Design scheme of fast active control system for turbine vane tip interval

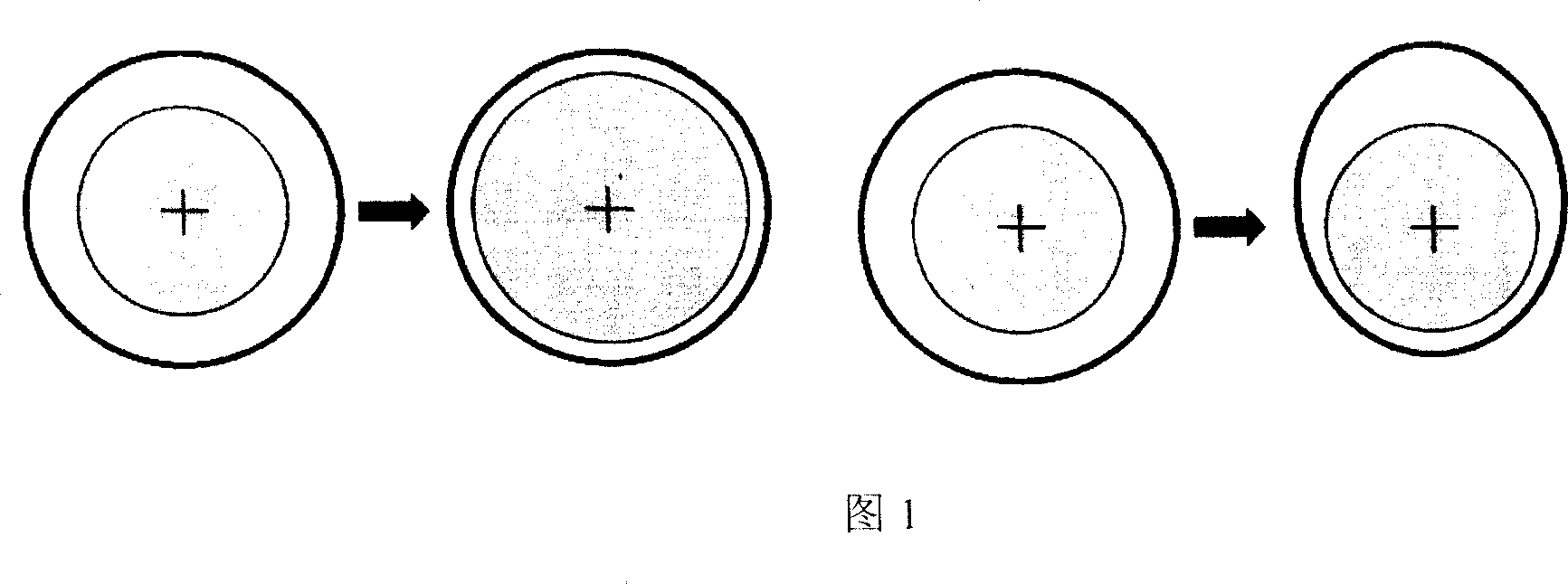

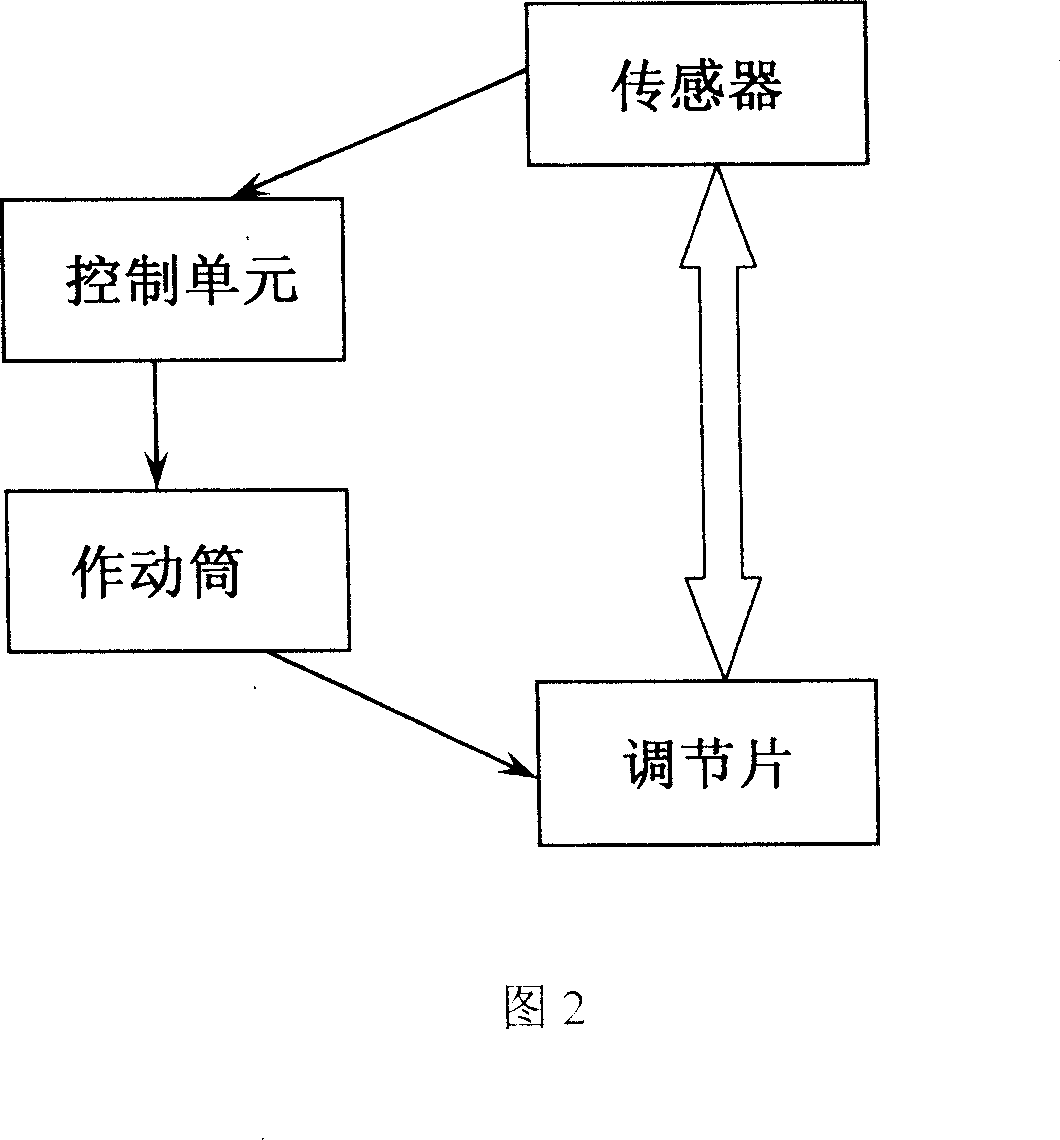

An active control system and blade tip clearance technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as component deformation, achieve the effects of prolonging life, prolonging overhaul period, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

