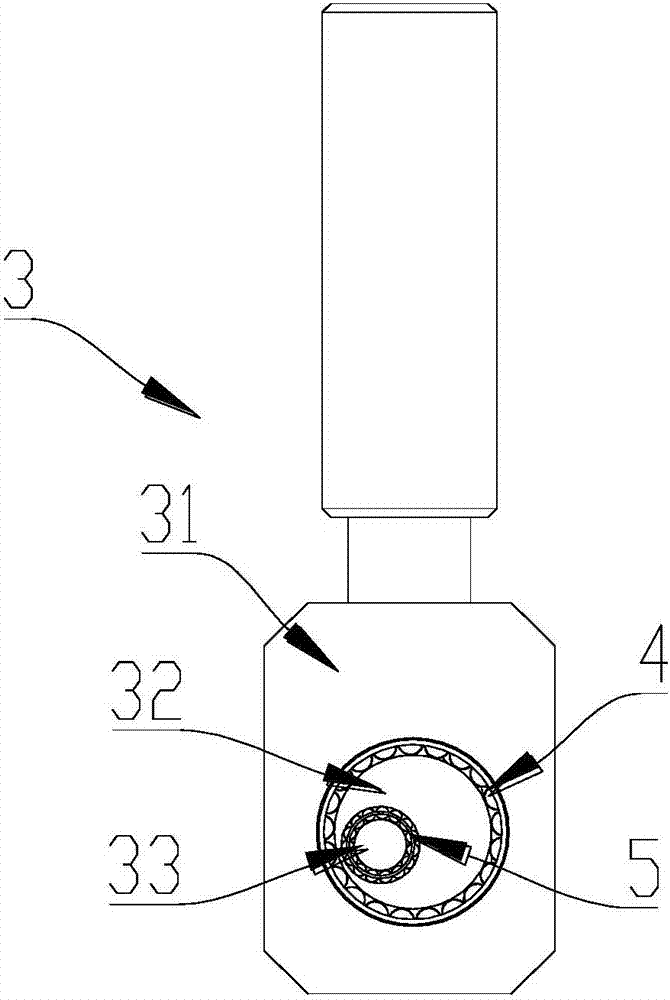

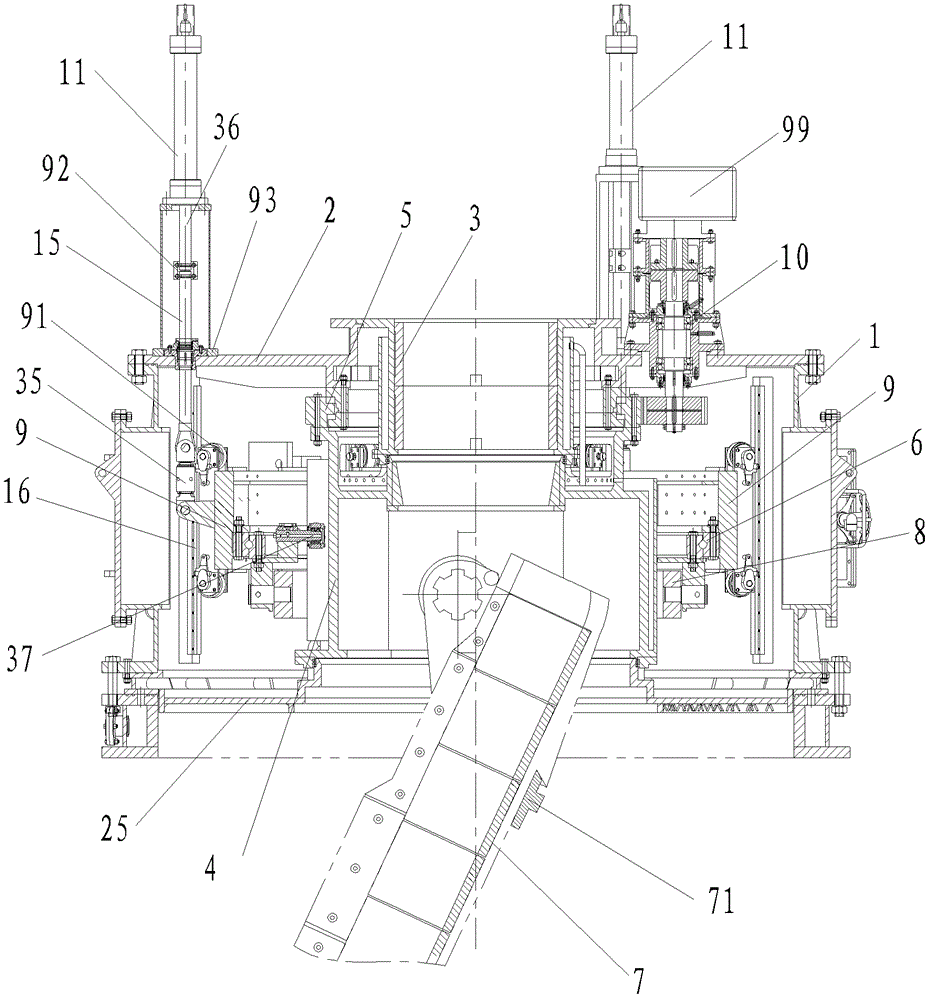

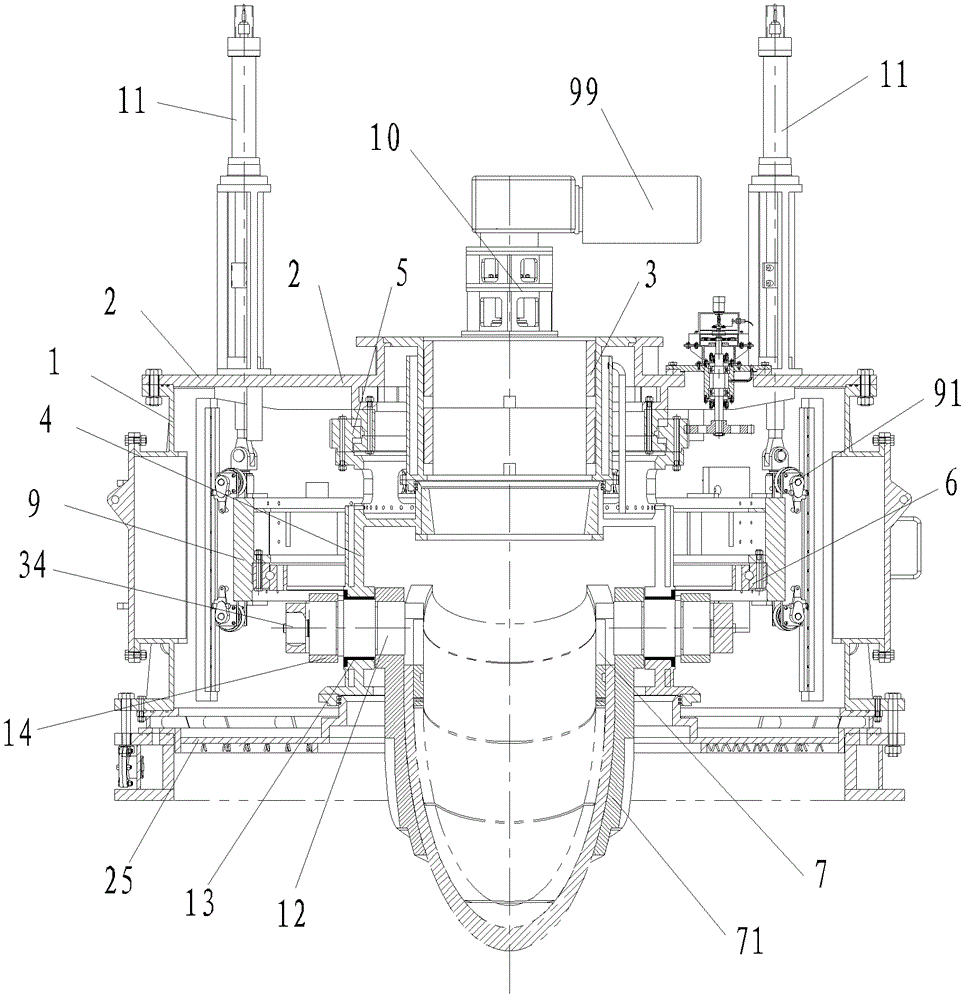

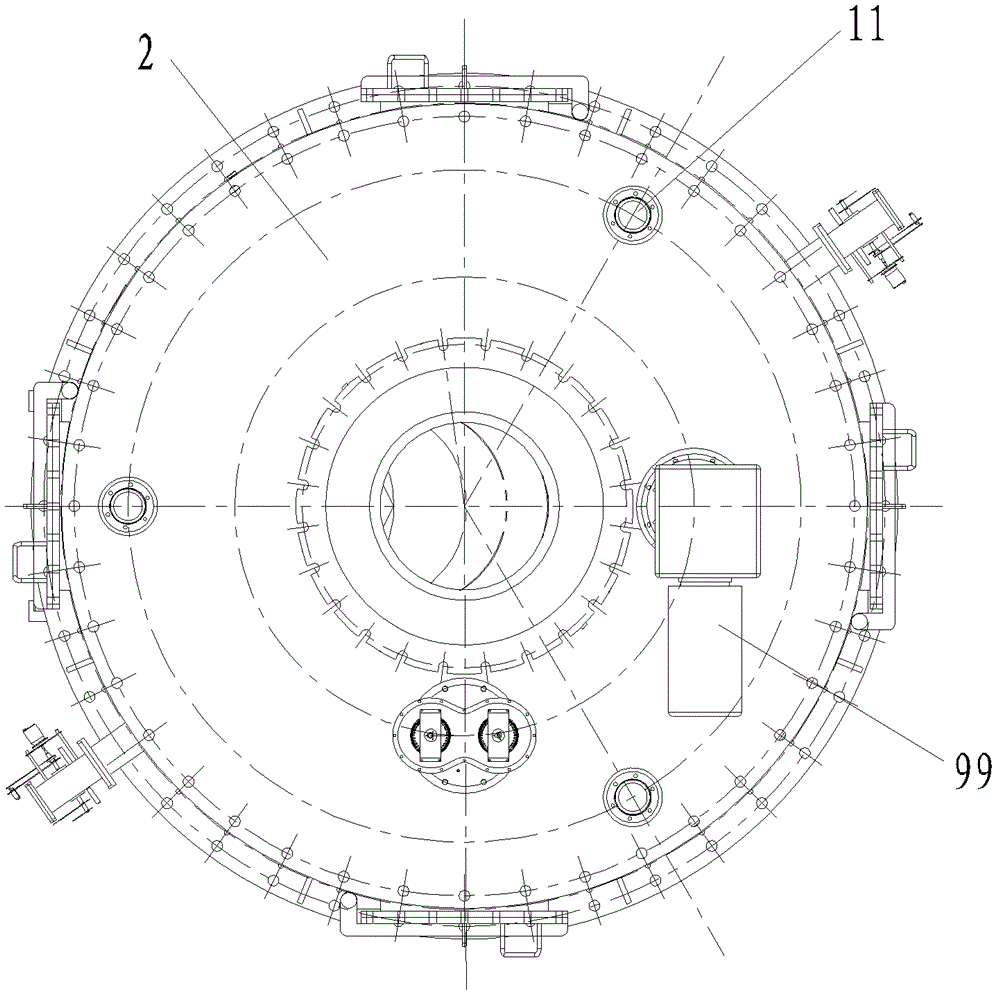

Blast furnace top chute distributing device

ActiveCN103215395AReasonable structureDrive chain shortBell-and-hopper arrangementBlast furnace detailsEngineeringSlewing bearing

The invention discloses a blast furnace top chute distributing device. The device comprises an airtight casing, a choke, an upper slewing bearing, a rotary sleeve, a chute, an universal frame, a lower slewing bearing, a star wheel assembly, oil cylinders and a horizontal driver used for driving the upper slewing bearing to rotate, and the choke traverses a top cover arranged at the top of the airtight casing; the inner ring of the upper slewing bearing is connected with the top cover; the rotary sleeve is connected with the outer ring of the upper slewing bearing, the rotary sleeve is provided with trunnions, and the chute is suspended in the rotary sleeve through the trunnions; the trunnions are connected with one end of a crank; the other end of the crank is arranged in the chute of the universal frame; the inner ring of the lower slewing bearing is connected with the universal frame; one end of the star wheel assembly is connected with the inner ring of the lower slewing bearing, and the other end of the star wheel assembly is positioned in the sliding slots of the rotary sleeve; and the oil cylinders are used for dragging the lower slewing bearing to move up and down. The blast furnace top chute distributing device has the advantages of reasonable structure, long service life, shortest driving chain, stable running, and no lateral force to a guide rail.

