A kind of piston ring, piston assembly and engine

A technology of piston rings and broken rings, which is used in piston rings, engine components, machines/engines, etc., can solve the problems of wear on the outer circumference of the piston, high gas pressure, and large distortion of the piston ring, so as to improve the wear resistance, The effect of prolonging the service life and prolonging the period of overhaul

Active Publication Date: 2021-03-16

WEICHAI POWER CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the actual working process, the circumferential deformation of the first gas ring is uneven, which makes the ring groove of the piston ring installed on the piston, the bottom surface of the piston ring and the outer surface of the piston wear more seriously, especially the opening of the first gas ring In the place where the gas pressure is high, the distortion and deformation of the piston ring is relatively large, especially when the engine running time is close to the overhaul life, the sharp corner of the top surface of the piston ring is very easy to contact the inner surface of the cylinder liner, causing the cylinder liner to be pulled when the piston ring moves upward. The engine oil on the engine is scraped into the combustion chamber, resulting in an increase in oil consumption, and in serious cases, it may even cause the piston to scuff

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

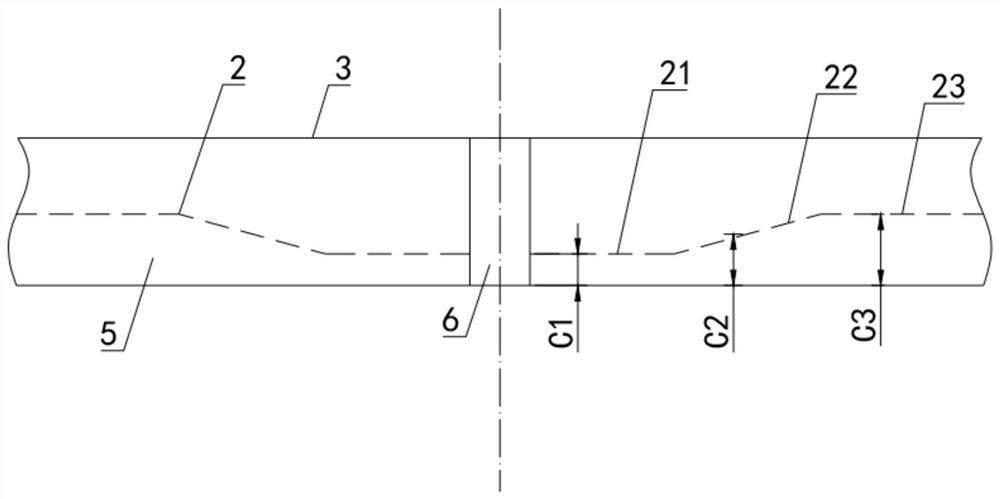

[0042] The difference between this embodiment and Embodiment 1 is that, as Figure 4 As shown, along the direction away from the opening 6, the distance from the point on the second curve 2 to the first plane changes continuously, that is, the distance from the point on the second curve 2 to the first plane gradually increases. Preferably, the distance from the point on the second curve 2 to the first plane increases linearly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

