Piston type internal combustion engine

An internal combustion engine, piston type technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of difficulty in manufacturing and maintenance, uneven force on the crankshaft, low transmission efficiency, etc., to avoid power loss and cylinder wear, Simple manufacturing and maintenance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

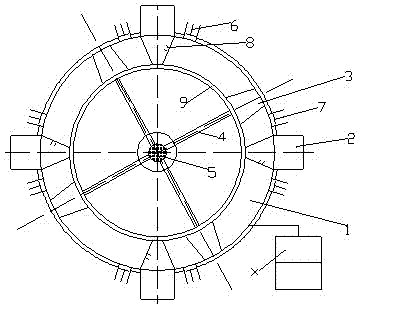

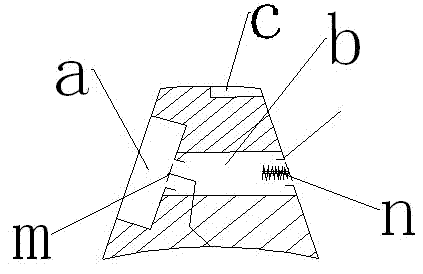

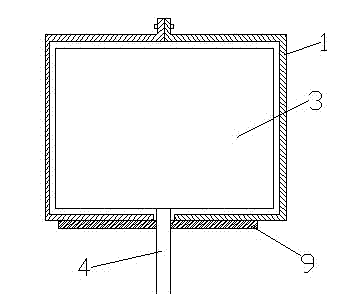

[0040] Such as figure 1 , the cylinder 1 is an annular cylinder, and four sliders 2 are evenly arranged on the cylinder 1 along the circumference, and the cylinder 1 is divided into 4 working rooms, and each working room is provided with a piston 3, an intake valve 6 and an exhaust valve 7, and the cylinder 1. It is formed by merging two halves of the cylinder wall. The outer edge of the outer circle is sealed and fixed with bolts. There is an annular seam on the inner circle of the cylinder wall of cylinder 1, and a sealing device 9 is set at the annular seam; piston connecting rod 4 It is connected to the piston 3 through the gap of the annular gap, and the other end is connected to the main power shaft 5 located in the center of the ring; the slider 2 is provided with an oil injection ignition device 8; the top of the piston 3 has an exhaust groove c, the length of which is the length of the top There is a combustion chamber a on the left side, a compressed gas storage cha...

Embodiment 2

[0054] Embodiment 2 adopts mechanical control system, such as Figure 5 and Figure 6 , the cylinder 1 is an annular cylinder, and four sliders 2 are evenly arranged on the cylinder 1 along the circumference, and the cylinder 1 is divided into 4 working rooms, and each working room is provided with a piston 3, an intake valve 6 and an exhaust valve 7, and the cylinder 1. It is formed by merging two halves of the cylinder wall. The outer edge of the outer circle is sealed and fixed with bolts. There is an annular seam on the inner circle of the cylinder wall of cylinder 1, and a sealing device 9 is set at the annular seam; piston connecting rod 4 It is connected to the piston 3 through the gap of the annular seam, and the other end is connected to the main power shaft 5 located in the center of the ring; the fuel injection and ignition device 8 is arranged on the slider 2; an exhaust groove c is opened on the top of the piston 3, and there is a The combustion chamber a has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com