Owner:QINHUANGDAO QINYE HEAVY IND

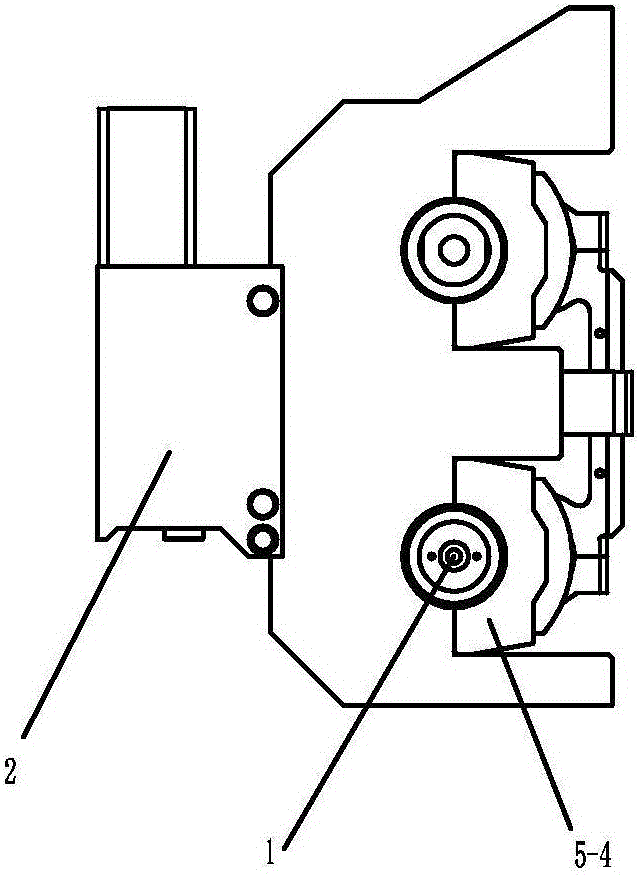

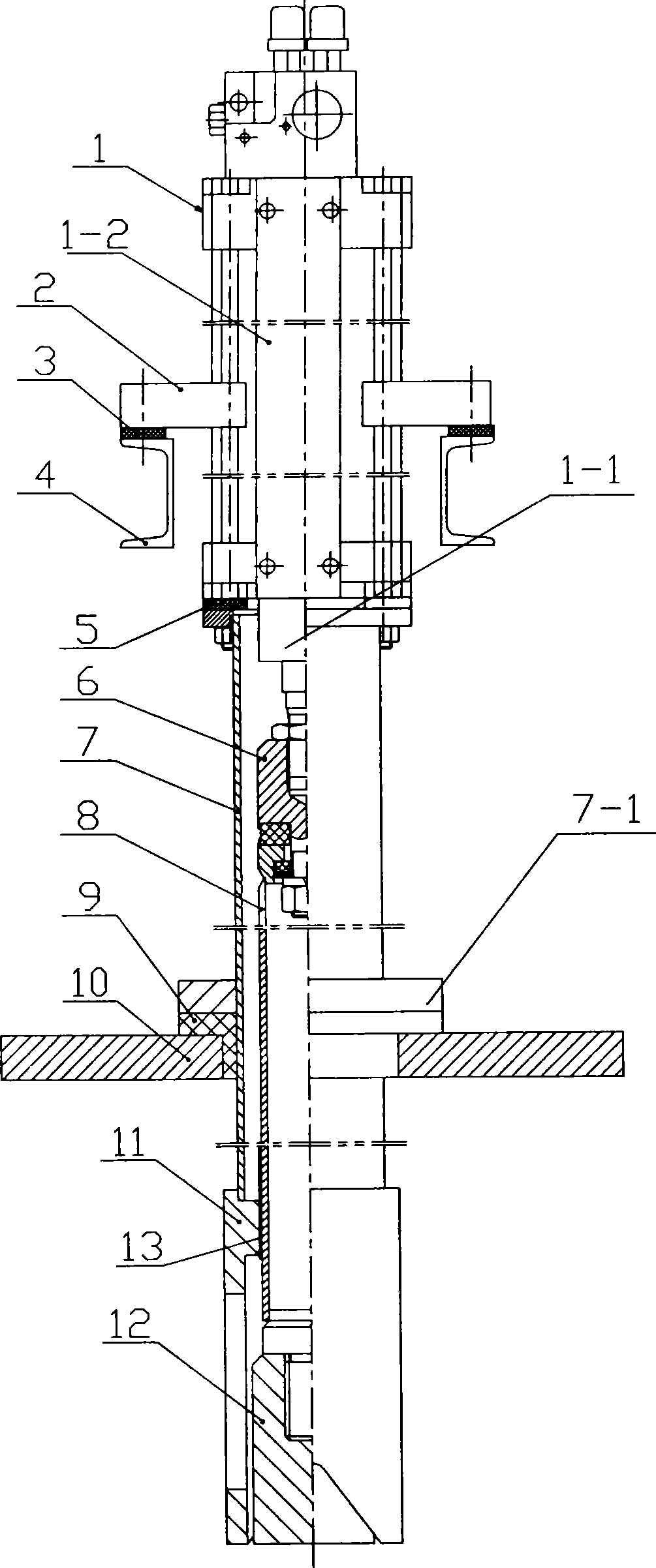

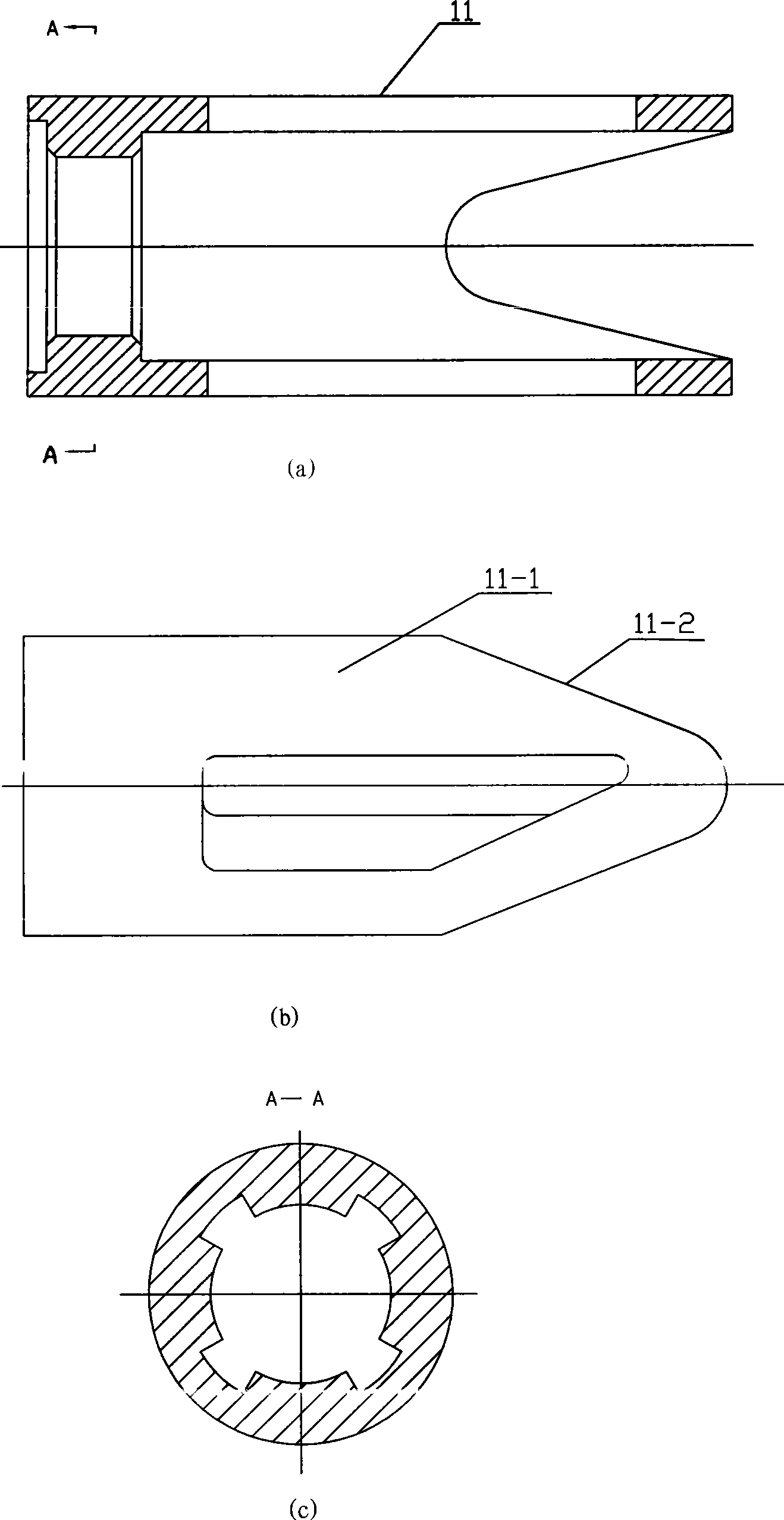

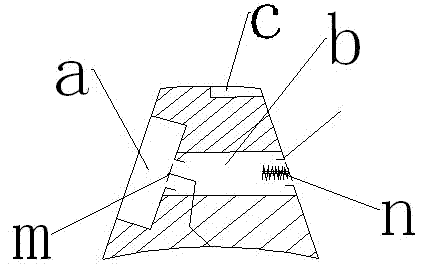

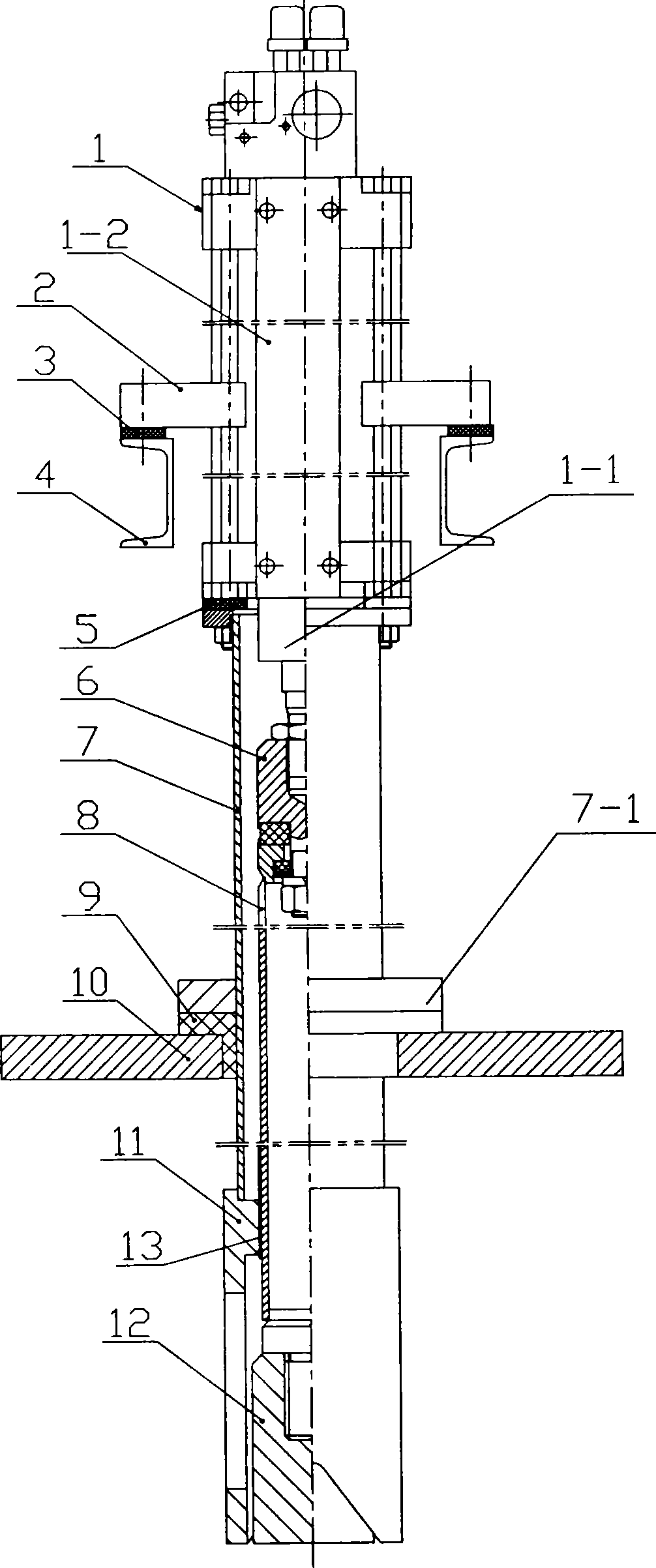

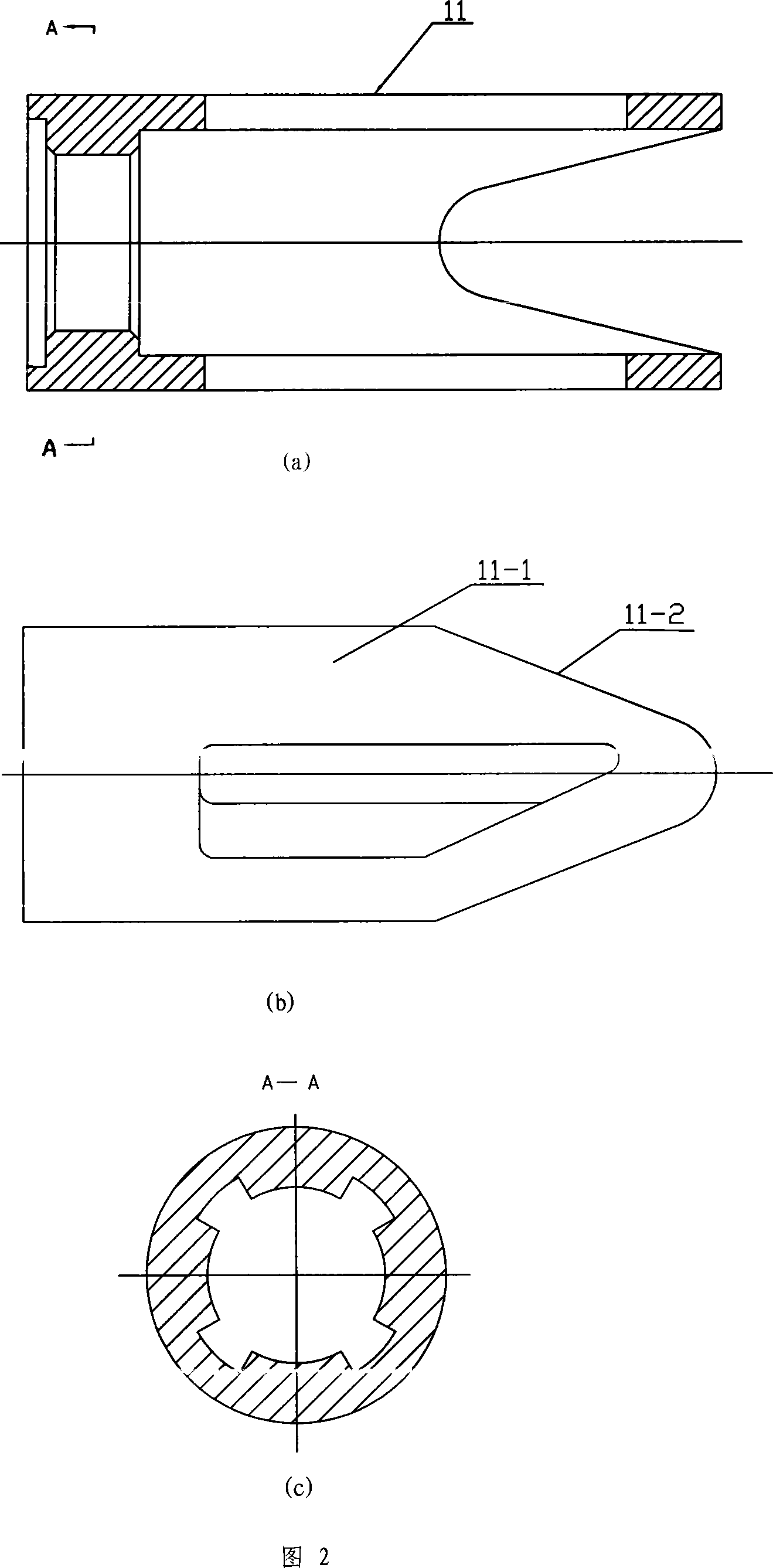

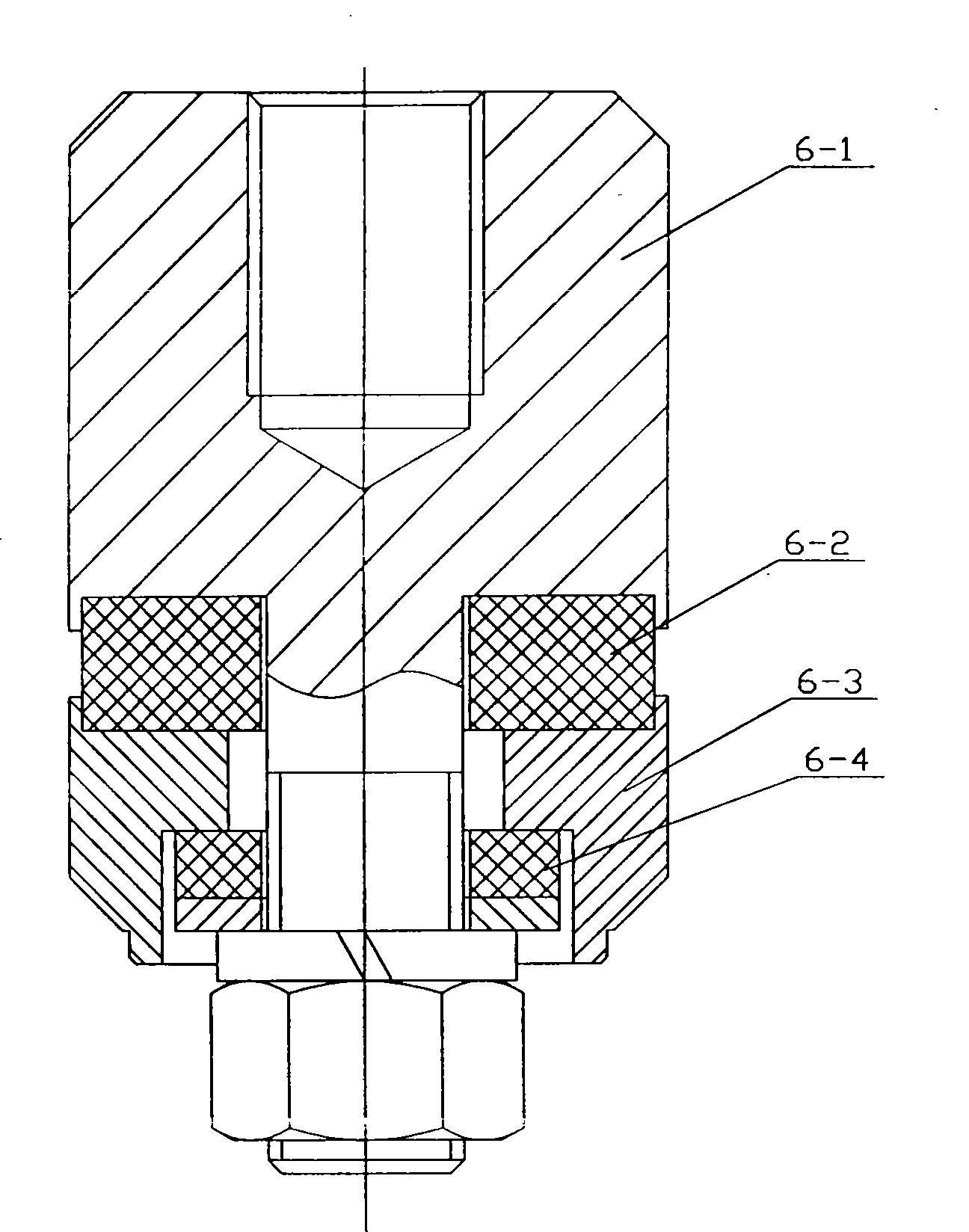

Scrape type crust breaking apparatus

The invention mainly relates to a groove body feeding and discharging device with easy material incrustation, in particular to an incrustation breaking device for an electrolysis bath or an electroplating bath. A scraping type incrustation breaking device comprises a flange (2) which is connected with a groove body mounting beam (4) and is arranged on an incrustation pressing cylinder or an incrustation breaking cylinder (1), and a hammer rod (8) connected with the end part of a cylinder piston (1-1); and the lower end of a cylinder sleeve (1-2) is connected with a guide cylinder (7), and the hammer rod moves upwards and downwards in the guide cylinder (7). The groove body feeding and discharging device is mainly characterized in that the lower ends of the guide cylinder (7) and the hammer rod (8) are provided with scaffolding and scraping devices (11); and the lower end part of the hammer rod (8) is connected with a hammer head (12) which is made of austenitic stainless steel. The groove body feeding and discharging device overcomes the defects of the prior incrustation breaking device for an aluminum electrolysis bath so that electrolyte scaffoldings on the surface of the hammer head of the incrustation breaking device need not be beaten away manually, and the phenomena that the hammer head is fractured and falls into aluminum liquid in the electrolysis bath can be precluded. The groove body feeding and discharging device increases insulating points, improves the insulating reliability, and solves the problem of abnormal spoilage of the cylinder. At the same time, the groove body feeding and discharging device solves the sealing problem of the incrustation breaking device and the upper structure of the electrolysis bath, and the problems of fast hammer replacement and no maintenance of a mechanism.

