Valve arrangement for reciprocating machinery such as a pump and a compressor

A reciprocating and valve device technology, which is applied to parts of pumping devices for elastic fluids, valve devices, liquid variable capacity machines, etc., can solve the problem of skewing, uneven wear, and disassembly of valve bodies and valve seats. open and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

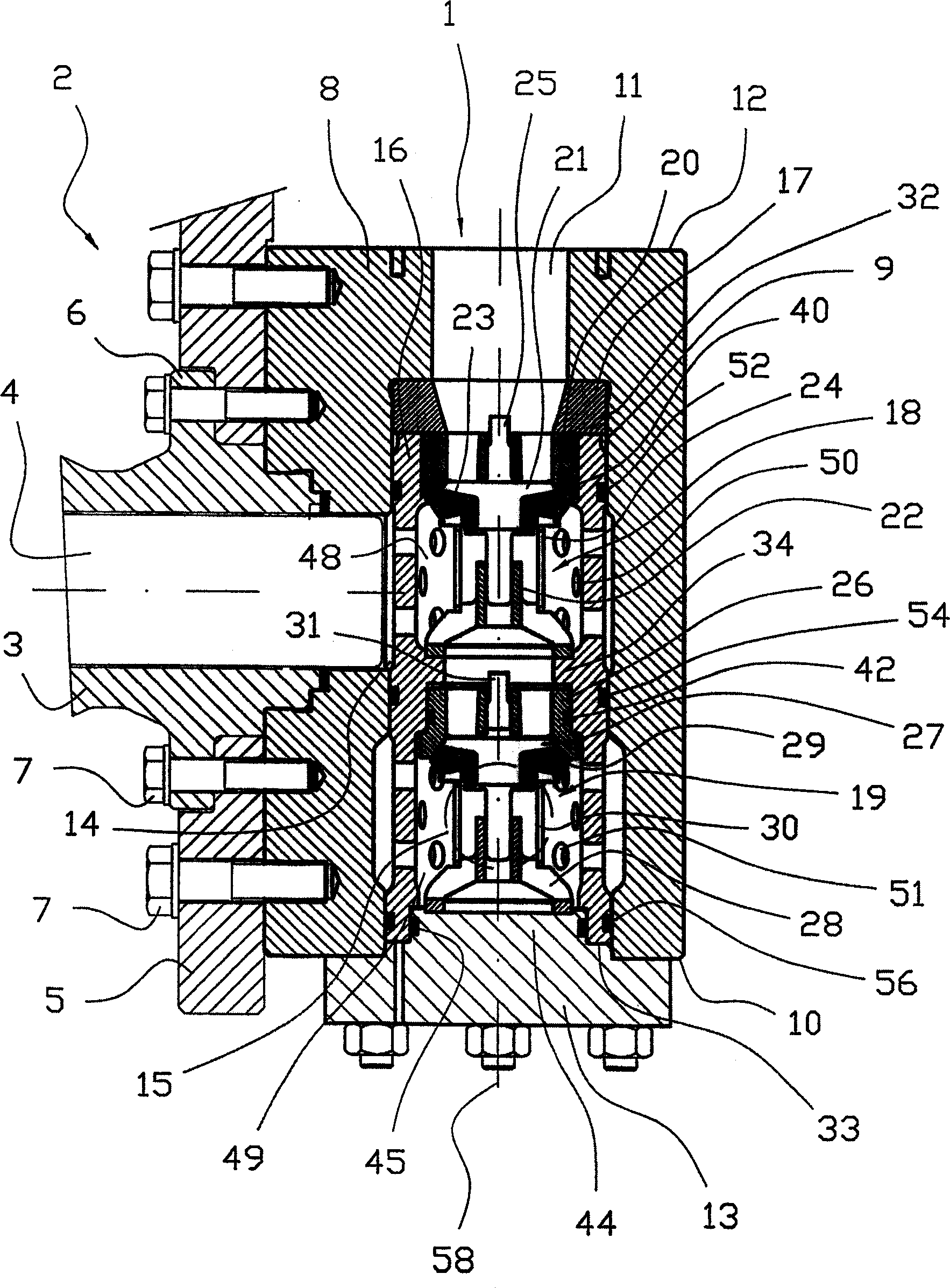

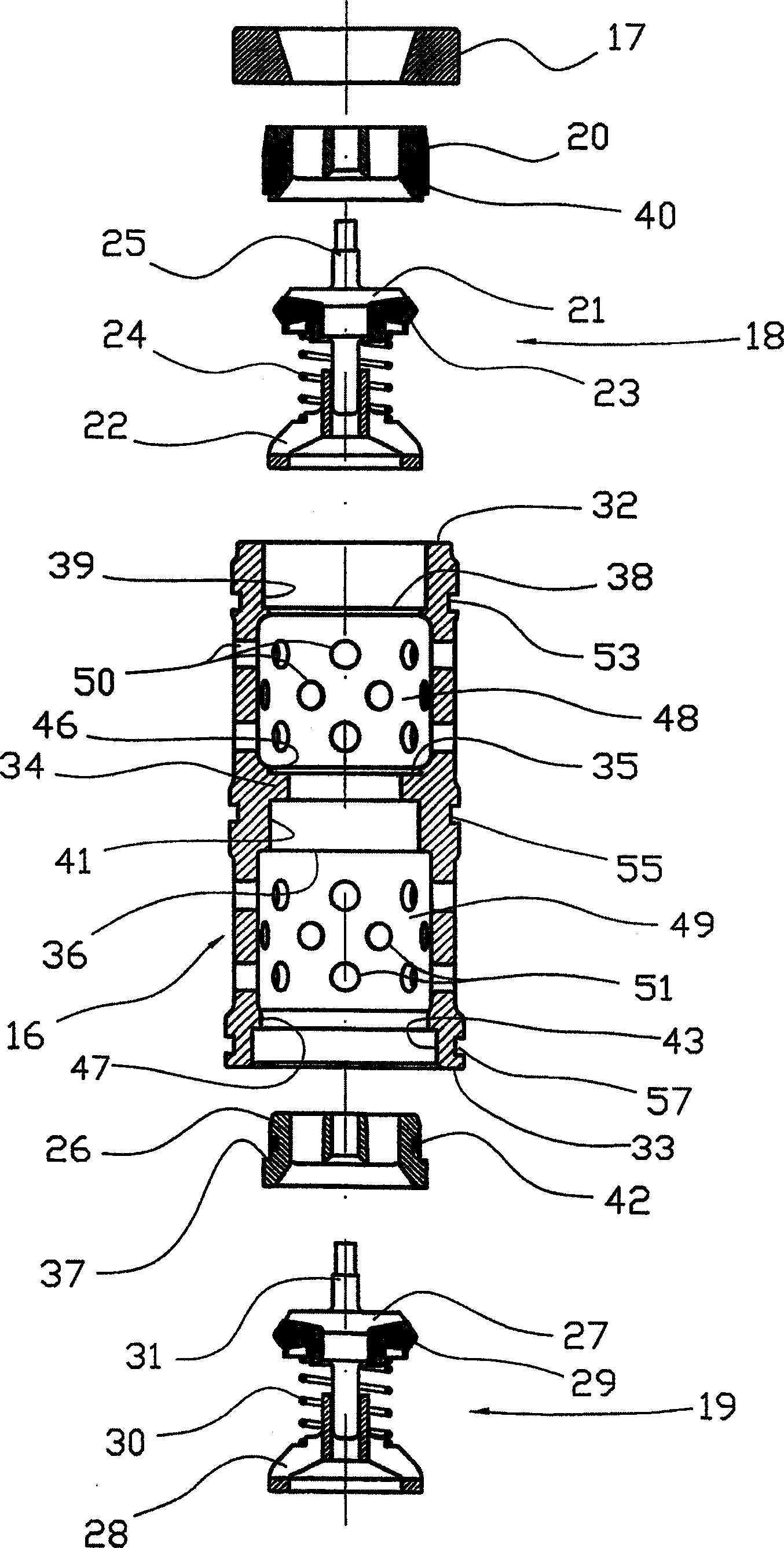

[0025] exist figure 1 In, reference 1 denotes the valve arrangement installed on the piston pump 2, and this valve arrangement is connected on the cylinder 3 of the piston pump, wherein a reciprocating piston 4 is installed in a known manner. A mounting plate 5 forms an extension of a flange 6 on the cylinder 3 . Both the mounting plate 5 and the valve device 1 are connected to the flange 6 and thus to the cylinder 3 by using a screw 7 .

[0026] The valve device 1 comprises a housing 8, wherein a bore 9 opening at one end 10 of the housing 8 terminates in the housing 8 and is connected to an outlet 11 opening at the other end, i.e. the opposite end, of the housing 8. connected. A cover 13 is designed to cover the hole 9 at the first end 10 of the housing 8 .

[0027] The working channel 14 in the housing 8 forms an extension of the cylinder 3 so as to communicate the cylinder with the bore 9 . An outlet 15 drawn out of the housing 8 from the hole is figure 1 Indicated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com