Double-shaft balance device of engine

An engine and shaft balancing technology, applied in inertia force compensation and other directions, can solve the problems of long balance shaft length, large space occupied by the balance shaft, and high cost, and achieve the effect of shortening the axial size and facilitating the layout of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

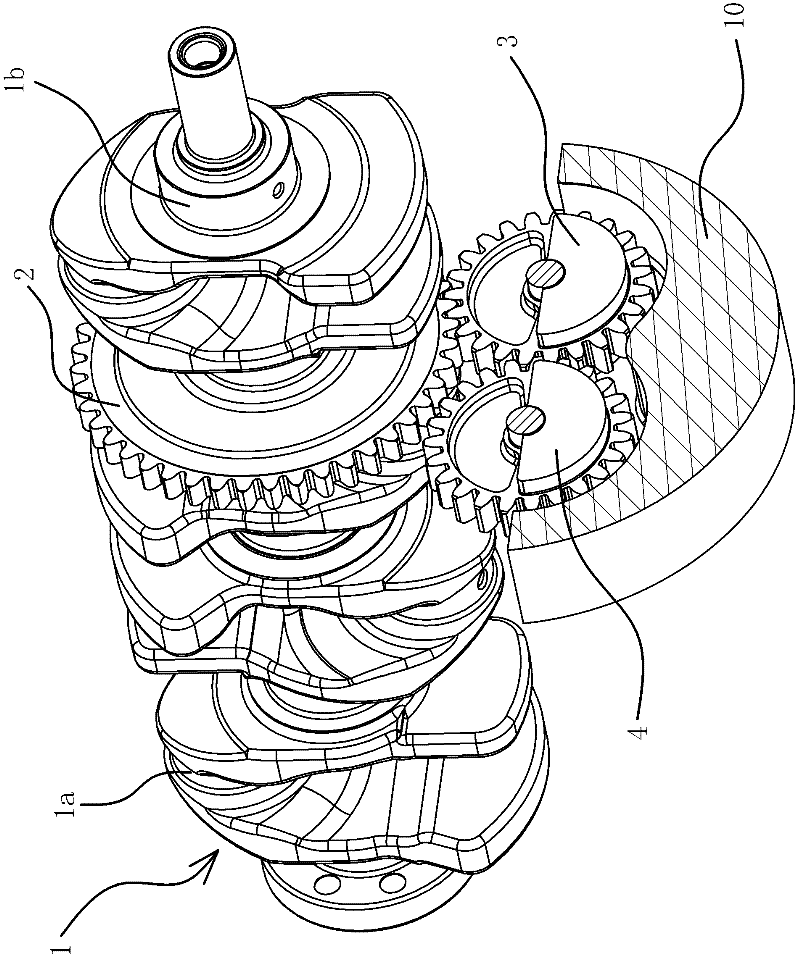

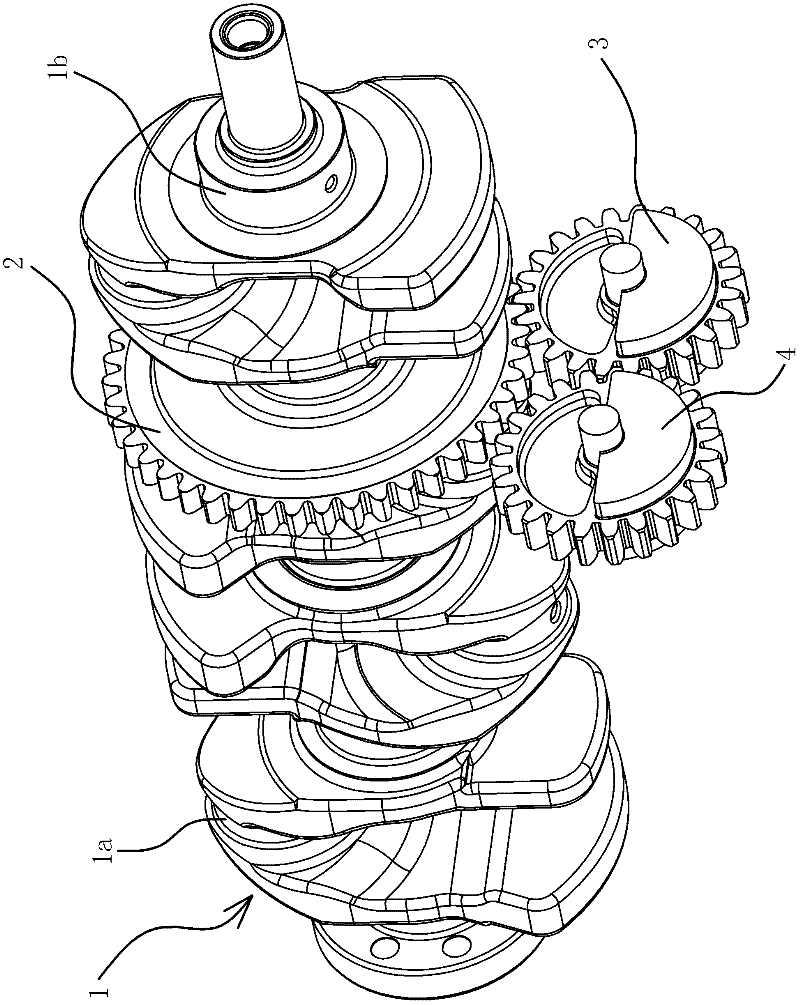

[0030] Such as figure 1 with figure 2 As shown, the engine includes a casing 10 and a crankshaft 1. The dual-axis balance device is arranged in the box body 10 and includes a driving gear 2, a first balance shaft 3 and a second balance shaft 4.