Owner:许磊

Piston-type direct-drive engine and design method for first taking force and then integrating

The invention provides a piston-type direct-drive engine and a design method for first taking force and then integrating; symmetric pistons are arranged in an engine shell to directly drive a double-sided rack between the pistons to move back and forth; the double-sided rack drives two sets of gears to drive a transmission shaft to rotate back and forth to externally output two circuits of intermittent rotating force in opposite directions; and then a crankshaft connecting rod-type or a single gear-type power integrating mechanism integrates the two circuits of intermittent rotating force in opposite directions into continuous rotating force in a direction. The pistons are arranged in a cylinder tube and are connected with both ends of the double-sided rack; the upper side and the lower side of the double-sided rack are respectively provided with an upper transmission shaft and a lower transmission shaft; an upper transmission gear and a lower transmission gear are respectively arranged on the upper and the lower transmission shafts and are meshed with the upper sided rack and the lower sided rack of the double-side rack, and the upper and the lower transmission shafts are connected with the power integrating mechanism; the power integrating mechanism comprises an eccentric wheel, a connecting rod and a crankshaft; the eccentric wheel is connected with the ends of the upper and the lower transmission shafts; and both ends of the connecting rod are connected with the eccentric wheel and the crankshaft.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

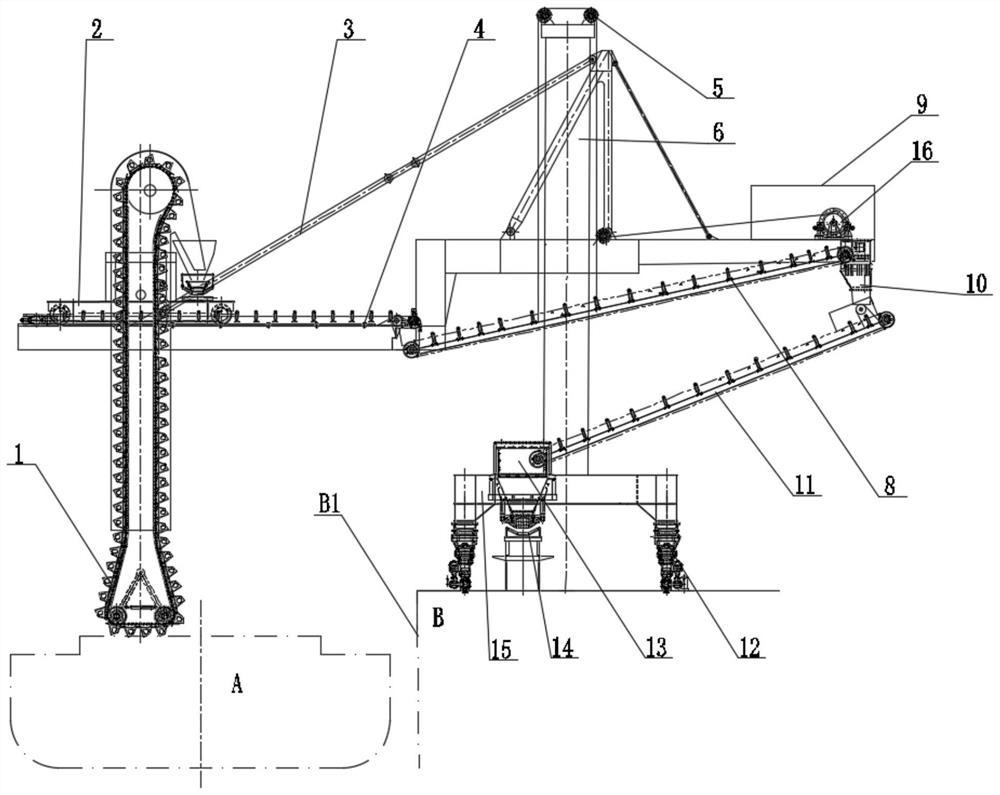

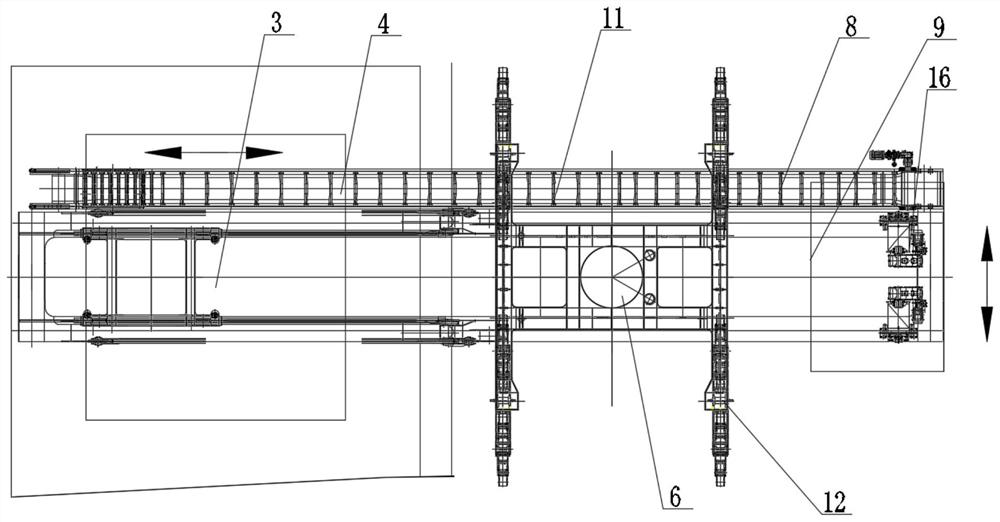

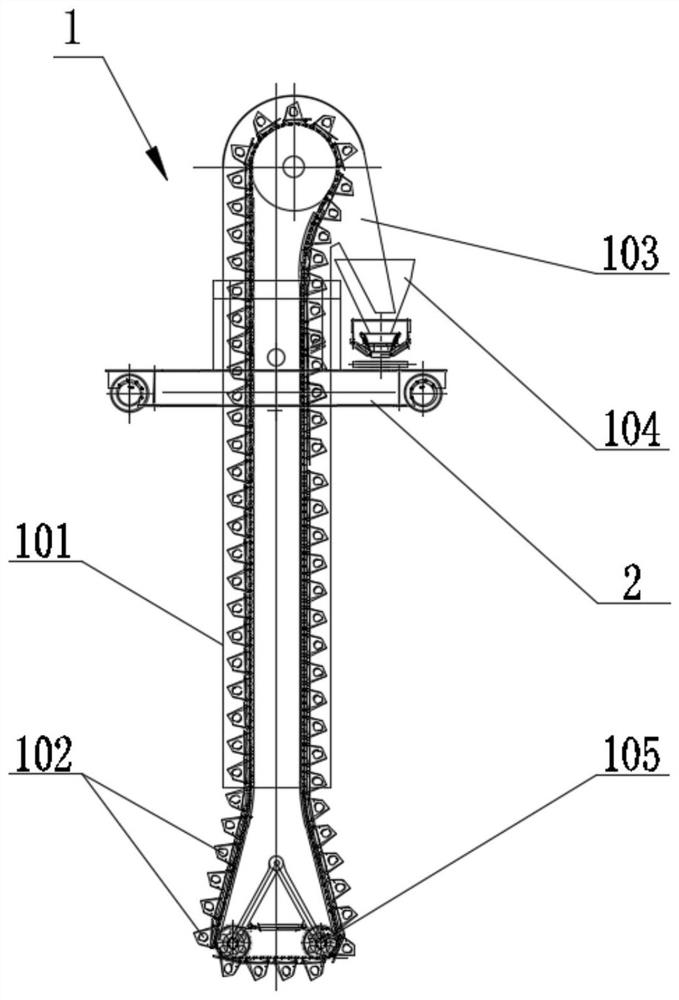

Novel rectilinear reciprocating type and high-efficiency intelligent environment-friendly type unloader with continuous chain buckets

PendingCN111606080ASatisfy the unloading requirementsCompact structureLoading/unloadingStructural engineeringReclaimer

The invention relates to a novel rectilinear reciprocating type and high-efficiency intelligent environment-friendly type unloader with continuous chain buckets. The unloader comprises a chain-buckettaking mechanism, the chain-bucket taking mechanism is fixed to a trolley assembly and follows the trolley assembly to walk along a track on a boom mechanism, and a boom belt connected with an outletof the chain-bucket taking mechanism and a transferring belt in butt joint with the boom belt are arranged on the boom mechanism. An output end of the transferring belt is in butt joint with an unloading belt through a transferring hopper, and an output end of the unloading belt is in butt joint with a wharf belt conveyor arranged on a wharf through a center hopper. The unloader further includes acart running system mechanism, a gantry is perpendicularly provided with a guide circular column, the boom mechanism is provided with a turn mechanism which is arranged on the guide circular column in a sleeving mode and turns around the guide circular column, and the boom mechanism is further provided with a lifting mechanism controlling the boom mechanism to slide up and down along the guide circular column. According to the unloader, the discharging requirements of different ship types and different operating modes are met, the efficiency is high, the cost is low, the unloader is convenient to use, the service life is long, and the utilization factor of the discharging space in a water front of the wharf is improved.

Owner:JIANGSU GONGLI HEAVY MACHINERY

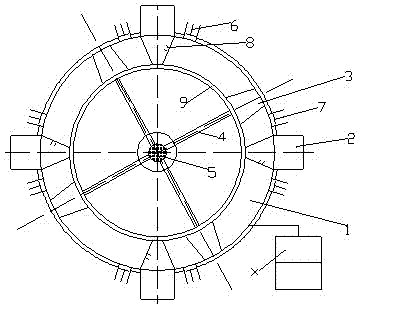

Piston type internal combustion engine

InactiveCN102305130ANo lateral forceAvoid wear and tearInternal combustion piston enginesExhaust valveCrank

The invention discloses a piston type internal combustion engine. An air cylinder (1) of the piston type internal combustion engine is an annular air cylinder; more than four sliding blocks (2) are uniformly arranged on the air cylinder (1) along the circumference so as to divide the air cylinder (1) into more than four working chambers; each working chamber is provided with an air inlet valve (6), an air exhaust valve (7) and a piston (3); one end of a piston connection rod (4) is connected with the piston (3) and the other end of the piston connection rod (4) is connected with a main power shaft (5) in an annular center; oil spraying ignition devices (8) are arranged on the sliding blocks (2); and the work of the air inlet valves (6), the air exhaust valves (7) and the sliding blocks (2) is controlled by a control system. The piston type internal combustion engine has a simple structure and is easy to manufacture; and by the piston type internal combustion engine, the problems that power loss is high, the air cylinder of the conventional reciprocating piston type internal combustion engine is easy to abrade and the stress on a crank shaft is unbalanced in the conventional reciprocating piston type internal combustion engine and the problems that a sealing sheet of a rotor engine is easy to abrade, waste gas cannot be emitted thoroughly, the torque is too small, only one spark ignition mode can be adopted and a rotor engine is hard to manufacture and maintain in the rotor engine are solved.

Owner:贵州创能科技有限公司

Scrape type crust breaking apparatus

The invention mainly relates to a groove body feeding and discharging device with easy material incrustation, in particular to an incrustation breaking device for an electrolysis bath or an electroplating bath. A scraping type incrustation breaking device comprises a flange (2) which is connected with a groove body mounting beam (4) and is arranged on an incrustation pressing cylinder or an incrustation breaking cylinder (1), and a hammer rod (8) connected with the end part of a cylinder piston (1-1); and the lower end of a cylinder sleeve (1-2) is connected with a guide cylinder (7), and thehammer rod moves upwards and downwards in the guide cylinder (7). The groove body feeding and discharging device is mainly characterized in that the lower ends of the guide cylinder (7) and the hammer rod (8) are provided with scaffolding and scraping devices (11); and the lower end part of the hammer rod (8) is connected with a hammer head (12) which is made of austenitic stainless steel. The groove body feeding and discharging device overcomes the defects of the prior incrustation breaking device for an aluminum electrolysis bath so that electrolyte scaffoldings on the surface of the hammerhead of the incrustation breaking device need not be beaten away manually, and the phenomena that the hammer head is fractured and falls into aluminum liquid in the electrolysis bath can be precluded. The groove body feeding and discharging device increases insulating points, improves the insulating reliability, and solves the problem of abnormal spoilage of the cylinder. At the same time, the groove body feeding and discharging device solves the sealing problem of the incrustation breaking device and the upper structure of the electrolysis bath, and the problems of fast hammer replacement and no maintenance of a mechanism.

