Scrape type crust breaking apparatus

A technology of shelling device and scraping device, which is applied in the field of tank body feeding and discharging device, to achieve the effects of solving abnormal damage, increasing insulation points, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

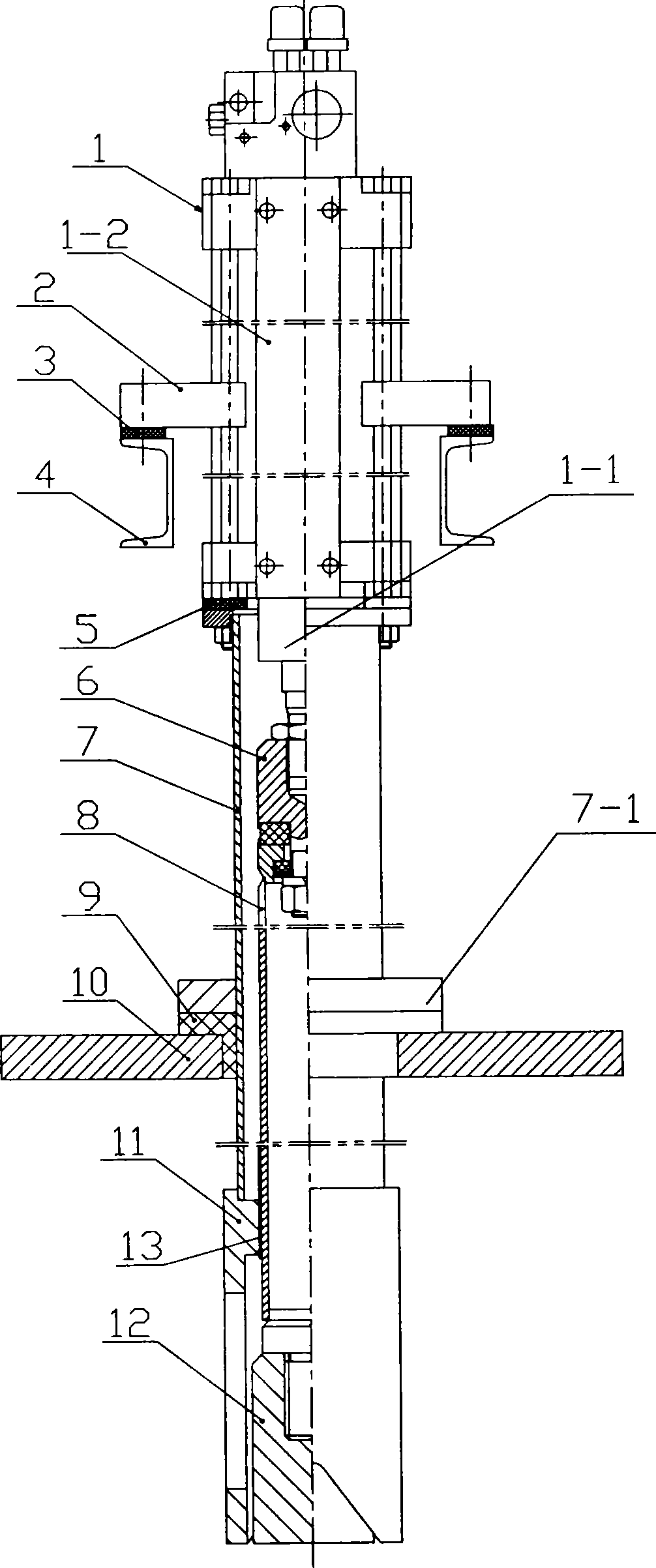

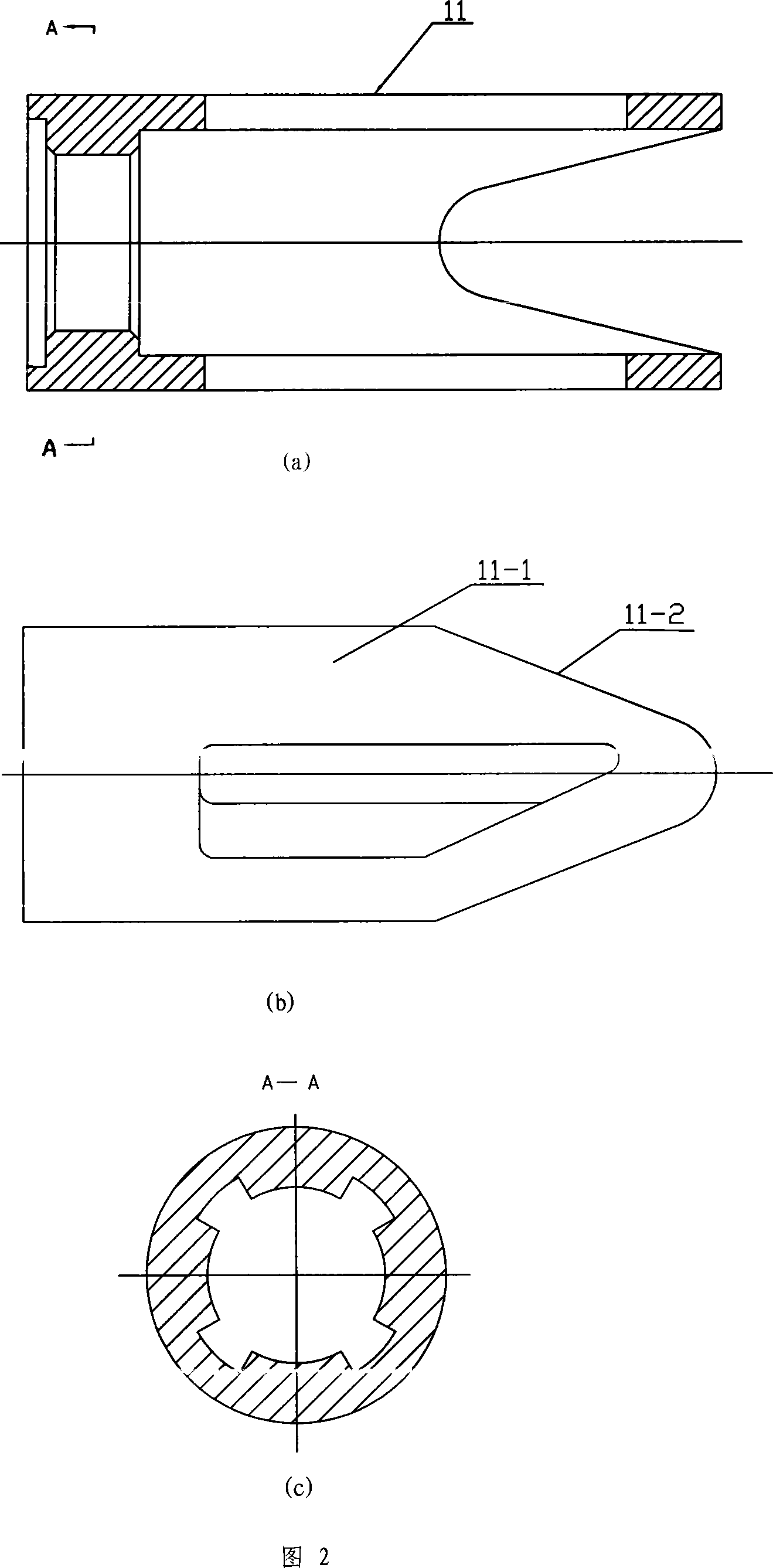

[0023] Example 1, see figure 1 , figure 2 (a), figure 2 (b), figure 2 (c), a kind of scraping type shelling device, comprises that the shelling cylinder 1 is provided with the flange 2 that is connected with the groove body installation beam 4, is connected with hammer rod 8 at the end of cylinder piston 1-1; The lower end of the cylinder liner 1-2 is connected with a guide cylinder 7, and the hammer rod moves up and down in the guide cylinder 7. A nodulation scraping device 11 is provided at the lower ends of the guide cylinder 7 and the hammer rod 8; the lower end of the hammer rod 8 is connected with a hammer head 12. The material of the hammer head 12 is austenitic stainless steel, and its material grade is 304. The connection between the nodulation scraping device 11 and the hammer rod 8 is a key connection, the connection part is provided with a spline groove, and the lower part is provided with an arc-shaped scraper 11-1. The cutting edge 11-2 of the scraper 11-1...

Embodiment 2

[0024] Example 2, see figure 1 , figure 2 (a), figure 2 (b), figure 2 (c), image 3 , a scraping type shell breaking device, a hammer rod guide ring 13 with splines is provided between the connection part of the nodulation scraping device 11 and the hammer rod 8 . The hammer rod 8 and the hammer head 12 are connected by trapezoidal thread. The cutting edge 11-2 of the scraper 11-1 is a helical line. The material of the hammer head 12 is austenitic stainless steel, and its material grade is 316. All the other structures are the same as in Example 1.