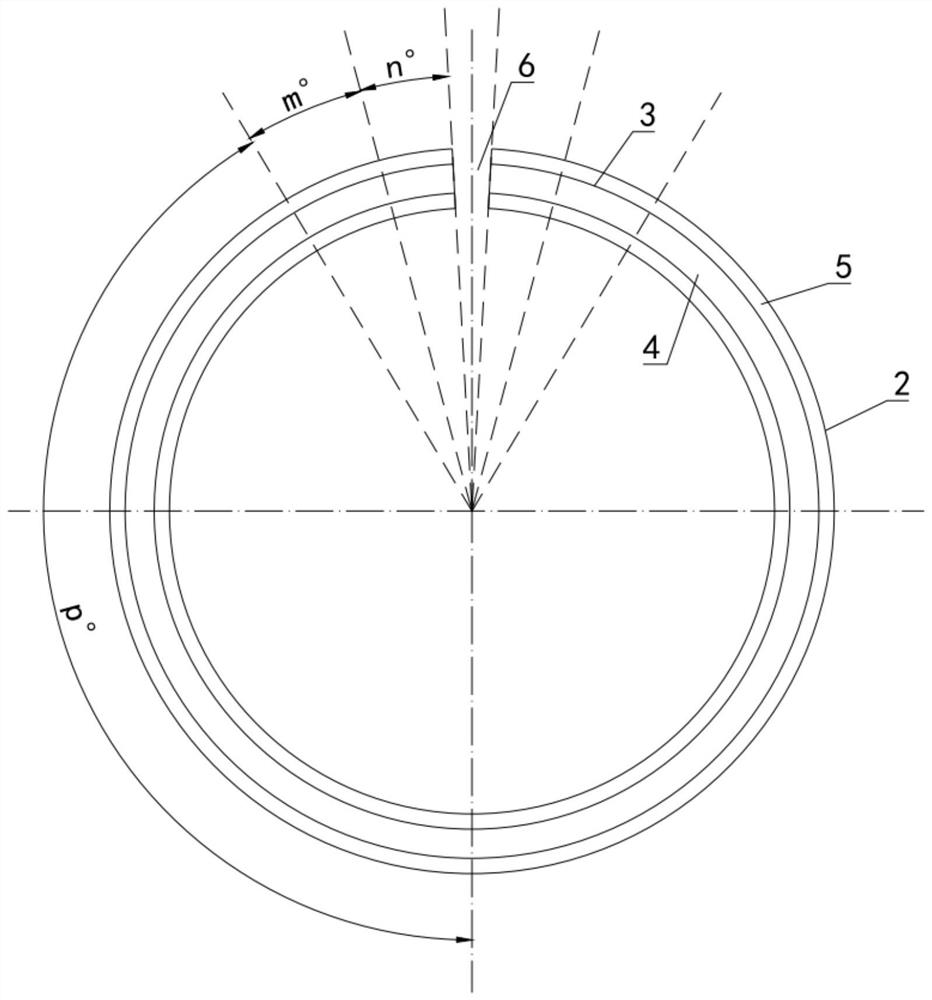

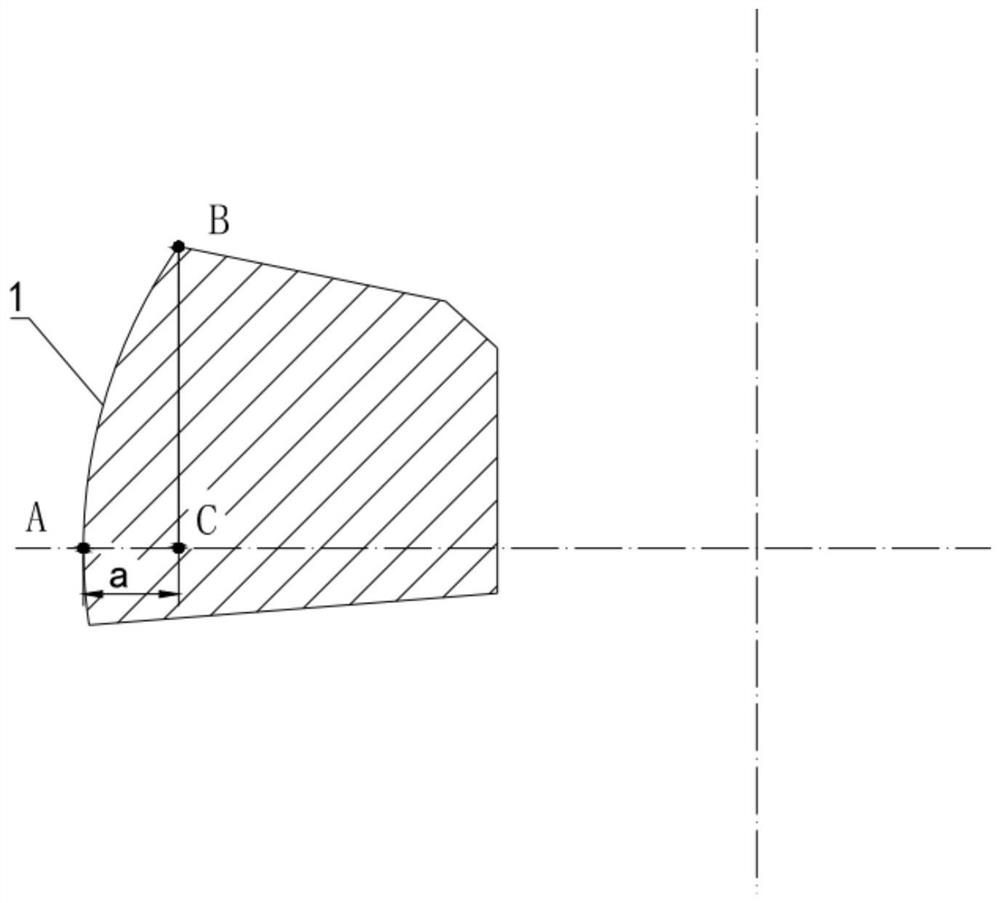

The invention relates to the field of engines, and discloses a piston ring, a piston assembly and an engine. The piston ring is a broken ring structure with an opening, each shaft section of the piston ring and the outer peripheral wall of the piston ring intersect to form a first curve, and points furthest from the central axis of the piston ring on the first curve are sequentially connected in the circumferential direction of the piston ring to form a second curve; and the end face, facing the bottom of the piston, of the piston ring is a first plane, and the distance from the points on thesecond curve to the first plane has an increased trend in the direction far away from the opening. On the premise of not greatly adjusting the structure of the piston ring, the type line of the outerperipheral wall of the piston ring is optimized, the contact pressure between the outer peripheral surface of the piston ring and the inner wall of a cylinder sleeve is almost consistent, the wear resistance of the outer peripheral surface of the piston ring, especially the wear resistance of the opening position of the piston ring, is improved, and after the piston ring is worn, the piston ring cannot be subjected to abnormal wear with the cylinder sleeve, so that the engine oil cannot be scraped into a combustion chamber when the piston ring moves upwards.

Description

technical field [0001] The invention relates to the field of engines, in particular to a piston ring, a piston assembly and an engine. Background technique [0002] Piston rings are divided into gas rings and oil rings, and the gas ring is used to seal between the piston and the cylinder liner to prevent the high-temperature gas in the combustion chamber from leaking through the gap between the piston and the cylinder liner, so that as little gas as possible leaks to the In the crankcase; the oil ring is used to control the scraping of the lubricating oil on the cylinder liner, scrape the excess lubricating oil into the crankcase, and at the same time ensure that an appropriate amount of lubricating oil remains on the inner surface of the cylinder liner, so that it is not harmful to the cylinder liner and the cylinder liner. The relative sliding surfaces between the rings are lubricated. [0003] There are usually multiple air rings, and the working environment of the first...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02F5/00

CPCF16J9/00F16J9/20F16J9/22

Inventor 崔凯何盛强马燕燕吕慧敏王雪

Owner WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com