Owner:许磊

Solenoid device and driver assistance device

ActiveCN102446613AGood repeatabilityReduce frictionOperating means/releasing devices for valvesElectromagnets with armaturesDriver/operatorBiomedical engineering

Owner:ROBERT BOSCH GMBH

A test device for detecting degradation performance in the production of degradable flexible packaging film

ActiveCN113533186BEffective shock absorptionImprove sealingWeather/light/corrosion resistanceChemical methods analysisEngineeringMechanical engineering

Owner:JIANGSU BEST RIEL PACKAGING MATERIALS CO LTD

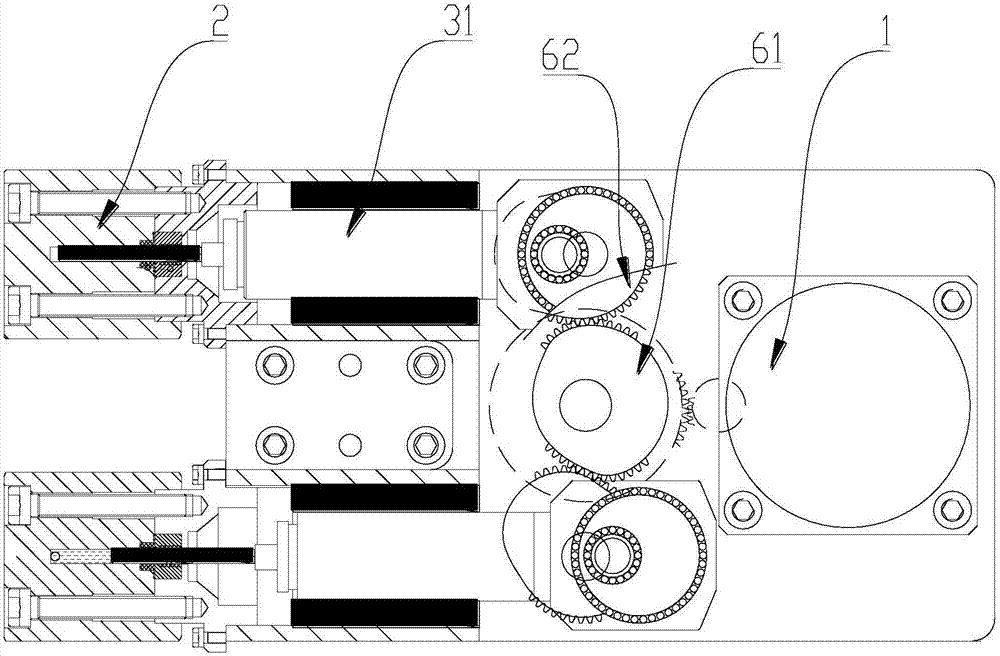

Plunger pump transmission device

InactiveCN107327554AReduce axial sizeEquipment is smallPositive displacement pump componentsGearingPlunger pumpEngineering

The invention relates to a plunger pump transmission device. The plunger pump transmission device comprises a driving device and pump bodies, and further comprises power executing assemblies, wherein the power executing assemblies comprise guide rod shafts which move in the pump bodies in a reciprocating mode, eccentric discs and eccentric shafts; round swinging holes are formed in the ends, extending the pump bodies, of the guide rod shafts; the eccentric discs are round, the eccentric discs are arranged in the swinging holes and are rotationally connected with the swinging holes, round eccentric holes are formed in the eccentric discs, and the rotation axes of the eccentric holes are parallel to the rotation axes of the eccentric discs; and the eccentric shafts comprise power output ends and power input ends, the power output ends are arranged in the eccentric holes and are rotationally connected with the eccentric holes, and the power input ends are connected with the driving device. The plunger pump transmission device cannot only be applied to a small-flow region for a long time, but also can be applied to a large-flow area; and the plunger pump transmission device is long in service life, compact in structure and small in size.

Owner:殷图源

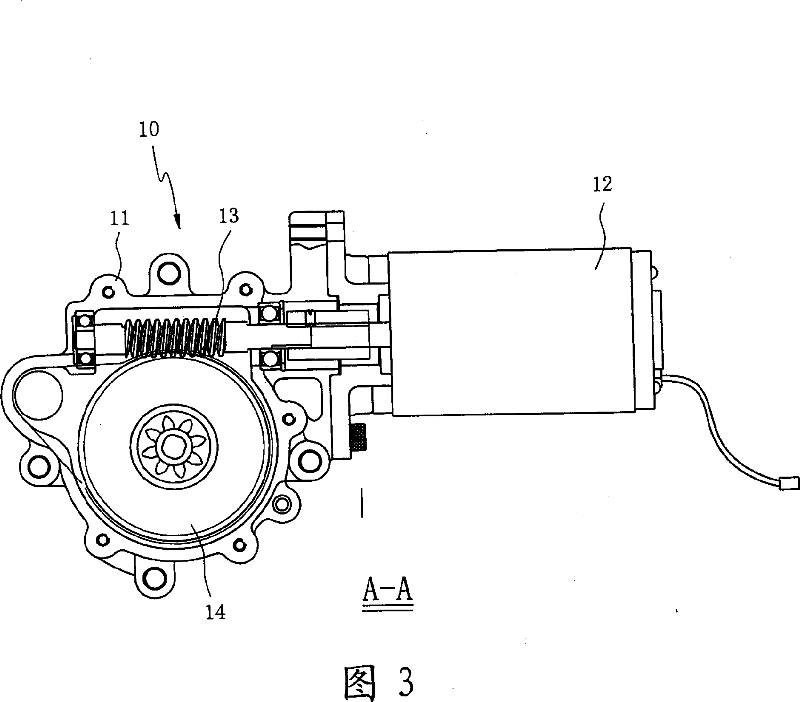

Structure of moving device using electromechanical to control clutch

ActiveCN100356078CEasy to use with transformationsReduce manufacturing costGearingElectrically actuated clutchesLinear motionElectric control

The invention consists of a worm and wormwheel set driven by an electric control motor, a driven gear engaged with a driving gear on the rotation shaft of the wormwheel for driving the rotation shaft of the driven gear to rotate, an oscillating arm firm-jointed at one end of the rotation shaft with a thrust pin. Using the rotation oscillating of the oscillating arm thrusts the pin-lift in the shaft seat to do the linear motion.

Owner:IND TECH RES INST

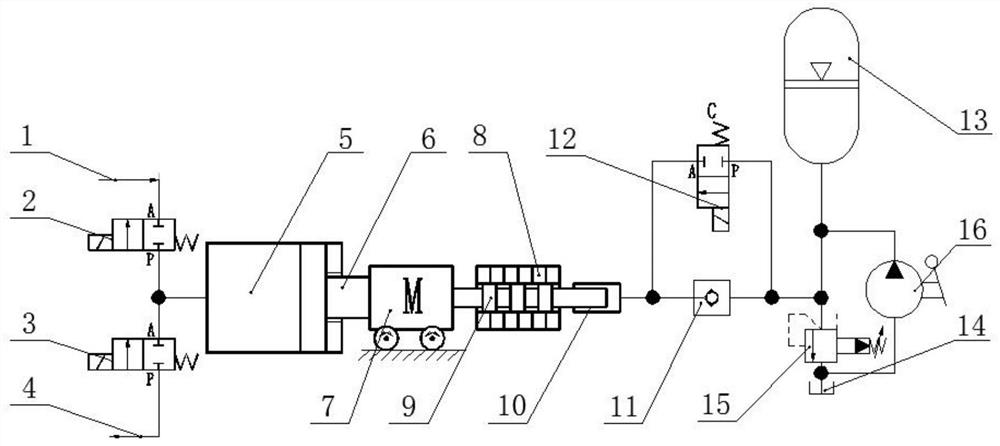

Hydraulic free-piston expander linear power generation unit with counterweight system

ActiveCN112746866BSolve the problem of adapting to the small range of working conditionsImprove instruction efficiencySafety/regulatory devicesEngines without rotary main shaftSolenoid valveEngineering

The invention belongs to the technical field of using high-pressure gas or low-grade heat source to output electric energy, and discloses a hydraulic free-piston expander linear power generation device with a counterweight system, including a first solenoid valve, a second solenoid valve, an expander body, a counterweight trolley, Linear generator, hydraulic plunger cylinder, one-way valve, third solenoid valve, accumulator, oil cylinder, pilot relief valve and manual pump, A end of the first solenoid valve is the gas inlet, P of the second solenoid valve The terminal is the gas outlet, the linear generator is provided with a stator, the stator slides along the track of the linear generator and cuts the magnetic induction line generated by the linear generator, the input terminal of the check valve is connected with the P terminal of the third solenoid valve, the accumulator It is pipe-connected with the pilot relief valve at the same time, the lower side of the pilot relief valve is pipe-connected with the oil cylinder, and the manual pump is connected in parallel at both ends of the pilot relief valve; the invention solves the problem that the expander in the prior art has a limited range of working conditions The problem applies to high pressure gas or low grade heat source to output electrical energy.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