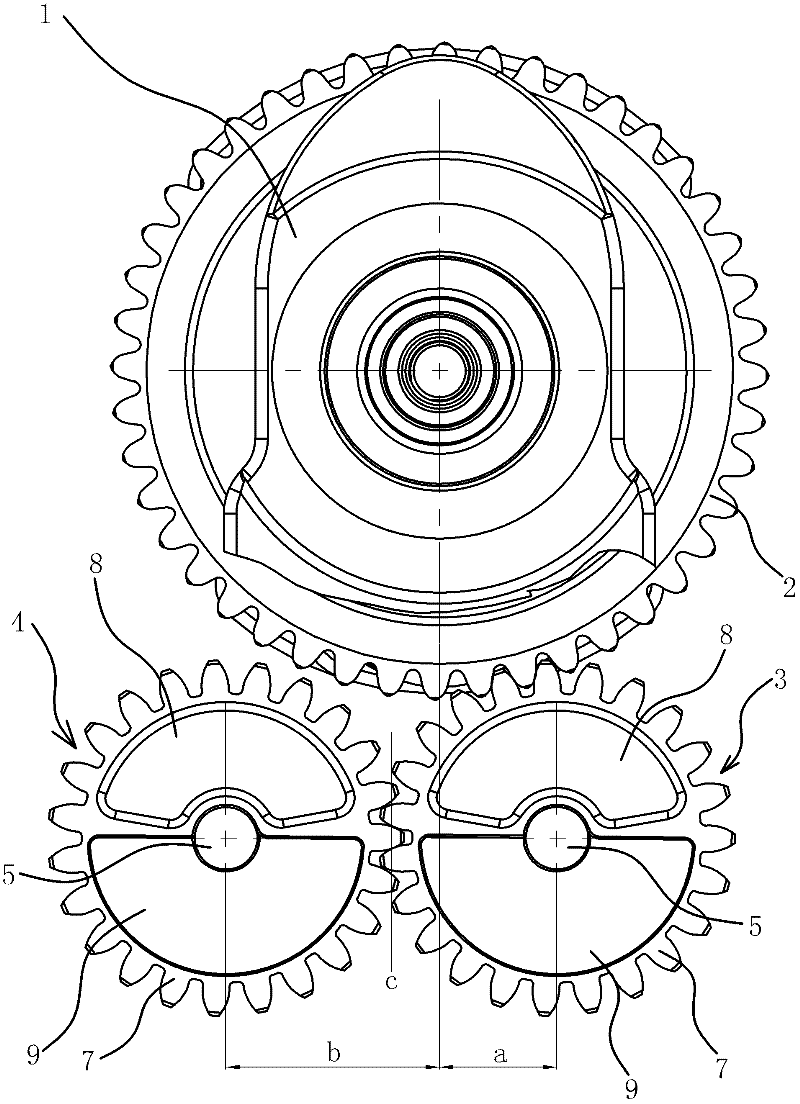

[0031] Specifically, such as figure 1 , figure 2 with image 3 As shown, the drive gear 2 is fixed on the crankshaft 1. The first balance shaft 3 and the second balance shaft 4 are arranged in parallel with respect to the main journal 1 b of the crankshaft 1 and located beside the crankshaft 1. The solution given in this embodiment is that the first balance shaft 3 and the second balance are located below the crankshaft 1; the first balance shaft 3 and the second balance are located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com