Embodiment 3

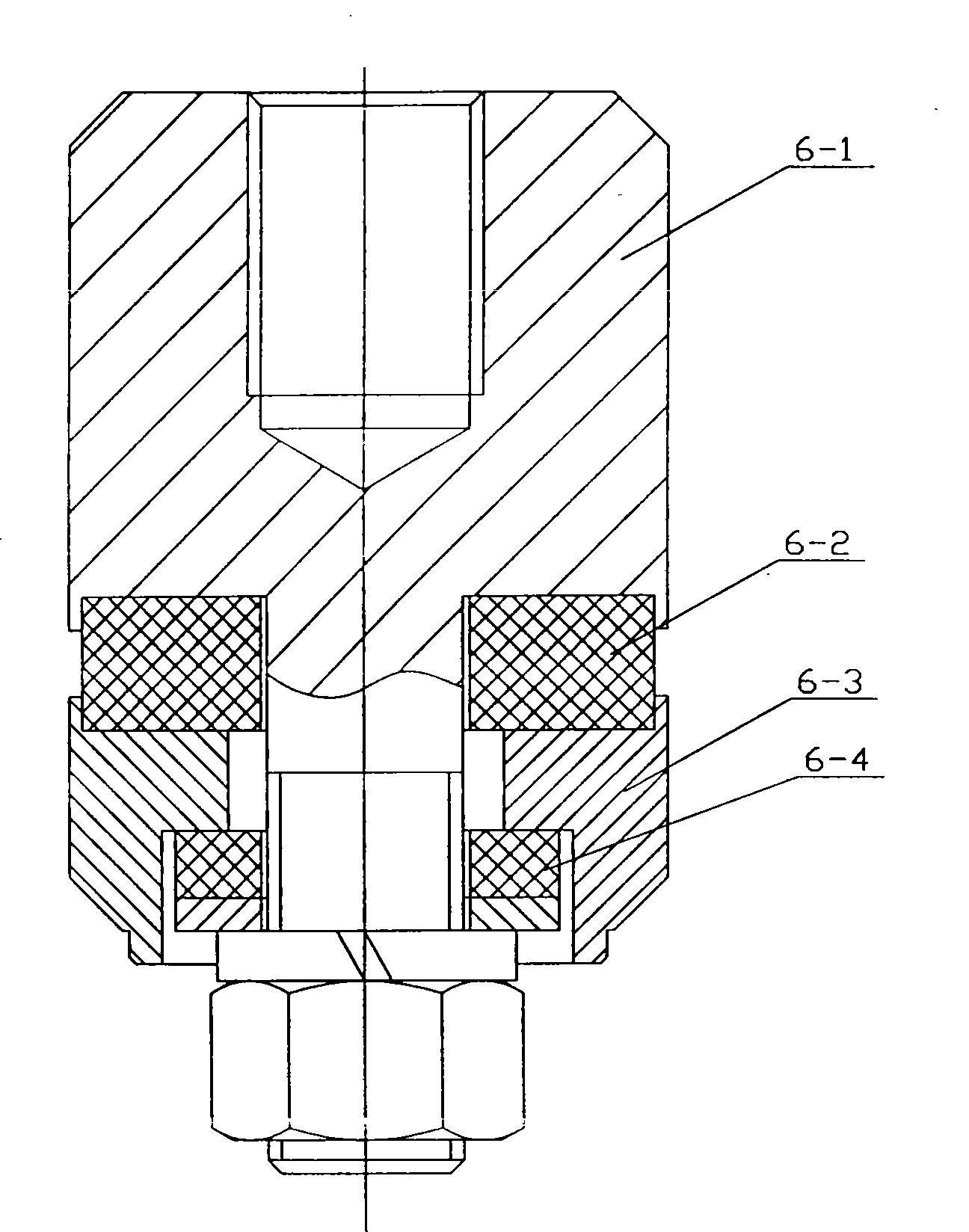

[0025] Example 3, see figure 1 , figure 2 (a), figure 2 (b), figure 2 (c), image 3 , a scraping type shelling device also includes a hammer rod insulating part 6 between the end of the cylinder piston 1-1 and the hammer rod 8 . The hammer rod insulation part 6 includes an upper connecting piece 6-1 connected with the cylinder piston 1-1, a lower connecting piece 6-3 connected with the hammer rod 8, and the upper connecting piece 6-1 and the lower connecting piece 6 -3 are provided with an insulating pad 6-2 and an insulating ring 6-4. The scraping shell breaking device also includes an insulating pad 3 between the electrolytic cell installation beam 4 and the flange 2 . An insulating dust cover 9 is provided between the flange 7-1 at the lower end of the guide cylinder 7 and the upper horizontal cover plate 10 of the electrolytic cell. The insulating dust cover 9 can seal between the guide cylinder 7 and the horizontal cover plate 10 on the upper part of the electrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com