Turning and milling machining clamp for aero-engine exhaust nozzle assembly

A technology for aero-engines and tail nozzles, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as difficulty in ensuring the stability of the workpiece, inability to be in place in one step, and alignment multiple times, so as to avoid loosening and running. Positioning and chattering, the effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

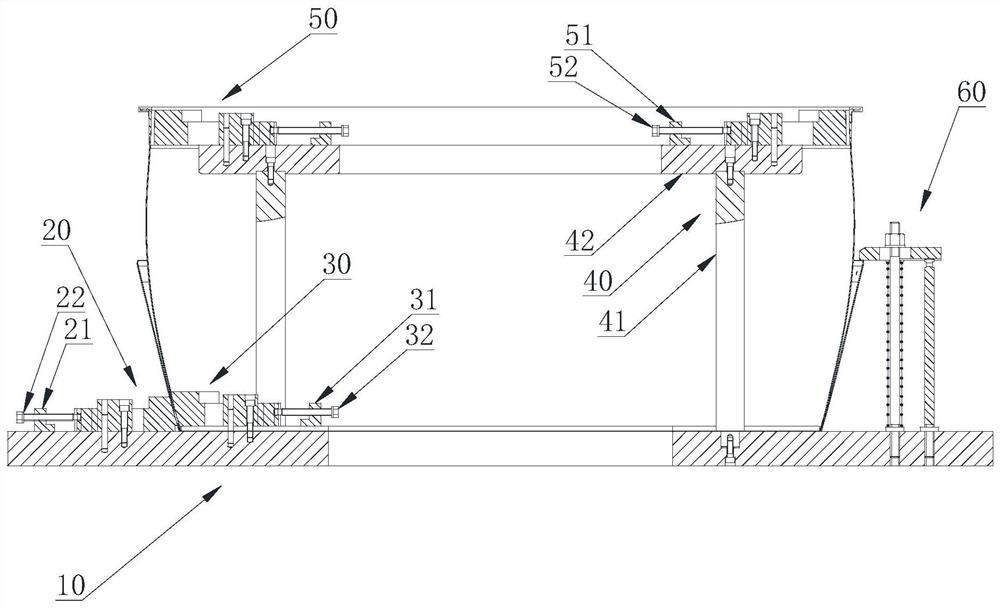

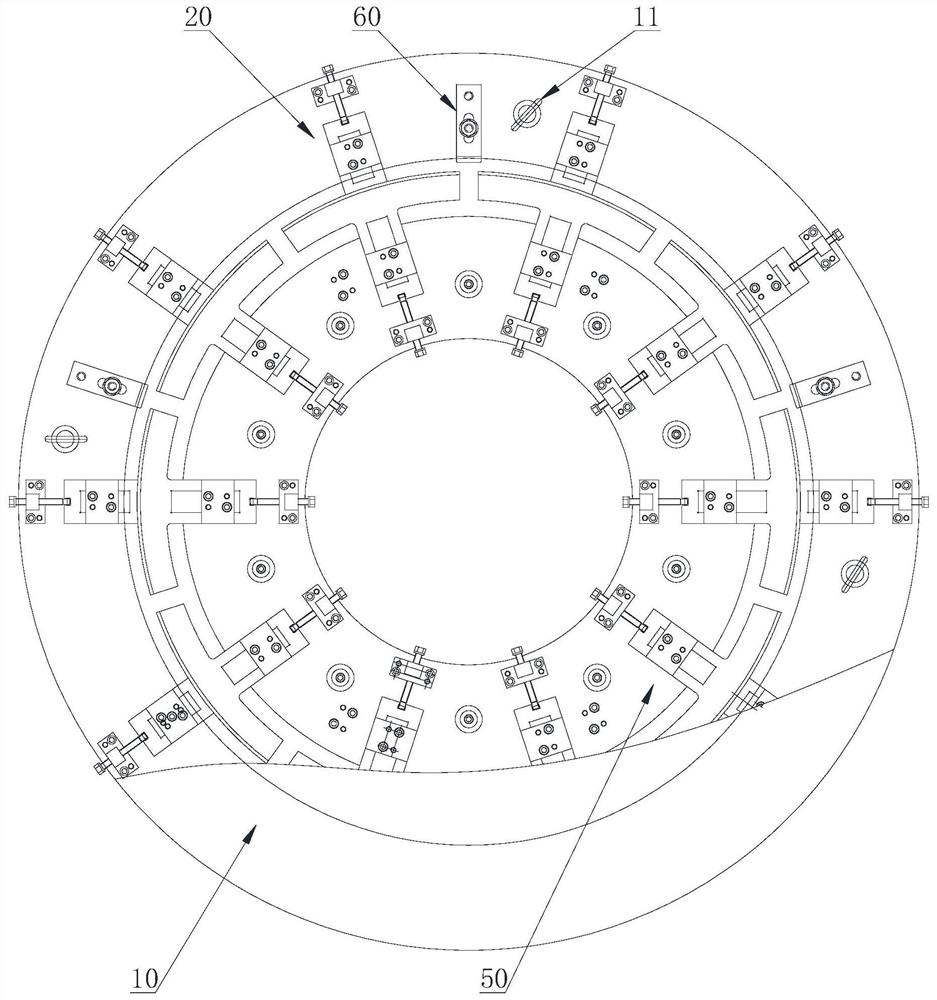

[0041] refer to figure 1 , a turning and milling fixture for an aero-engine exhaust nozzle assembly, comprising: a base 10 , a bottom outer limit assembly 20 , a bottom inner limit assembly 30 , a support assembly 40 , a top limit assembly 50 and an outer pressing assembly 60 .