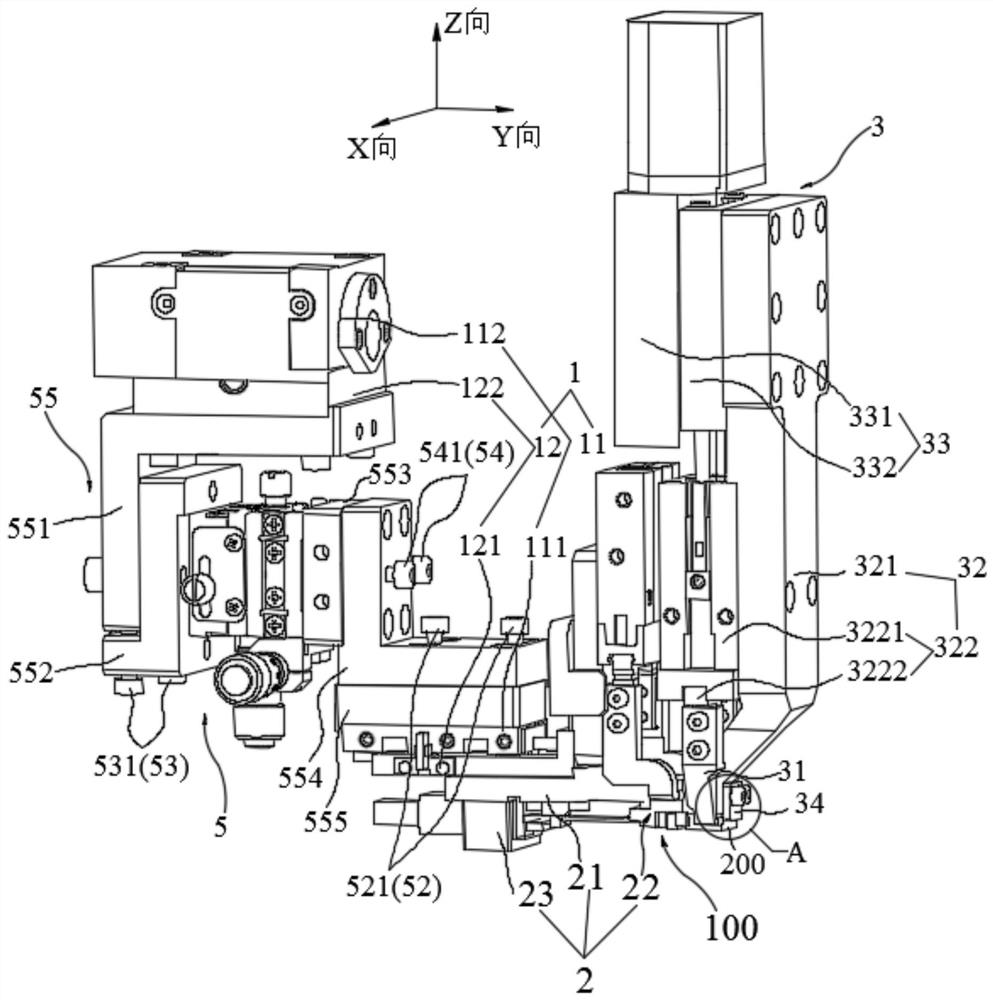

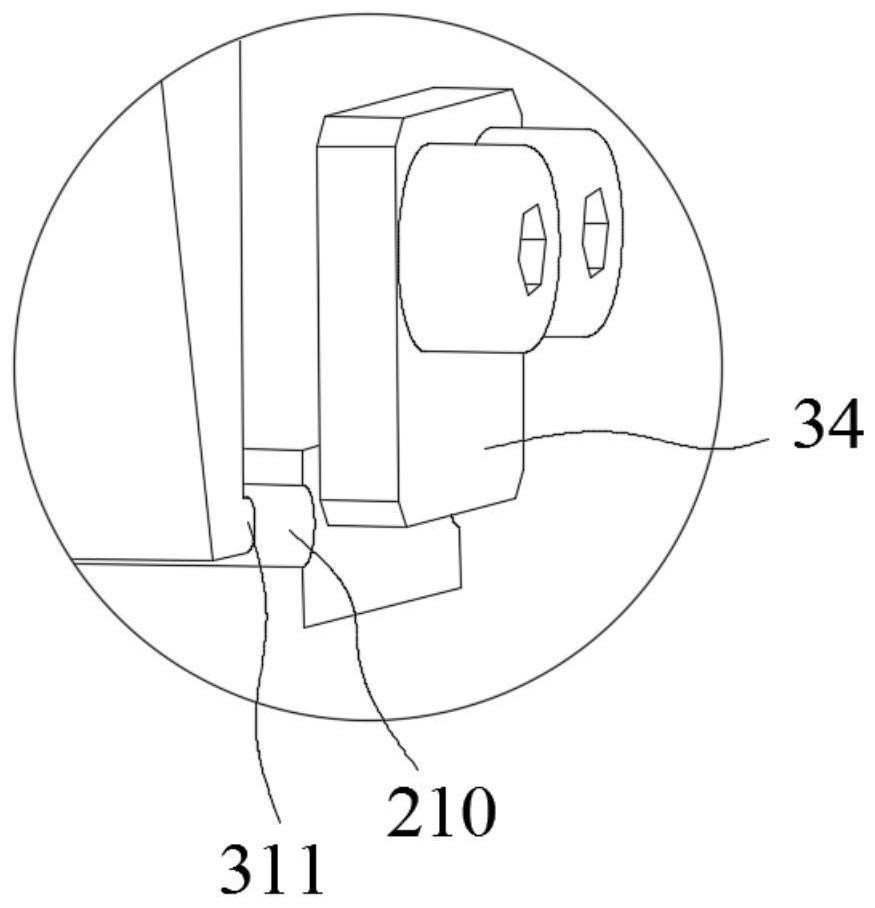

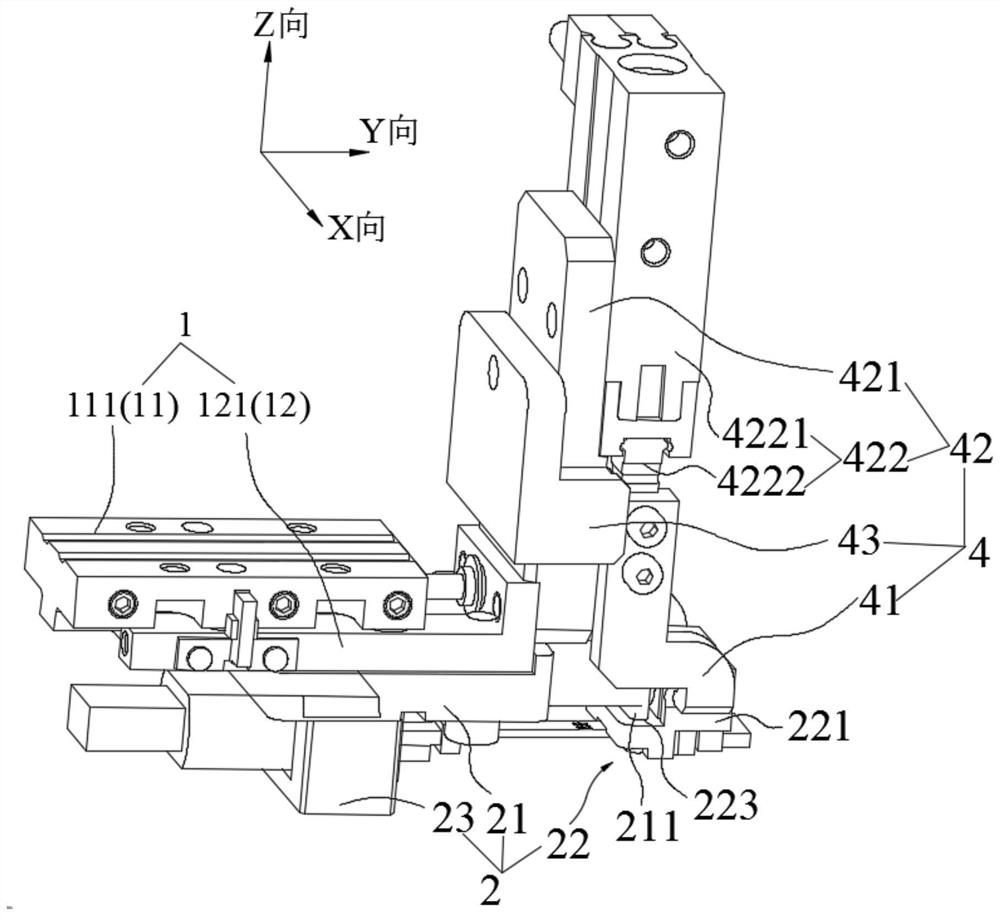

Plugging device and plugging method for optical fiber component

The present application provides a device for inserting and extracting an optical fiber assembly and a method for inserting and extracting the optical fiber assembly, which are used for inserting or extracting the optical fiber assembly into or from the lens assembly. The plugging device includes a push-pull part, a fixing part, a material picking part and a positioning part. The first fixing part of the fixing part can move relative to the fixing body along a plane perpendicular to the plugging-out direction, and the first fixing part is used for fixing the connector at one end of the optical fiber assembly. The positioning jaws of the positioning part are connected to the positioning driving part, and the positioning driving part controls the positioning jaws to clamp the first fixing part so that the connecting head is aligned with the lens assembly, and the positioning jaws loosen the first fixing part, and the configuration is only for the first fixing part. The fixture provides support in the direction of gravity. In the plug-in device provided by this application, during the process of inserting the optical fiber assembly into the lens assembly, the positioning jaws only provide support in the direction of gravity for the connector, so that no lateral force is generated on the connector, effectively reducing the impact on the optical fiber. Risk of component sideways deflection during insertion into the lens assembly.

Owner:GUANGXUN SCI & TECH WUHAN

Piston type internal combustion engine

InactiveCN102305130BNo lateral forceAvoid wear and tearInternal combustion piston enginesExhaust valveCrank

The invention discloses a piston type internal combustion engine. An air cylinder (1) of the piston type internal combustion engine is an annular air cylinder; more than four sliding blocks (2) are uniformly arranged on the air cylinder (1) along the circumference so as to divide the air cylinder (1) into more than four working chambers; each working chamber is provided with an air inlet valve (6), an air exhaust valve (7) and a piston (3); one end of a piston connection rod (4) is connected with the piston (3) and the other end of the piston connection rod (4) is connected with a main power shaft (5) in an annular center; oil spraying ignition devices (8) are arranged on the sliding blocks (2); and the work of the air inlet valves (6), the air exhaust valves (7) and the sliding blocks (2) is controlled by a control system. The piston type internal combustion engine has a simple structure and is easy to manufacture; and by the piston type internal combustion engine, the problems that power loss is high, the air cylinder of the conventional reciprocating piston type internal combustion engine is easy to abrade and the stress on a crank shaft is unbalanced in the conventional reciprocating piston type internal combustion engine and the problems that a sealing sheet of a rotor engine is easy to abrade, waste gas cannot be emitted thoroughly, the torque is too small, only one spark ignition mode can be adopted and a rotor engine is hard to manufacture and maintain in the rotor engine are solved.

Owner:贵州创能科技有限公司

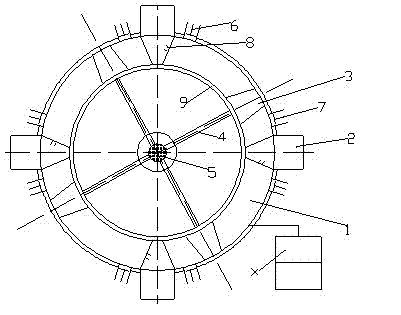

Blast furnace top chute distributing device

ActiveCN103215395BReasonable structureDrive chain shortBell-and-hopper arrangementCharge manipulationEngineeringSlewing bearing

The present invention discloses a furnace top chute distributor for a blast furnace, including an airtight case, a choke, an upper slewing bearing, a rotating sleeve, a chute, a universal frame, a lower slewing bearing, a dial wheel assembly, a cylinder and a horizontal driving apparatus for driving the upper slewing bearing to rotate. The choke extends through a top cover provided on top of the airtight case and into the airtight case. An inner ring of the upper slewing bearing is connected with the top cover. The rotating sleeve on which a lug is provided is connected with an outer ring of the upper slewing bearing, and the chute is hung within the rotating sleeve via the lug. The lug is connected to one end of a crank, while the other end of the crank is positioned within a slideway of the universal frame. An inner ring of the lower slewing bearing is connected with the universal frame. One end of the dial wheel assembly is connected with the inner ring of the lower slewing bearing, while the other end thereof is positioned within a runner of the rotating sleeve. The cylinder is used for drawing the lower slewing bearing to move up and down. The furnace top chute distributor for a blast furnace according to the present invention has advantages, such as reasonable structure, long lifetime, the shortest gearing chain, more stable operation, and no lateral force to the guide rail.

