Rolling method for exhaust valve surface

A technology of exhaust valve and valve face, which is applied in the field of rolling, can solve the problems of low hardness of the valve face and short service life, and achieve the effect of extending the overhaul period and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] When the material of the valve surface of the exhaust valve is NiCr18Fe18Nb alloy, the specific steps of the rolling method for the valve surface of the exhaust valve are as follows:

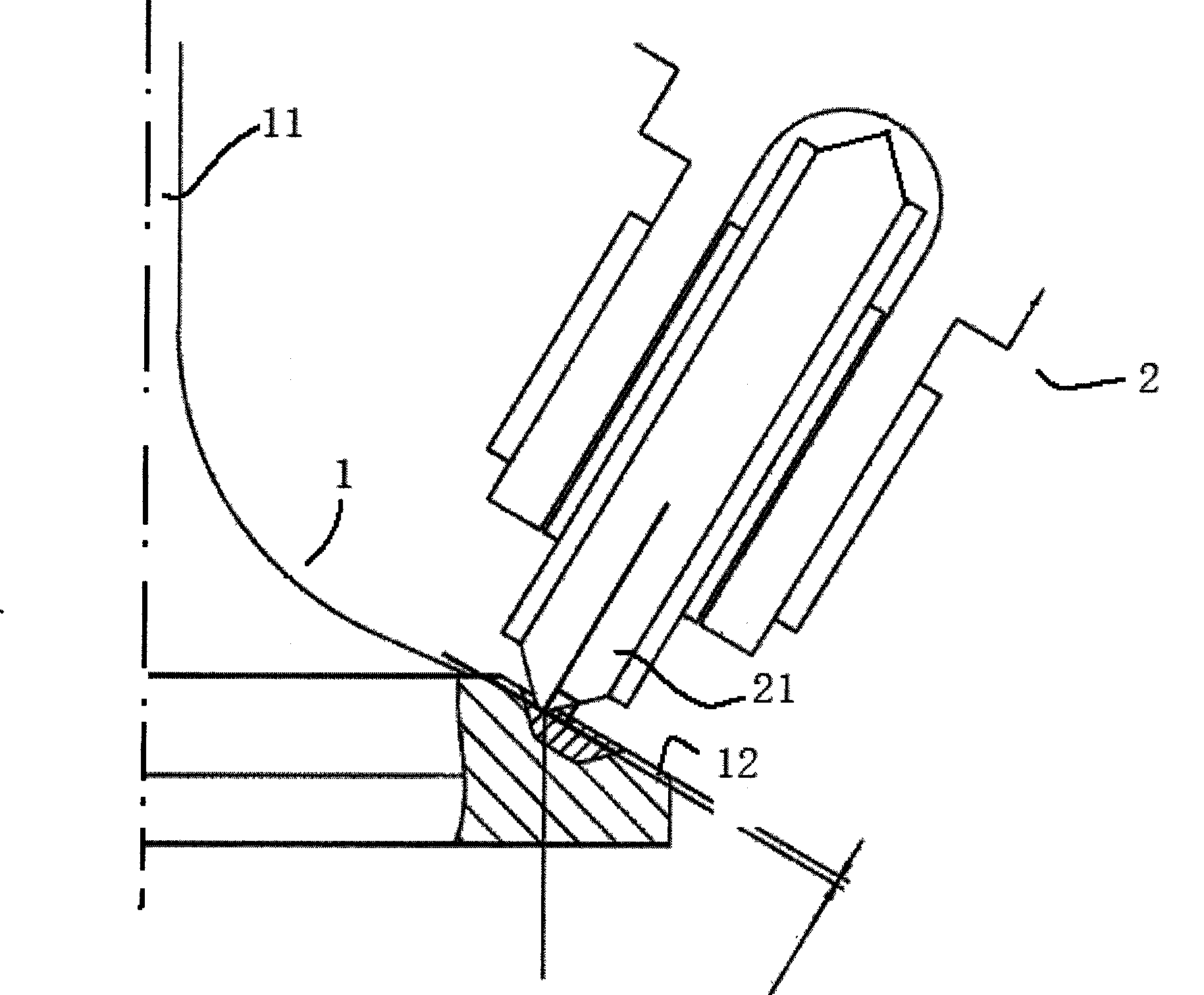

[0031] Fix the exhaust valve on the turntable of the rolling device, and then press the roller near the valve surface of the exhaust valve, and the surface of the roller is coated with molybdenum disulfide as a lubricant;