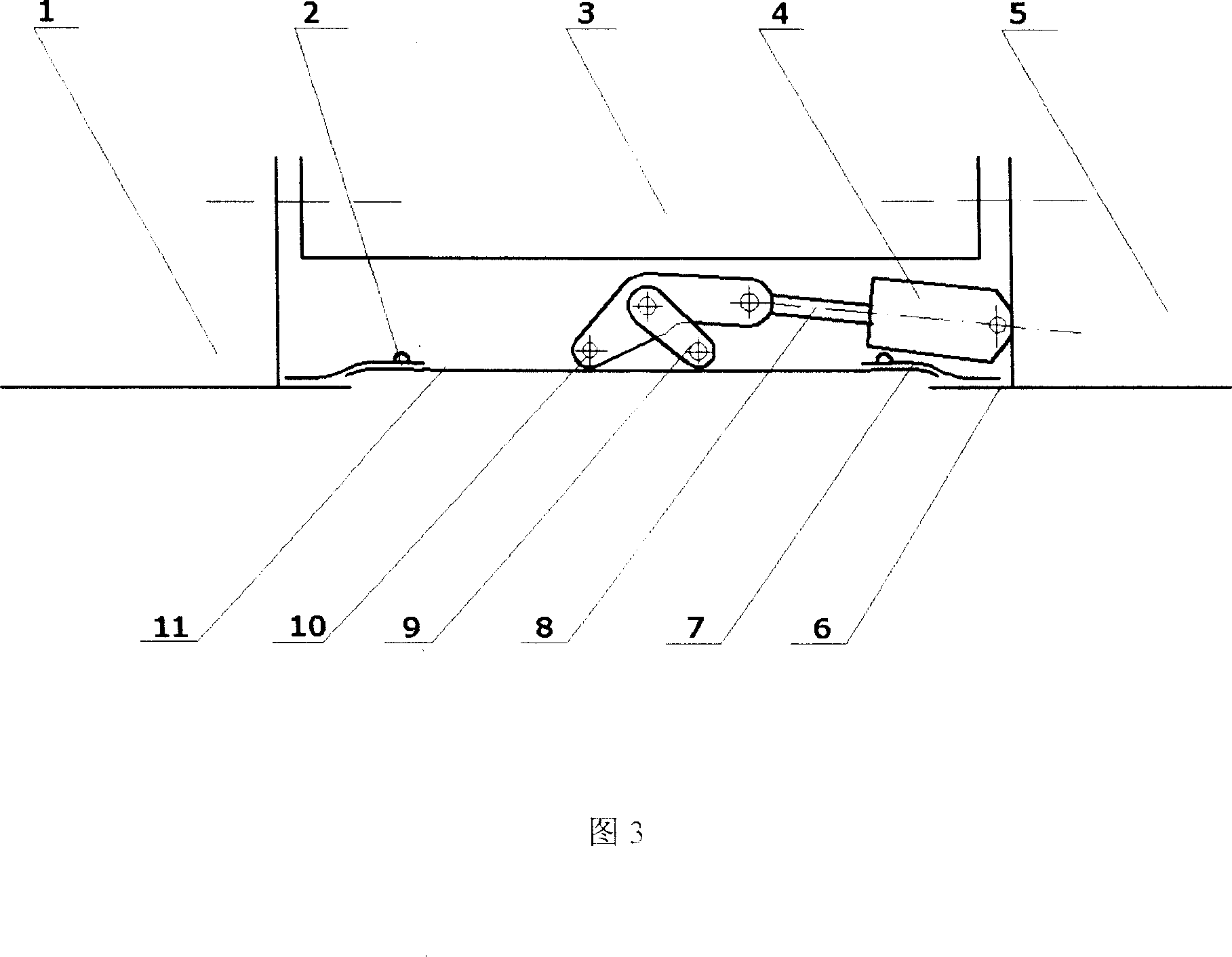

Embodiment Construction

[0041] Appropriately modifying and redesigning the mature aero-engine variable tail nozzle control technology and applying it to the rapid active control system of the turbine blade tip clearance can reduce technical risks and development costs. At the same time, the temperature of the flow field at the tail nozzle is also above 1000K, which is similar to the temperature of the flow field of the turbine, and the use of efficient cooling system materials and structural changes are also reduced accordingly. Therefore, the feasibility of this scheme can be verified on the active control of the turbine blade tip of the steam turbine. Improvements in materials and cooling systems were then made for ground and marine gas turbines. After the size and weight requirements of the aero-engine are met, it is applied to the rapid tip clearance active control of the aero-engine turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com