Rail clamping device

A technology of rail clamps and rails, which is applied in the direction of formwork/formwork/work frame, erection/assembly of bridges, connectors of formwork/formwork/work frame, etc. Control difficulty and other issues, to achieve the effect of short start-up work stroke, reduce control difficulty, and avoid equipment overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

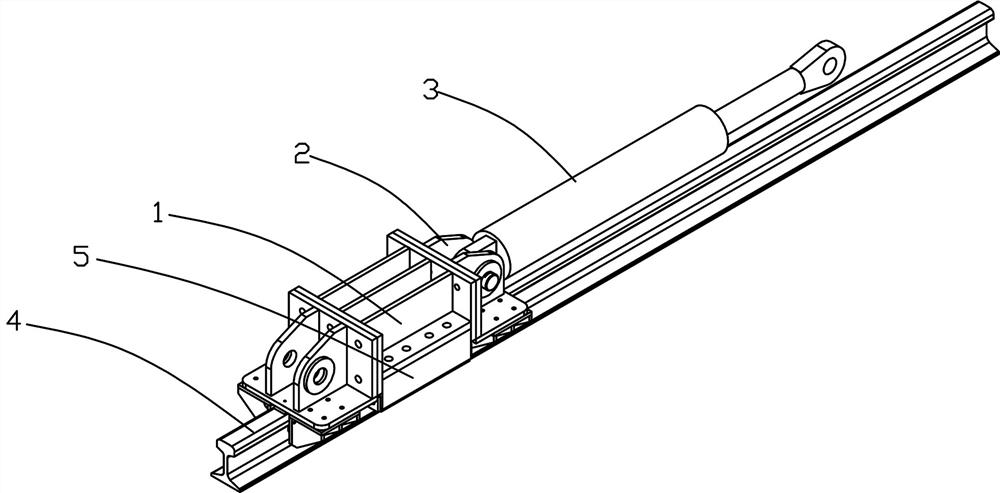

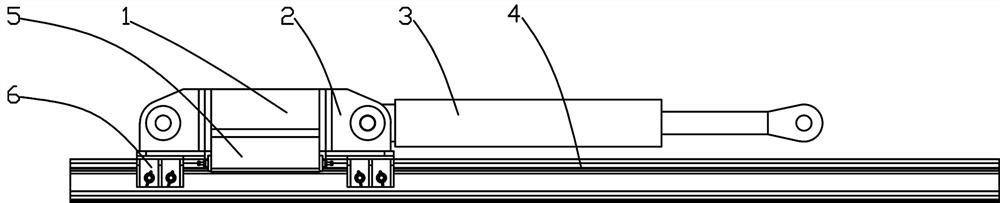

[0036] like Figures 1~4 Among them, a rail clamp includes a clamping seat 1, a connecting seat 2 and a reverse pulley seat 6. There are baffle plates 5 on both sides of the clamping seat 1, and an "X"-shaped space is formed between the baffle plates 5 on both sides. A wedge 108 is provided in the cavity formed by the baffles 5 on both sides, and the wedge 108 is provided with an inclined surface. The inclined surface of the wedge 108 is in contact with the inclined surface of the inner wall of the cavity formed by the baffle One side is the working surface 123, and the working surface 123 is used to contact the side surface of the track 4;

[0037] The connecting seat 2 is fixedly connected with the clamping seat 1, the connecting seat 2 is located at at least one end of the clamping seat 1, and the connecting seat 2 is used for connecting with the driving mechanism 3;

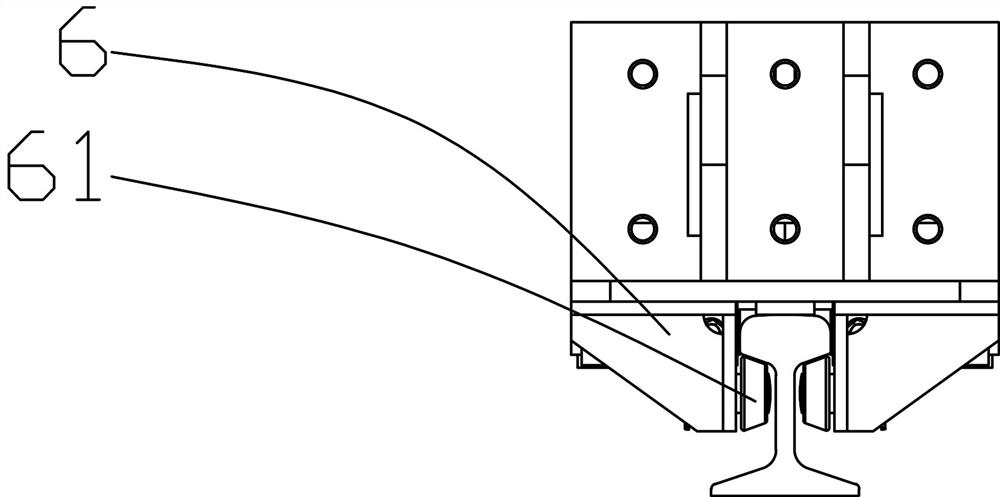

[0038] like figure 2 , 3 In the middle, the reverse hook wheel seat 6 is fixedly connected with the co...

Embodiment 2

[0042] On the basis of Example 1, the preferred scheme is as follows Figure 5 In the middle, a friction block 107 is provided at the position where the baffle 5 is in contact with the wedge block 108. The friction block 107 is made of wear-resistant material, such as wear-resistant rubber or wear-resistant steel block, such as high-chromium steel. The friction block 107 is connected to the The baffle 5 is fixedly connected. With this configuration, it is possible to reduce the service life of the parts that are difficult to replace. And the wedge 108 is correspondingly easy to replace.

Embodiment 3

[0044] On the basis of embodiment 1 or 2, the preferred scheme is as follows Figure 5 The two ends of the cavity formed by the baffle 5 are also provided with adjusting nuts 105 , and a spring 106 is provided between the adjusting nut 105 and the wedge 108 , and the spring 106 is used to pre-compress the wedge 108 . With this structure, the preloading force can be adjusted to shorten the starting working stroke as much as possible, and the starting working stroke refers to the stroke from starting to complete locking. Moreover, the adjustment of the pre-tightening force of the adjusting nut 105 can also control the rail clamp to achieve one-way locking, which is very effective in the working condition of jacking. tight, as Figure 5 The adjustment nut 105 on the left side of the Figure 5The right side adjusting nut 105 in the middle, when the drive mechanism 3, usually the piston rod of the hydraulic cylinder, is retracted, because the wedge 108 close to the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com