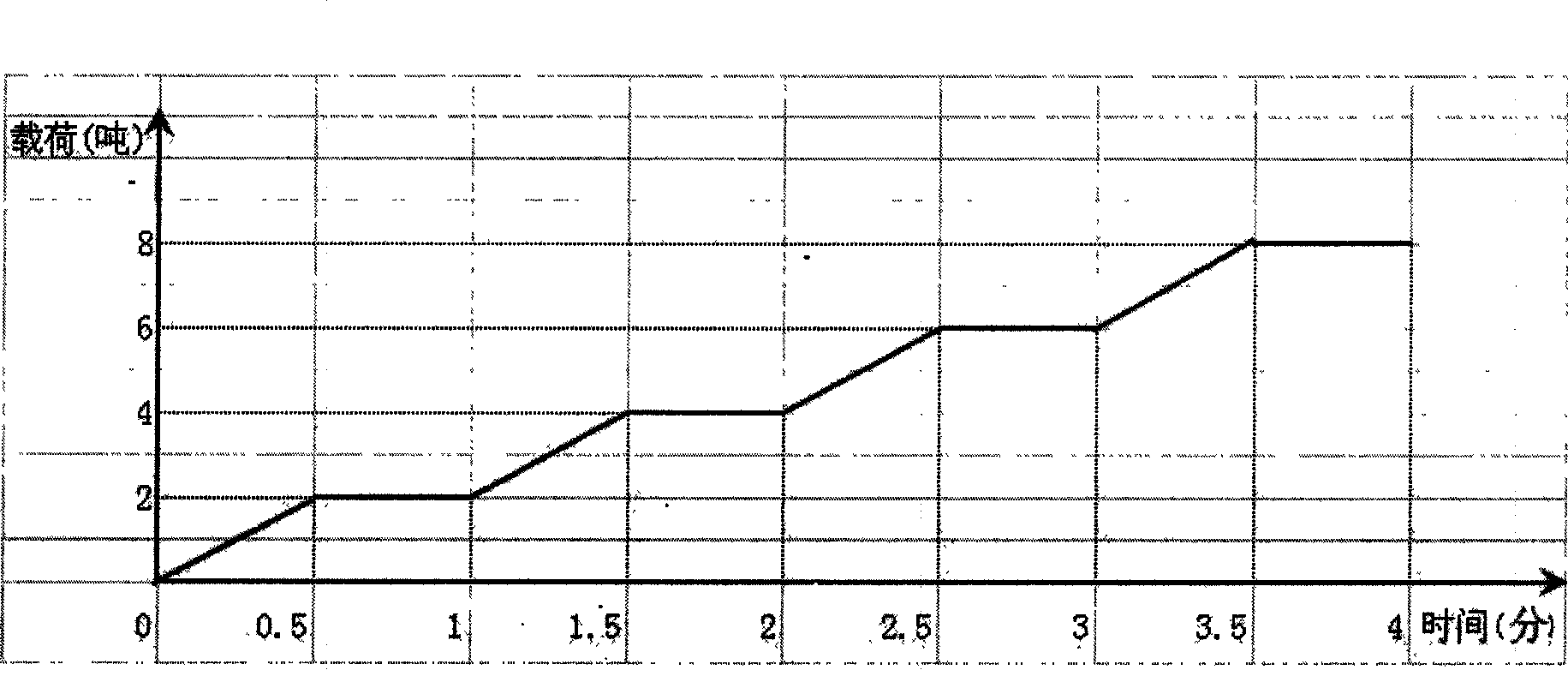

[0032] Align the roller of the rolling device with the inner side of the valve surface, and then apply pressure to the valve surface through the roller. The pressure application process is a fixed pressure within a set period of time, and the pressure increases stepwise with each step. , in this embodiment, the hydraulic system is used to apply pressure to the rollers, and the load is increased by 2 tons every 30 seconds, and the final load is 8 tons. The pressure applied on the valve surface increases from 0 tons to 2 tons; in the second 30 seconds, the hydraulic syst...

Embodiment 2

[0036] When the material of the valve surface of the exhaust valve is NiCr18Co12Nb alloy, the specific steps of the rolling method for the valve surface of the exhaust valve are as follows:

[0037] Fix the exhaust valve on the turntable of the rolling device, and then press the roller near the valve surface of the exhaust valve, and the surface of the roller is coated with tallow as a lubricant;

[0038] Align the roller of the rolling device with the inner side of the valve surface, and then apply pressure to the valve surface through the roller. The pressure application process is a fixed pressure within a set period of time, and the pressure increases stepwise with each step. , in the present embodiment, the hydraulic system is used to apply pressure to the roller, and the load is increased by 2 tons every 30 seconds, and the final load is 10 tons;

[0039] After rolling out the first groove with a depth of 2.2mm on the valve surface, loosen the roller, and then continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com