Owner:QINHUANGDAO QINYE HEAVY IND

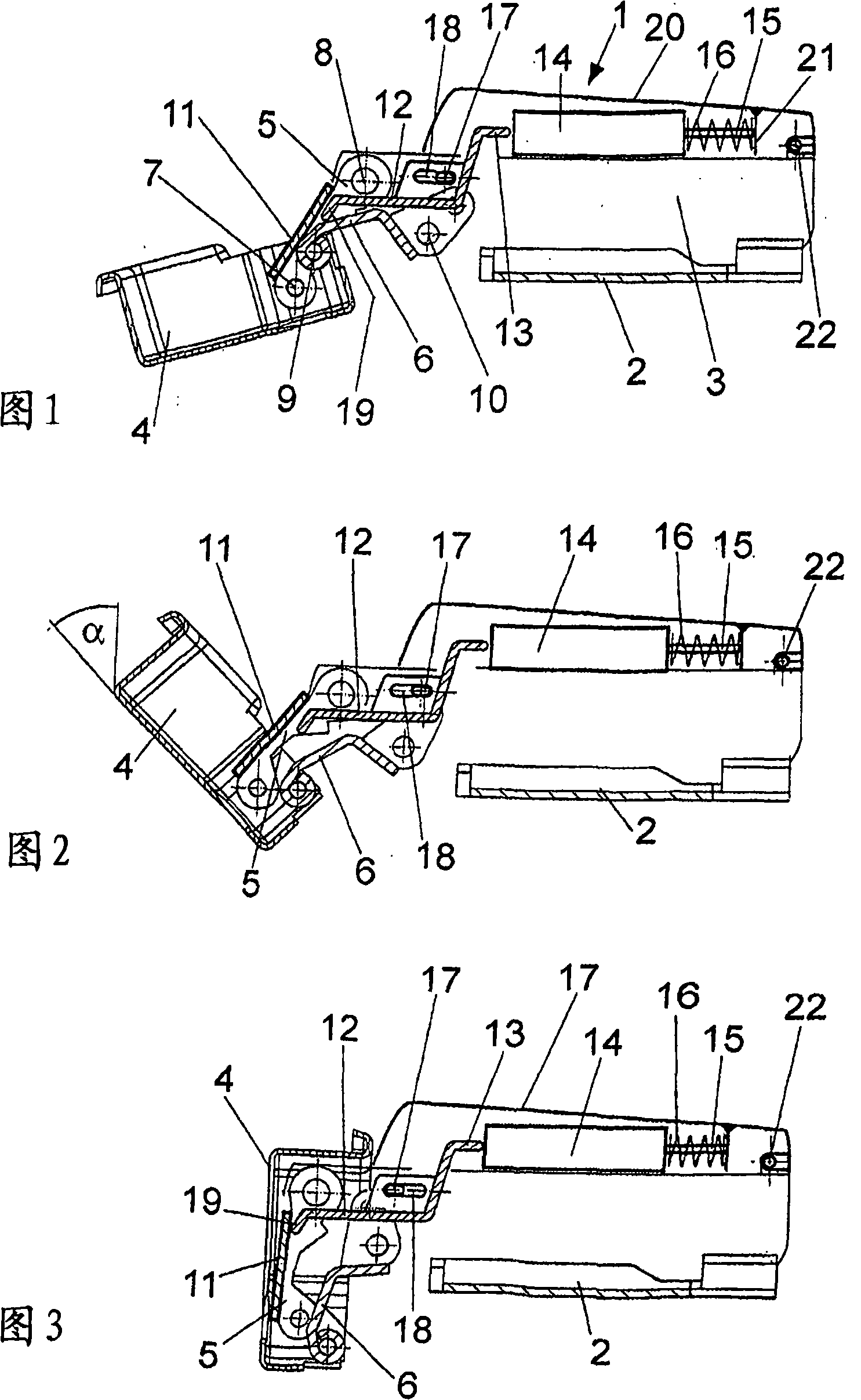

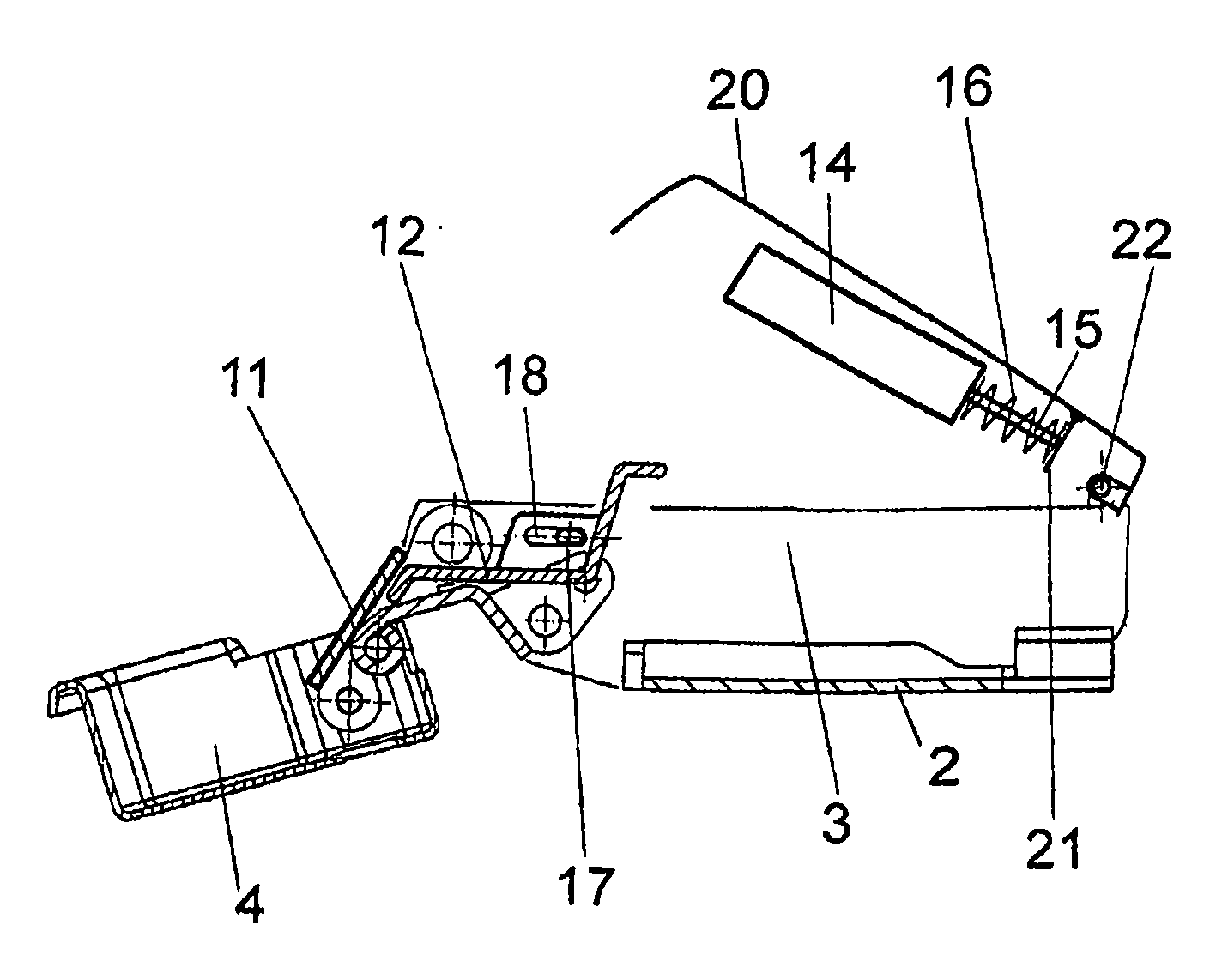

Furniture hinge

ActiveCN101512090BSimple structureAchieve tolerance compensationBuilding braking devicesWing accessoriesCouplingEngineering

A furniture hinge (1), comprising a mounting plate (2), on which a side part (3) is arranged; and a hinge part (4), which is connected via a support rod (11) and a guide rod (6) ) is rotatably supported on the side part (3), wherein a damper (14, 15) is provided for damping the movement of the hinge part (4) relative to the side part (3). A slide plate (12) is also installed on the side part (3), which abuts against a contact surface on the buffer (14, 15) and is established between the buffer (14, 15) and the support rod (11) , the coupling between the guide rod (6) or the hinge part (4). Wherein, the slide plate (12) constitutes a movable intermediate link, which is not fixedly assembled with the buffer through shaft connection, so tolerance compensation can be realized.

Owner:HETTICH ONI

object grabbing device

ActiveCN106002997BWith self-adjusting functionAvoid wear and tearProgramme-controlled manipulatorGripping headsCentre of rotationEngineering

The invention relates to an object grabbing device. The object grabbing device comprises a base, a driving device, a slide rail assembly, an adjusting assembly, an elastic part and a gripper, wherein the slide rail assembly is mounted on the side, opposite to the driving device, of the base, and comprises a guide rail and two sliding blocks capable of moving along the guide rail relative to each other; a rotary part of the adjusting assembly is connected with the driving device; two support pillars are vertically arranged on the two sliding blocks; the rotation center of the rotary part and the axes of the two support pillars are in the same plane; the two ends of the elastic part are connected with the two sliding blocks; a first clamping part and a second clamping part of the gripper are oppositely arranged on the sides, opposite to the support pillars, of the two sliding blocks; and when the gripper grabs an object, the rotary part is not in contact with the two support pillars. According to the object grabbing device, a self-adjusting function is achieved, and when the gripper and the object deviate from each other, the gripper can be automatically adjusted along the guide rail according to the position of the object to align to the object, so that the purpose that the gripper can successfully grab the object is guaranteed, and the abrasion of the gripper and the object is reduced.