[0042] refer to figure 1 and figure 2 , The base 10 is disc-shaped, and a plurality of screw holes and pin holes are opened on the base 10 for carrying the aero-engine exhaust nozzle assembly and various fixture components. The base 10 is connected with a plurality of suspension rings 11, and the base 10 can be driven to move by the suspension rings 11, thereby facilitating the hoisting of the overall fixture. The aero-engine exhaust nozzle assembly is welded by the sheet metal cylinder placed below and the flange. In this process, the top mounting edge of the flange away from the sheet metal cylinder needs to be turned and milled.

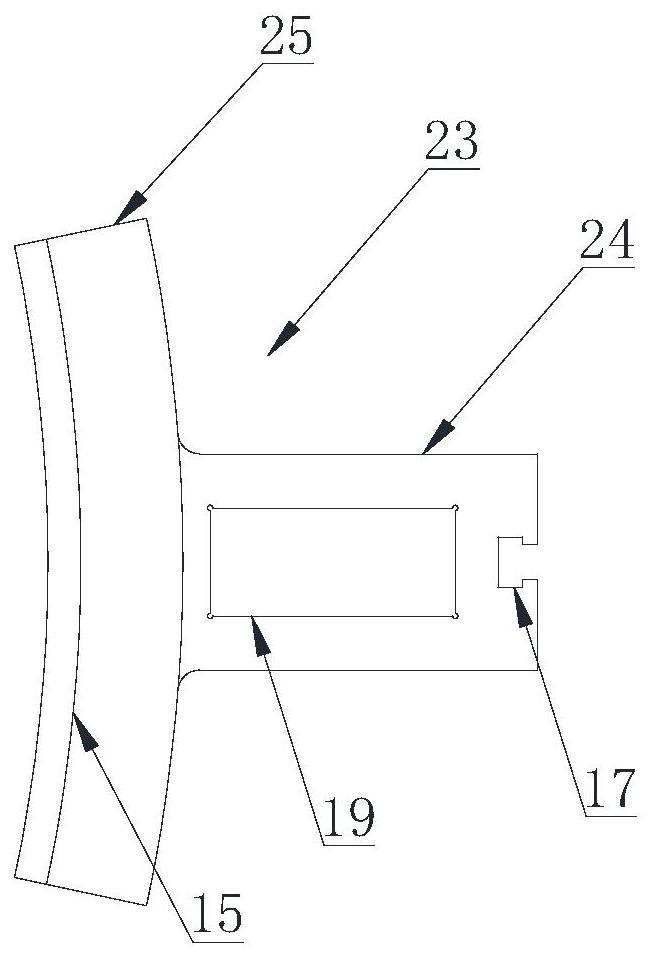

[0043] refer to figure 1 , figure 2 and image 3, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com