Production process of environment-friendly energy-saving lubricating oil additive

A technology for lubricating oil additives and production processes, which is applied in the fields of fuel additives, petroleum industry, and liquid carbon-containing fuels, etc., can solve the problems of unsatisfactory use efficiency, inability to effectively reduce the amount of gas contained in automobile exhaust, and low fuel-saving efficiency. , to achieve the effect of fast starting, increased power and extended service life of the locomotive

Inactive Publication Date: 2018-05-11

绵阳双甘科技有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the lubricating oil additives widely used at home and abroad have the problems of low fuel-saving efficiency, inability to effectively reduce the emission of contained gas in automobile exhaust, and unsatisfactory use efficiency under severe weather conditions (under severe cold temperature conditions)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

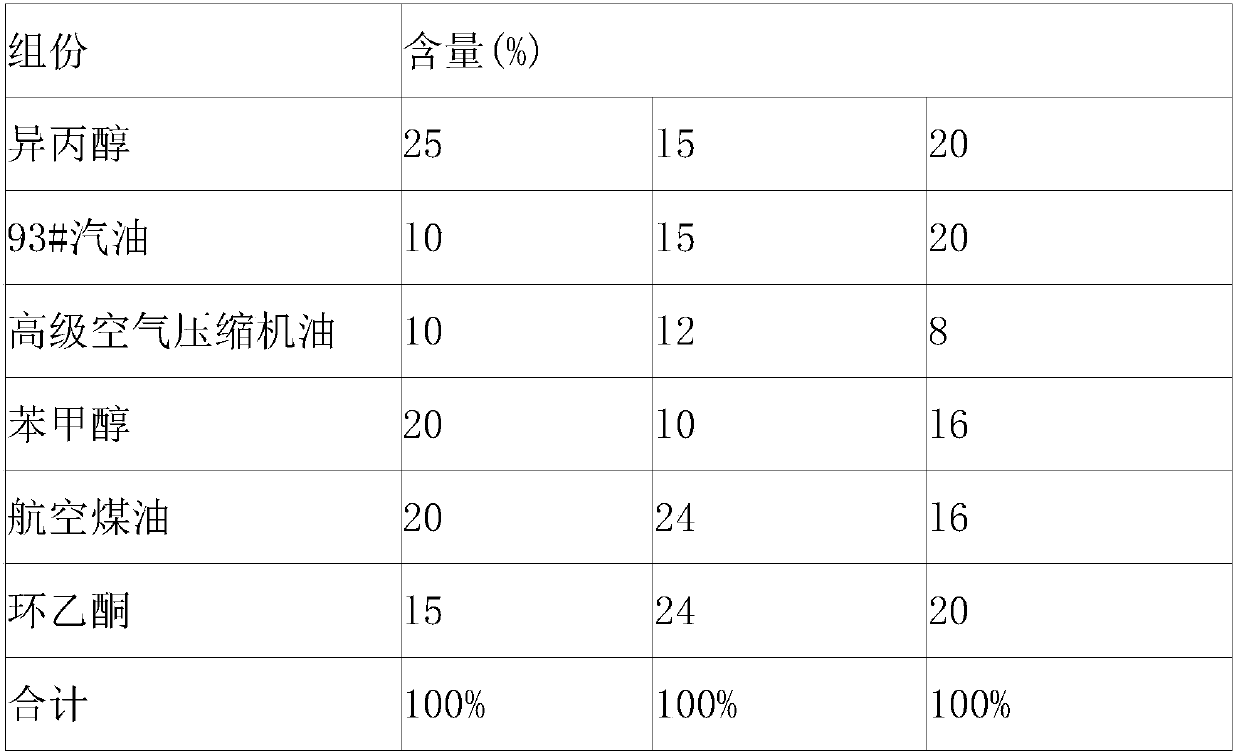

[0020] The three embodiments of the present invention are shown in the following table, and the specific manufacturing process can be implemented strictly according to the steps described above, and no further praises will be given.

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a production process of an environment-friendly energy-saving lubricating oil additive. The production process comprises the following steps: isopropanol is put into a reaction kettle, then 93# gasoline is mixed with the isopropanol, and after 1.5-2.5 h, an advanced air compressor oil is put into the reaction kettle, and then benzyl alcohol is put into the reaction kettlefor mixing, so as to obtain a solution A; an aviation kerosene (D40) is put into another reaction kettle, and then cyclohexanone is mixed with the aviation kerosene, and after 8-14 h, a solution B isobtained; and the solution A and the solution B are mixed, and the mixture is filtered for 2-5 times, so that the environment-friendly energy-saving lubricating oil additive is prepared. After the environment-friendly energy-saving lubricating oil additive is added into lubricating oil, pyrolysis of the paraffin is facilitated, thereby making the distillation range, condensation point and viscosity of the lubricating oil all show a downward trend, so that flowing and atomization of the fuel are facilitated, and power of an engine is obviously increased, therefore, the motor vehicle starts fast, noise is small, an injector head is not easily blocked, and the service life of the engine and machine parts can be effectively prolonged.

Description

technical field [0001] The invention relates to an environment-friendly and energy-saving lubricating oil additive production process. Background technique [0002] At present, the lubricating oil additives widely used at home and abroad have the problems of low fuel-saving efficiency, inability to effectively reduce the emission of contained gas in automobile exhaust, and unsatisfactory use efficiency under severe weather conditions (under severe cold temperature conditions) . Contents of the invention [0003] The technical problem to be solved by the present invention is to provide an environmentally friendly and energy-saving oil-collecting additive shared by various grades of lubricating oil with high fuel-saving efficiency, which can effectively improve the combustion efficiency of lubricating oil and reduce the emission of contained gas in the tail gas. The present invention adopts the following technologies Scheme: the present invention adopts following weight per...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L1/16C10L1/182C10L1/185C10L10/14

CPCC10L1/14C10L1/1616C10L1/182C10L1/1857C10L10/14C10L2300/30C10L2300/20

Inventor 徐叶

Owner 绵阳双甘科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com