Owner:SHENZHEN YHLO BIOTECH

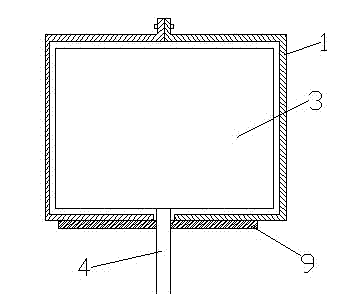

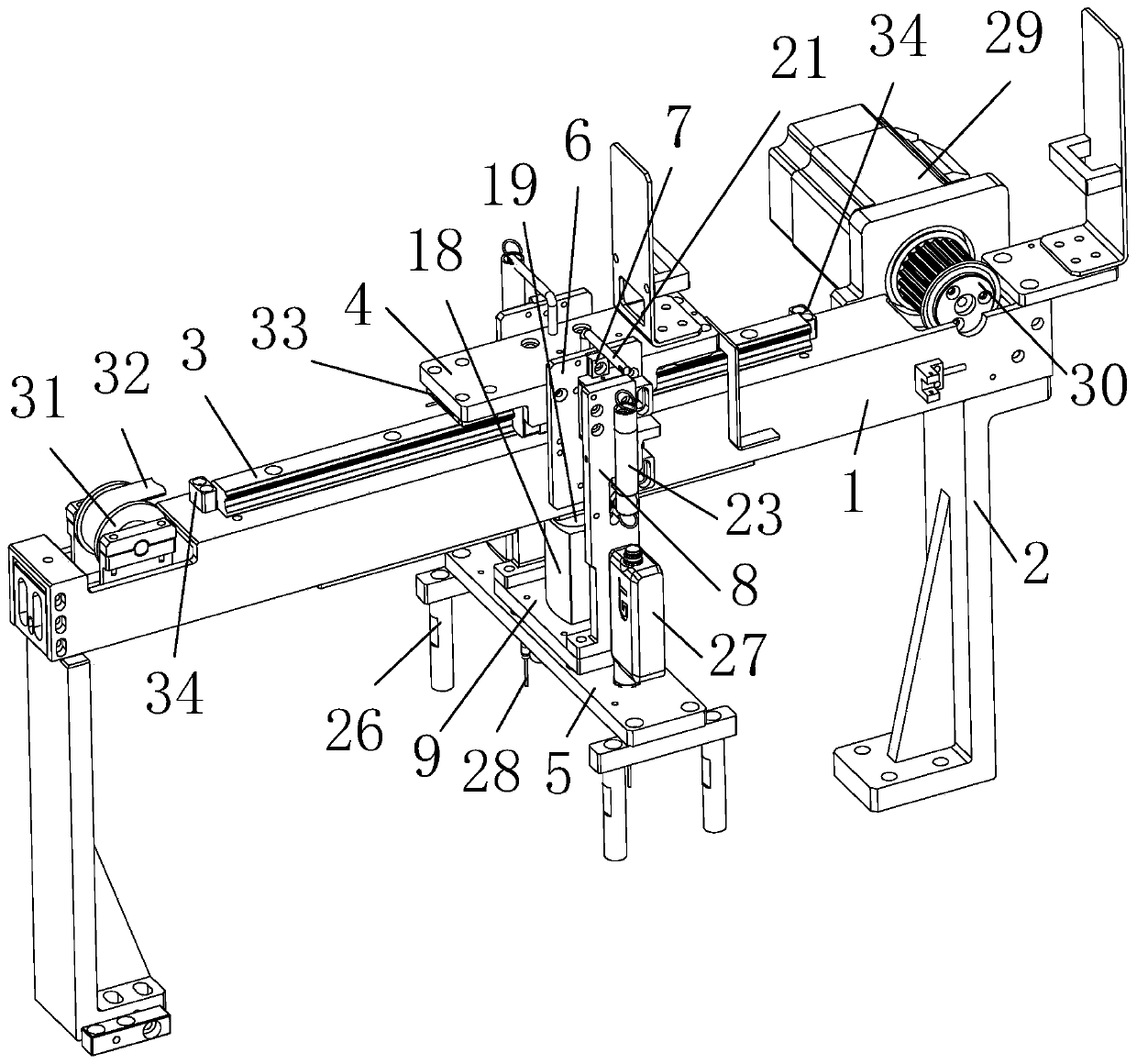

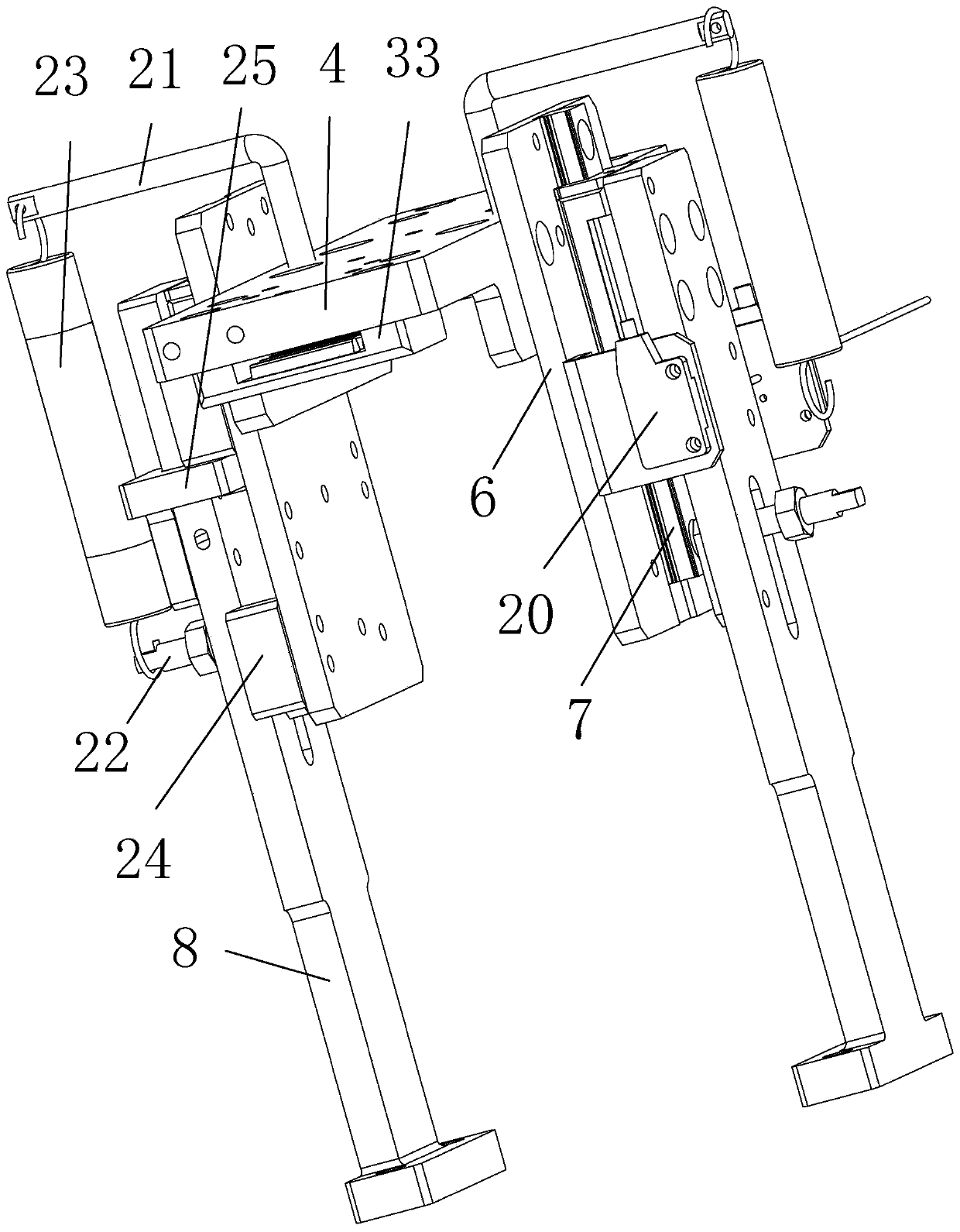

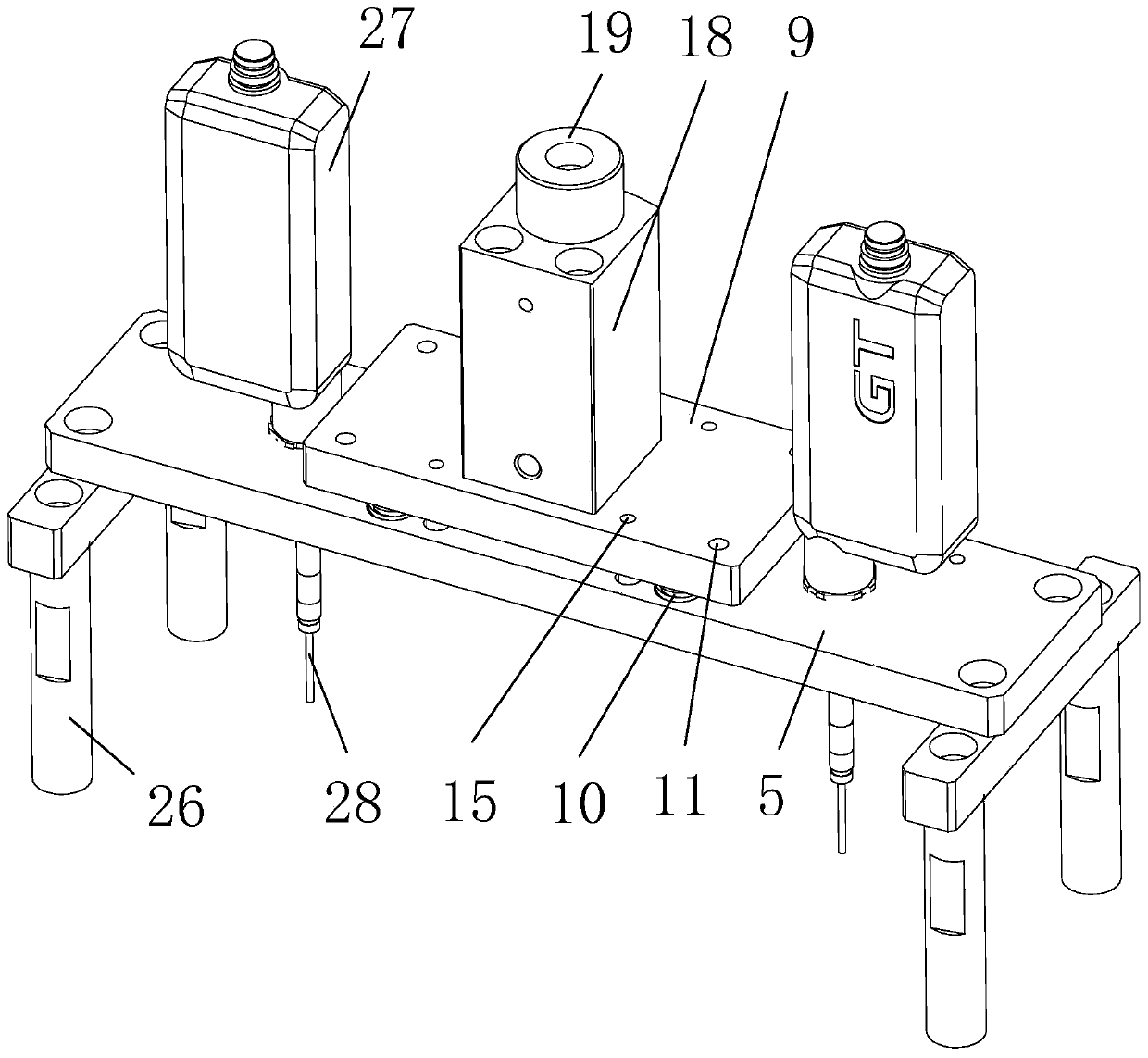

Fingerprint module standing height measuring mechanism and standing height measuring method

ActiveCN108827213BHigh station and high test accuracySimple structureMeasurement devicesStructural engineeringControl theory

The invention aims to provide a fingerprint module station height measuring mechanism and a station height measuring method; the fingerprint module station height measuring mechanism comprises a support with a crossbeam, a mobile linear guiderail arranged on top of the crossbeam, a mobile seat connected with a slide block of the mobile linear guiderail, a mobile drive device, two lift assemblies matched with two side ends of the mobile seat one by one, a station height measuring device arranged on a mount base below the lift assemblies, and a lift; the lift assembly comprises a substrate connected with the side end of the mobile seat, and a lift plate connected with the substrate in a slide manner via the vertical linear guiderail; a float assembly is arranged between the bottom of the lift plate and the mount base. The float assembly is arranged between the bottom of the lift plate and the mount base of the fingerprint module station height measuring mechanism, and can float in X, Y and Z directions in 6 degrees of freedom, thus reducing lifting driving impact without forming a lateral force; the fingerprint module station height measuring precision is high.

Owner:长川科技(内江)有限公司

A coil pressing device

The invention discloses a coil pressing device, and belongs to the technical field of transformer production, which includes a support portion, a drive portion and a pressing portion; The support portion includes a base, a cross beam, a chute and a lug; a lateral beam extends circumferentially outwardly of that base, the cross beam is provided with a sliding groove penetrating the cross beam, a pair of lugs are arranged below the cross beam, and the transmission part comprises a screw, a sliding block, a lower hook, a steel cable, a bevel gear and a pulley; the screw is installed on the lugs of the support part, a sliding block is installed on the screw, the sliding block and the screw are threadably matched, the sliding block is connected with the lower hook, and the lower hook is exposedabove the cross beam through the sliding groove of the support part. The steel cable is connected to the lower hook and the upper hook of the pressing part, the screw extends to the center below thebase, the inner side end of the screw has a bevel gear, the pressing part includes a top cover and an upper hook, the top cover is installed above the coil, and the top cover peripheral ring has an upper hook.

Owner:JIANGXI YAWEI ELECTRIC

Solenoids and Driver Assistance Devices

ActiveCN102446613BSmall cross sectionReduce frictionOperating means/releasing devices for valvesElectromagnets with armaturesDriver/operatorEngineering

Owner:ROBERT BOSCH GMBH

Valve arrangement for reciprocating machinery such as a pump and a compressor

InactiveCN100400873CEasy to installEasy to removePositive displacement pump componentsCheck valvesCylinder headEngineering

A valve arrangement for reciprocating machine, where the arrangement (1) comprises an in-valve (18) and an out-valve (19), each valve (18), (19) being a springloaded one-way valve designed to open for flow when the pressure differential in the direction of flow provides a force that exceeds the spring tension, wherein the valves (18, 19) are mounted in a casing (8) that forms or is connected to the cylinder head of the reciprocating engine (2). The in-valve (18) and the out-valve (19) are mounted in a sleeve (16) designed to be fitted in a bore (9) in the casing (8), and where fluid may flow to the sleeve (16) from an inlet (11) in the casing (8) and into the sleeve (16) via the in-valve (18), and where the sleeve (16) is provided with at least one perforated area where fluid may flow radially out of or into the sleeve (16) via holes (50, 51), thereby flowing to or from a passage (14, 15) that forms a perpendicular or near perpendicular connection with the bore (9).

Owner:NAT OILWELL NORWAY

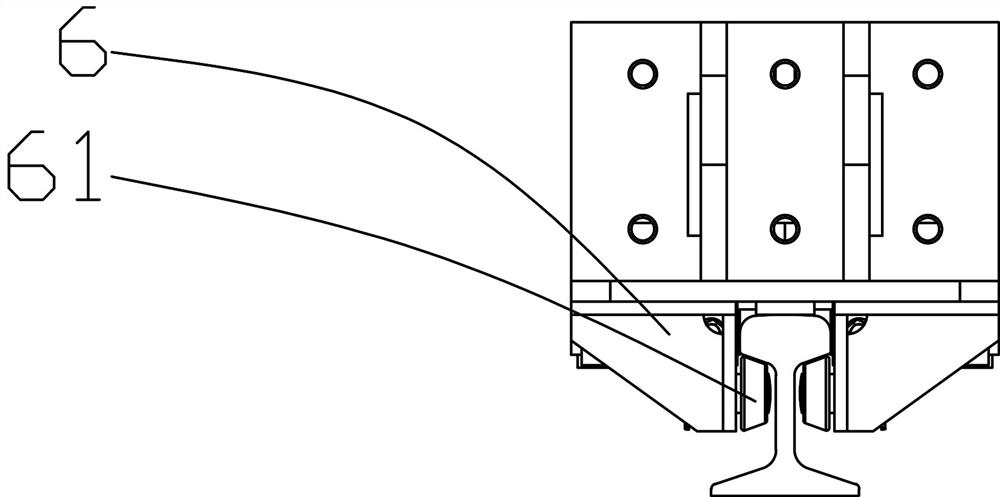

Rail clamping device

PendingCN114717948AAvoid overall overturningReliable forceForms/shuttering/falseworksBridge erection/assemblyClassical mechanicsEngineering

The rail clamping device comprises a clamping base, a connecting base and a reverse hooking wheel base, baffles are arranged on the two sides of the clamping base, an X-shaped cavity is formed between the baffles on the two sides, a wedge block is arranged in the cavity formed by the baffles on the two sides, the wedge block is provided with an inclined face, the inclined face of the wedge block makes contact with the inclined face of the inner wall of the cavity formed by the baffles, and the other face, opposite to the inclined face of the wedge block, of the wedge block is a working face. The working surface is contacted with the side surface of the track; the connecting seat is fixedly connected with the clamping seat, the connecting seat is located at least one end of the clamping seat, and the connecting seat is used for being connected with a driving mechanism; the reverse hooking wheel base is fixedly connected with the connecting base and located below the connecting base, and reverse hooking wheels are arranged on the two sides of the reverse hooking wheel base and used for being hooked to the lateral lower portion of a track. And through the combination of the clamping seat and the reverse hooking wheel seat, the equipment is prevented from overturning. The structure of the four wedge blocks is arranged, so that bidirectional fixation can be realized, and the device is particularly suitable for large-scale pushing and jacking equipment, such as bridge pushing construction, construction of large-scale creeping formworks and stair climbing machines, and other working conditions.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com