Structure of moving device using electromechanical to control clutch

An electromechanical control and clutch technology, applied in the direction of electric clutches, non-mechanical drive clutches, clutches, etc., can solve the problems of difficult force specifications, changes in action speed and action range, inability to effectively reduce production costs, and reduced service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

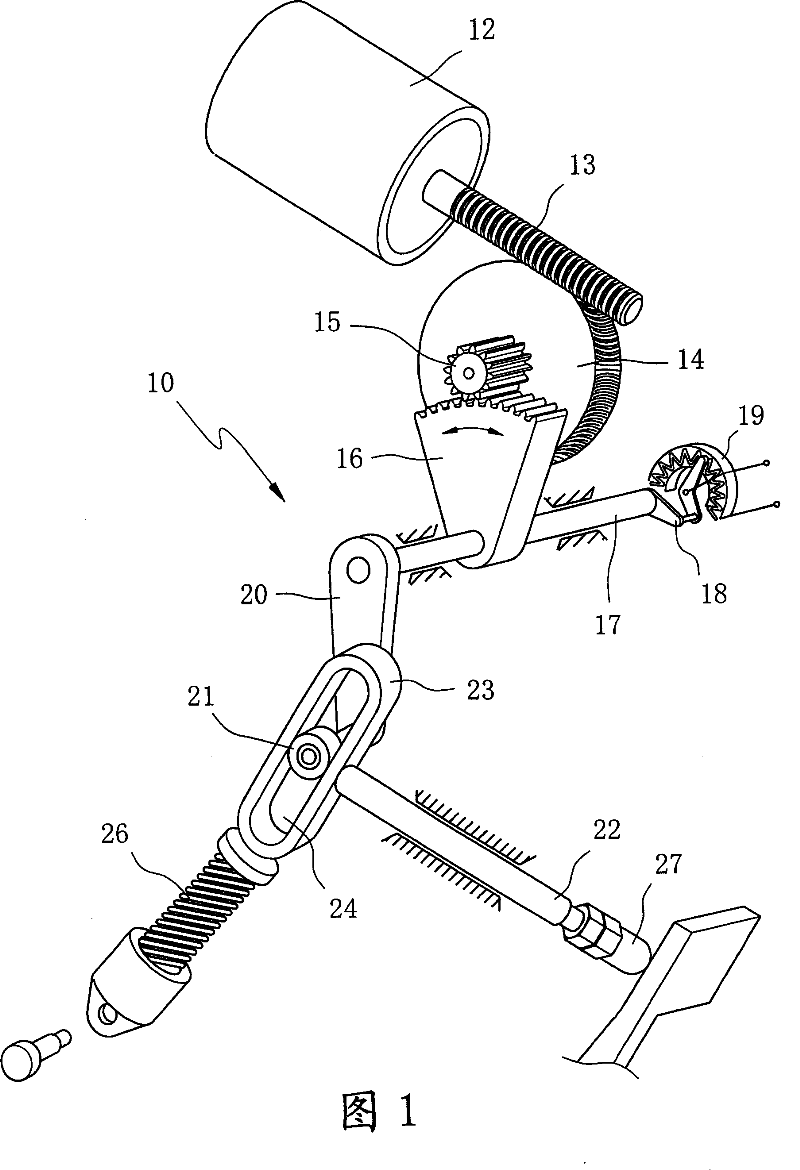

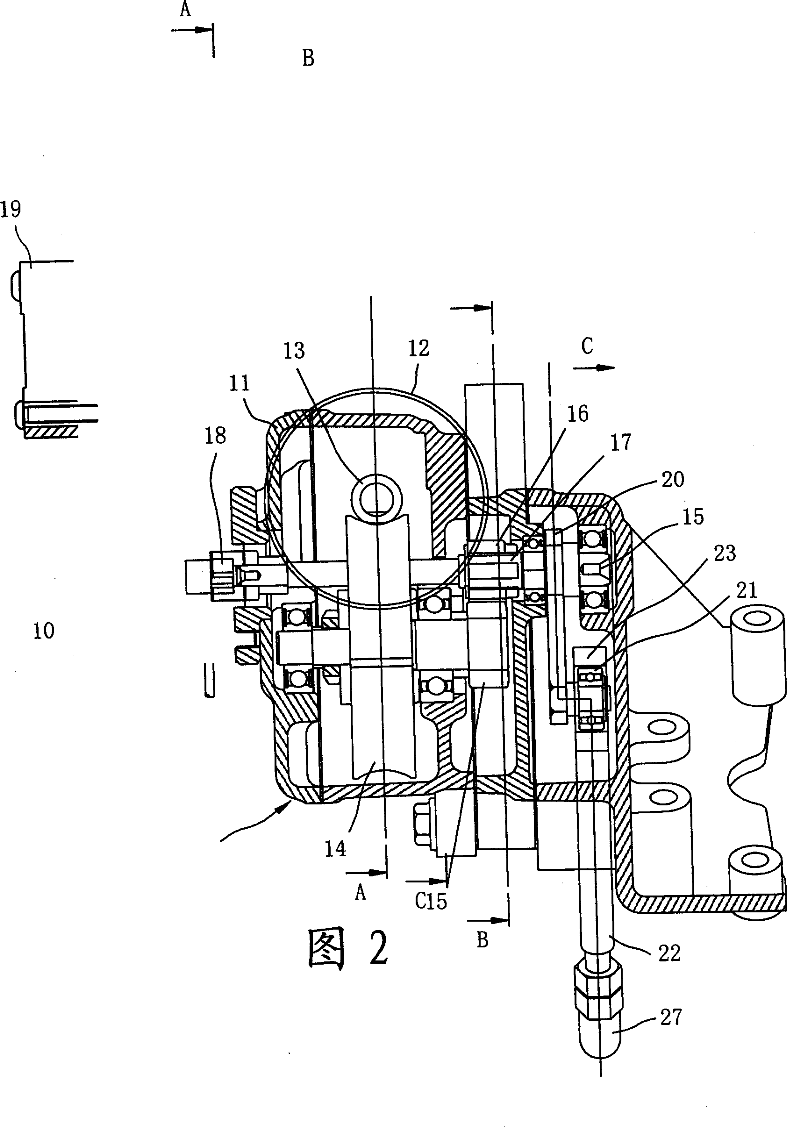

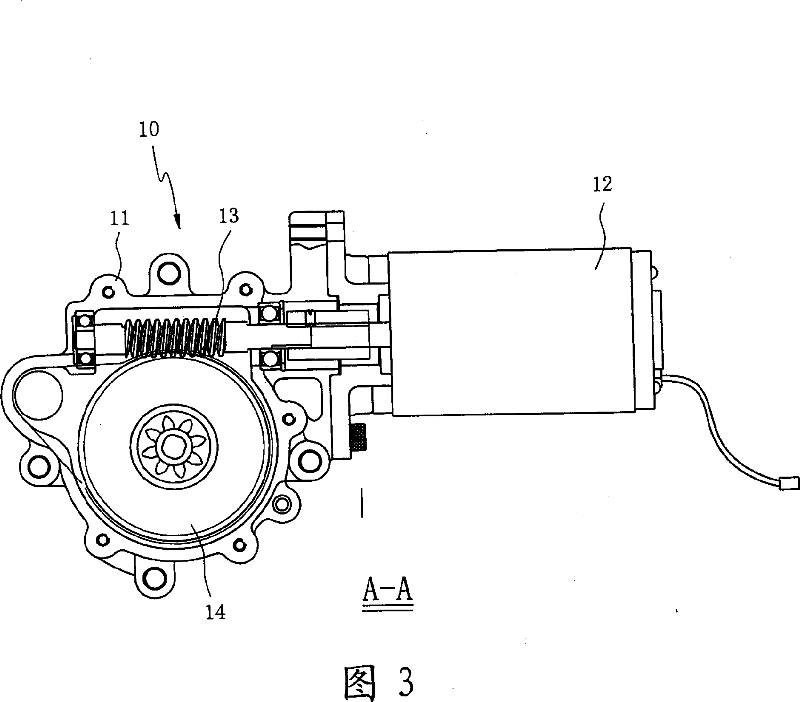

[0021] Please refer to Fig. 1, Fig. 2, Fig. 3, the structure of the actuator 10 of the present invention is that an electric control motor 12 is fixed on the outside of the casing 11, and the rotating shaft of the electric control motor 12 extends into the casing 11 to connect a worm 13, And mesh transmission with a worm gear 14, and utilize the transmission of worm gear set, can obtain very big reduction ratio and enlarge the output torque of electric control motor 12; One side of the rotating shaft is provided with a driving gear 15, which utilizes the rotation of the worm wheel 14 to drive the driven gear 16 meshed with it. The driven gear 16 is placed in order to reduce the excessive space occupied by the casing 11 without affecting the rotation stroke. Made into a fan shape, and this active and passive gear set can carry out the deceleration motion of the second stage; please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, the driven gear 16 is fixed on a rotating shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com